Powder material discharge transmission system for batch-type packaging machine and control method thereof

A system controller and intermittent technology, applied in packaging and other directions, can solve problems such as insufficient rotation force of stirring fan blades, energy consumption in complex installation and debugging process, high driving power, etc., and achieve mechanism accuracy and mechanical transmission process efficiency reduction, The effect of reducing supporting costs and system power consumption and improving the packaging speed of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

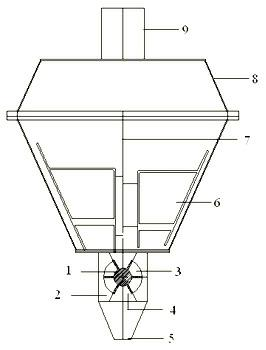

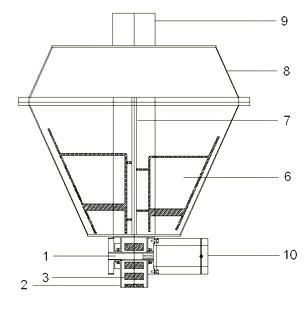

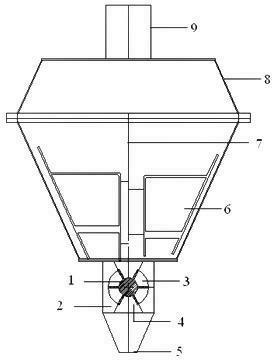

[0022] The specific implementation, structure, features and effects provided by the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0023] Such as Figure 1~2 The powder material feeding transmission system of an intermittent packaging machine shown includes a powder material stirring transmission mechanism, a feeding filling transmission mechanism, a feeding driving stepping motor, and a feeding stepping motor driver. The powder material stirring transmission The mechanism includes a stirring motor, a stirring motor shaft, and a powder material stirring fan blade. The stirring motor 9 is connected to the powder material stirring fan blade 6 in the powder material silo 8 through the stirring motor shaft 7; the blanking and filling transmission mechanism includes a blanking and filling pump , The feeding and storage pump 2 is installed under the powder material hopper, and the feeding and storage pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com