Patents

Literature

40 results about "Vertical slice" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A vertical slice, sometimes abbreviated to VS, is a type of milestone, benchmark, or deadline, with emphasis on demonstrating progress across all components of a project. It may have originated in the video game industry.

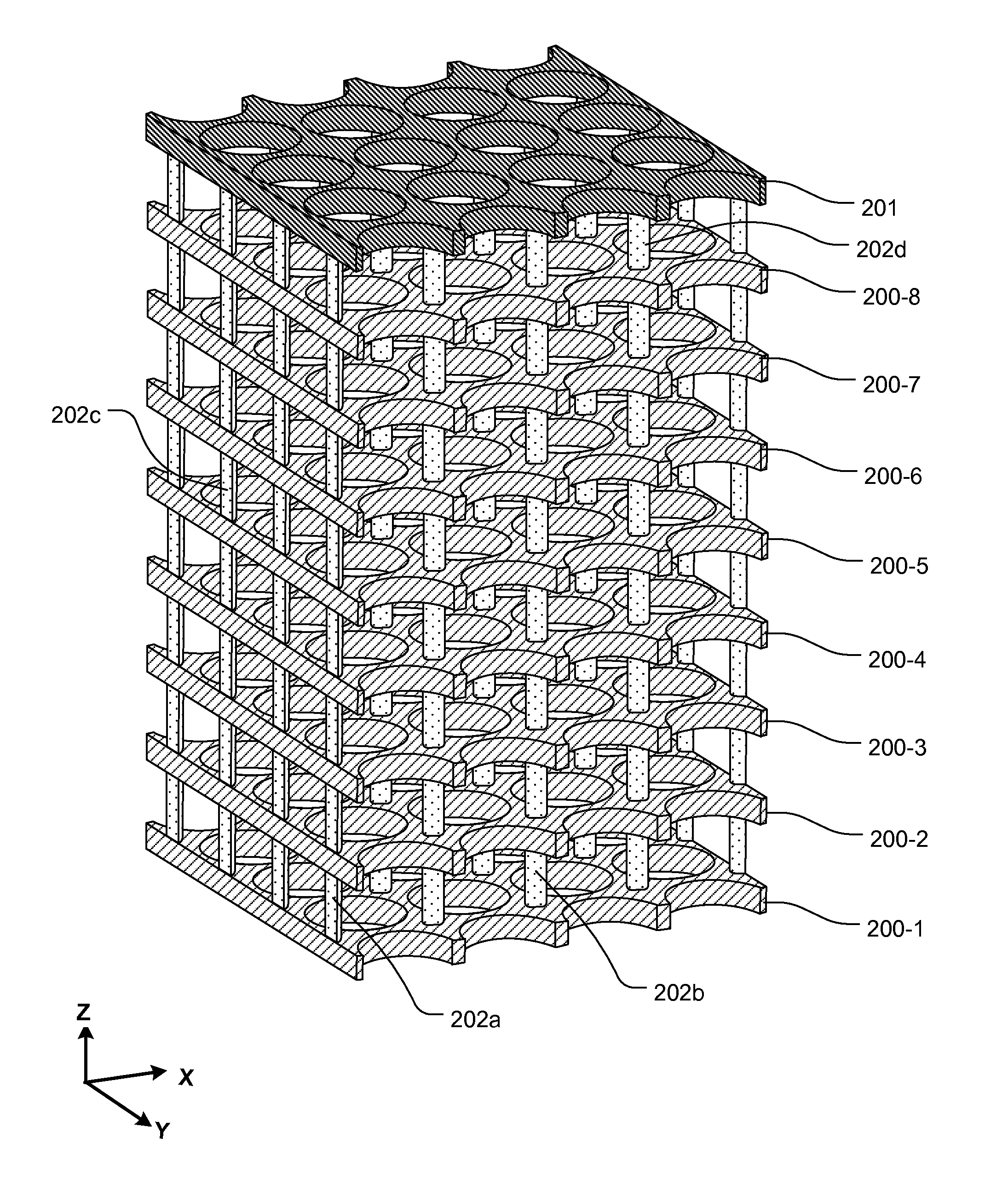

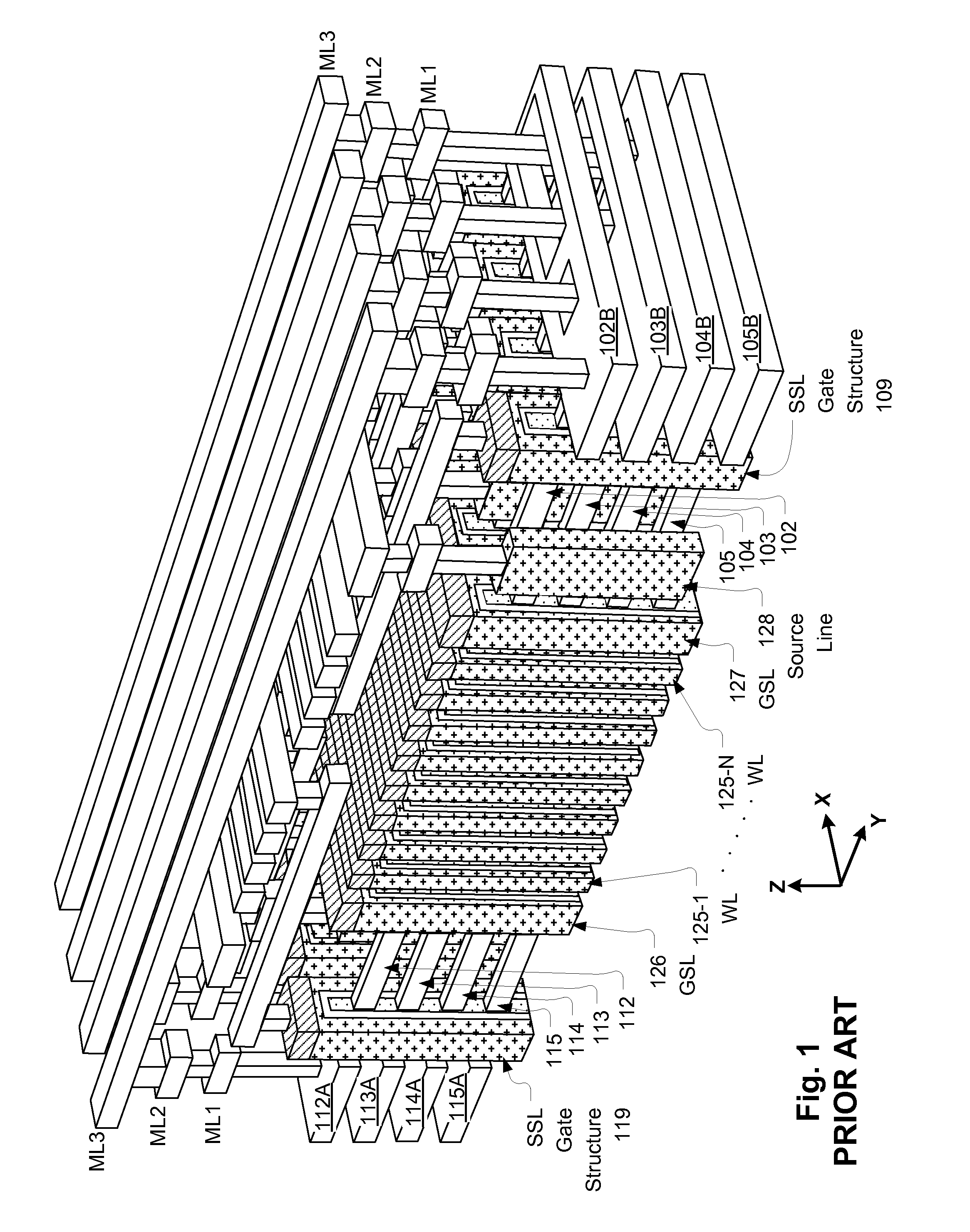

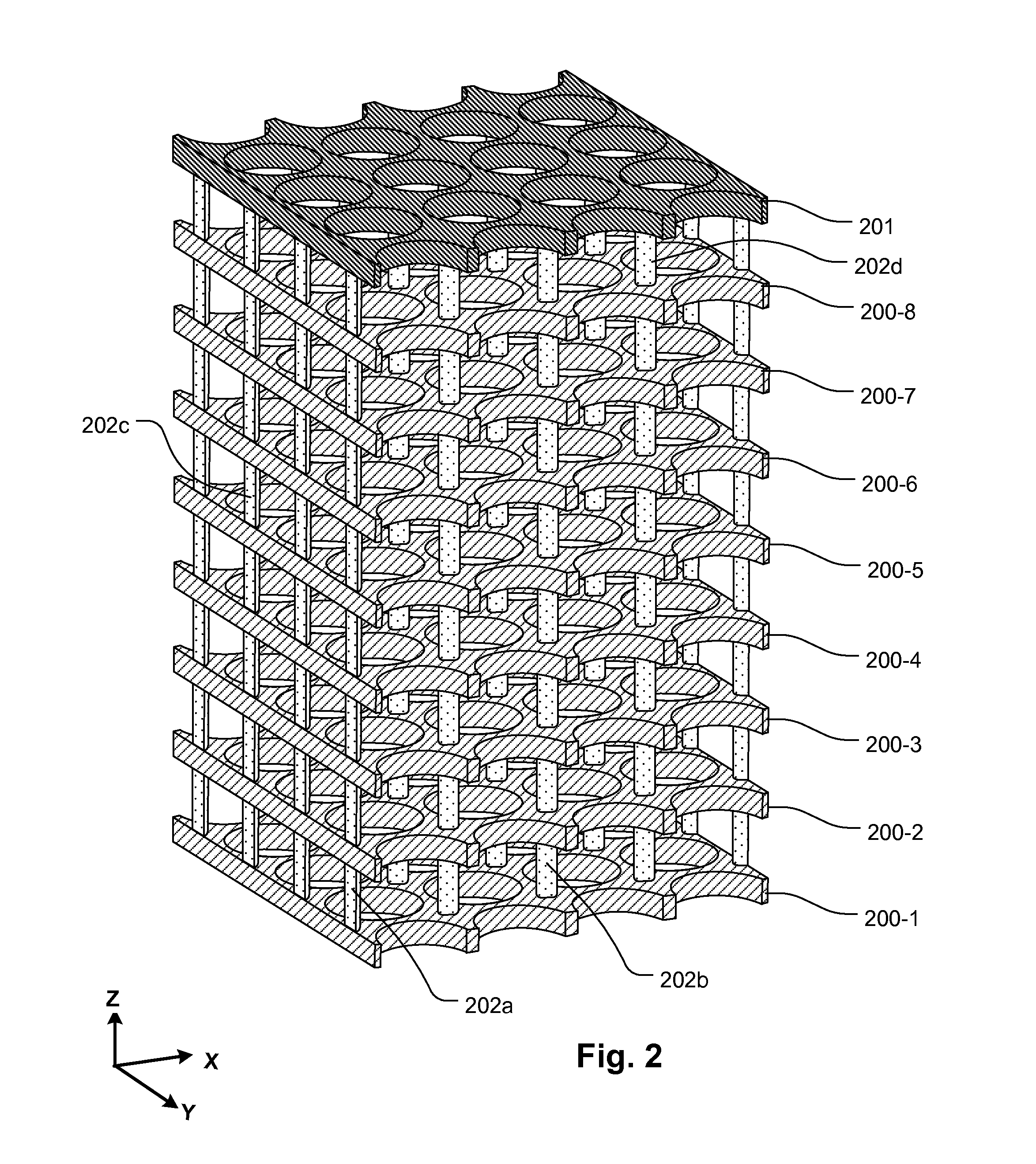

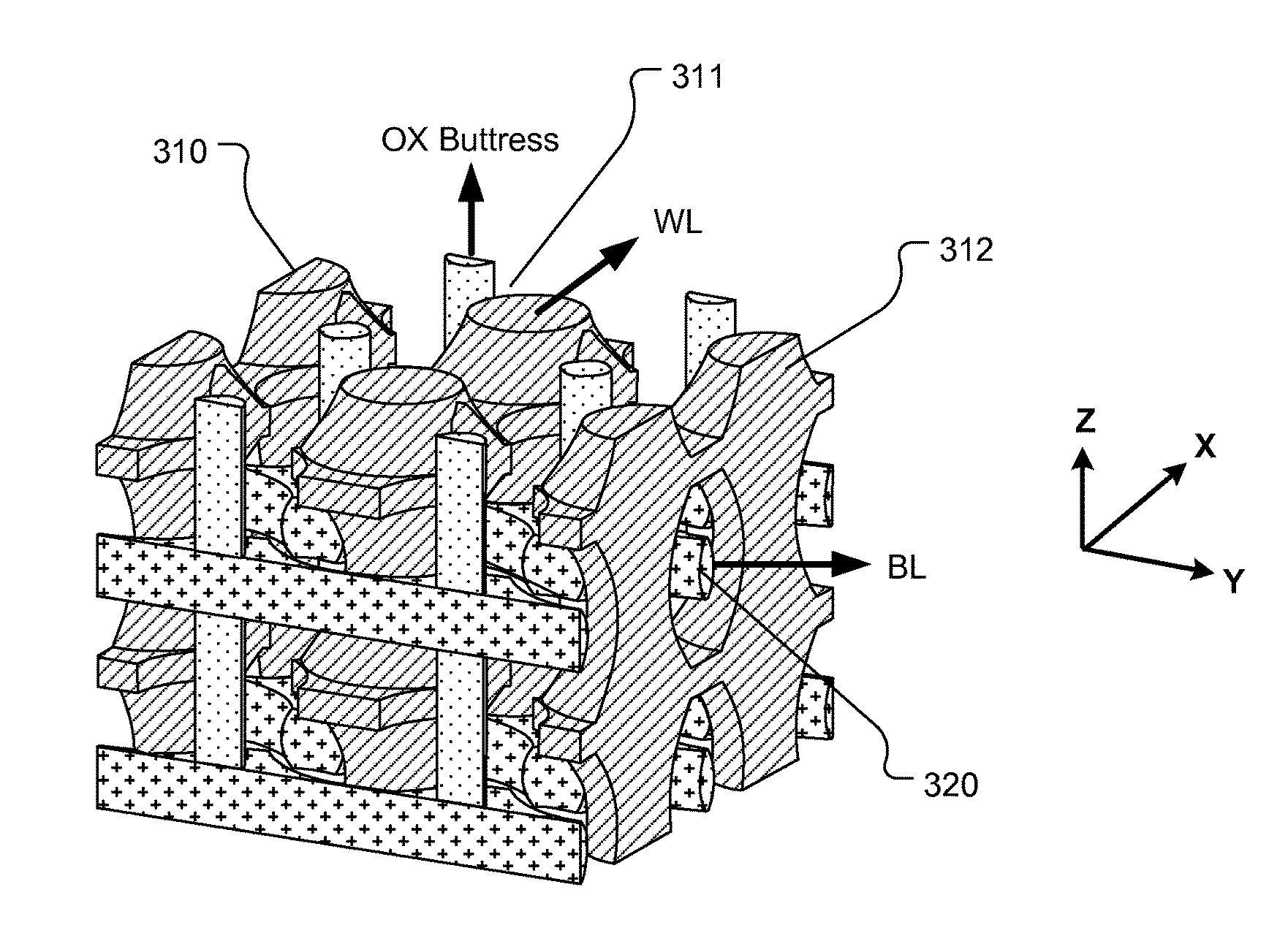

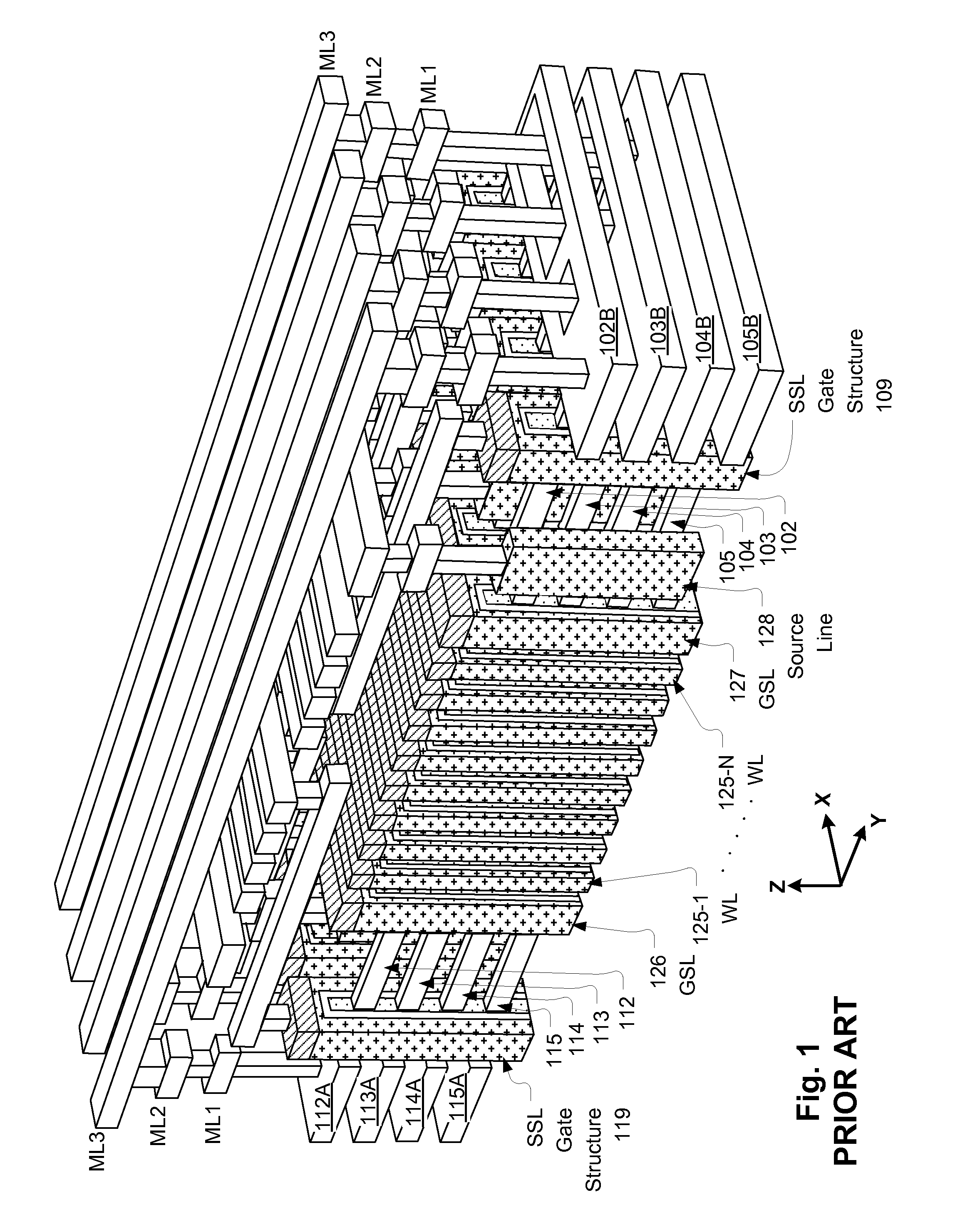

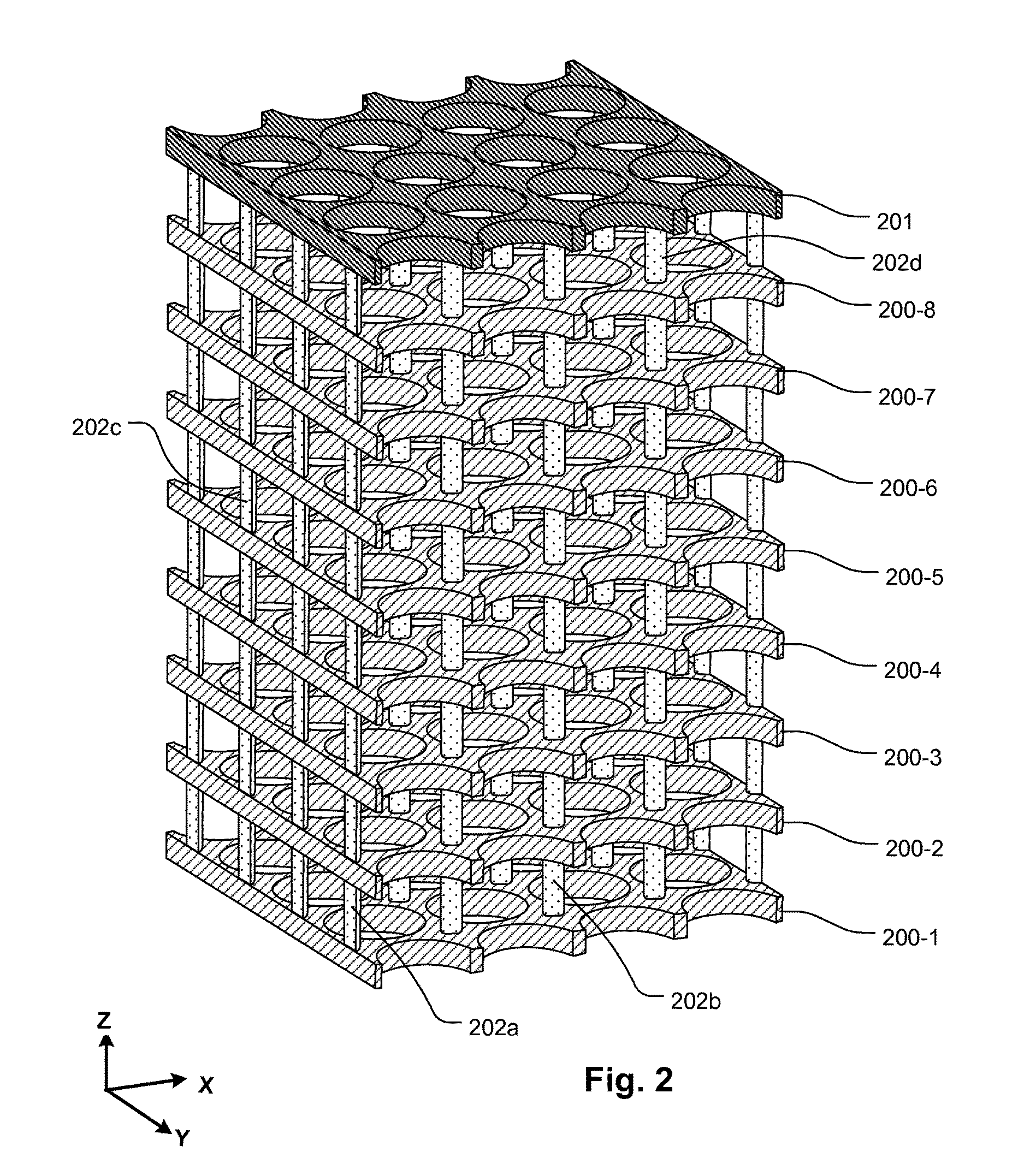

Vertical and 3D memory devices and methods of manufacturing the same

ActiveUS20160141299A1Solid-state devicesSemiconductor/solid-state device manufacturingEngineeringVertical slice

A memory device is described, which includes a block of memory cells comprising a plurality of stacks of horizontal active lines such as NAND string channel lines, with a plurality of vertical slices penetrated by, and surrounding, the horizontal active lines to provide a gate-all-around structure. A memory film is disposed between the horizontal active lines in the plurality of stacks and the vertical slices in the plurality of vertical slices. A 3D, horizontal channel, gate-all-around NAND flash memory is provided. A method for manufacturing a memory involves a buttress process. The buttress process enables horizontal channel, gate-all-around structures.

