Production equipment for smoke-extinguishing glass sand

A glass sand and smoke extinguishing technology, which is applied in the field of glass sand production equipment, achieves the effect of simple process, maintaining consistency and saving manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

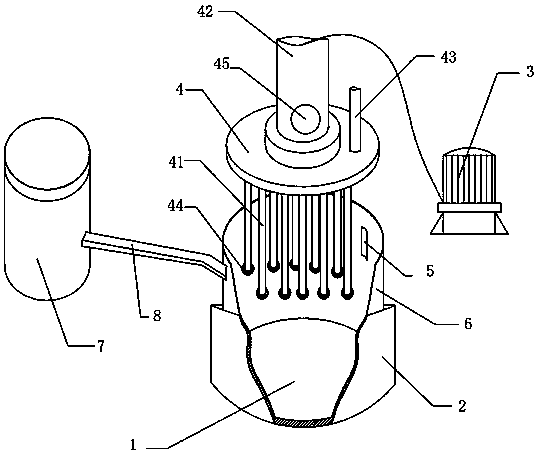

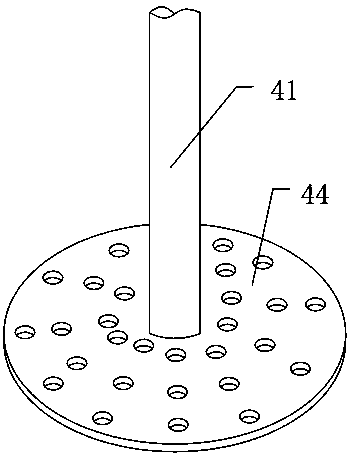

[0022] The reference signs in the drawings of the description include: wax coating machine 1, heating layer 2, motor 3, top cover 4, observation window 5, melting furnace 6, glass breaker 7, conveyor belt 8, stirring rod 41, drive shaft 42, Condenser pipe 43, screen cloth 44, feeding port 45.

[0023] Such as figure 1 As shown: the glass breaker 7 is connected to the wax wrapping machine 1 through the transmission belt 8, the bottom surface of the melting furnace 6 of the wax wrapping machine 1 is provided with a heating layer 2, the side of the melting furnace 6 is provided with a switchable observation window 5, and the top of the melting furnace 6 is provided with a Top cover 4, the bottom surface of top cover 4 is connected with stirring rod 41, and the lower end of stirring rod 41 is provided with screen cloth 44, and the upper surface of top cover 4 is connected wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com