Spiral feeding system in front of circulating fluidized bed garbage incinerator

A waste incinerator and circulating fluidized bed technology, applied in the direction of incinerator, combustion type, combustion method, etc., can solve the problems of garbage agglomeration, unstable furnace pressure, insufficient fuel combustion stability, etc., to ensure looseness, Improve efficiency and effectiveness, avoid the effect of insufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

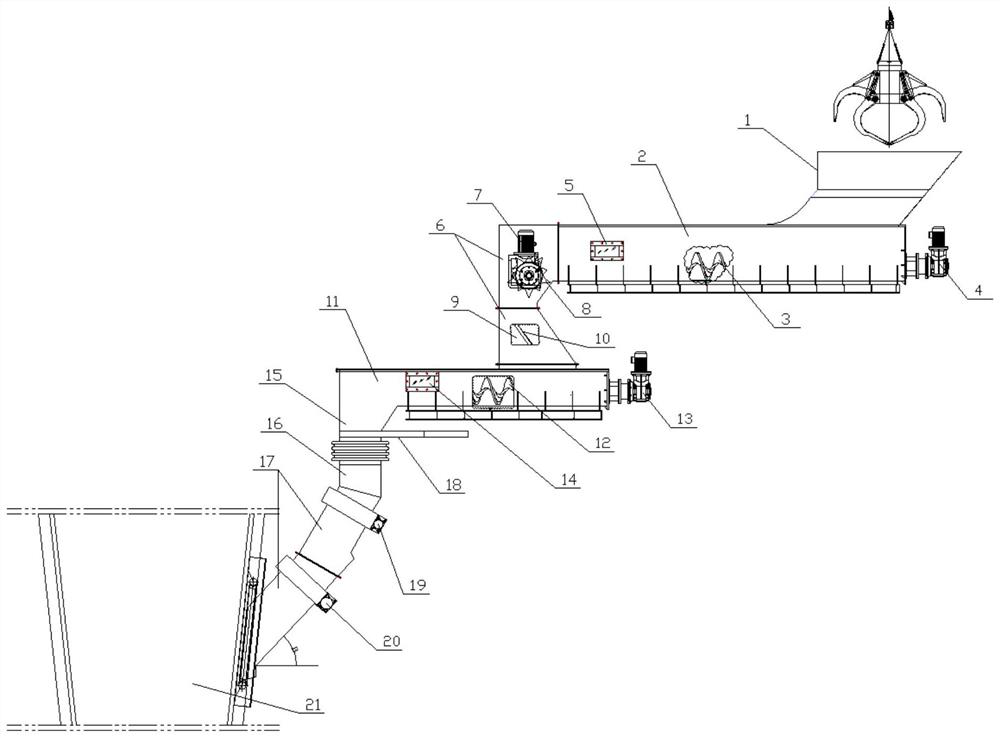

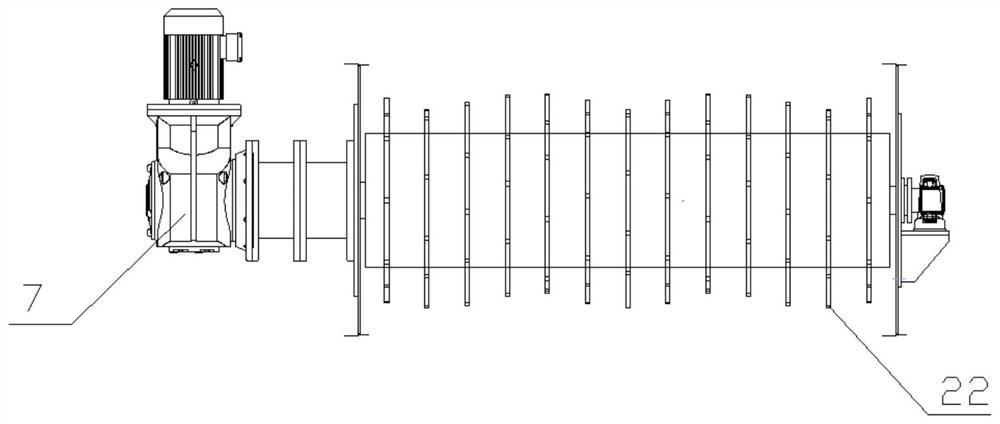

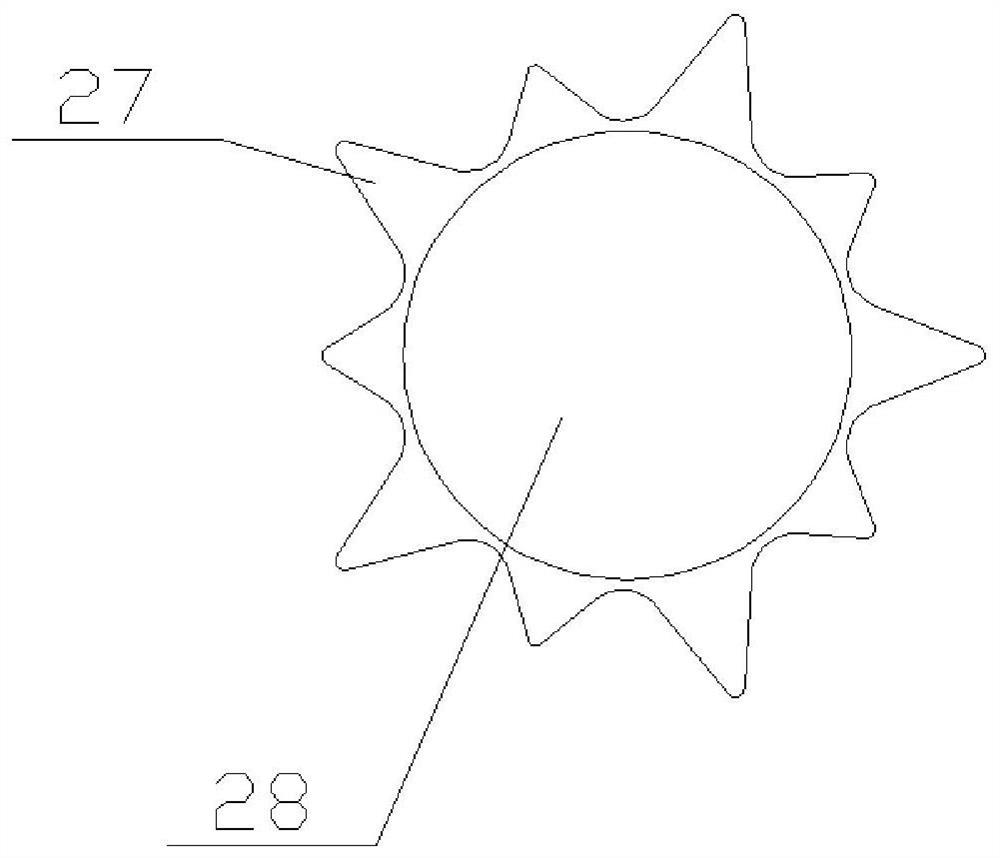

[0050] figure 1 It is a schematic structural diagram of the spiral feeding system in front of the circulating fluidized bed waste incinerator, figure 2 It is a schematic diagram of the structure of the feeder, image 3 It is a schematic diagram of the structure of the dial tooth plate, Figure 4 is the side view of the feeder, Figure 5 A-A sectional view of the feeder, Image 6 It is a schematic diagram of the installation of the T-shaped screen, Figure 7 It is the front view of the T-shaped screen.

[0051] Such as figure 1 As shown, the spiral feeding system in front of the circulating fluidized bed garbage incinerator includes:

[0052] The first-level feeder 2 is used to transport garbage to the incinerator 21; the first-level feeder 2 is provided with a hopper 1, and the first-level feeder 2 communicates with the incinerator 21 through a connecting channel;

[0053] Specifically, the first-level feeder 2 can choose the first-level feeder equipment commonly used ...

Embodiment 2