Owner:MACRONIX INT CO LTD

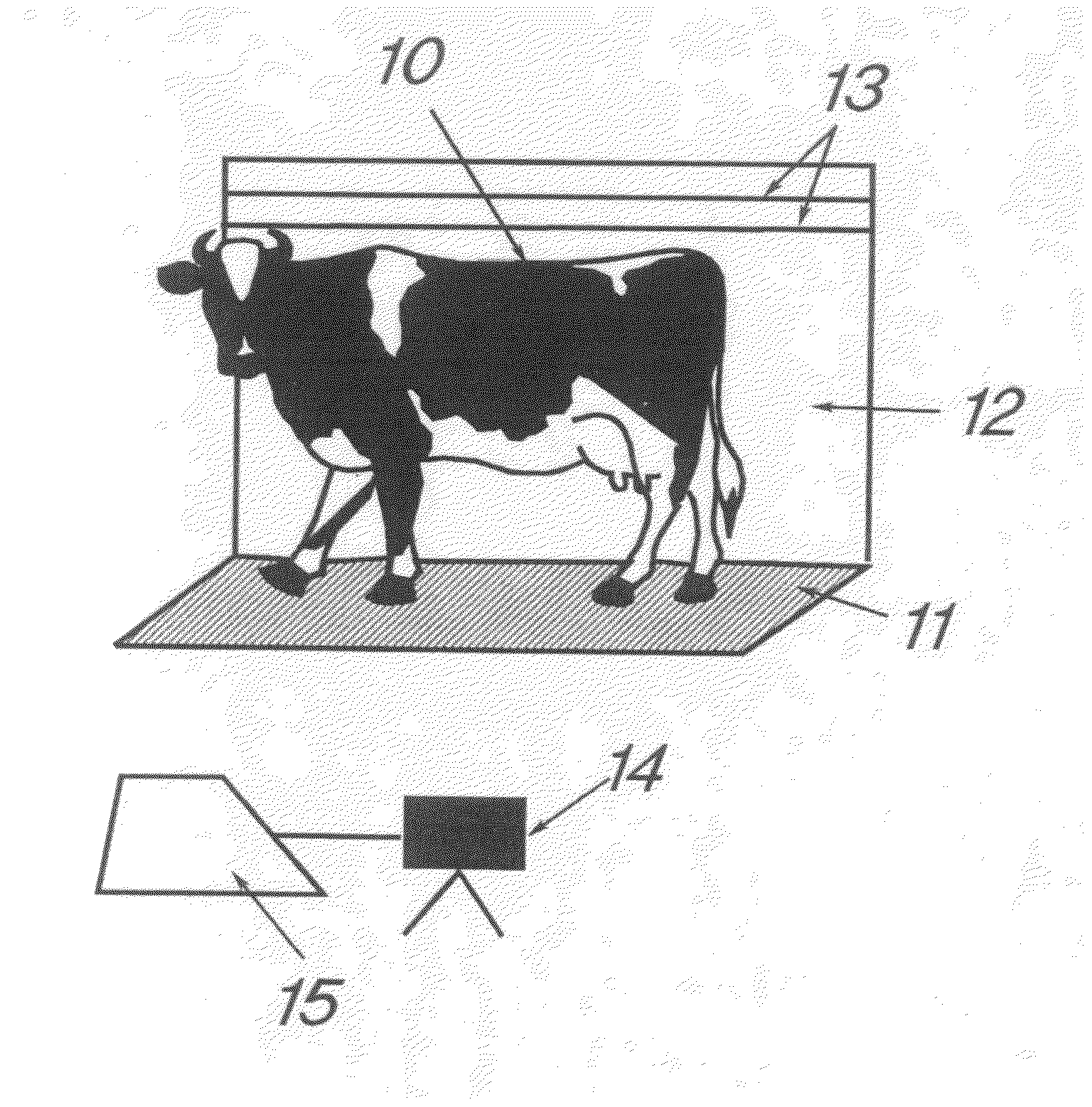

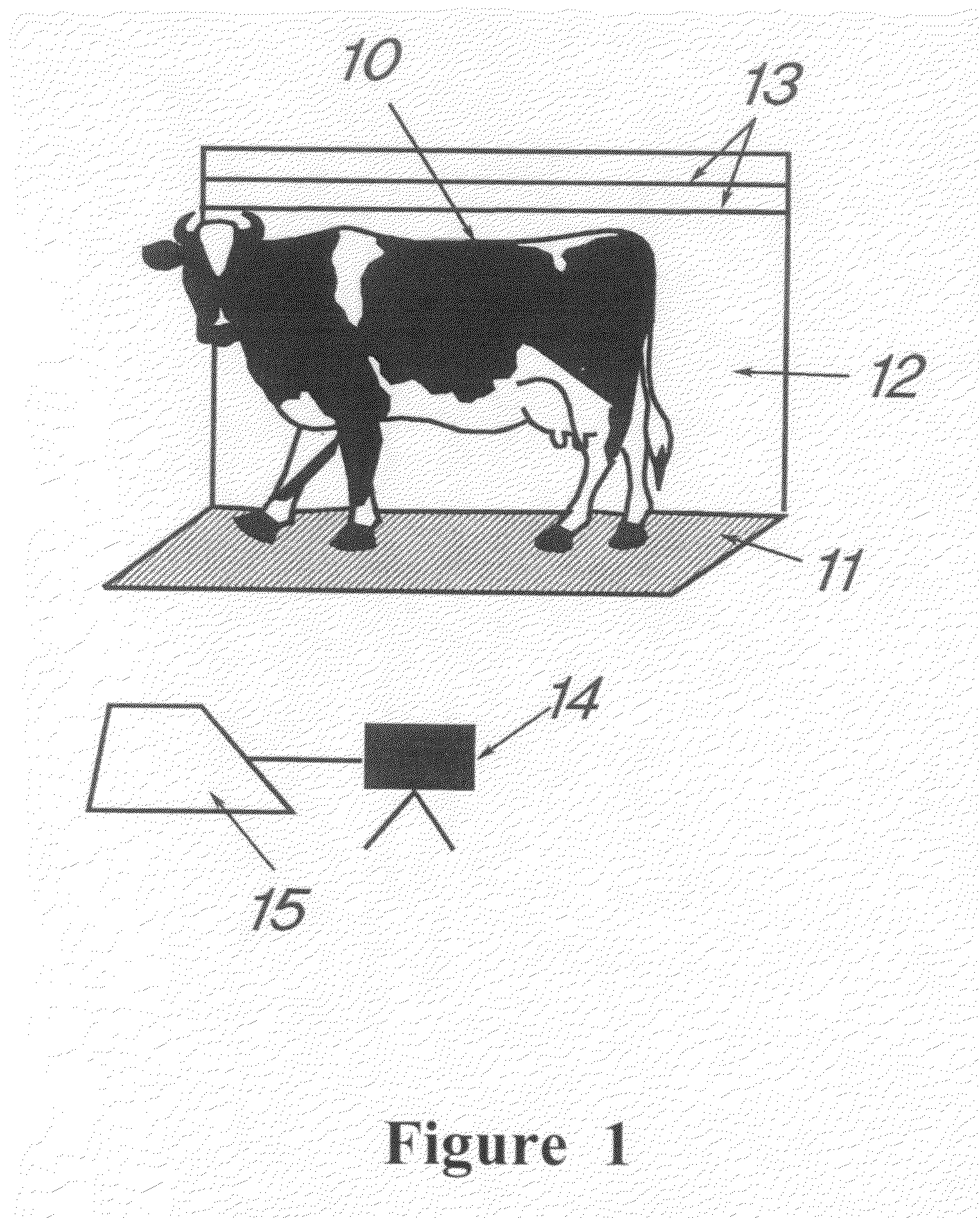

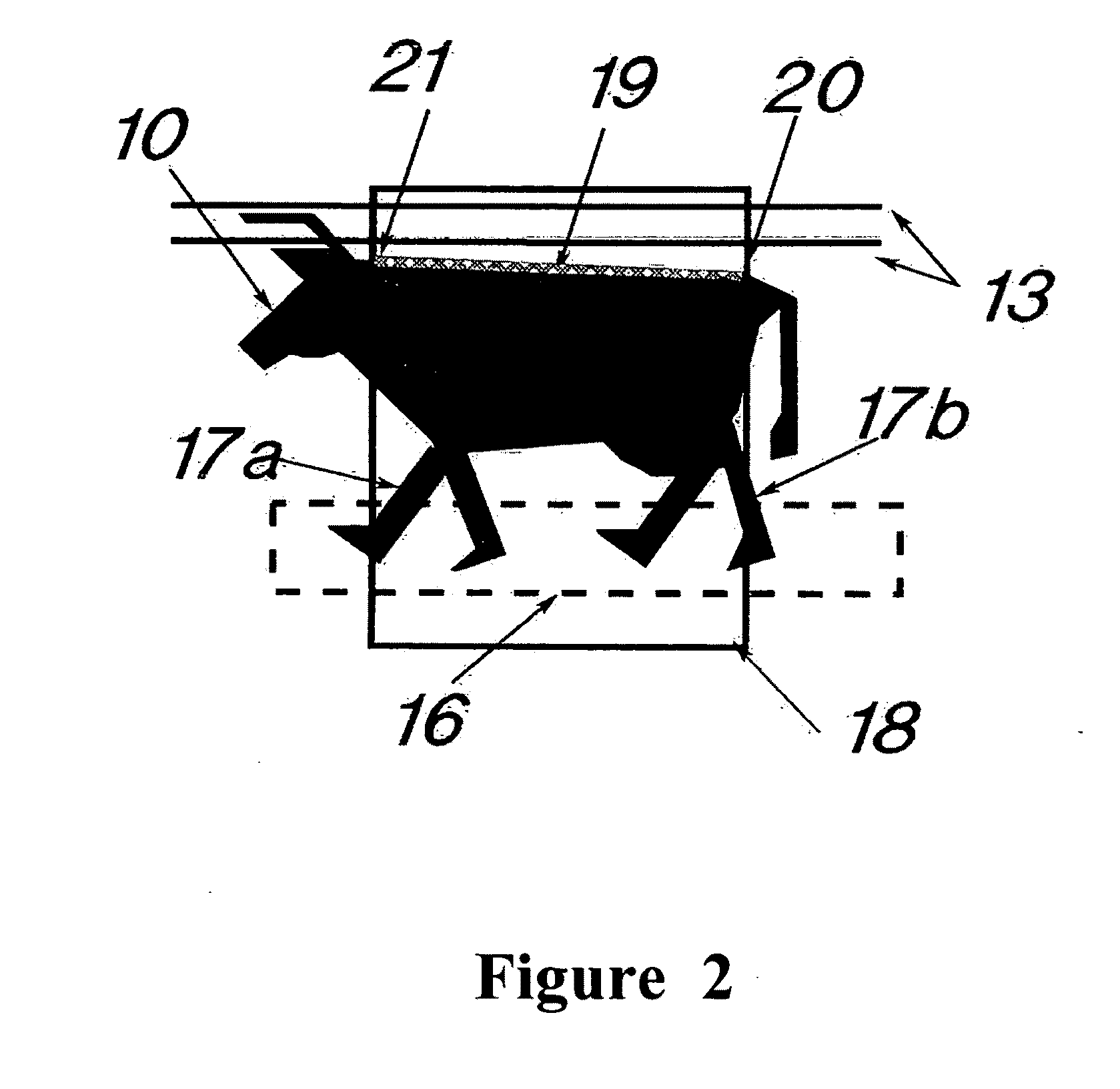

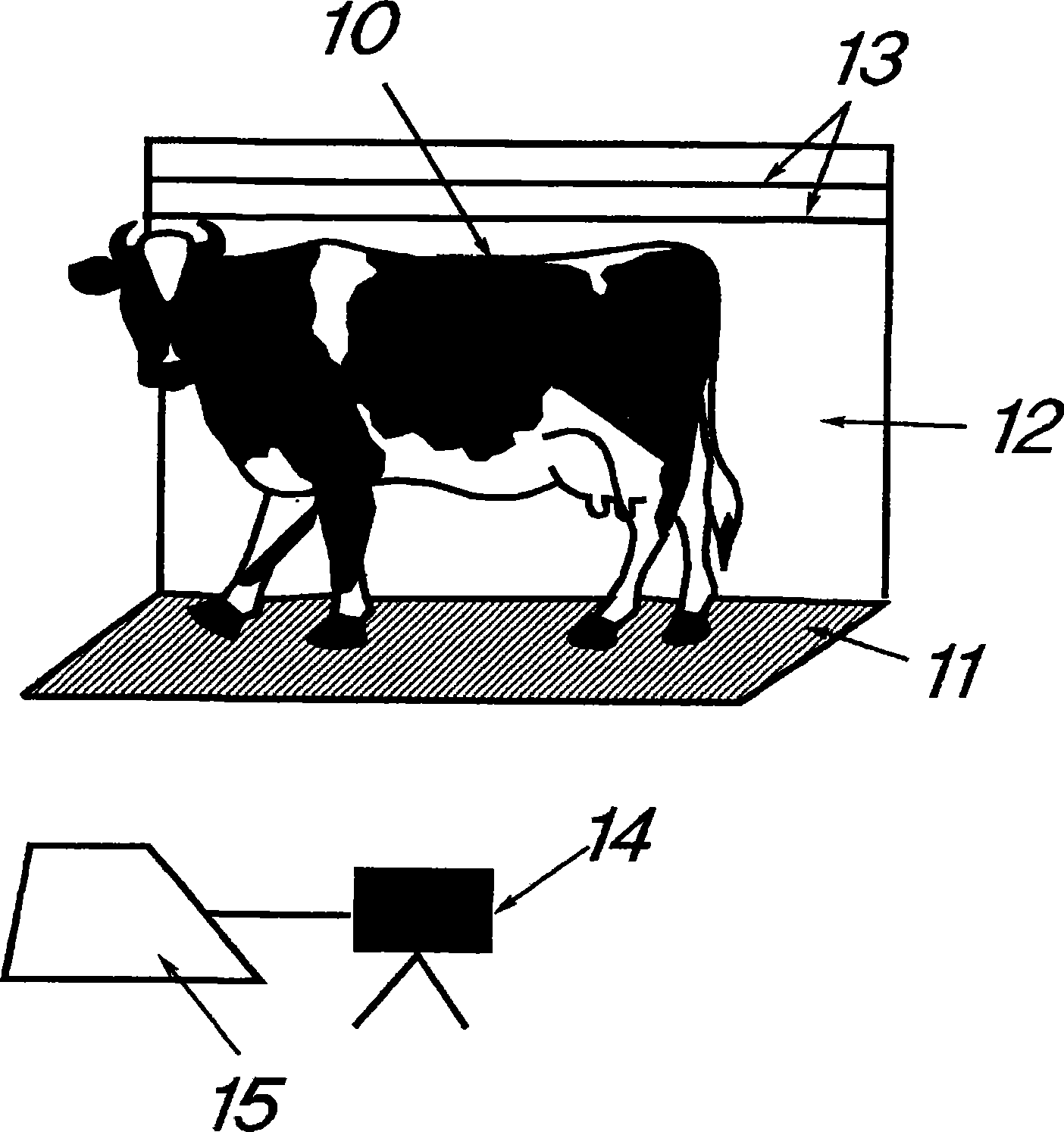

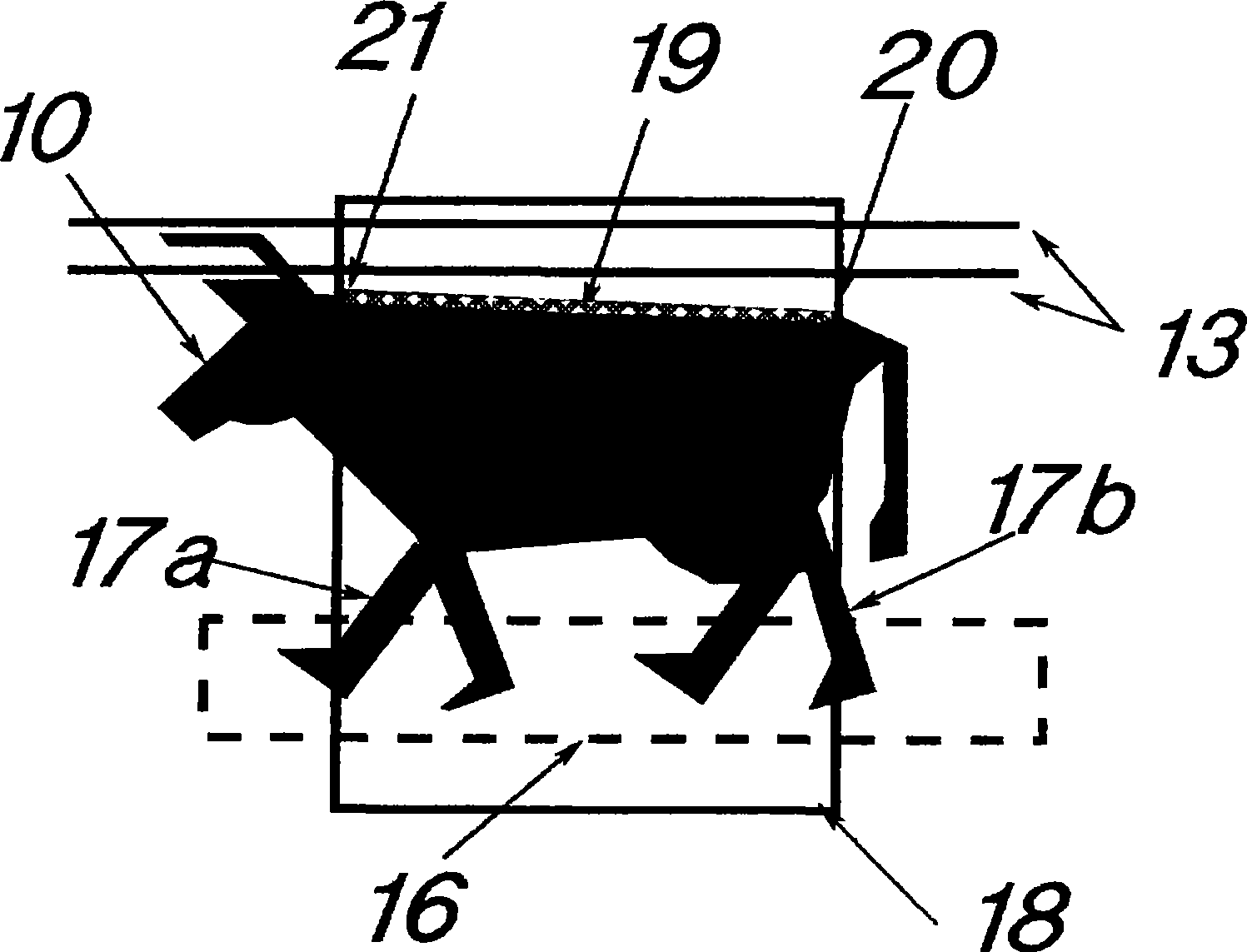

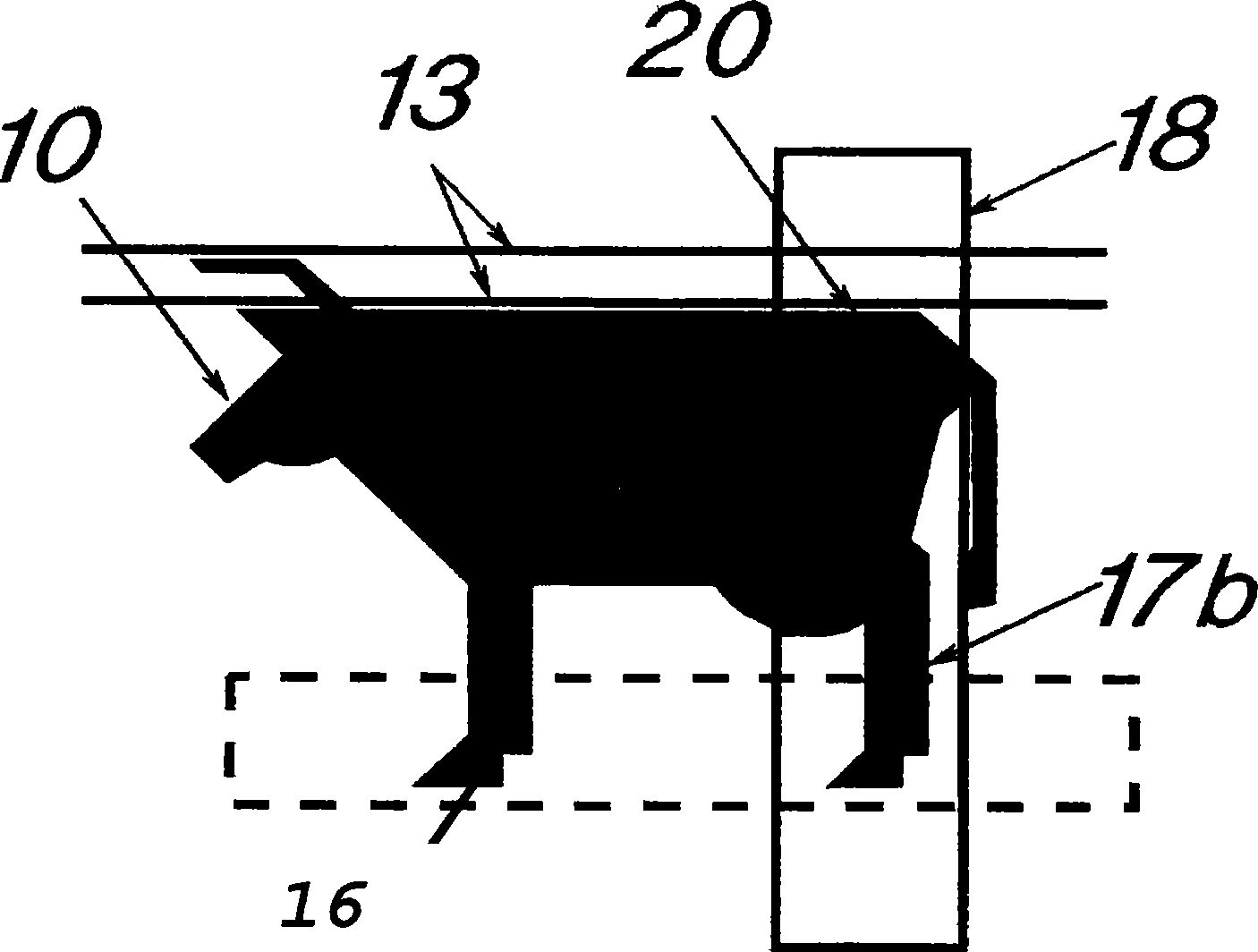

Method and a System for Measuring an Animal's Height

InactiveUS20100224140A1Weighting height resultsImage analysisCharacter and pattern recognitionImaging processingTail

A method and a system for measuring animal's height is disclosed. The method, and the system as well, is comprised of the following steps: allowing the animal to pass through a passage with measurement-references; capturing plurality of images of the animal while the animal is passing; on each image of the captured images applying the following steps: filtering the background from the image; applying imaging-process technique on the lower area of the measuring-image to recognize the location of the legs; defining a vertical slice of the measuring-image, in which the back's contour of the animal—from neck to tail—appears and applying imaging processing and mathematical calculations to obtain the real height, as defined, of the animal.

