Negative-pressure quantitative powdery material adding system

A powdery material and negative pressure technology, which is applied in the direction of conveying bulk materials, loading/unloading, conveyors, etc., to achieve the effect of ensuring unloading, reducing material waste, and meeting high-efficiency and rapid production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

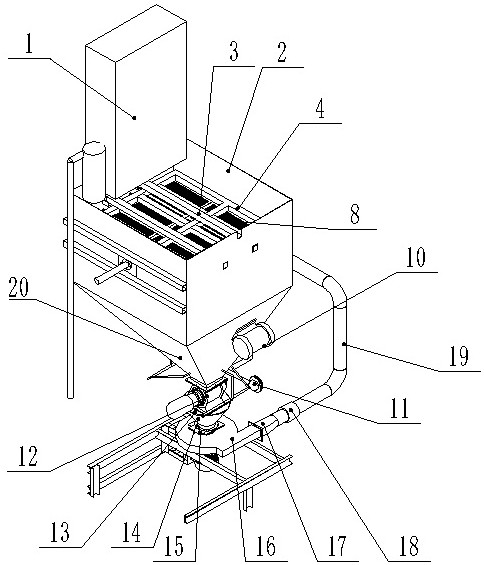

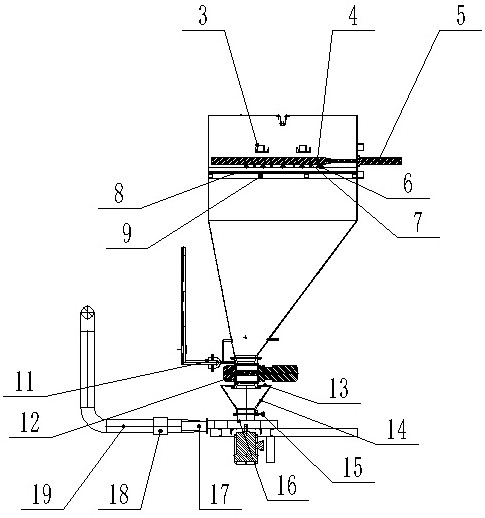

[0020] Embodiment one: by Figure 1 to Figure 2 Provided, the negative pressure quantitative powdery material addition system includes a sequentially connected silo 2, a lower hopper 20, a feeder 12, a material receiver 14, a negative pressure fan 16 and a feeding pipeline 19, and the silo 2 is provided with Mesh screen 8, a powder quantifier is set in the feeder 12, a steel wire mesh 13 is set between the upper port of the receiver 14 and the feeder 12, and an air regulating device is set between the lower port and the negative pressure fan 16. Valve 15, the bottom of the feeder 12 is equipped with a connecting frame, and the side wall of the upper port of the receiver 14 is provided with a plurality of notches for the mounting of the connecting frame. This system is applied to powder materials. Therefore, starting from the silo , it is necessary to ensure that there will be no large pieces of material in the entire system. The powder metering device in the feeder 12 is set b...

Embodiment 2

[0021] Embodiment 2: On the basis of Embodiment 1, the inner wall of the silo 2 is provided with an installation frame and the ton bag cross arm 3 is movably installed through the installation frame, and the material ton bag is placed above the ton bag cross arm 3. Since the silo 2 is an opening Therefore, vibration motors cannot be used to assist blanking. A powder pushing frame 4 is arranged above the mesh screen 8 in the silo 2, and a horizontal guide rail 6 and a vertical guide rail 7 are arranged staggeredly below the powder pushing frame 4. The powder pushing frame 4 is a hollow frame structure and is driven by the hydraulic cylinder 5. By moving the powder pushing frame 4 back and forth, it can prevent material accumulation, avoid dust, and can push the large particle materials that are knotted together.

Embodiment 3

[0022] Embodiment Three: On the basis of the above-mentioned embodiments, a vibrating motor 10 and an air gun 11 are arranged on the lower hopper, and the vibrating motor 10 and the air gun 11 all have a vibration function, and the vibrating motor 10 is mainly used for auxiliary material blanking. However, relying on the vibration motor 10 alone is likely to cause materials to accumulate at the bottom of the lower hopper, and it is also easy to cause the materials to become solid. The setting of the air gun 11 cooperates with the vibration motor 10. Regular blowing can prevent the materials from becoming solid and avoid affecting the follow-up powder metering device. precision.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com