Method for preparing green and environmentally-friendly building material from building wastes

A technology of construction waste and building materials, which is applied in the field of preparing green and environmentally friendly building materials, and can solve problems such as environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

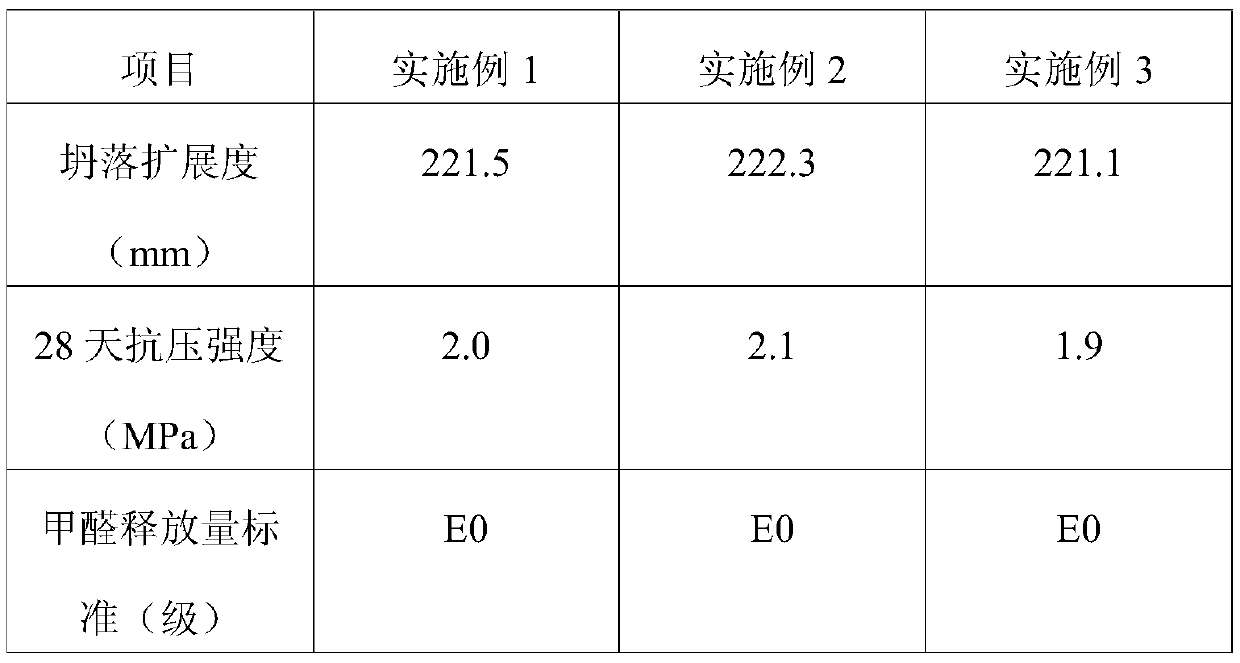

Embodiment 1

[0027] This embodiment provides a method for preparing green building materials from construction waste, comprising the following steps:

[0028] (1) Construction waste pretreatment: use a magnetic separation device to remove metal substances in the construction waste, and use a disinfectant to spray and disinfect the construction waste; then put the construction waste into a mixer for stirring, and then slowly add dilute sulfuric acid into the construction waste mixture Acidification treatment, followed by primary crushing to obtain granular materials with a particle size of ≤60mm, put the granular materials into a rotary kiln and roast for 40 minutes, and then pass the roasted and cooled granular materials through secondary crushing and screening system to obtain granular materials. It is the granular material of 5mm, that is, the regenerated fine aggregate of construction waste, for subsequent use; wherein, the disinfectant solution is composed of the following raw materials...

Embodiment 2

[0033] This embodiment provides a method for preparing green building materials from construction waste, comprising the following steps:

[0034] (1) Construction waste pretreatment: use a magnetic separation device to remove metal substances in the construction waste, and use a disinfectant to spray and disinfect the construction waste; then put the construction waste into a mixer for stirring, and then slowly add dilute sulfuric acid into the construction waste mixture Acidification treatment, followed by primary crushing to obtain granular materials with a particle size of ≤60mm, put the granular materials into a rotary kiln and roast for 45 minutes, and then pass the roasted and cooled granular materials through secondary crushing and screening system to obtain granules It is the granular material of 8mm, that is, the regenerated fine aggregate of construction waste, for subsequent use; wherein, the disinfectant solution is made up of the following raw materials in parts by...

Embodiment 3

[0039] This embodiment provides a method for preparing green building materials from construction waste, comprising the following steps:

[0040] (1) Construction waste pretreatment: use a magnetic separation device to remove metal substances in the construction waste, and use a disinfectant to spray and disinfect the construction waste; then put the construction waste into a mixer for stirring, and then slowly add dilute sulfuric acid into the construction waste mixture Acidification treatment, followed by primary crushing to obtain granular materials with a particle size of ≤60mm, put the granular materials into a rotary kiln and roast for 50 minutes, and then pass the roasted and cooled granular materials through secondary crushing and screening system to obtain granular materials. It is the granular material of 12mm, that is, the regenerated fine aggregate of construction waste, for subsequent use; wherein, the disinfectant solution is made up of the following raw materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com