Owner:S A E AFIKIM COMPIZED DAIRY MANAGEMENT SYST

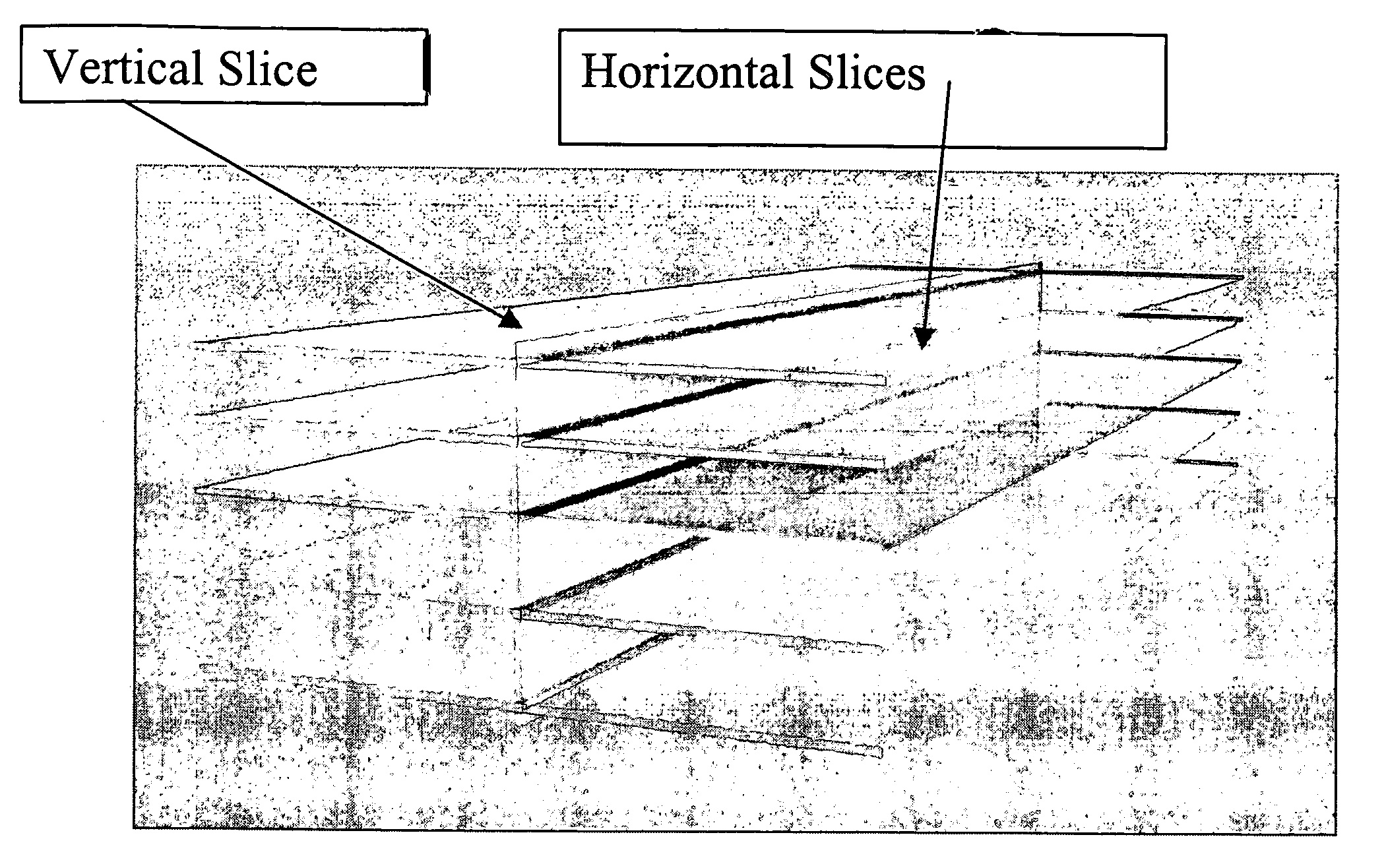

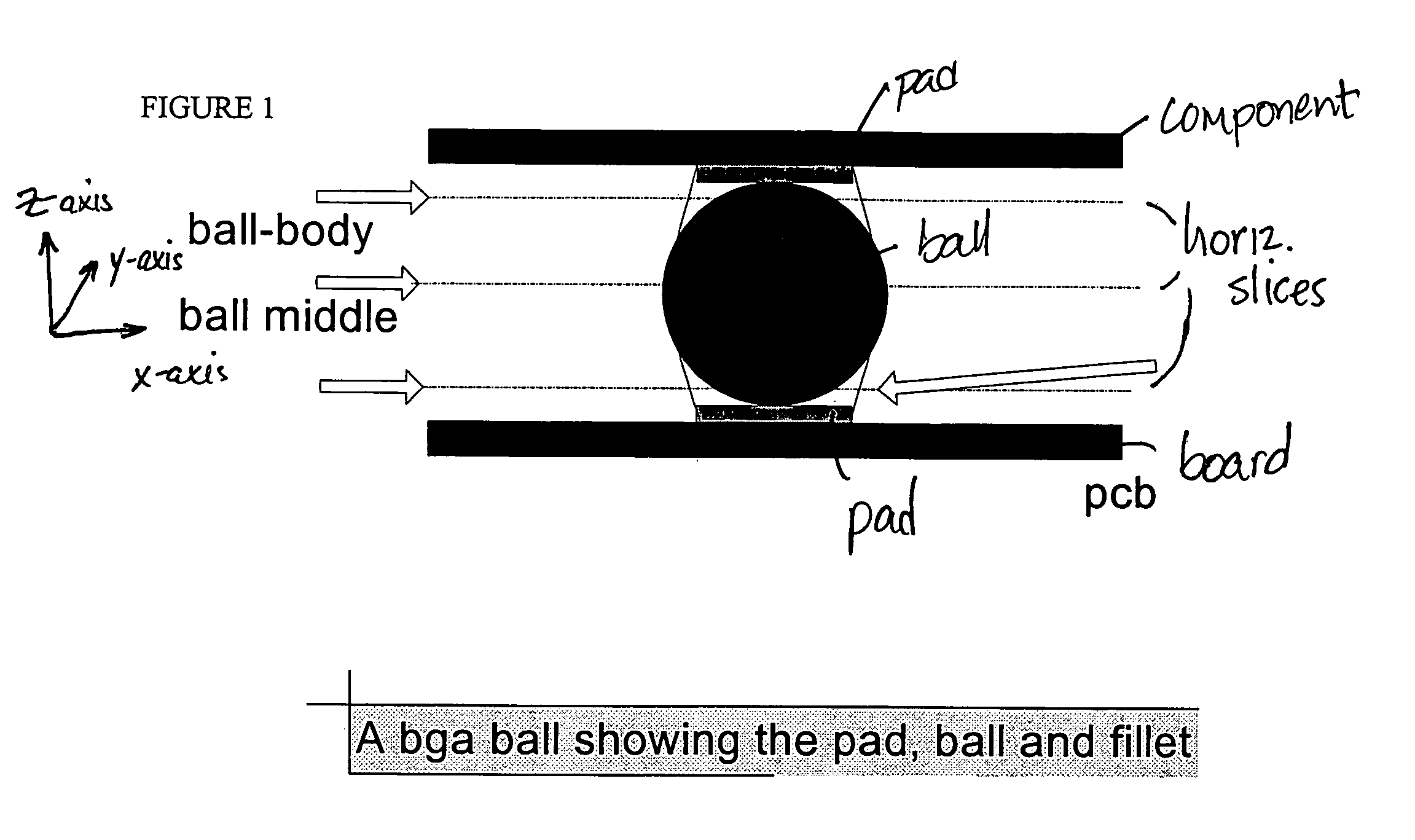

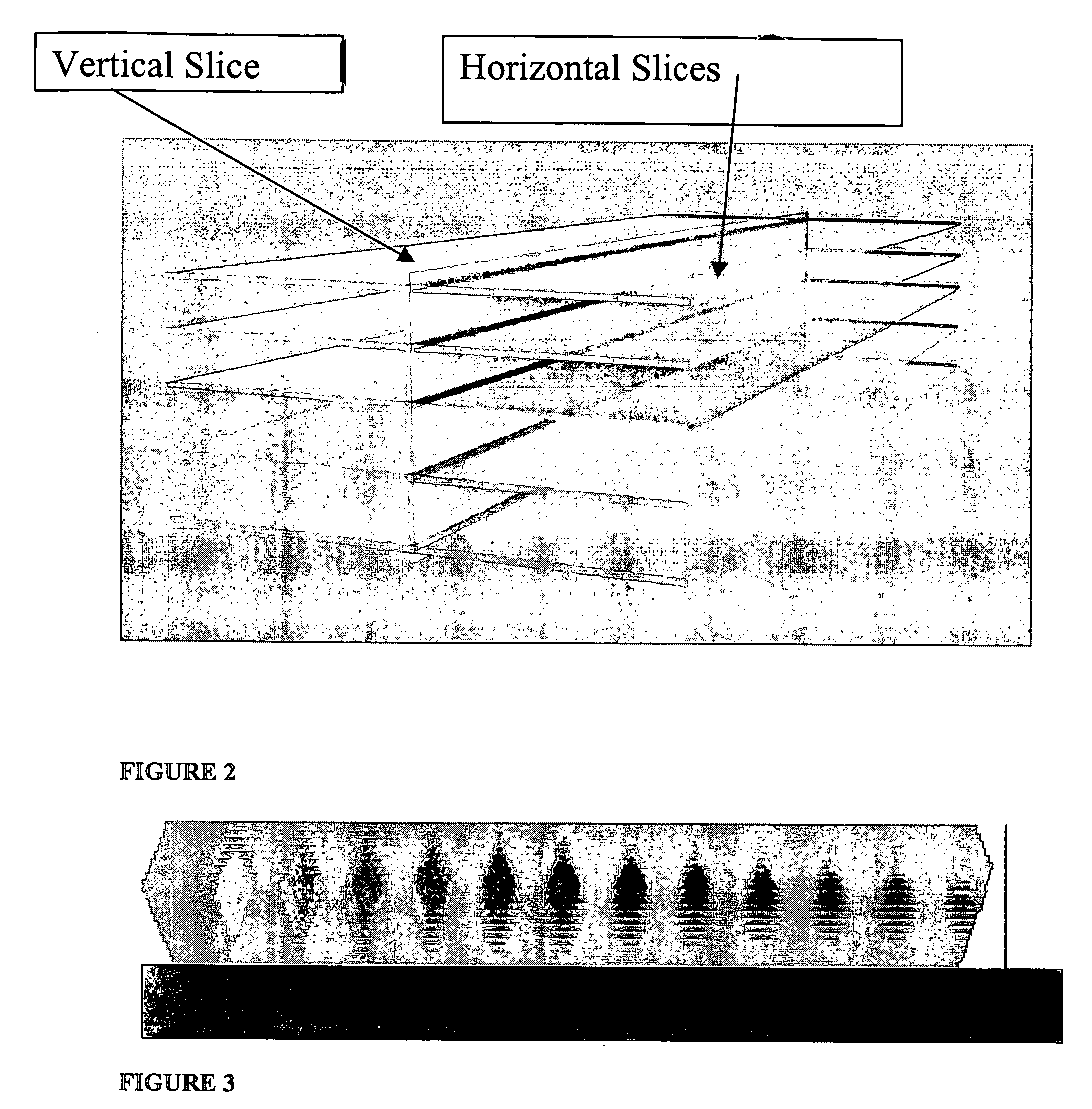

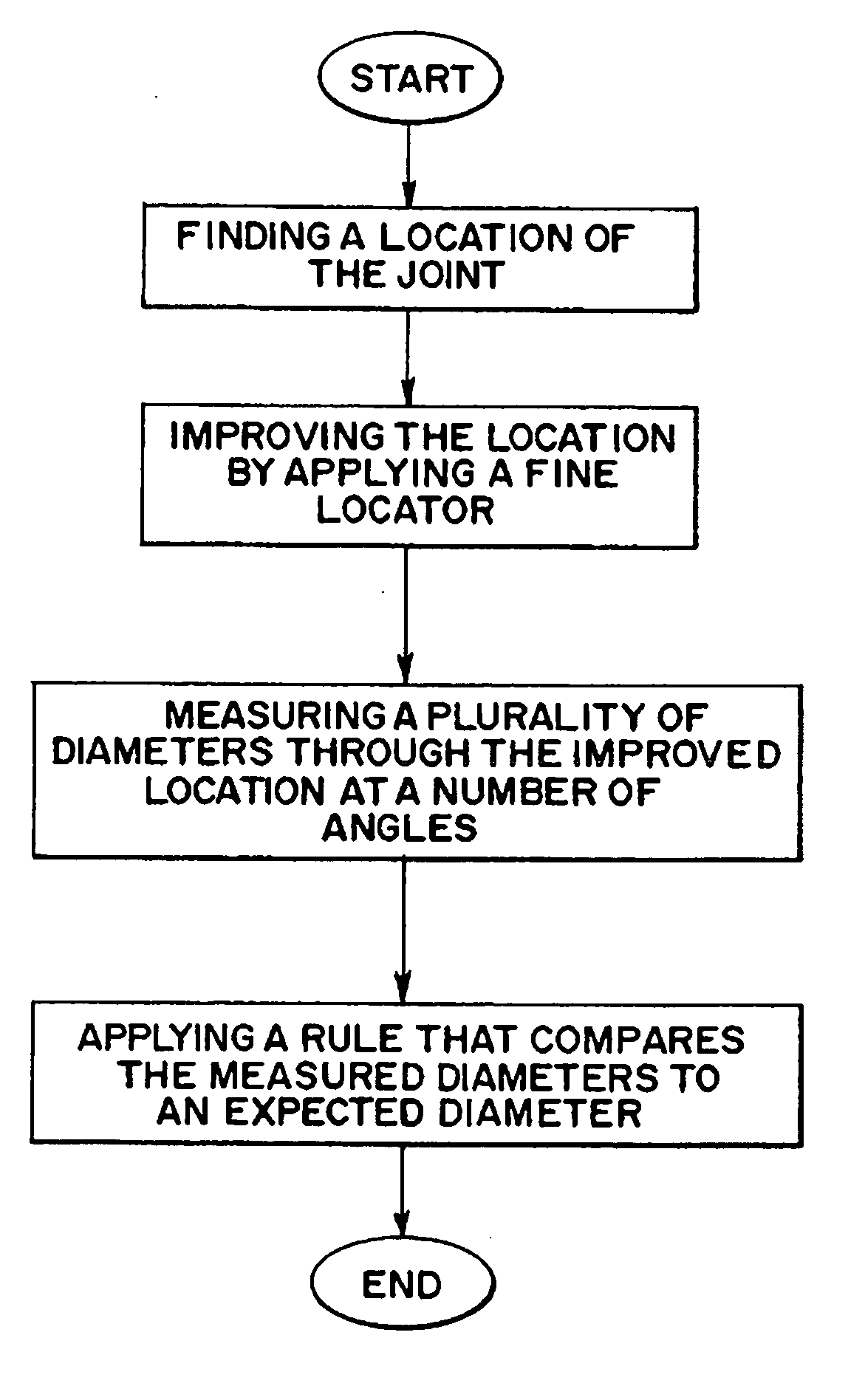

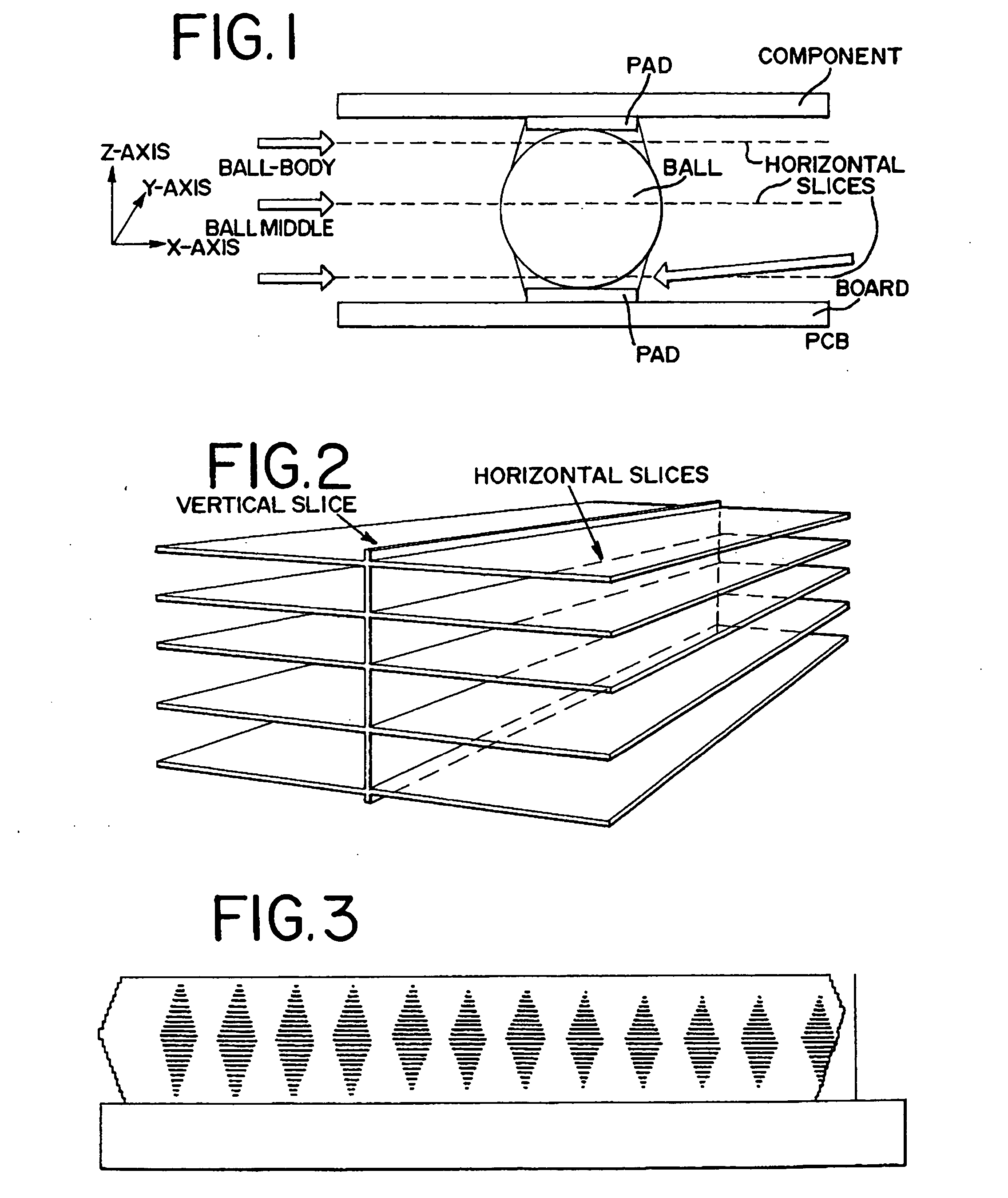

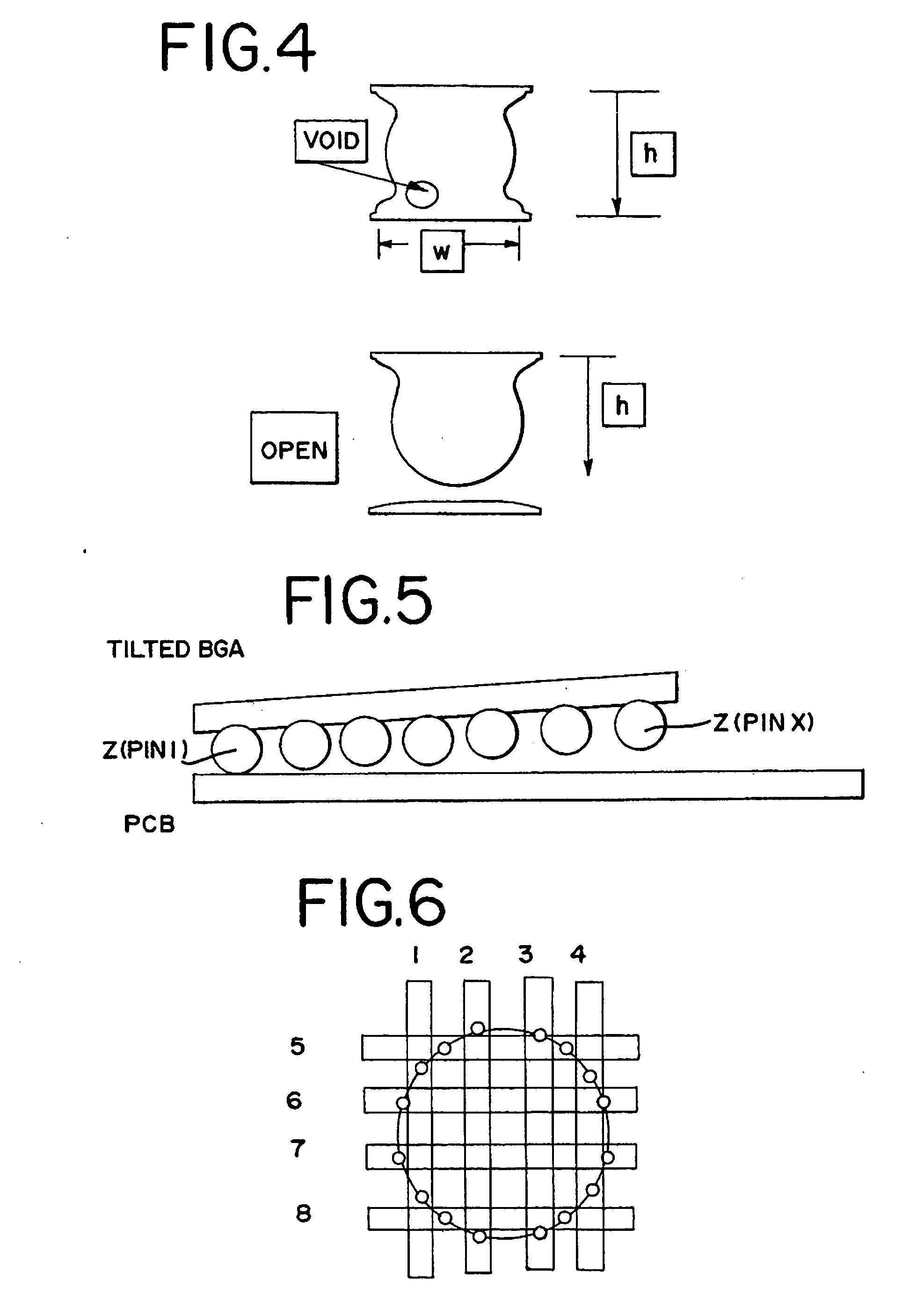

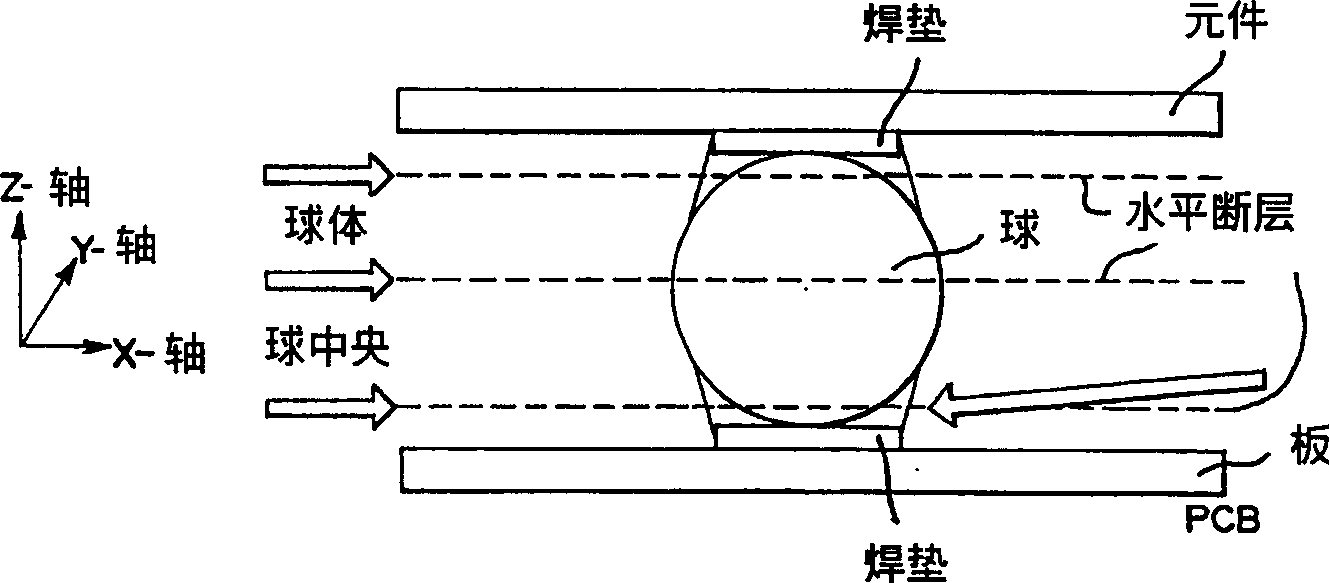

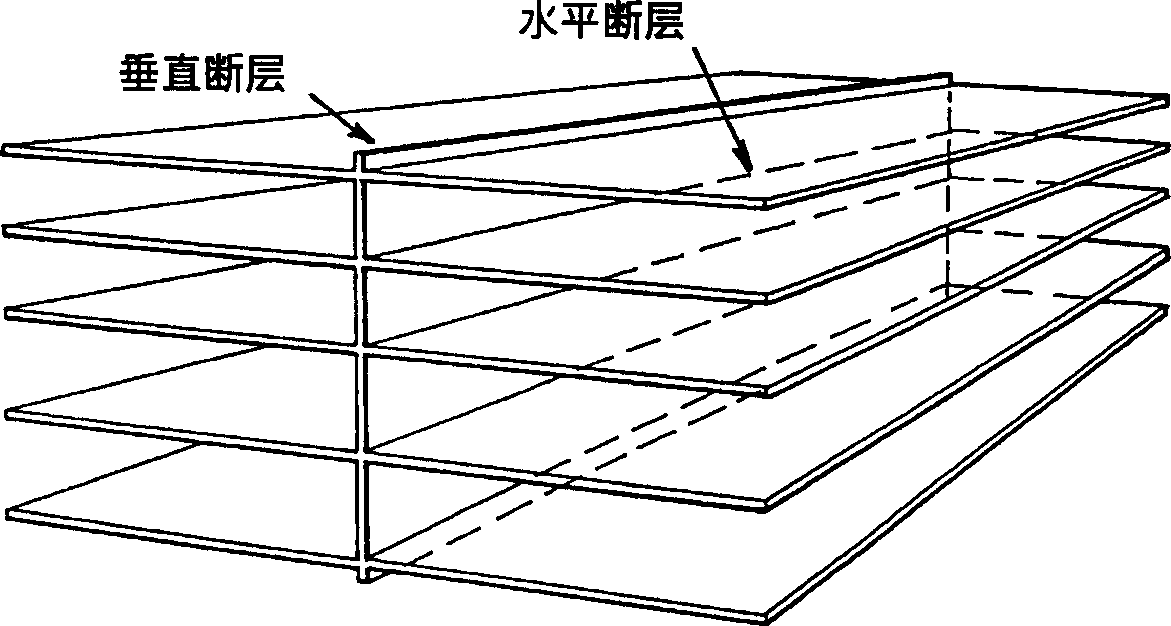

Inspection method utilizing vertical slice imaging

An inspection method utilizing vertical slice imaging. A number of horizontal slice images, extending through an object of interest, are acquired. A vertical region of interest is defined from the data representing the horizontal slice images. A vertical slice image is constructed based upon the horizontal slice image data falling within the vertical region of interest. The vertical slice image data may be analyzed to detect defects. In addition, a method is provided to detect defects in a BGA joint. The method includes locating a center of the joint. The method may further include measuring a number of diameters through the center of the joint and applying a rule to compare the measured diameters to an expected diameter.

