Concrete bridge face aggregate laying device

A paving device and concrete technology, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of construction speed influence, steel bar or steel mesh damage, low efficiency, etc., and achieve the effect of ensuring uniformity and looseness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

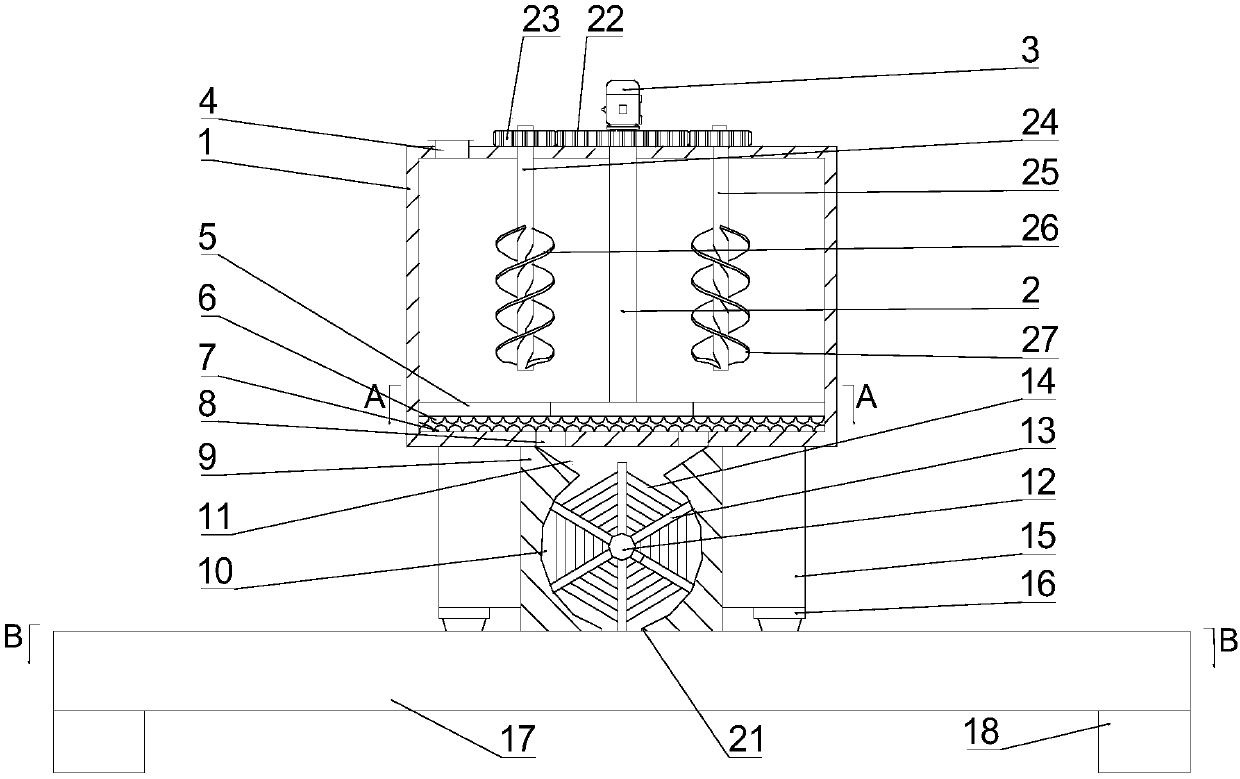

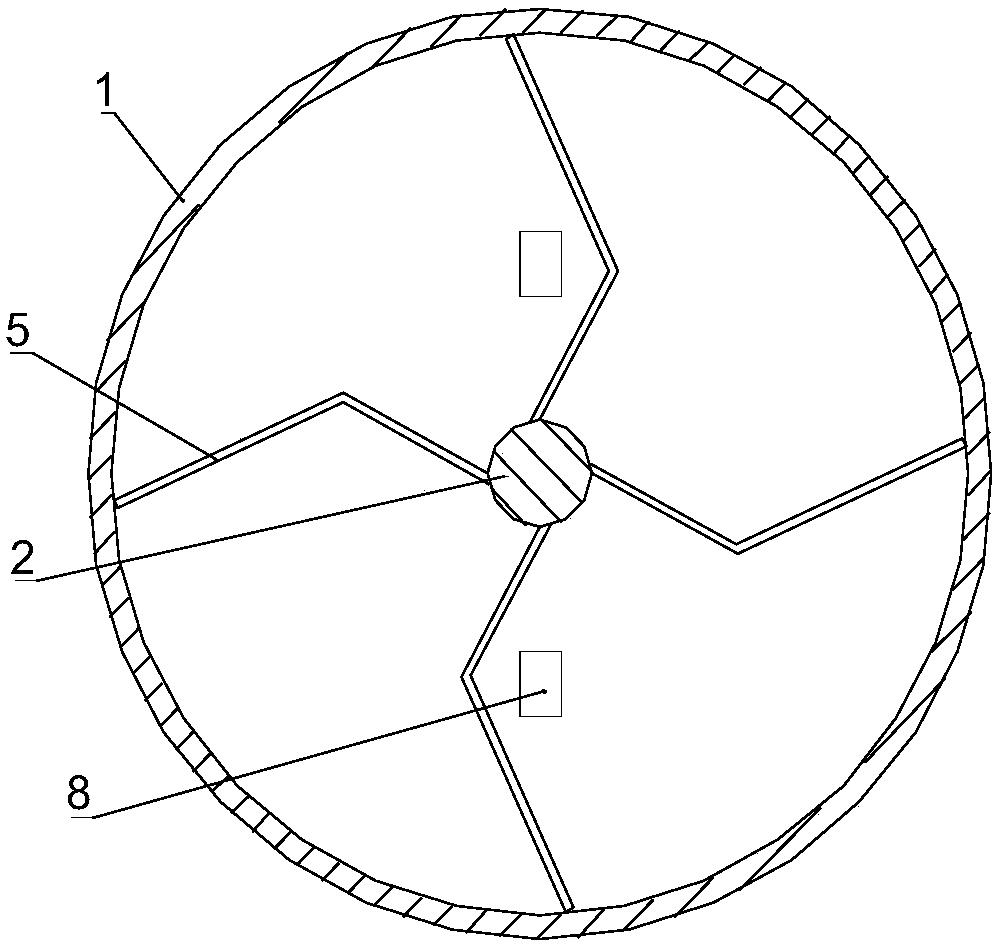

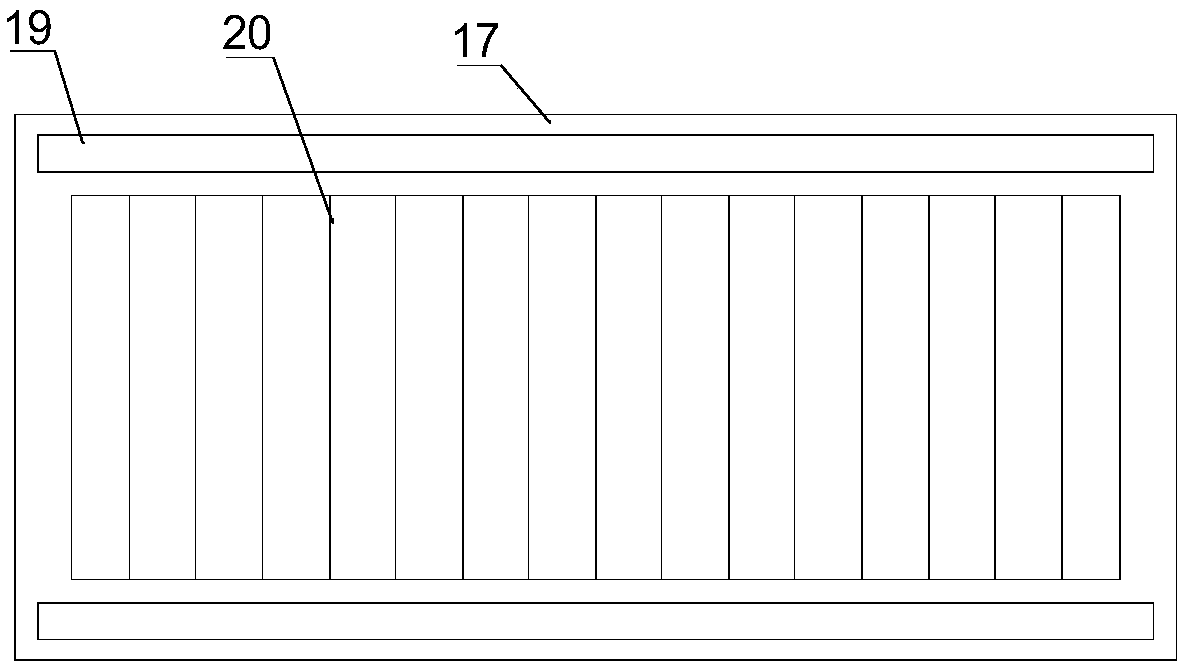

[0020] see Figure 1-3 , a concrete bridge surface paving device, comprising a moving material box 1, the inside of the moving material box 1 is provided with a rotating shaft 2, the top of the rotating shaft 2 passes through the upper side wall of the moving material box 1 and is connected with the moving material box 1 The upper side wall body of the upper side wall is connected in rotation, the upper side of the moving material box 1 is fixedly installed with a motor 3, the output end of the motor 3 is fixedly connected with the top of the rotating shaft 2, and the lower surface of the rotating shaft 2 is evenly and fixedly connected with several Bending plate 5, the lower part of bending plate 5 is evenly fixedly connected with No. 1 grinding protrusion 6, and the inner wall of the lower side of the moving material box 1 is evenly and fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com