Automatic bottle sorting machine

A bottle unscrambler and automatic technology, which is applied in the field of bottle unscrambler, can solve the problems of relatively long time, affecting the quality of discharging materials, not being able to discharge or continuously discharging, etc., to increase the manufacturing cost, simple structure and easy to use. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

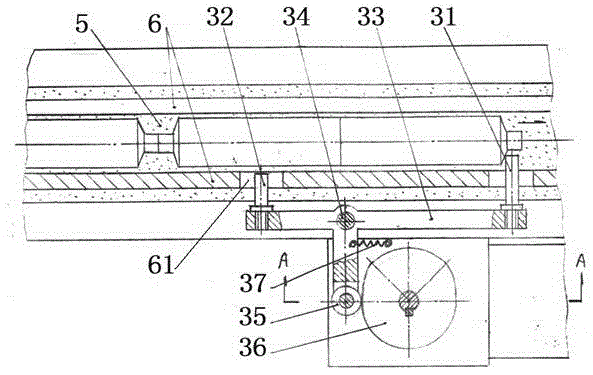

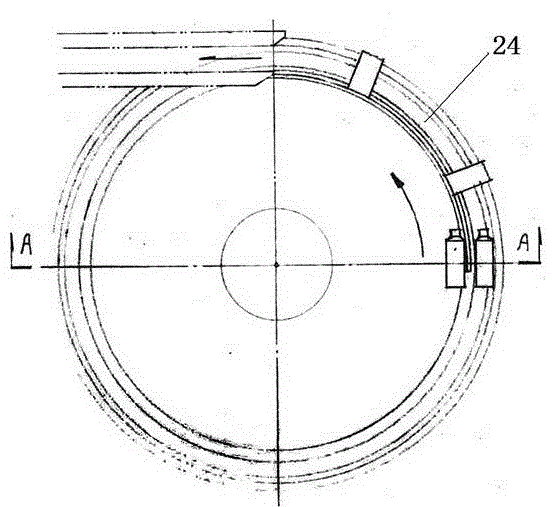

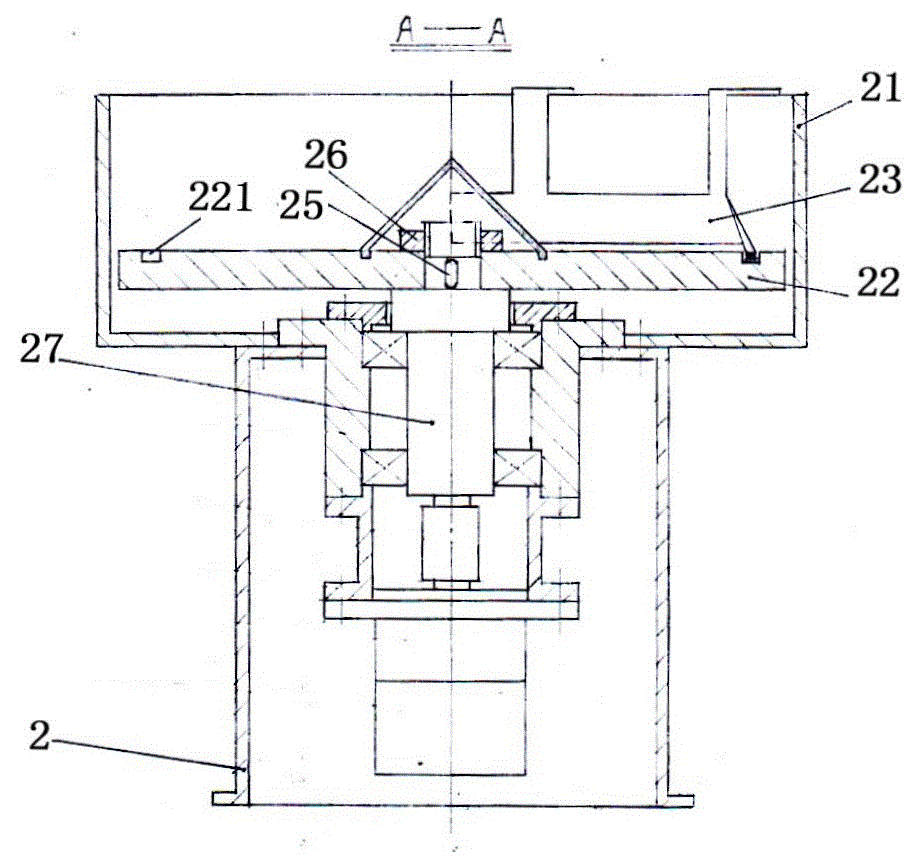

[0042] The present invention includes a self-falling feeder 1, the lower part of the self-falling feeder 1 is connected with a split-flow centrifugal feeder 2, and the rear of the split-flow centrifugal feeder 2 is connected with a multi-block discharge mechanism 3 A U-turn mechanism 4 is connected to the rear of the multi-block feeding mechanism 3.

[0043] The self-falling feeder includes a barrel 11, the barrel 11 forms a space for the workpiece to fall longitudinally, the barrel 11 is provided with a rotatable blade 12, and the barrel 11 is provided with A blade cover 13 with a tapered structure on the upper part of the blade 12, and an inverted cone discharge port 14 corresponding to the blade cover 13 is provided below the barrel 11, and the blade cover 13 and the discharge port 14 are formed between For the gap for the workpiece to fall, the blade 12 is arranged between the blade cover 13 and the discharge port 14.

[0044] A shaft seat 15 is fixedly provided on the barrel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com