Owner:TERADYNE +1

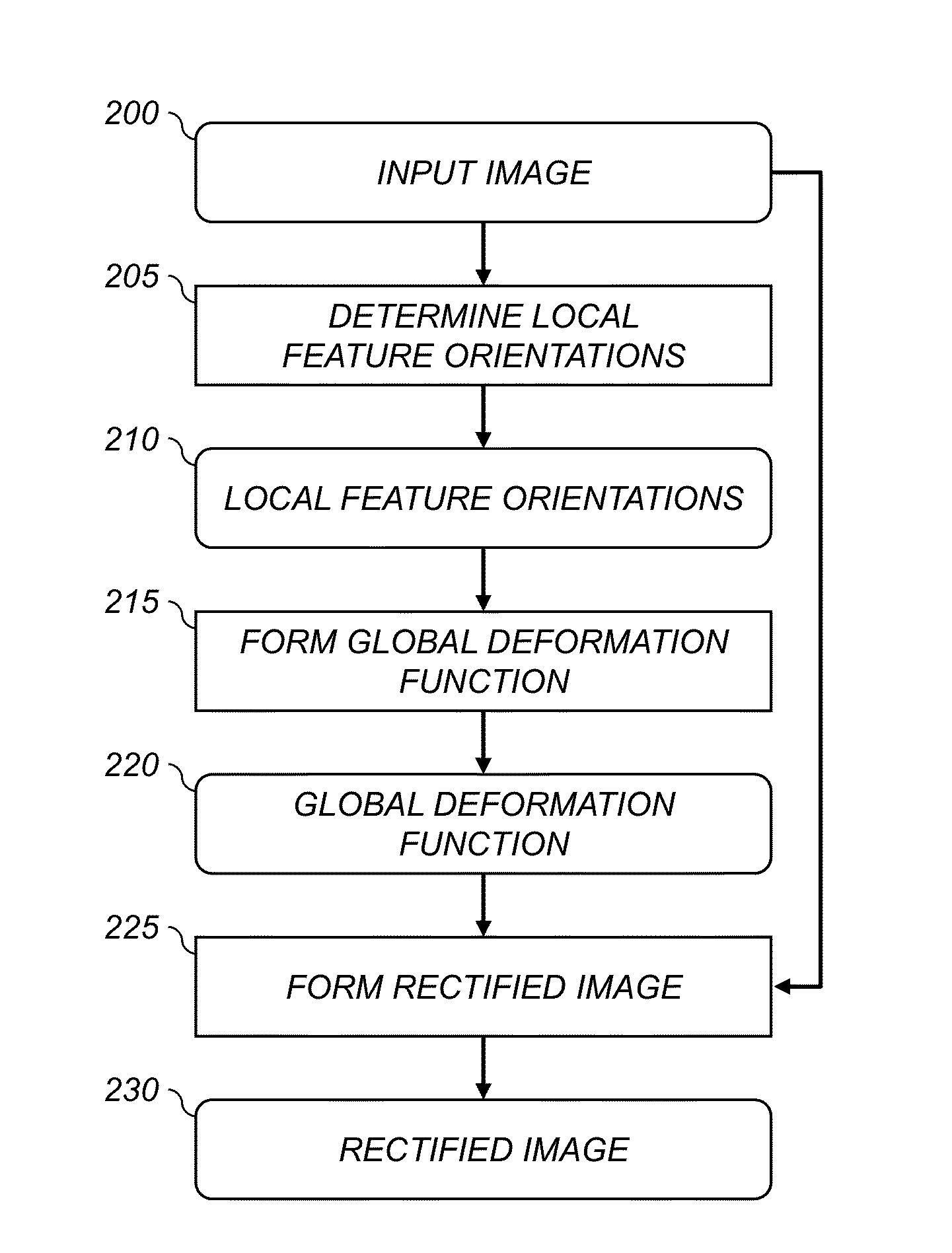

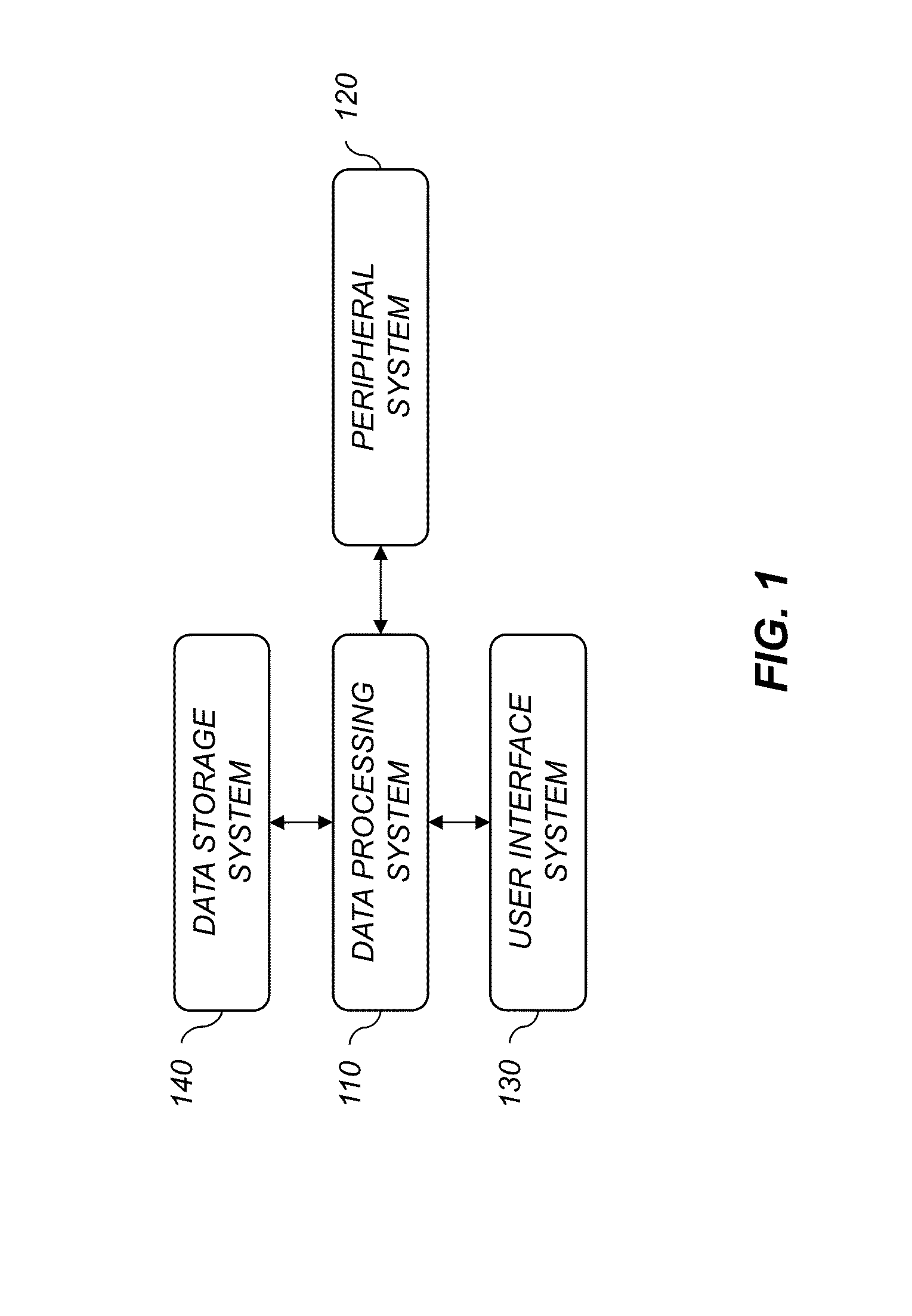

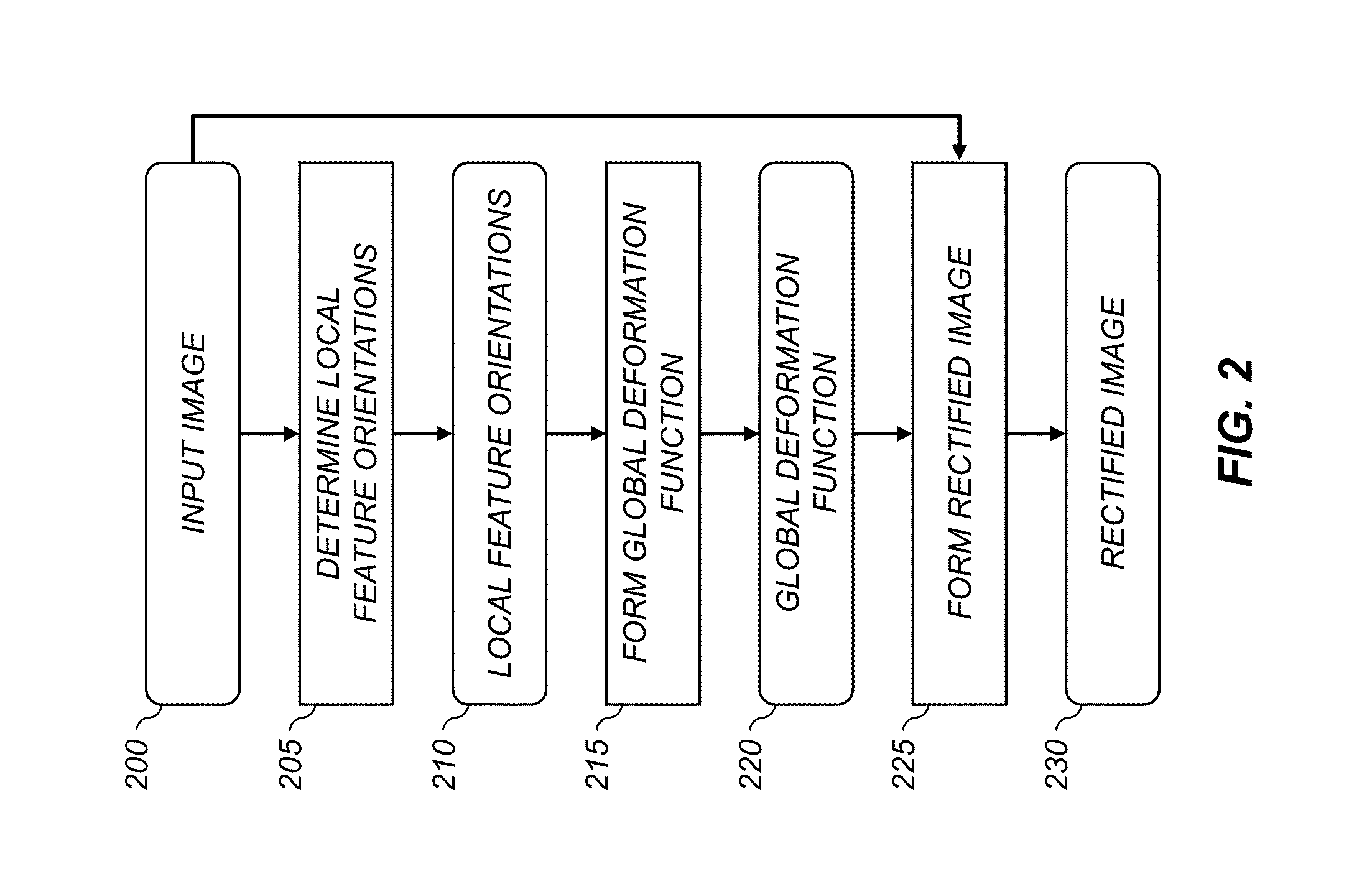

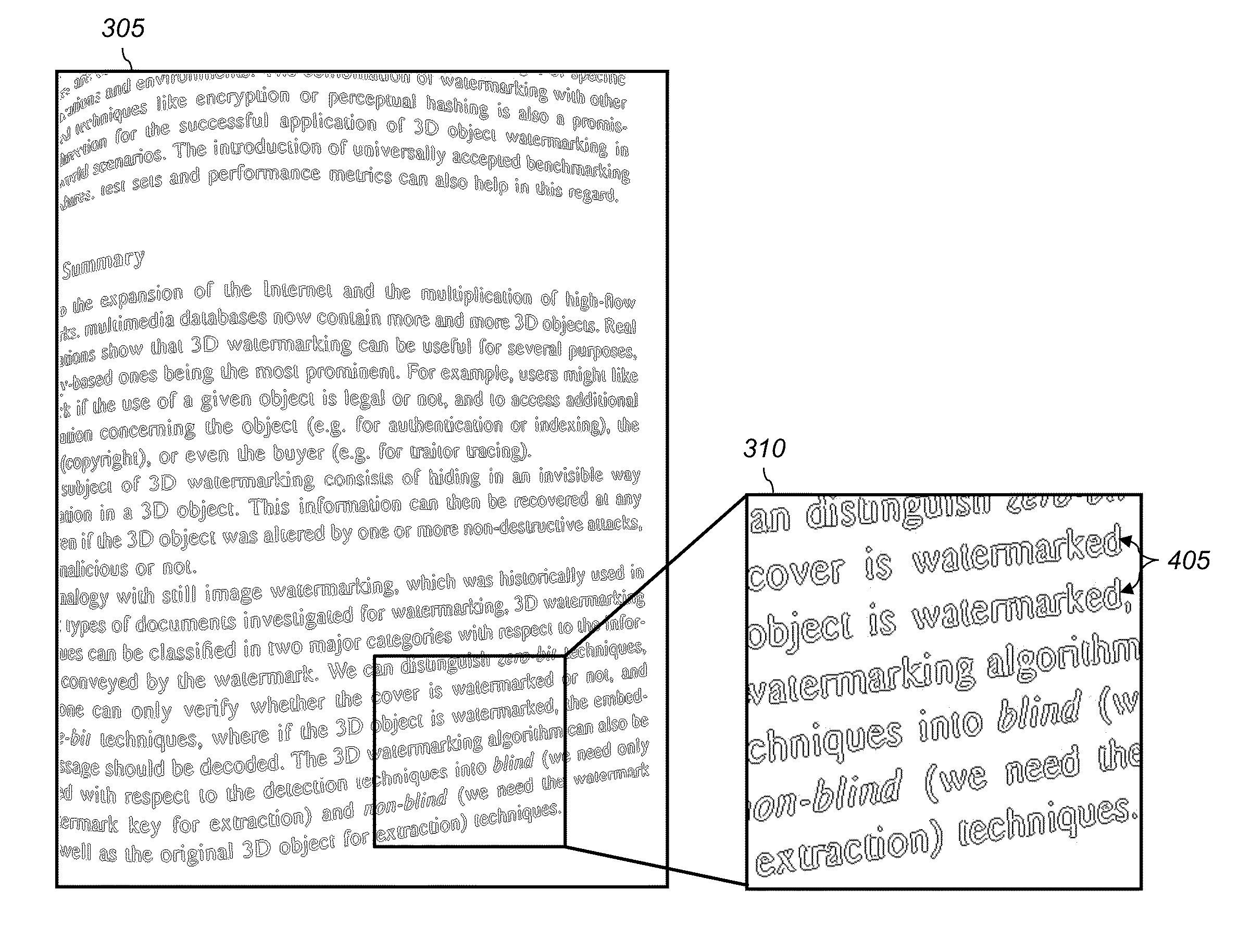

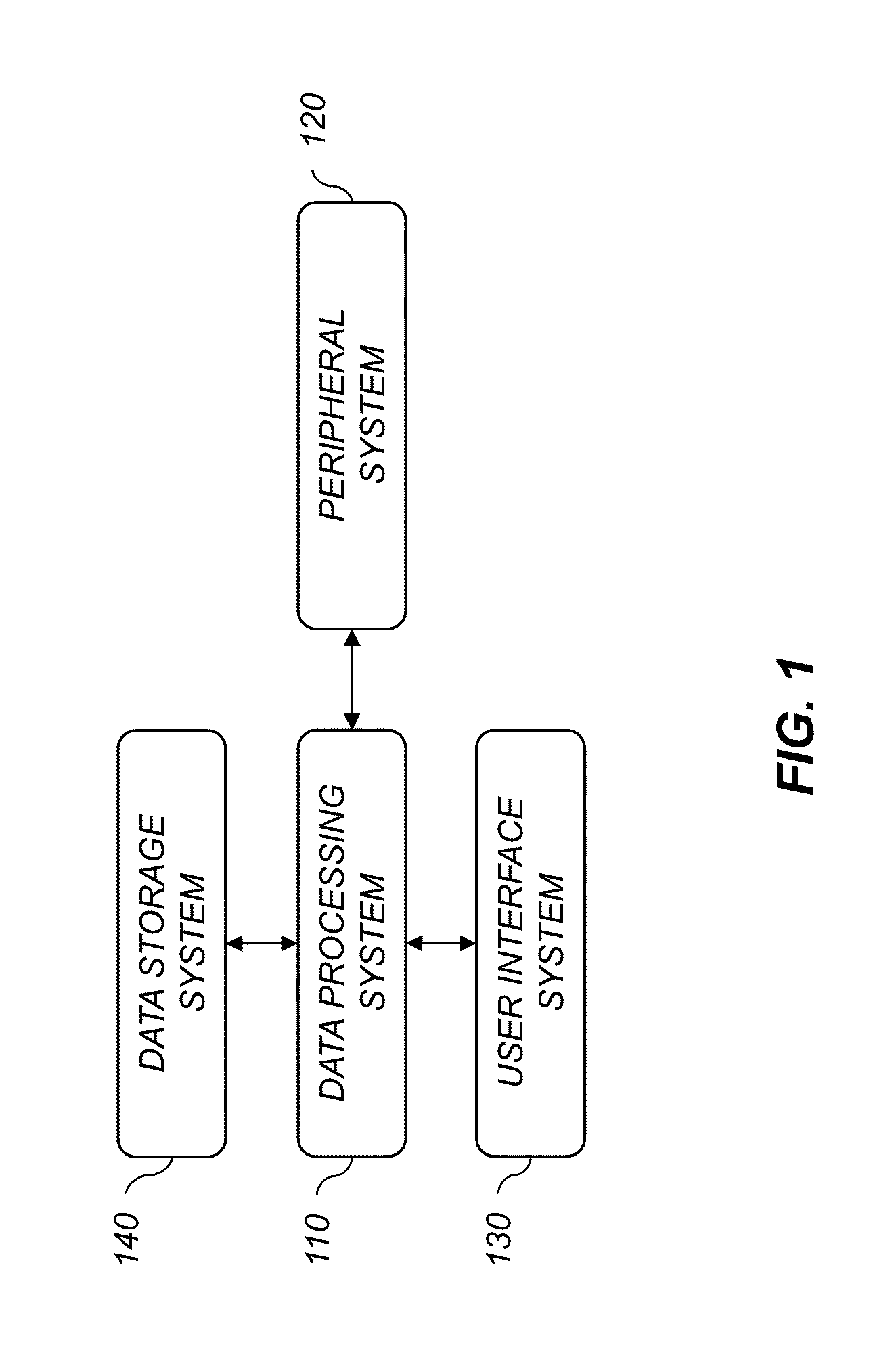

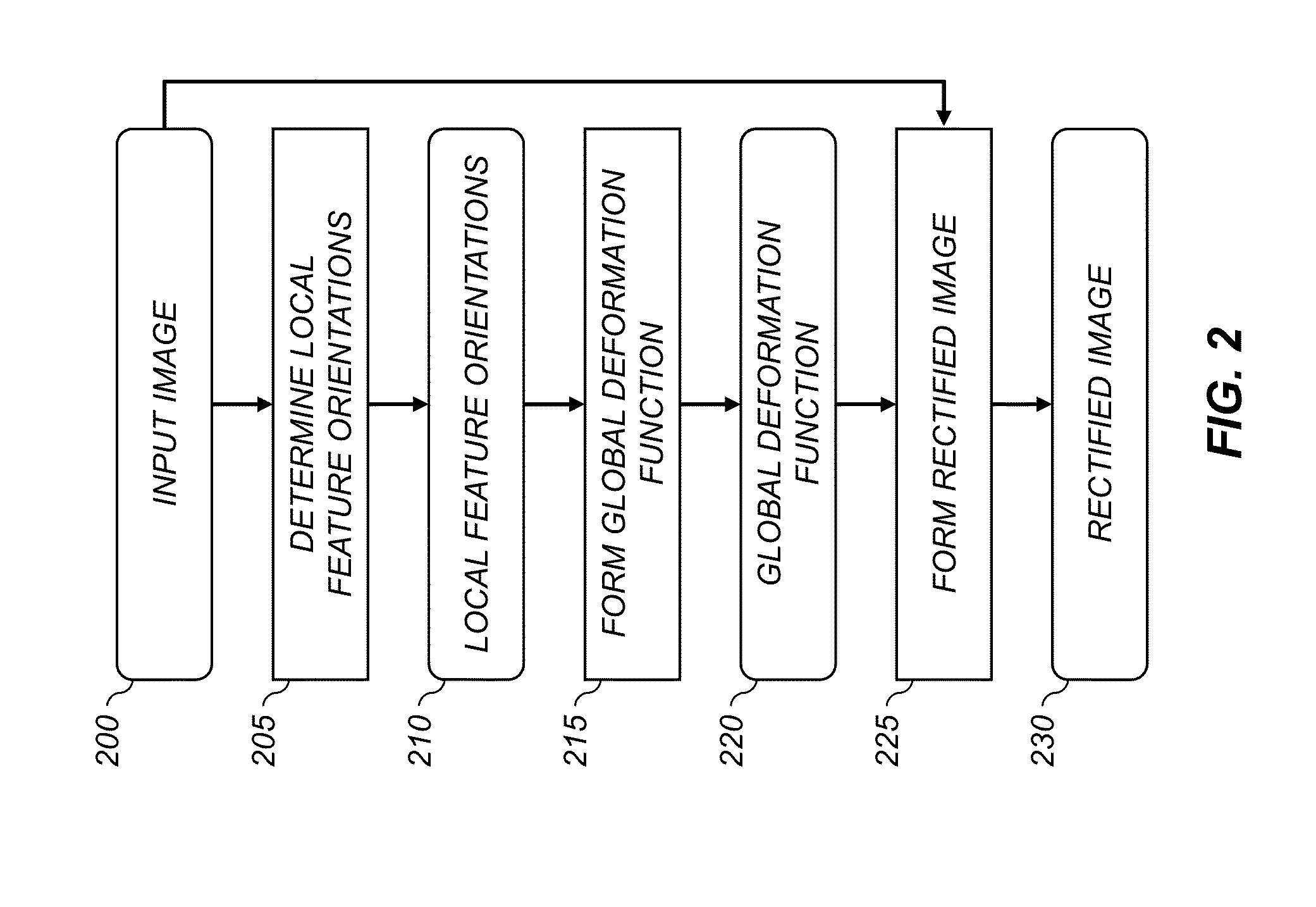

Image rectification using text line tracks

InactiveUS8787695B2Efficient and robustImage enhancementImage analysisComputer graphics (images)Digital image

This invention is a method for rectifying an input digital image including warped textual information. The method includes analyzing the input digital image to determine a plurality of text line traces that track along with the warped textual lines in a substantially parallel fashion. The input digital image is subdivided into a plurality of vertical slices, each having associated first and second slice edges and an associated slice width. Vertical slice deformation models are formed for the vertical slices by identifying a plurality of text line traces that cross a particular vertical slice, and fitting a parametric function that predicts second-edge vertical coordinates for the text line traces as a function of corresponding first-edge vertical coordinates. A plurality of streamlines are formed responsive to the vertical slice deformation models. A global deformation function is formed by interpolating between the streamlines and is used to form a rectified image.

