Slice control method of vertical slice cutter

A technology of vertical slicing and control methods, which is applied in the direction of electrical program control, program control in sequence/logic controllers, tobacco, etc., and can solve problems such as poor flow stability, large fluctuations in slicing flow, and large human factors. Fluctuation of slice flow, stable inner quality, promotion of stable improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

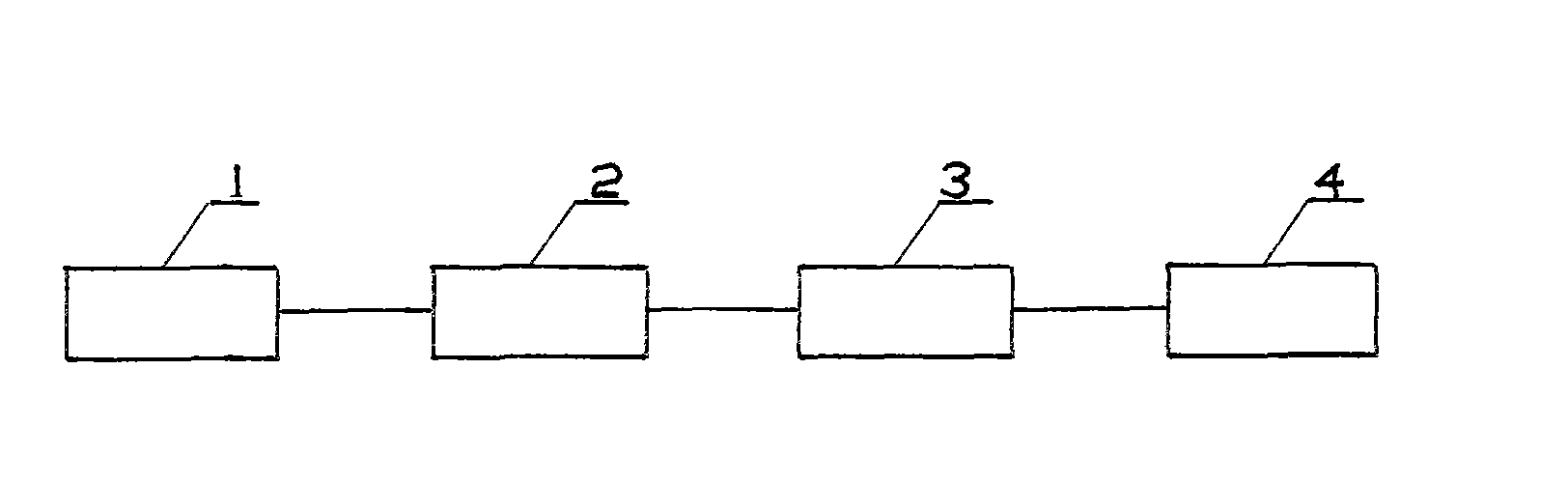

[0010] Such as figure 1 , is a flowchart of the present invention. Cigarette packs of various specifications and sizes are measured on the static weighing electronic belt scale 1 to obtain corresponding data. When cigarette packs of a certain size enter the online static weighing electronic belt scale 1, the corresponding measured data is transmitted to the automatic control system, and the cigarette packs enter the buffer belt 2. After the automatic control system recognizes and finds the corresponding slice control mode, The cigarette pack is sent into the slicer 3 to slice according to the corresponding slice control mode, and the cut tobacco leaves are sent to the next process by the conveyor belt and the control type electronic belt scale 4.

[0011] The present invention designs a set of schemes for automatically identifying the size a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com