Full-automatic film banknote bundling machine

A fully automatic and banknote binding machine technology, which is applied in the direction of automatic packaging control, binding machine parts, paper product packaging, etc., can solve the problems of difficult production management, banknotes are easy to be damp and moldy, and low safety factor, so as to save packaging The effect of material cost, high professional promotion value, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Various embodiments of the present invention will be described in detail below with reference to the accompanying drawings, in which the same structures or functions are marked with the same numerals. It should be pointed out that the purpose of the drawings is only to facilitate the description of the specific embodiments of the present invention, and is not a redundant description or limitation to the scope of the present invention. In addition, the drawings are not necessarily drawn to scale.

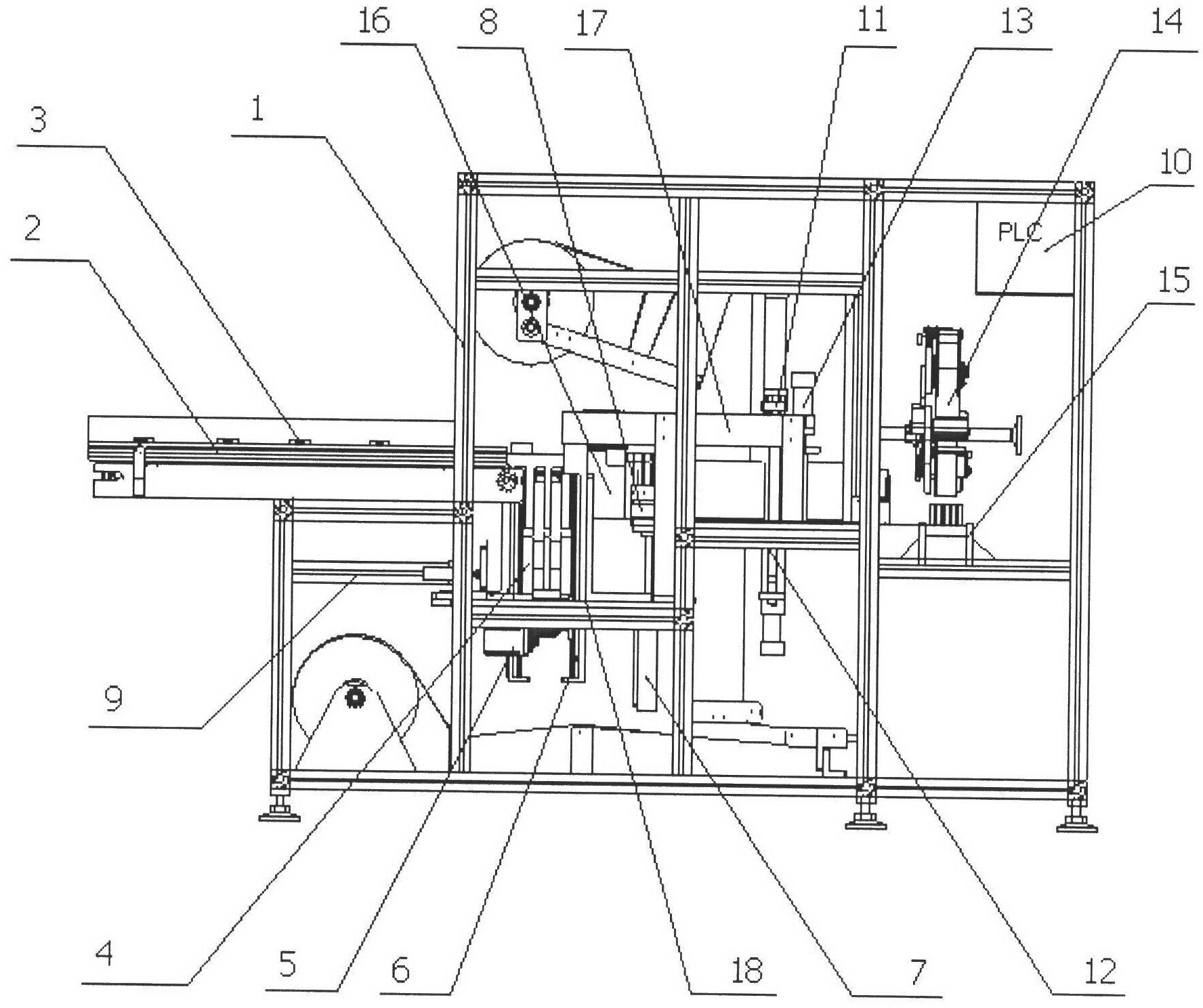

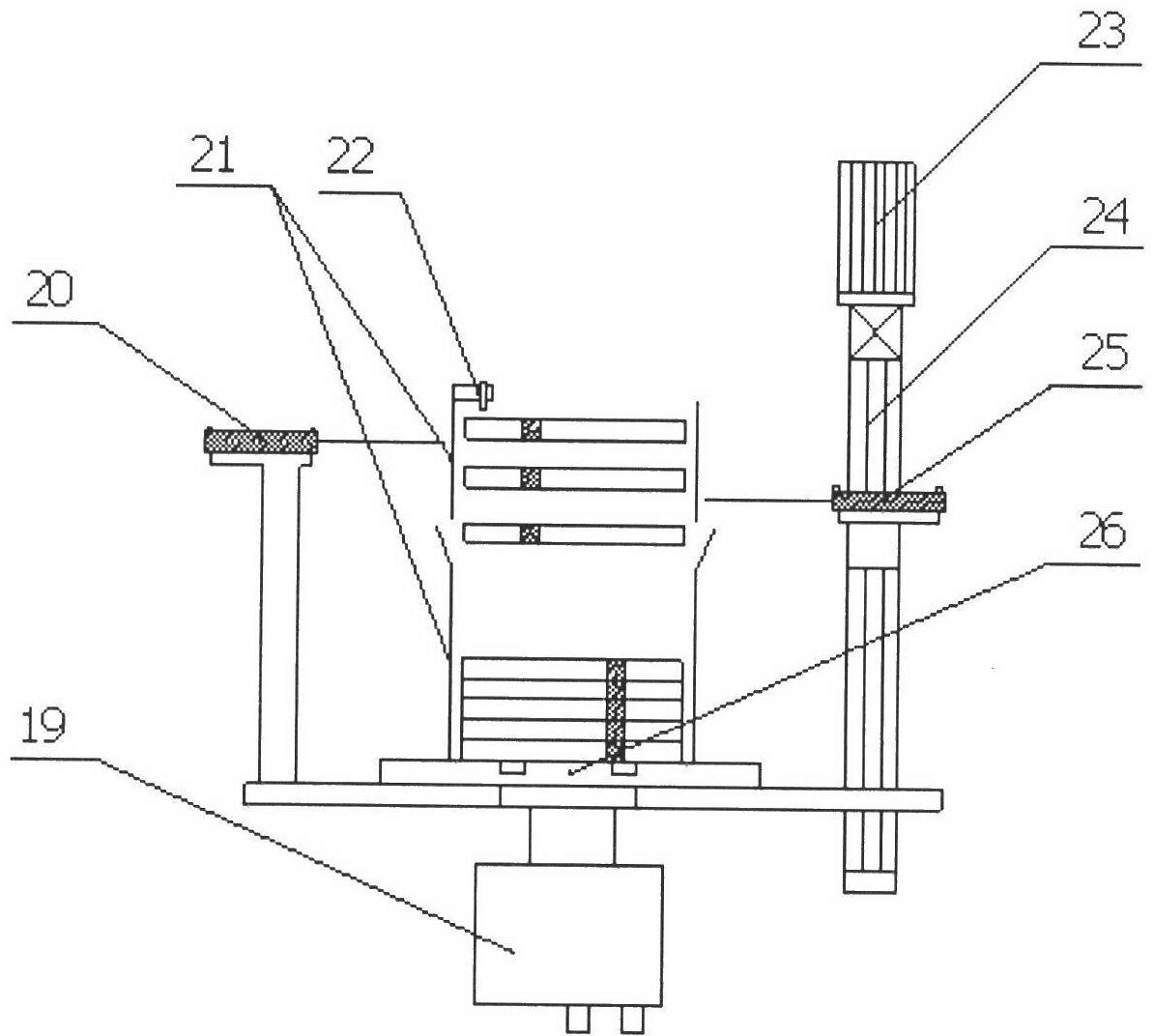

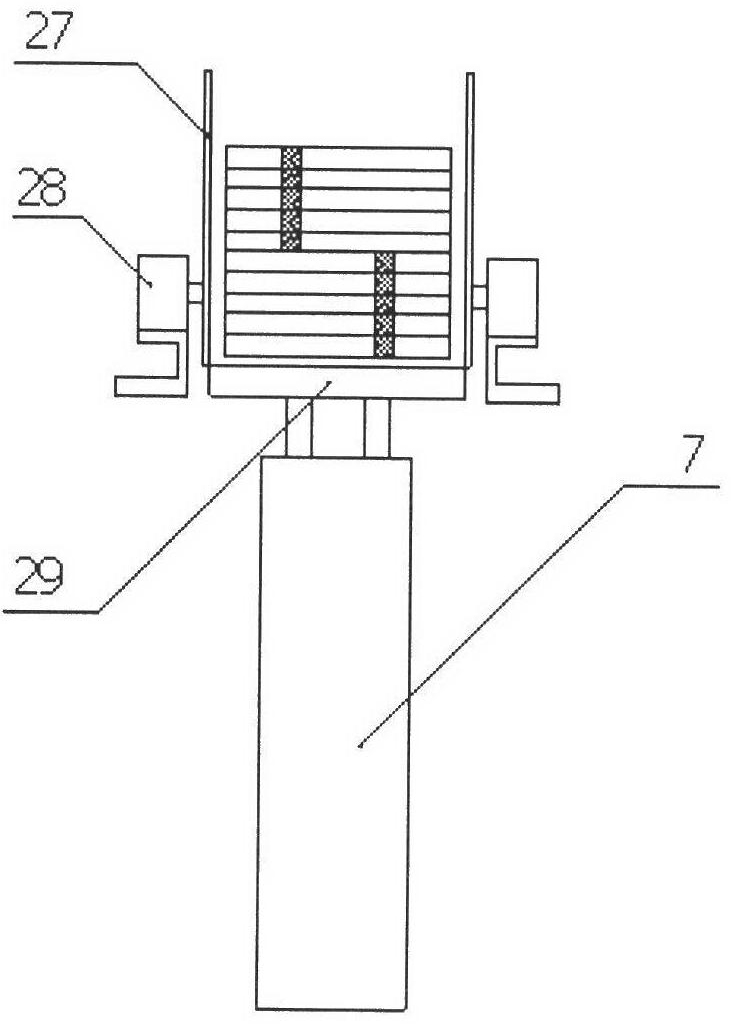

[0032] As shown in the figure, the present invention provides a fully automatic film banknote binding machine for packaging printed matter such as banknotes, which includes a frame (1) and a feed conveying mechanism (2) installed from front to back on the frame, stack Steering mechanism (4), primary pushing mechanism (9), sorting and topping mechanism (8), secondary pushing mechanism (17), heat sealing mechanism (11), discharge mechanism (16), labeling mechanism (14 ) and PLC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com