Owner:EASTMAN KODAK CO

A method and a system for measuring an animal's height

A method and a system for measuring animal's height is disclosed. The method, and the system as well, is comprised of the following steps: allowing the animal to pass through a passage with measurement-references; capturing plurality of images of the animal while the animal is passing; on each image of the captured images applying the following steps: filtering the background from the image; applying imaging-process technique on the lower area of the measuring-image to recognize the location of the legs; defining a vertical slice of the measuring-image, in which the back's contour of the animal - from neck to tail - appears and applying imaging processing and mathematical calculations to obtain the real height, as defined, of the animal.

Owner:阿菲克姆智能牧场管理系统公司

Image rectification using text line tracks

InactiveUS20140140635A1Robust and efficient methodInsensitive to contentImage enhancementImage analysisComputer graphics (images)Digital image

This invention is a method for rectifying an input digital image including warped textual information. The method includes analyzing the input digital image to determine a plurality of text line traces that track along with the warped textual lines in a substantially parallel fashion. The input digital image is subdivided into a plurality of vertical slices, each having associated first and second slice edges and an associated slice width. Vertical slice deformation models are formed for the vertical slices by identifying a plurality of text line traces that cross a particular vertical slice, and fitting a parametric function that predicts second-edge vertical coordinates for the text line traces as a function of corresponding first-edge vertical coordinates. A plurality of streamlines are formed responsive to the vertical slice deformation models. A global deformation function is formed by interpolating between the streamlines and is used to form a rectified image

Owner:EASTMAN KODAK CO

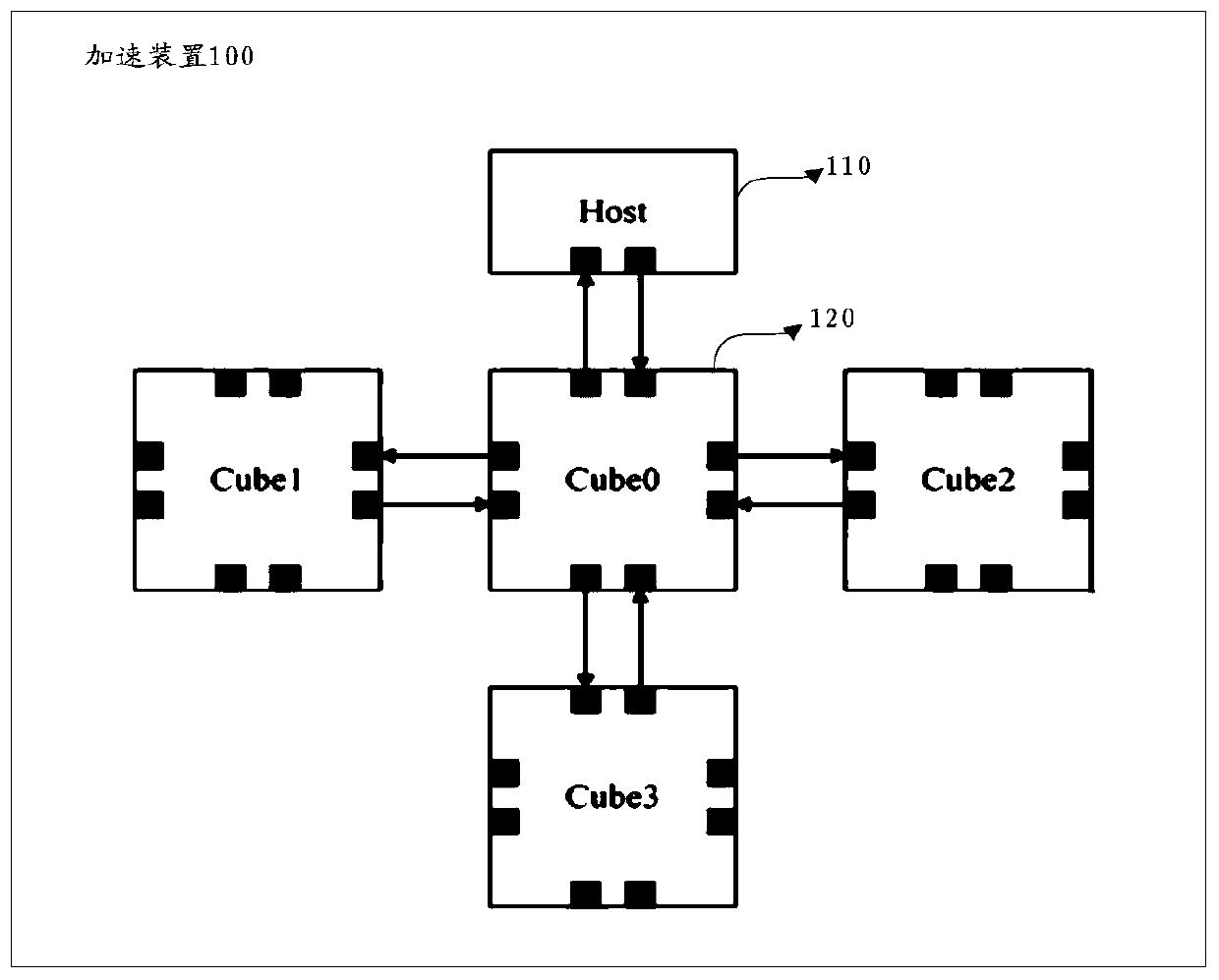

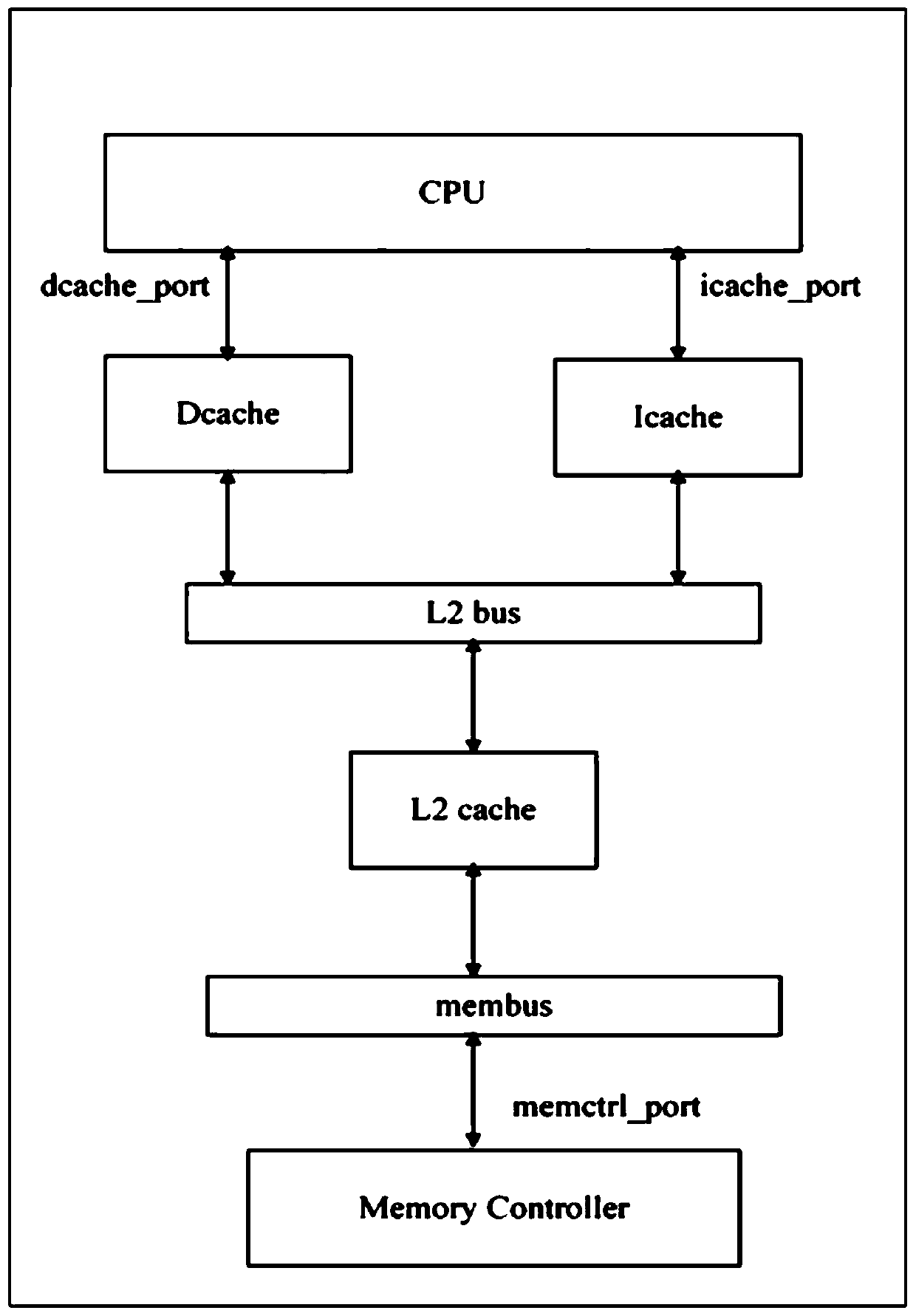

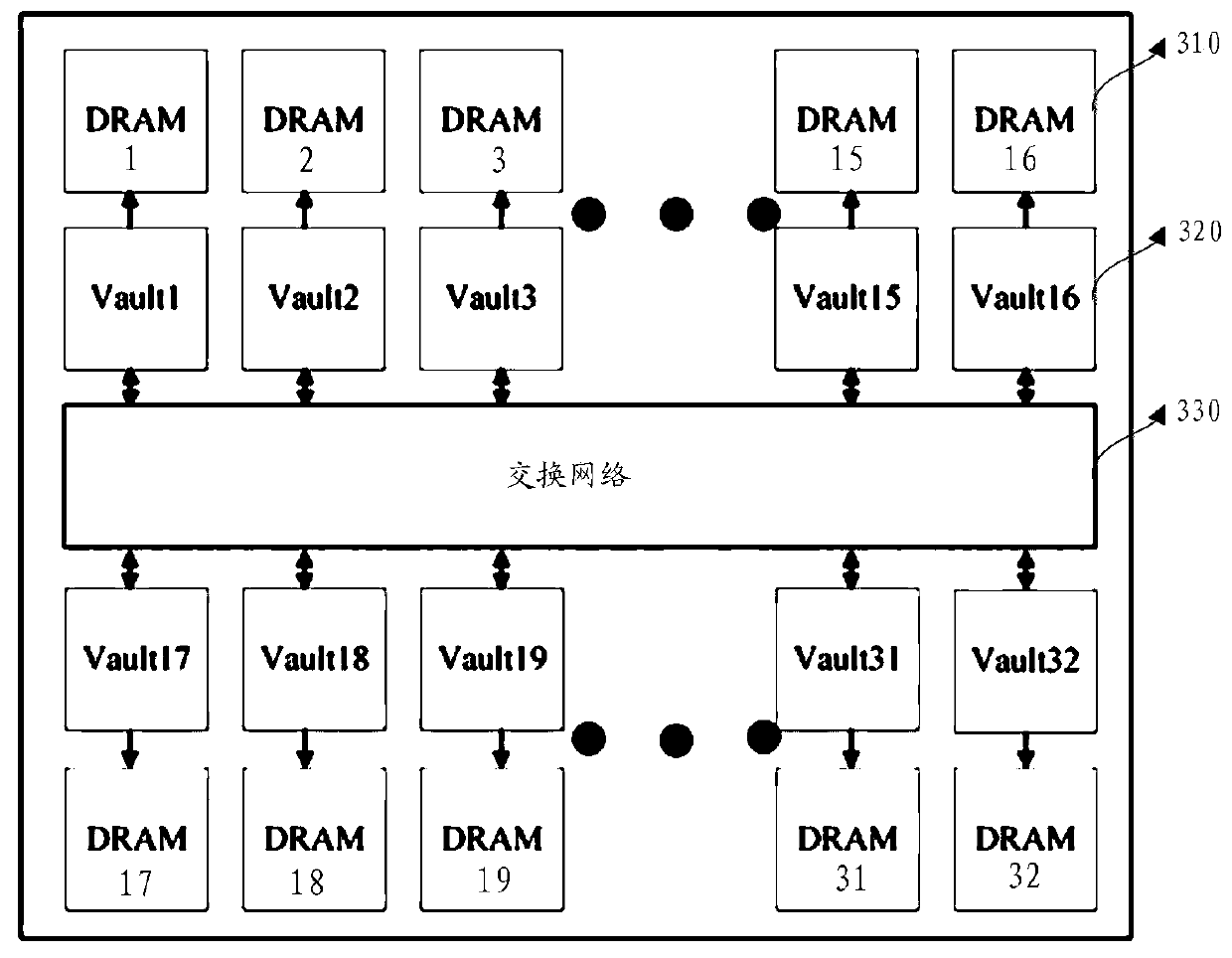

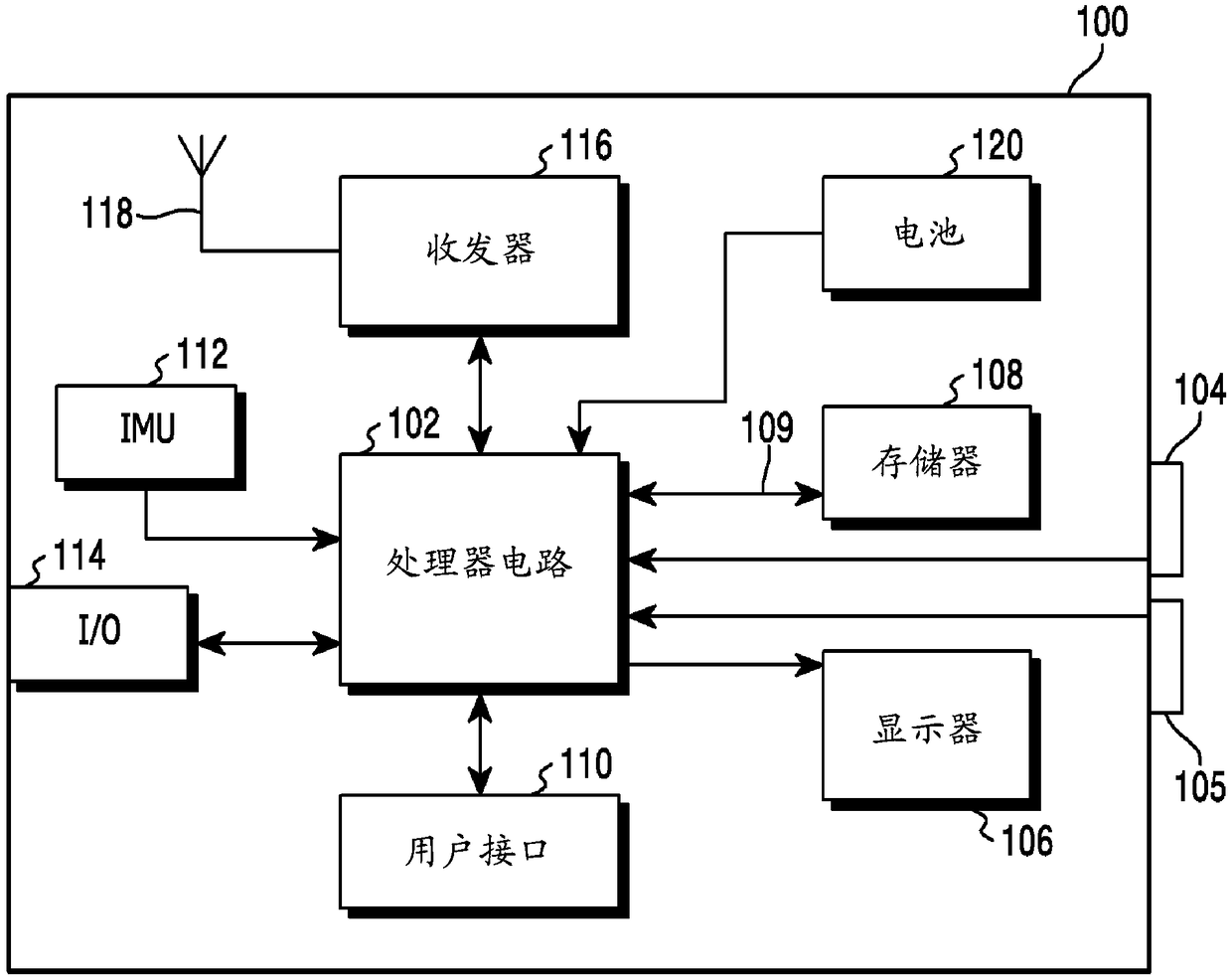

Accelerating device for gene comparison algorithm

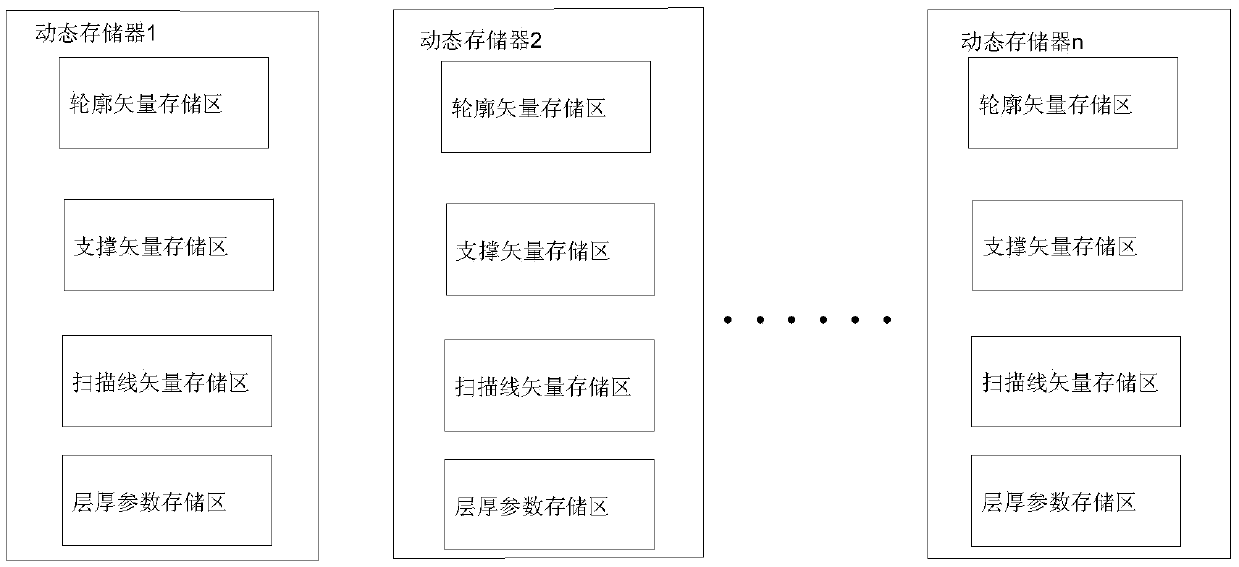

ActiveCN109785905AHigh speedImprove performance per wattSequence analysisInstrumentsManagement unitVertical slice

The invention provides an accelerating device for a gene comparison algorithm. The accelerating device comprises a host terminal and a plurality of accelerating modules. Each accelerating module comprises a plurality of storage layers, a vertical slice management unit and a switching network. The host terminal is used for controlling distribution of gene sequencing sequences to the accelerating modules and receiving of gene comparison results. The storage layers of the accelerating modules are used for storing gene reference sequences. The vertical slice management units of the accelerating modules are used for managing slices formed by vertically dividing the plurality of storage layers and executing a gene comparison algorithm to obtain a gene comparison result. The switching networks ofthe accelerating modules are used for controlling data exchange inside the accelerating modules and data exchange between the accelerating modules and the outside. The accelerating device disclosed by the invention can improve the processing speed of a gene comparison algorithm by utilizing a customized structure.