[0060] On the basis of the above embodiments, for example, the shifter 8 includes several shifting toothed plates 22 arranged side by side, and the installation distance of the shifting toothed plates 22 is 200mm. The shifting teeth 27, the shifting teeth 27 include low shifting teeth and high shifting teeth with different tooth heights, and the low shifting teeth and high shifting teeth are arranged alternately, so that the installed shifting teeth 22 The low shifting teeth and the high shifting teeth are respectively arranged alternately according to a certain helix angle; the shifting teeth 27 on the adjacent shifting tooth discs 22 are arranged alternately.

[0061] Specifically, the pusher 8 also includes a rotating shaft 24 connected to the driving motor 7 of the pusher, a rotating cylinder 23 fixedly sleeved on the rotating shaft 23, and a through hole 28 is provided in the center of the shifting toothed disc 22, The dial tooth plate 22 is sheathed on the drum 23 throug...

Embodiment 3

[0071] On the basis of the above-mentioned embodiments, as an example, the feeding system is also provided with a secondary feeder 11 between the primary feeder 2 and the incinerator 21, and the connecting channel includes the vertical shaft 6 and the blanking Pipe 15, the secondary feeder 11 communicates with the primary feeder 2 through the shaft 6, and the secondary feeder 11 communicates with the incinerator 21 through the drop pipe 15; the setter 8 and T The type screen 10 is arranged in the vertical shaft 6 connecting the primary feeder 2 and the secondary feeder 1 .

[0072] Wherein, the secondary feeder 11 can choose a secondary feeder with a screw blade with crushing function.

[0073] Specifically, the T-shaped screen 10 is arranged obliquely downwards and backwards along the running direction of the garbage in the secondary feeder 11, so as to ensure that the garbage with a small particle size falls in the direction of the running direction of the garbage in the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com