Owner:INST OF COMPUTING TECH CHINESE ACAD OF SCI

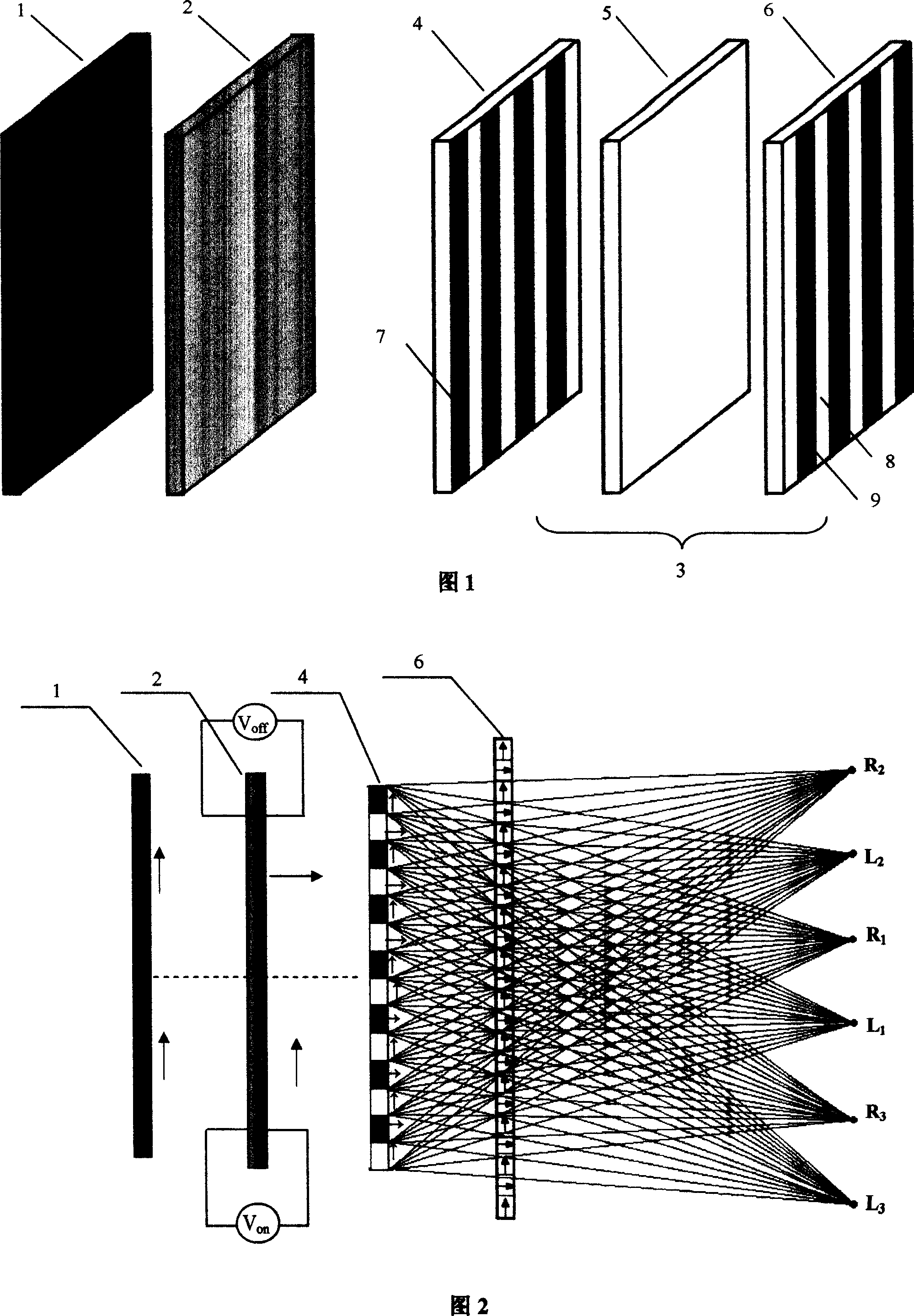

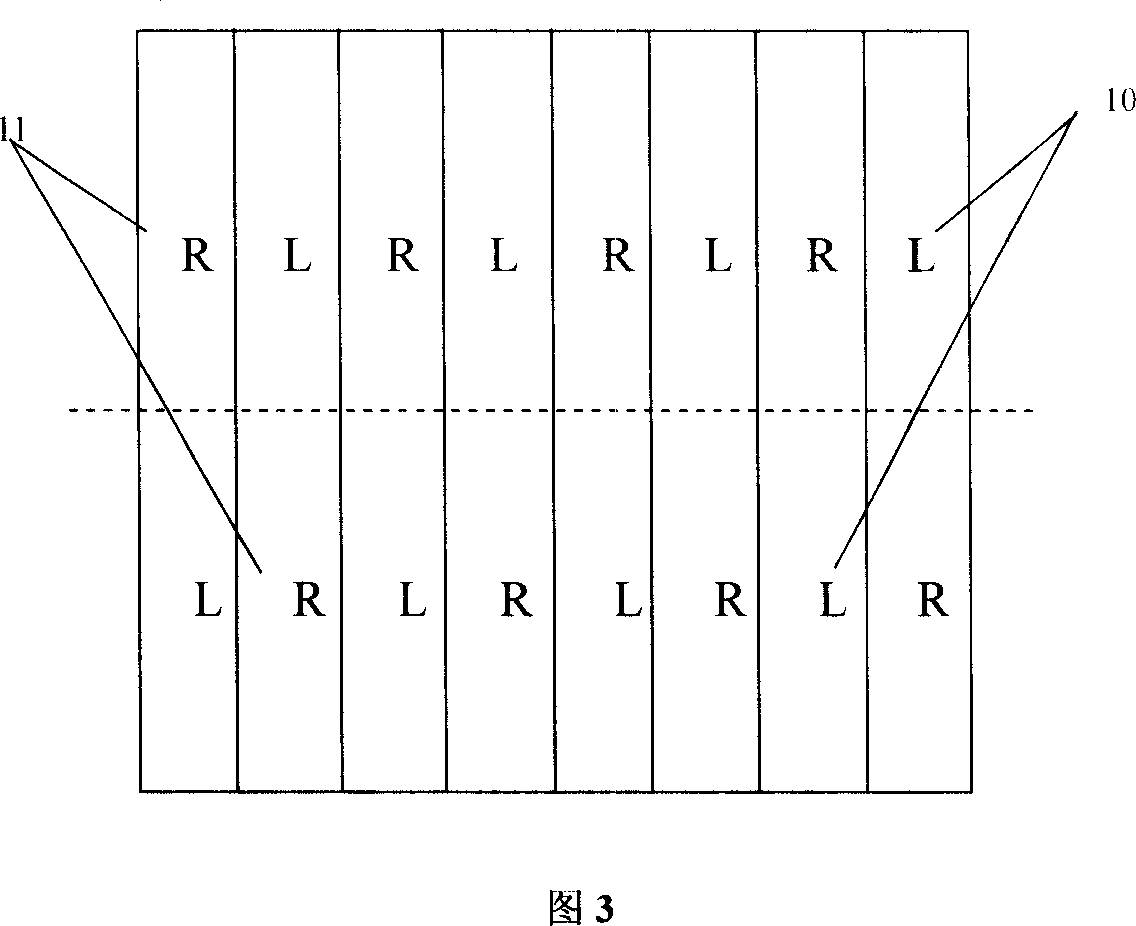

Three-dimensional auto-stereoscopic display device based on light polarizing parallax strip and grid screen

This invention discloses one whole resolution 3D free space display device and its method based on bias vision difference grating screen, wherein, the device comprises plane display screen, bias switch screen and bias vision difference grating screen; the bias grating screen comprises part semi-wave screen, infraction screen and bias grating screen; the infraction screen has infraction property in vertical direction and the bias grating screen is formed by two bias vertical slices; the plane display screen is to display one semi-wave resolution pattern in open status and other half vision pattern in close status.

Owner:SICHUAN UNIV

Vertical and 3D memory devices and methods of manufacturing the same

ActiveUS9589979B2Solid-state devicesSemiconductor/solid-state device manufacturingVertical slice3d memory

A memory device is described, which includes a block of memory cells comprising a plurality of stacks of horizontal active lines such as NAND string channel lines, with a plurality of vertical slices penetrated by, and surrounding, the horizontal active lines to provide a gate-all-around structure. A memory film is disposed between the horizontal active lines in the plurality of stacks and the vertical slices in the plurality of vertical slices. A 3D, horizontal channel, gate-all-around NAND flash memory is provided. A method for manufacturing a memory involves a buttress process. The buttress process enables horizontal channel, gate-all-around structures.

Owner:MACRONIX INT CO LTD

Low-pressure-drop foreign matter prevention type lower pipe seat of fuel assembly

ActiveCN103247351AStrength balanceStrong enoughNuclear energy generationFuel element assembliesForeign matterGrating

The invention provides a low-pressure-drop foreign matter prevention type lower pipe seat of a fuel assembly. The lower pipe seat comprises a supporting framework and a lower pipe seat grating fixed above the supporting framework, wherein the lower pipe seat grating comprises two layers of plates, the plate on one layer is a macroporous plate, and the plate on the other layer is a grid plate arranged above or below the macroporous plate; the grid plate is of a netty grid structure composed of vertical slices; the macroporous plate is of a flat plate structure matched with the grid plate in size, and a plurality of columns and rows of drain holes are uniformly formed in the macroporous plate; and each large circular drain hole is divided by grids of the grid plate into a plurality of parts on the overlooking projection, and each large circular drain hole is formed to avoid the projection position of a fuel bar. According to the lower pipe seat of the fuel assembly, provided by the invention, has the function of uniform flow rate distribution and can realize the balance of the strength, pressure drop and a foreign matter prevention function of the lower pipe seat as the macroporous plate is matched with the grid plate. The grid plate structure ensures the sufficient foreign matter filtering capability after the aperture is increased.

Owner:SHANGHAI NUCLEAR ENG RES & DESIGN INST CO LTD

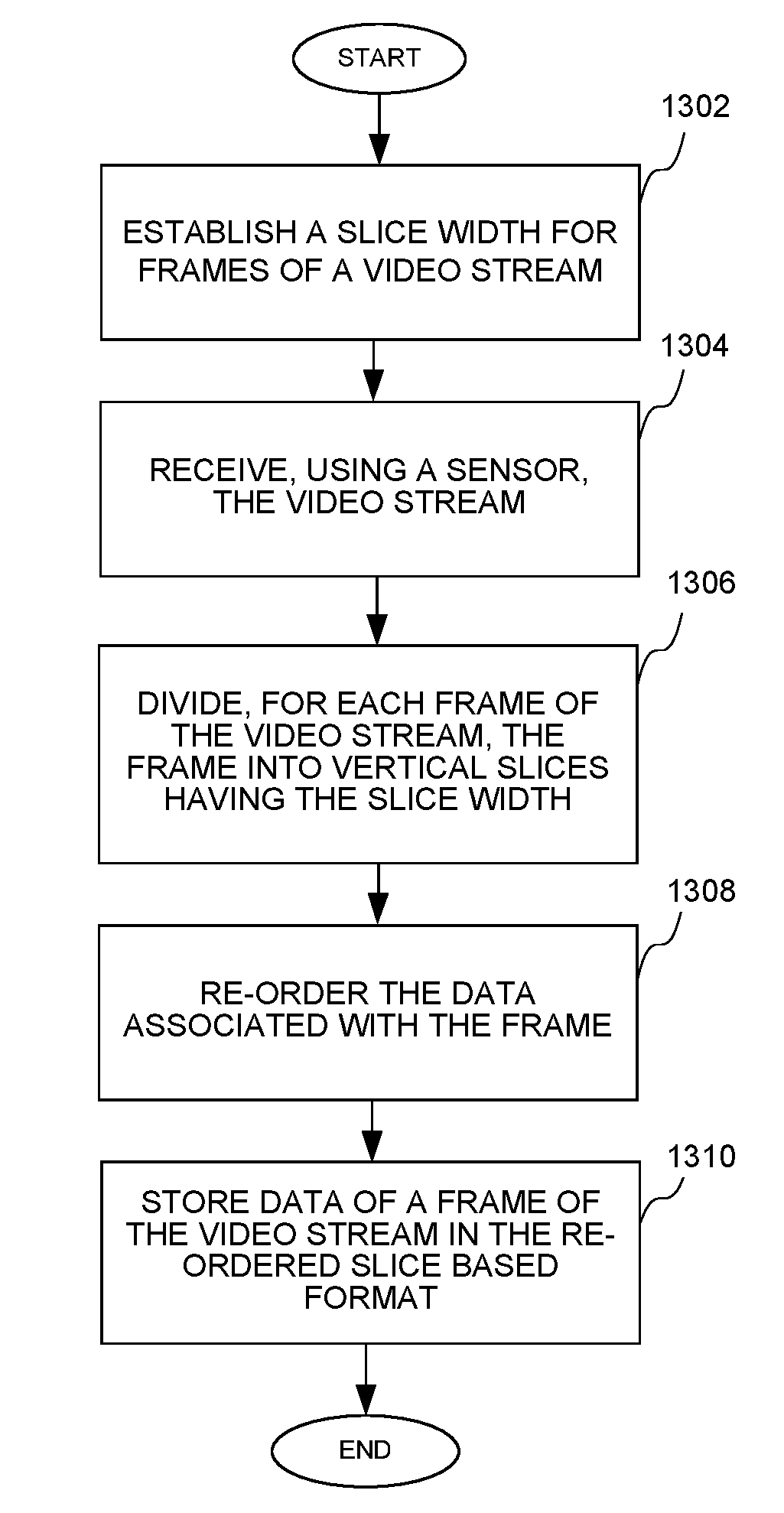

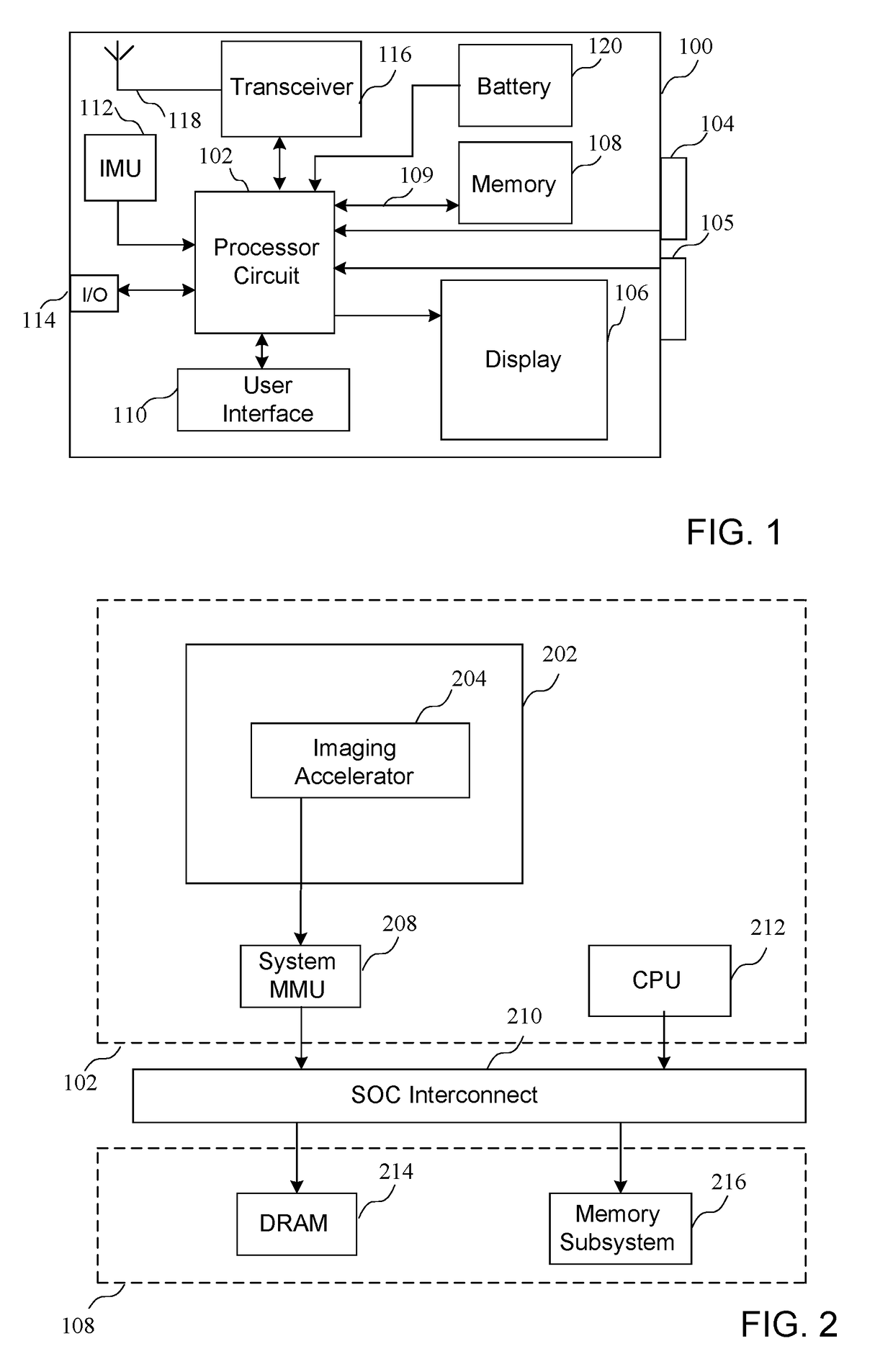

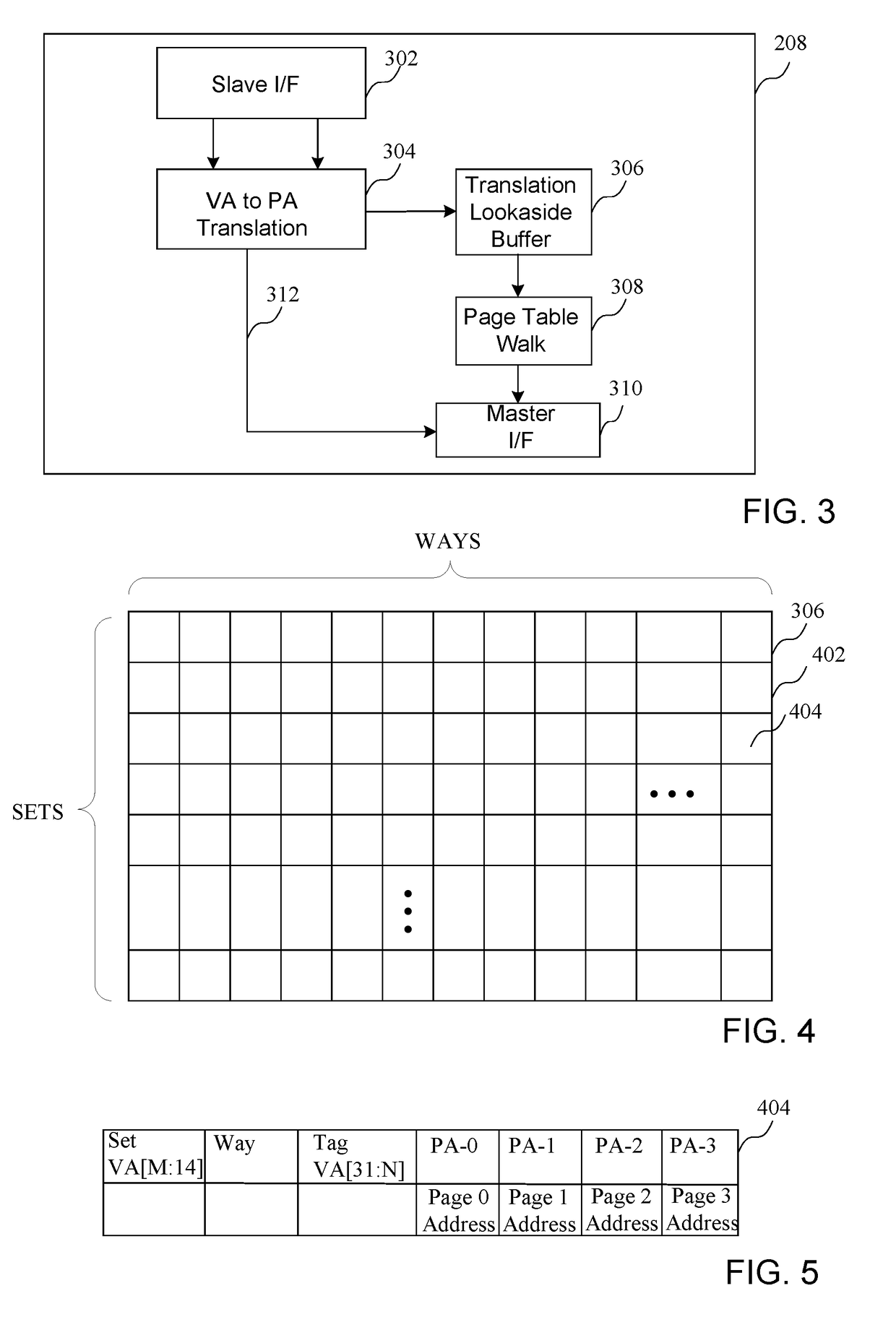

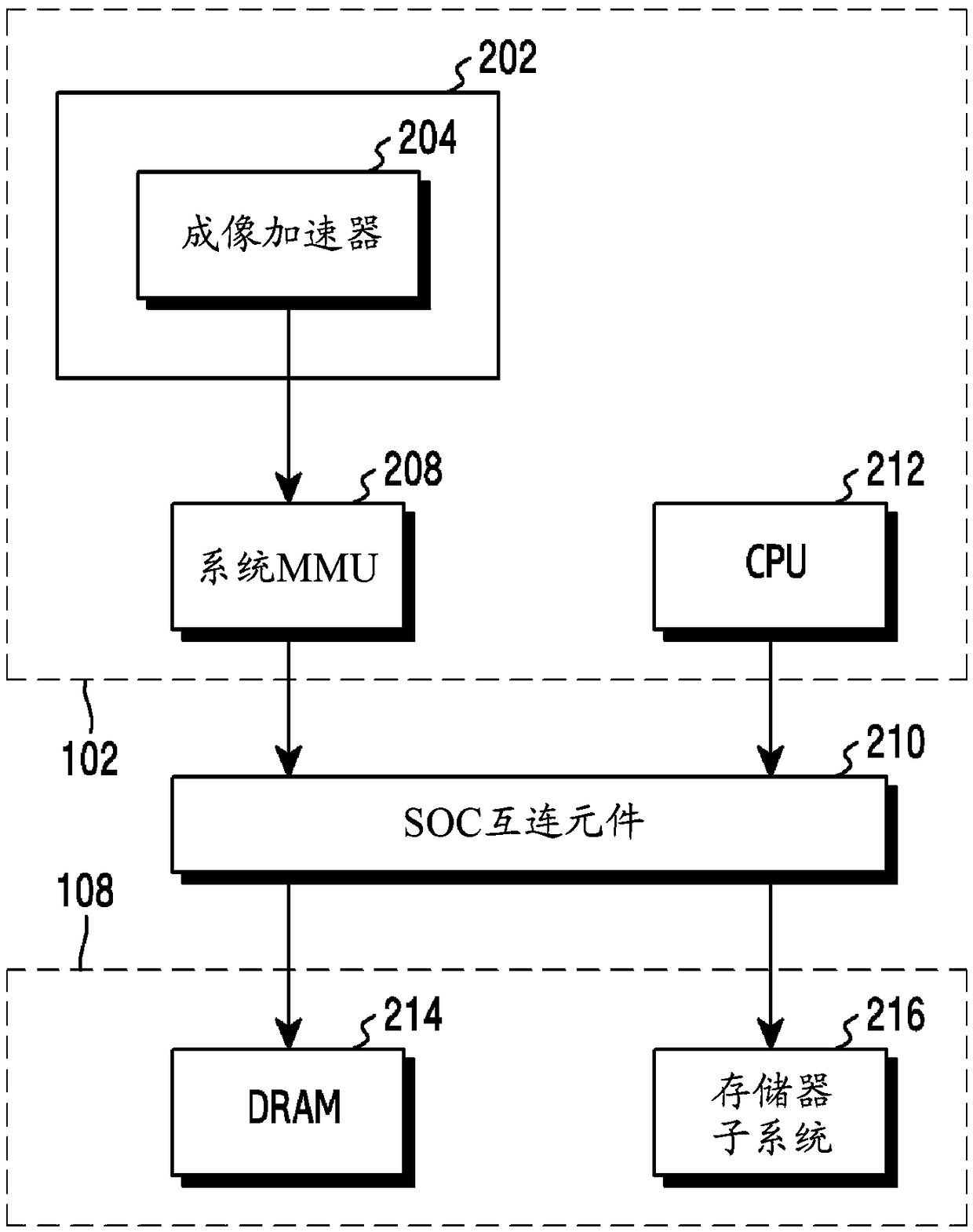

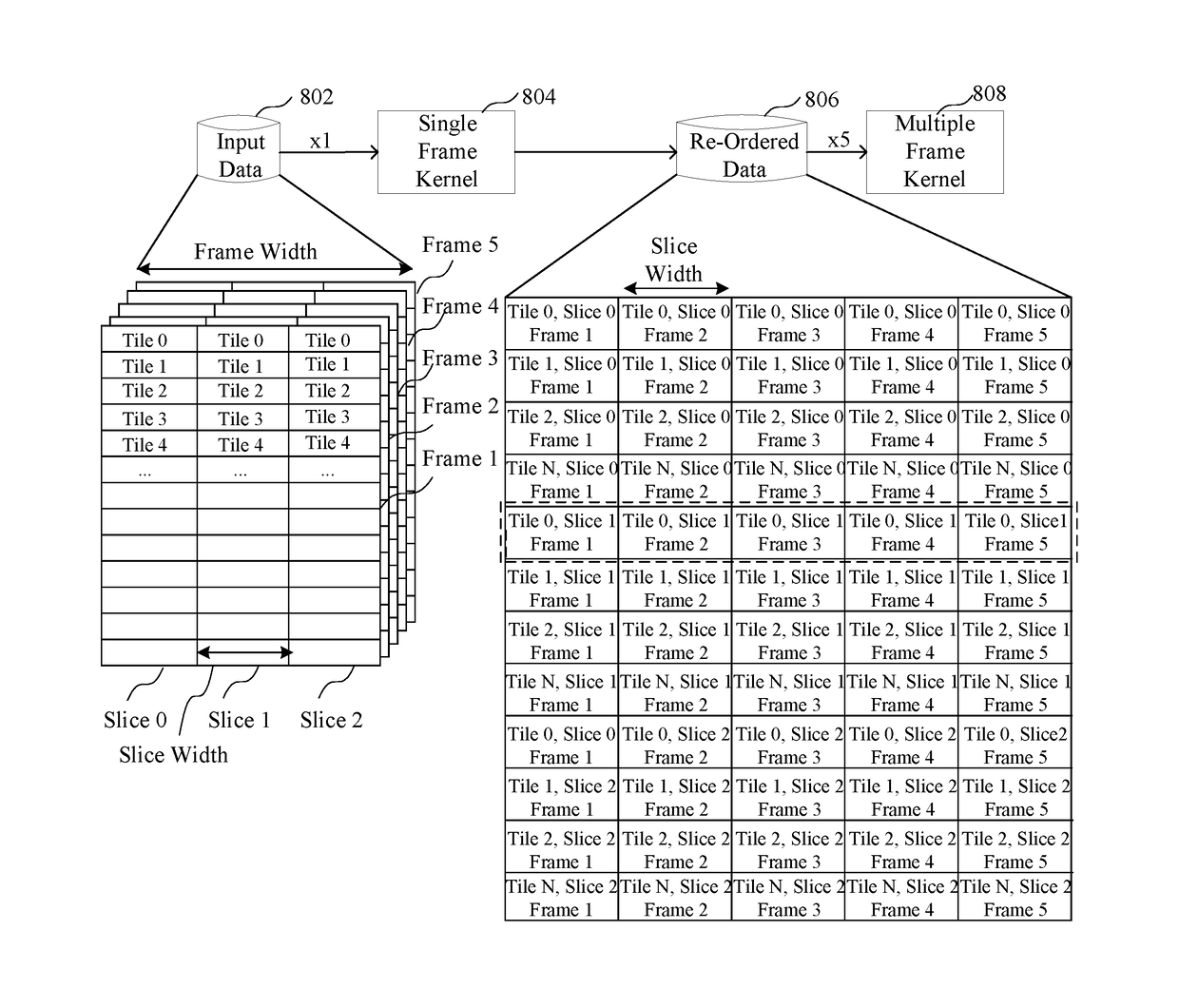

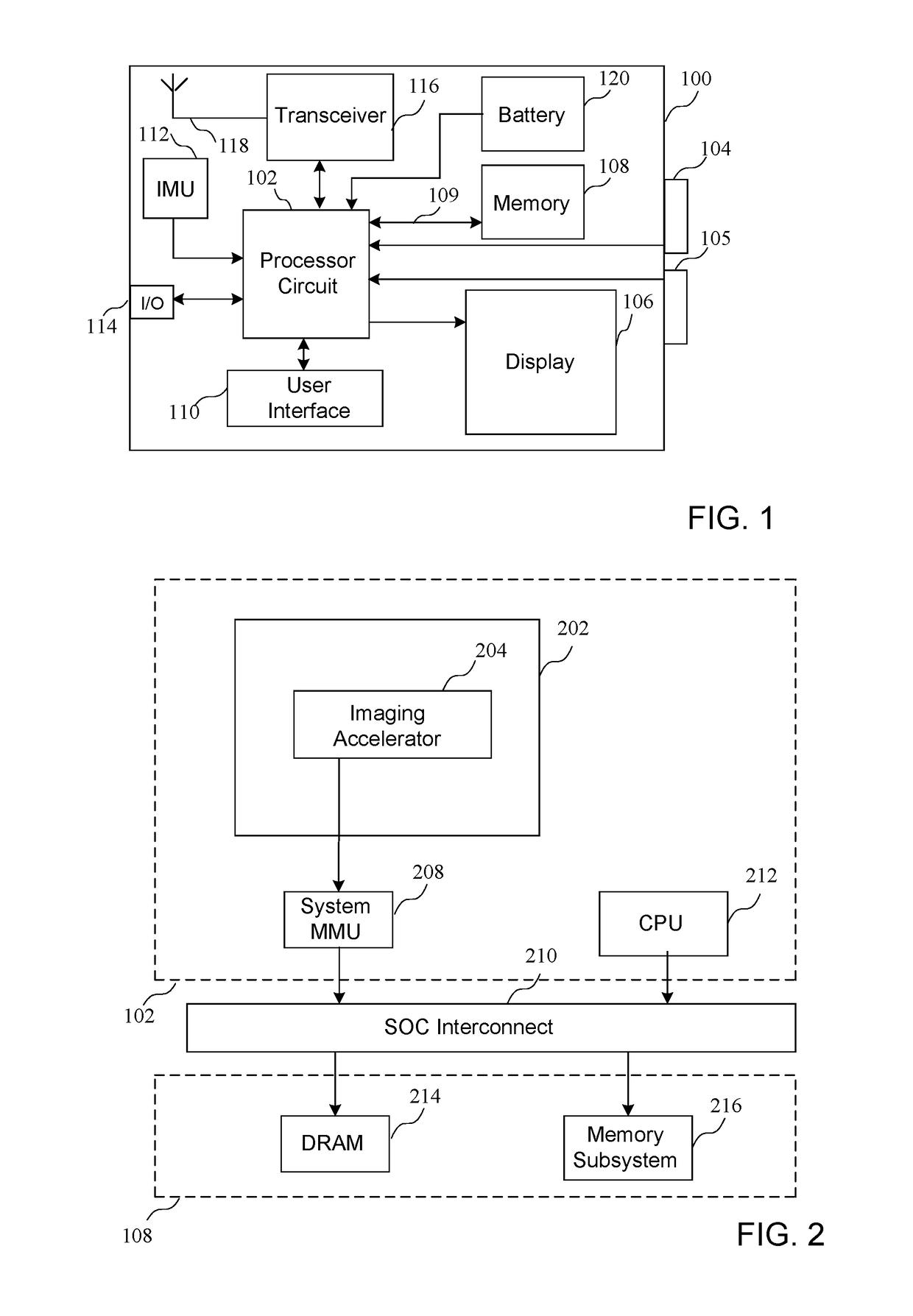

Device for and method of enabling the processing of a video stream

ActiveUS20170309306A1Speed up the processReduce latencyRecord information storageDigital signal formattingComputer graphics (images)Vertical slice

A method of enabling processing of a video stream is described. The method comprises establishing a slice width for frames of the video stream; receiving the video stream; dividing, for each frame of the video stream, the frame into vertical slices having the slice width; storing a frame of the video stream in a re-ordered slice based format. Computer-readable storage medium and a device for enabling processing of a video stream are also described

Owner:SAMSUNG ELECTRONICS CO LTD

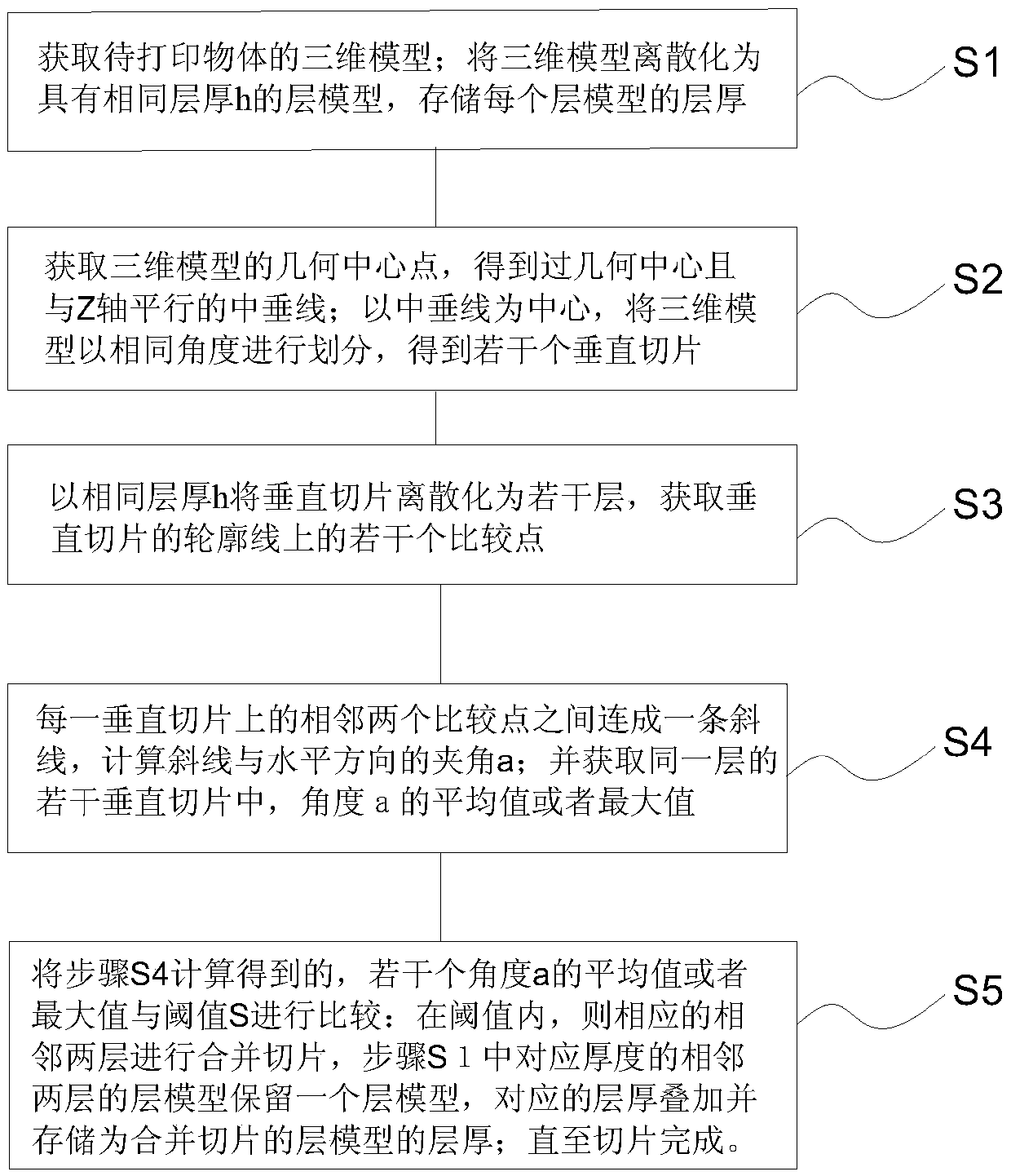

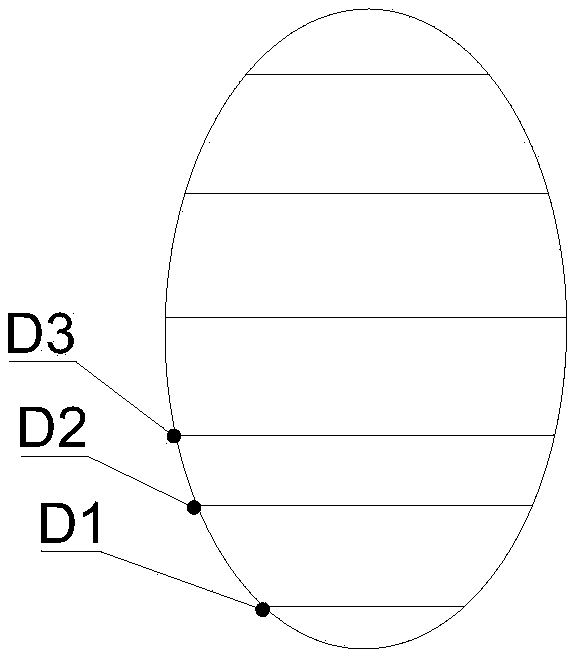

Self-layer-thickness-adaptive slicing method and printing system

ActiveCN109532006AQuality is not affectedDoes not affect printing accuracyAdditive manufacturing apparatus3D object support structuresComputer graphics (images)Layer thickness

The invention provides a self-layer-thickness-adaptive slicing method and a printing system. The self-layer-thickness-adaptive slicing method comprises the steps that a 3D model of a to-be-printed object is acquired; the 3D model is dispersed into d1, d2 to dn layers of models with an identical layer thickness; the midperpendicular of the 3D model is acquired; the 3D model is divided with the sameangle by taking the midperpendicular as the center, so that a plurality of vertical slices are obtained; the vertical slices are dispersed into a plurality of layers with the same layer thickness h,so that a plurality of comparison points on the outlines of the vertical slices are acquired; every two adjacent comparison points on each vertical slice are connected to form a slash, and an includedangle a between each slash and the horizontal direction is calculated; and the angles a are compared with a threshold S, and whether two adjacent layers are combined for slicing or not is determined.By adopting the self-layer-thickness-adaptive slicing method, self-adaptive slicing is performed on the 3D model of the to-be-printed object with different layer thicknesses; and the printing systemis provided for directly printing the self-layer-thickness-adaptive layer models; and printing speed is accelerated on the premise of not affecting printing precision and printing object quality.

Owner:J H TECH ELECTRONICS GZ LTD

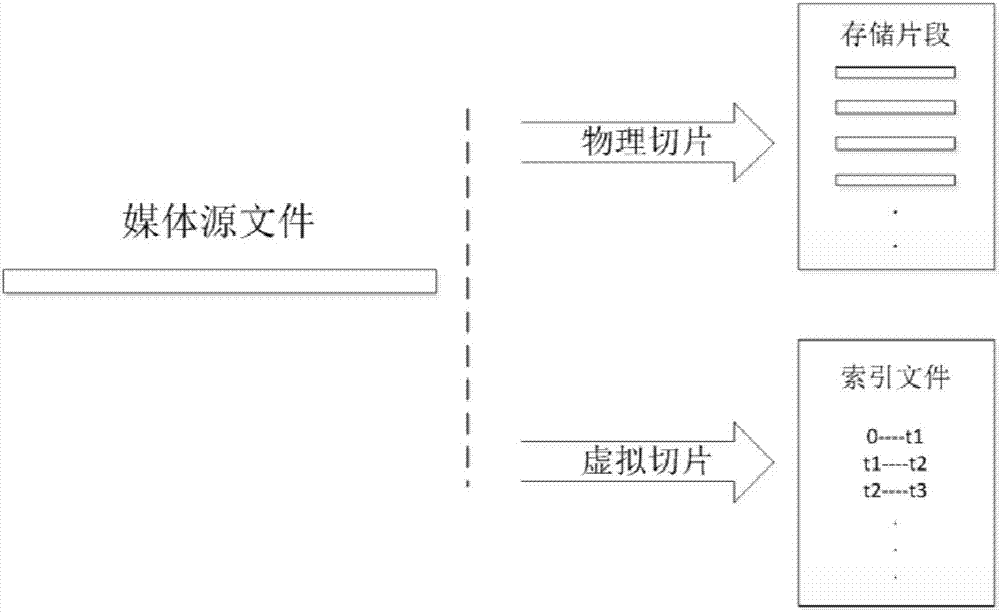

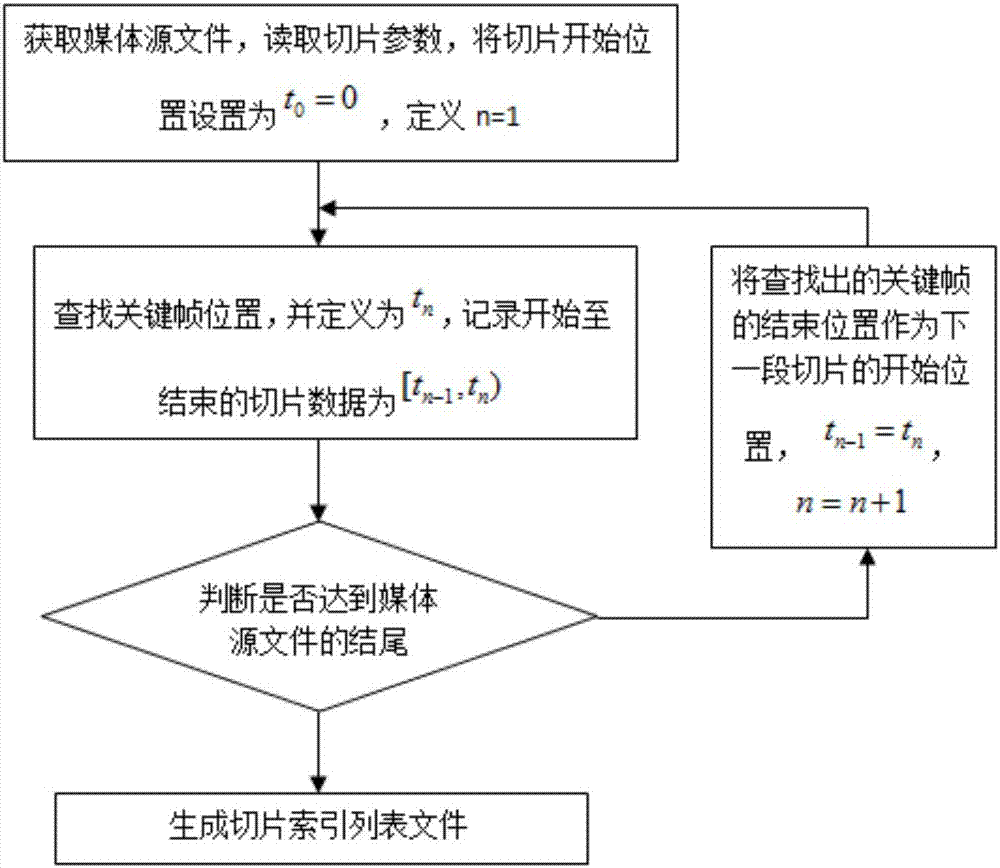

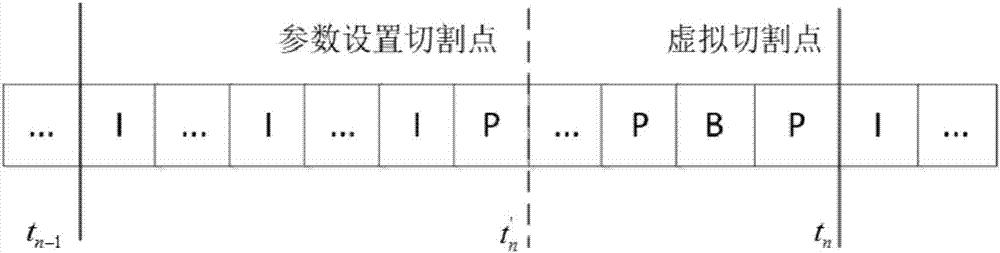

Virtual slicing method and system used for distributed media file transcoding system

The invention relates to the technical field of multimedia processing, specifically to a virtual slicing method and system used for a distributed media file transcoding system. The method utilizes characteristics of key frames in media file video data, through a mode of presetting cutting points, searches actual key frame cutting points of the video, processing data of video segmenting are defined between two key frames, at the same time, location information of the segmenting points is recorded in a vertical slice index file, thereby efficiently completing transcoding of the media file.

Owner:上海网达软件股份有限公司

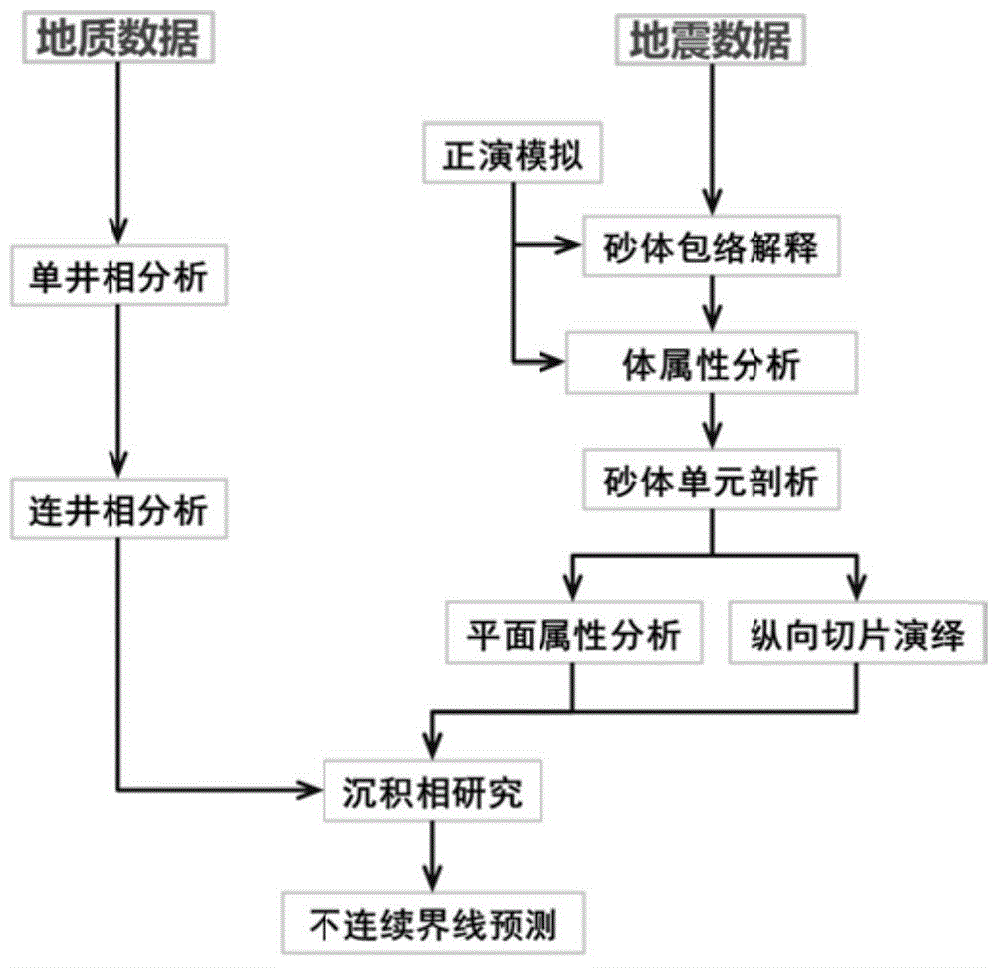

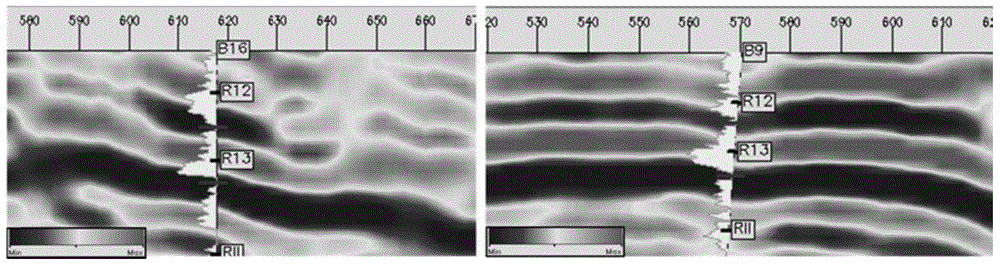

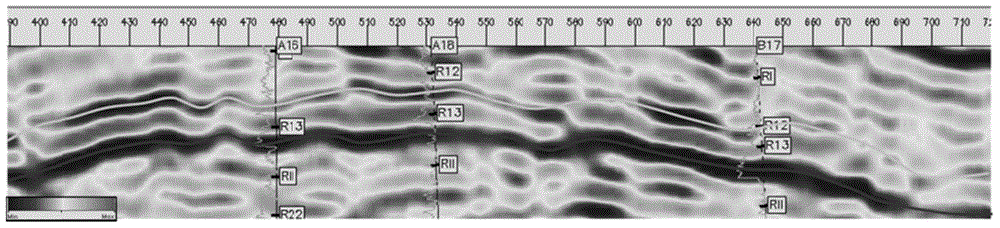

Fluvial facies sand body discontinuous boundary fine characterization seismic interpretation method

ActiveCN105093303AImprove interpretation accuracyThe recognition effect is accurateSeismic signal processingGeomorphologyVertical slice

The invention relates to a fluvial facies sand body discontinuous boundary fine characterization seismic interpretation method. The method comprises the following steps: 1) according to fluvial facies sand body positive rhythmic deposition characteristics, in combination with demands on property extraction time window by subsequent property analysis, a sand body enveloping method is adopted to interpret construction of a sand body unit; 2) an ant tracking property and a curvature property are extracted on a target reservoir section; 3) the interpreted sand body is used for enveloping an extracted amplitude plane property, a curvature plane property and an ant tracking plane property with top bottom as time window; 4) a curvature plane property and an ant tracking plane property of a seismic profile are taken for comparison and analysis, and thus a sand body discontinuous boundary is judged; 5) vertical slice interpretation is carried out on the amplitude property, the discontinuous boundary caused by vertical overlapping of sand bodies are judged auxiliarily and a sand body deposition period is divided; 6) according to the discontinuous boundary plane judgment result acquired in the fourth step and the vertical sand body period dividing conclusion acquired in the fifth step, building of sedimentary facies recognition is assisted.

Owner:CHINA NAT OFFSHORE OIL CORP +1

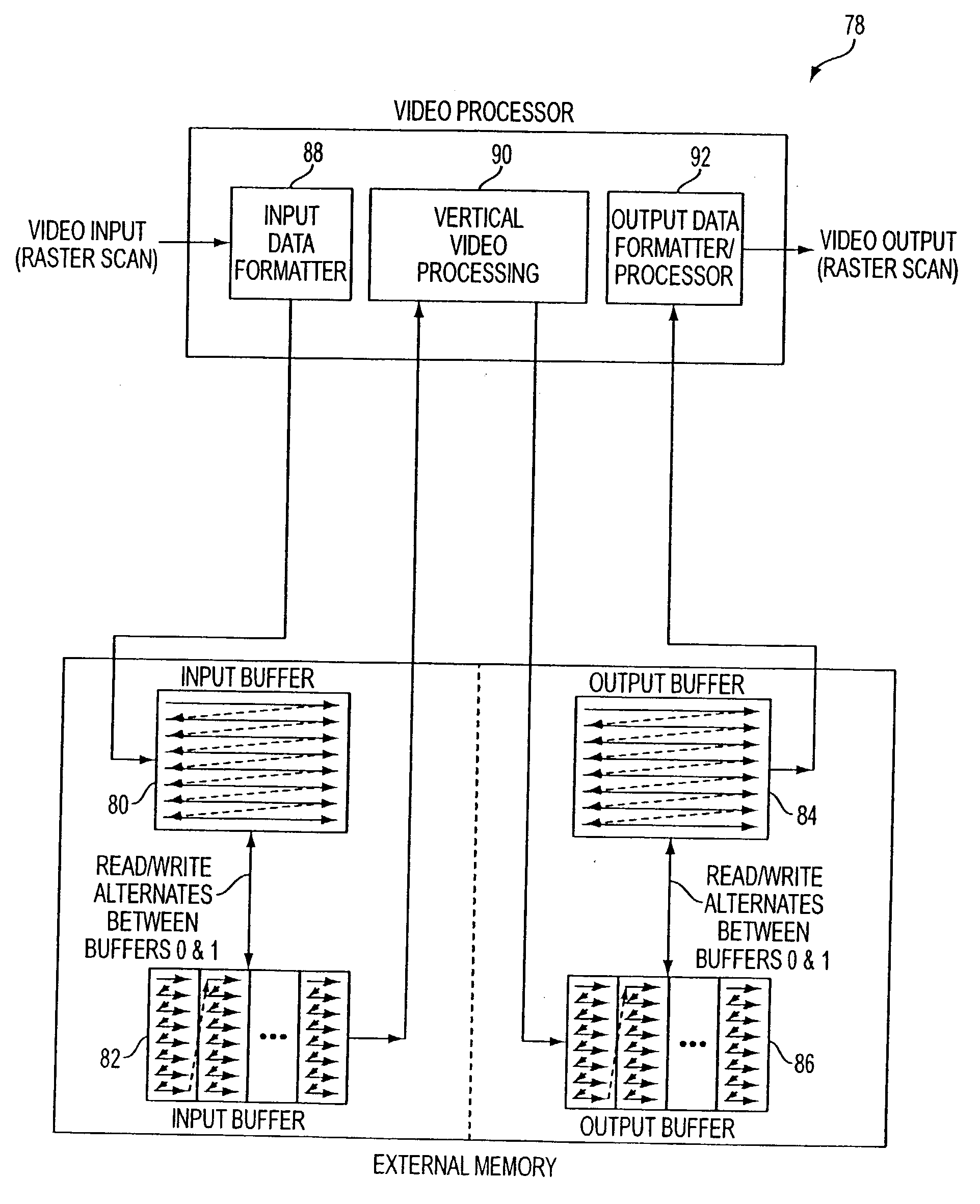

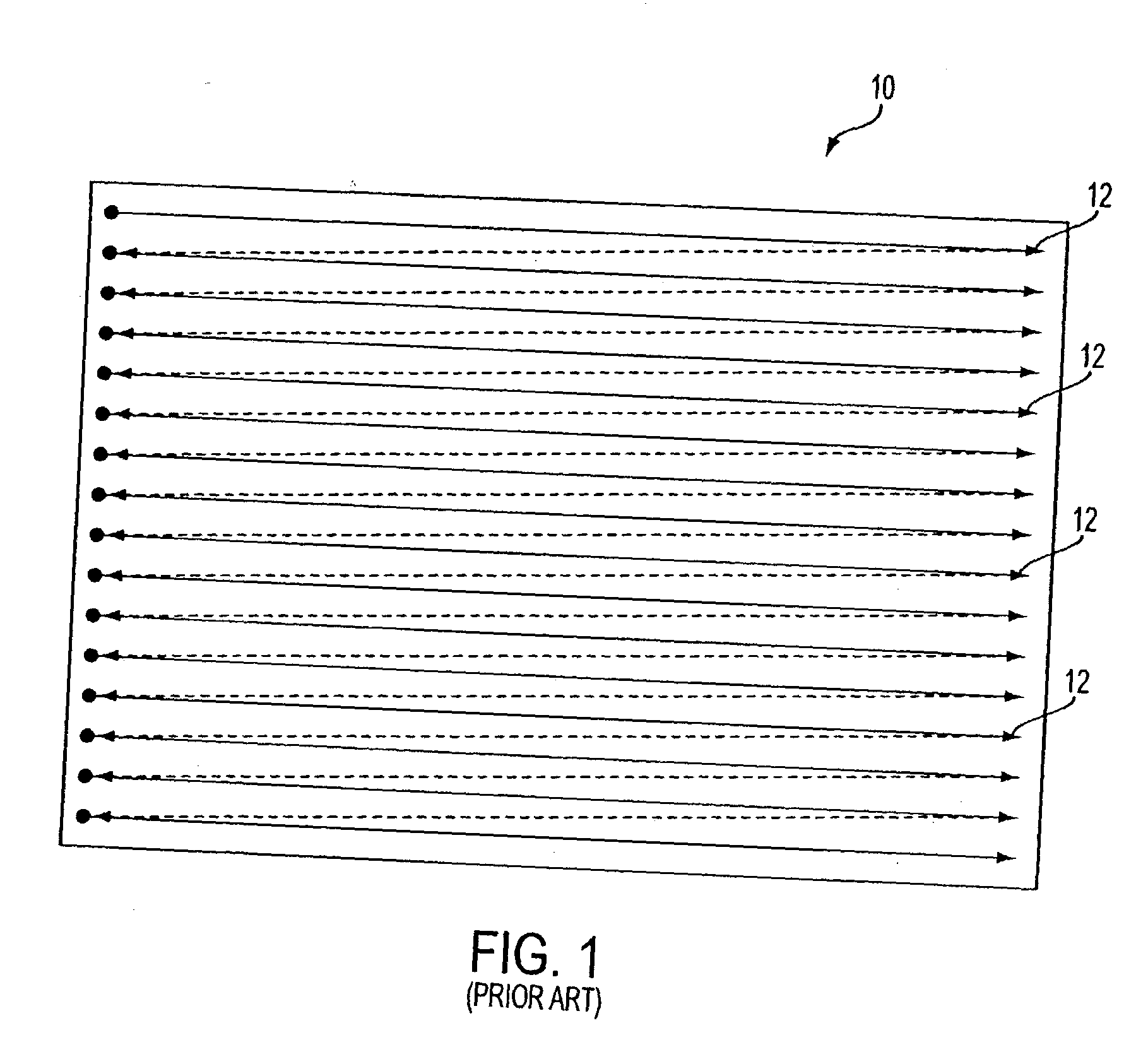

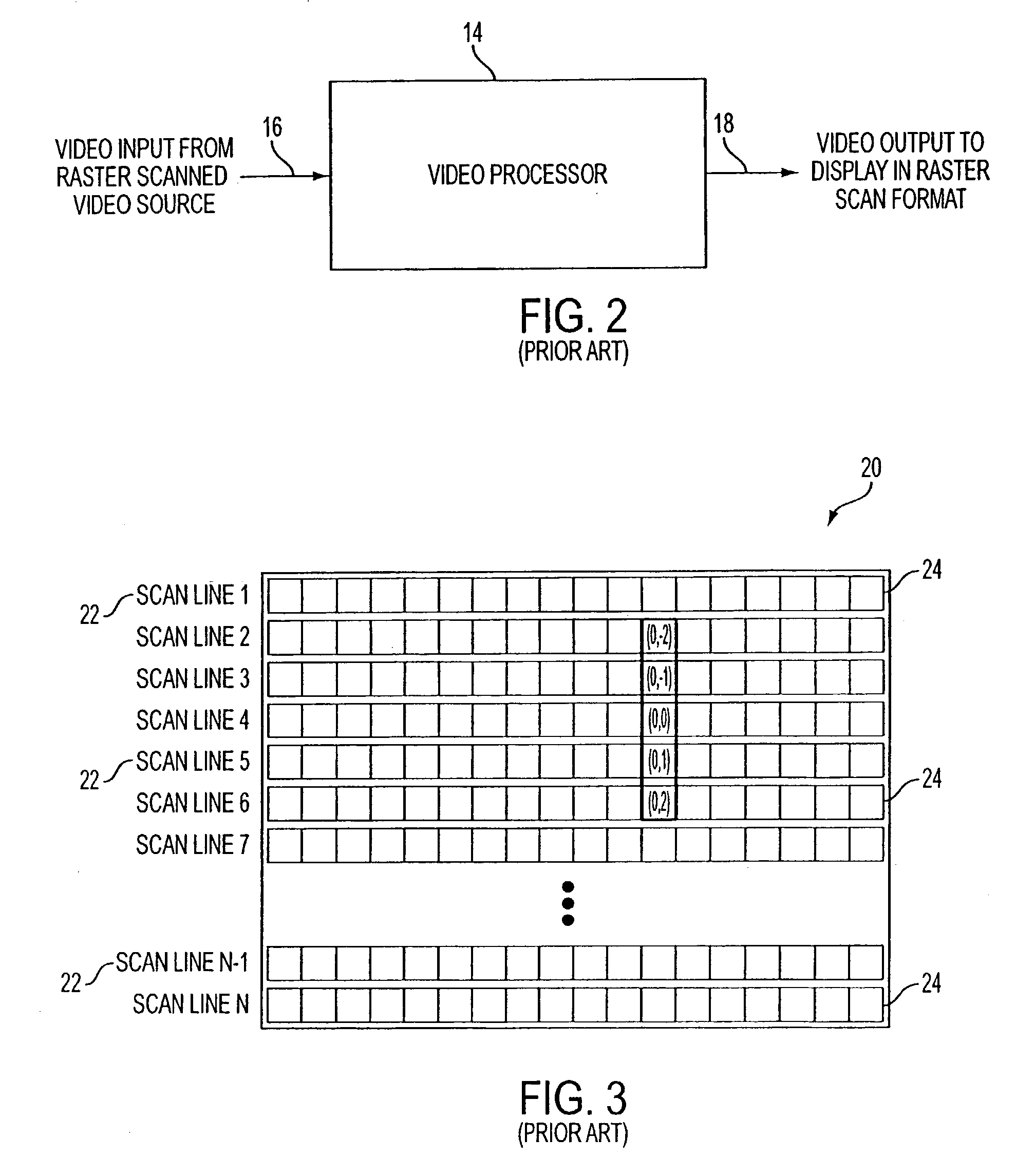

Method and apparatus for reducing on-chip memory in vertical video processing

InactiveUS20050062892A1Quality improvementLow system requirementsTelevision system detailsColor signal processing circuitsGratingVideo processing

A digital image processor includes an input buffer for storing raster-scanned data. A slice-buffer memory is coupled to the input buffer to store a portion of a vertical slice of said raster-scanned data. The vertical slice is processed by a vertical slice processor having an input coupled to the slice-buffer memory. The vertical slice processor reassembles the vertical slices into processed raster-scanned data in an output buffer that is coupled to the output of the vertical slice processor. The digital image processor preferably utilizes multiple sequential processing stages and processes the raster-scanned data along the horizontal axis of the vertical slices.

Owner:DVDO +1

Slice control method of vertical slice cutter

ActiveCN101632488AAvoid volatilityIntrinsic quality is stableTobacco treatmentProgramme control in sequence/logic controllersProduction lineAutomatic control

The invention discloses a slice control method of a vertical slice cutter, comprising the steps: firstly, making corresponding slice control modes of the prior cigarette packets of various specifications and dimensions according to production requirements; inputting the slice control modes into an automatic control system; automatically identifying the slice control modes of the cigarette packetsafter the cigarette packets of certain specifications enter a production line; and slicing and processing the cigarette packets according to the identified specifications and dimensions by the automatic control system in the corresponding slice control modes. If the cigarette packets of new specifications and dimensions are brought into a factory, the corresponding slice control modes of the cigarette packets of the new specifications and dimensions are made according to the production requirements and are inputted into the automatic control system for realizing the automatic control over thecigarette packets of the new specifications and dimensions. The invention achieves the consistency between slice times and flow rate, avoids the fluctuation of the flow rate and water due to different specifications and dimensions of the cigarette packets, solves the single control mode of processing slices, stabilizes the internal quality of cigarette products, promotes the stable enhancement ofslice processing quality, ensures the internal quality of tobacco in the process of making the tobacco and is suitable for making the slices of the cigarette packets with different tobacco specifications and dimensions.

Owner:HONGTA TOBACCO GRP

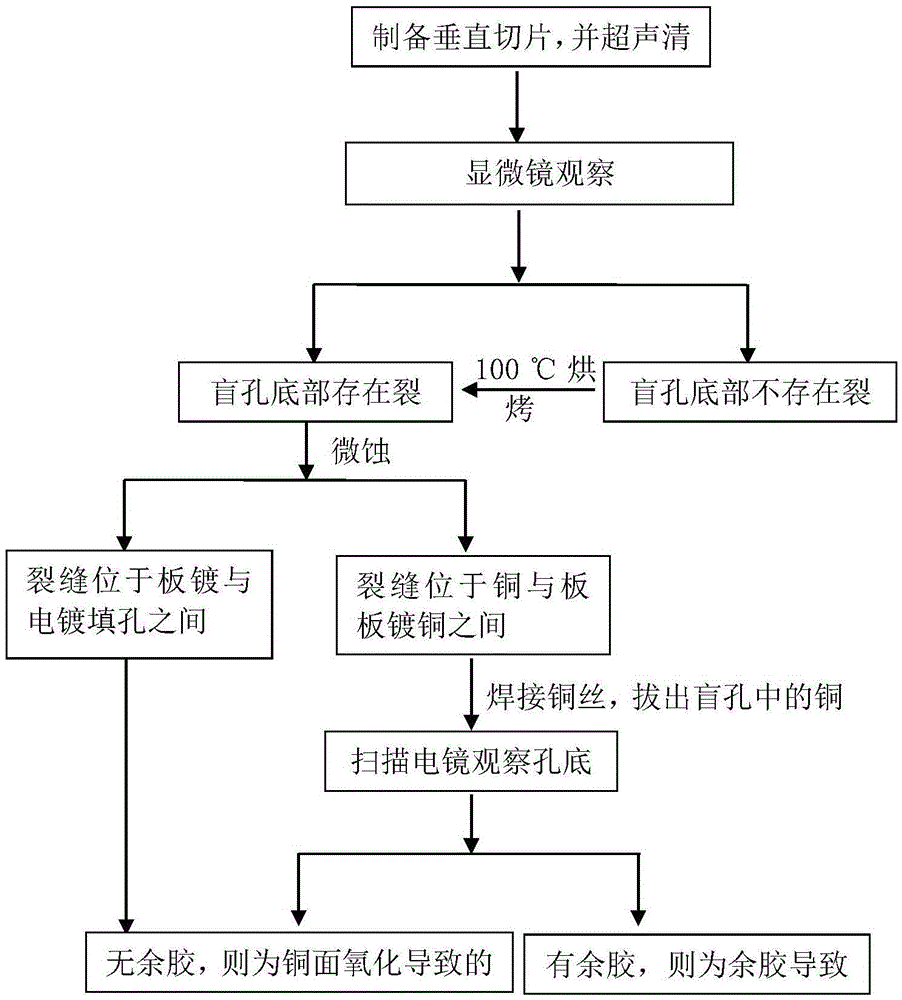

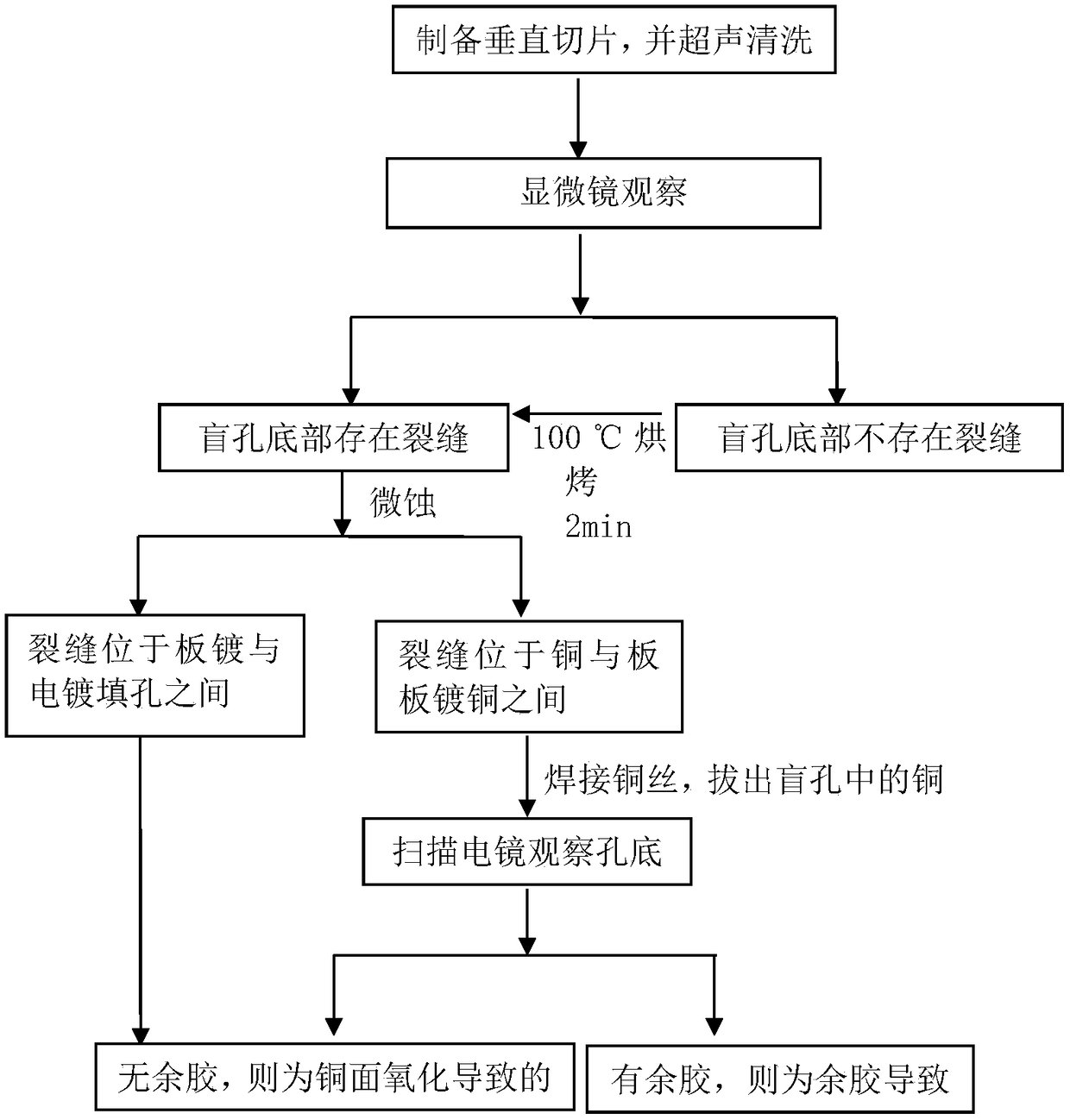

Analysis method for opening of laser blind hole

The invention discloses an analysis method for opening of a laser blind hole. The analysis method comprises the following steps: S1) preparing a vertical slice for the laser blind hole with invalid opening; S2) observing by a microscope if a crack exists at the bottom of the laser blind hole; S3) if a crack is detected, using a micro-etching fluid for micro-etching a copper surface of the vertical slice and observing the position of the layer on which the crack is located; S4): a) confirming as opening of the laser blind hole caused by the oxidation of the copper surface if the crack is located between plating copper and an electroplate filling hole and no residual glue exists at the bottom of the laser blind hole, and b) confirming as opening of the laser blind hole caused by the oxidation of the copper surface if the crack is located between base copper and the plating copper and no residual glue exists at the bottom of the laser blind hole, and confirming as opening of the laser blind hole caused by the residual glue if the residual glue exists at the bottom of the laser blind hole. According to the analysis method provided by the invention, the reason of opening of the laser blind hole can be accurately acquired, so that the opening problem of the laser blind hole can be solved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

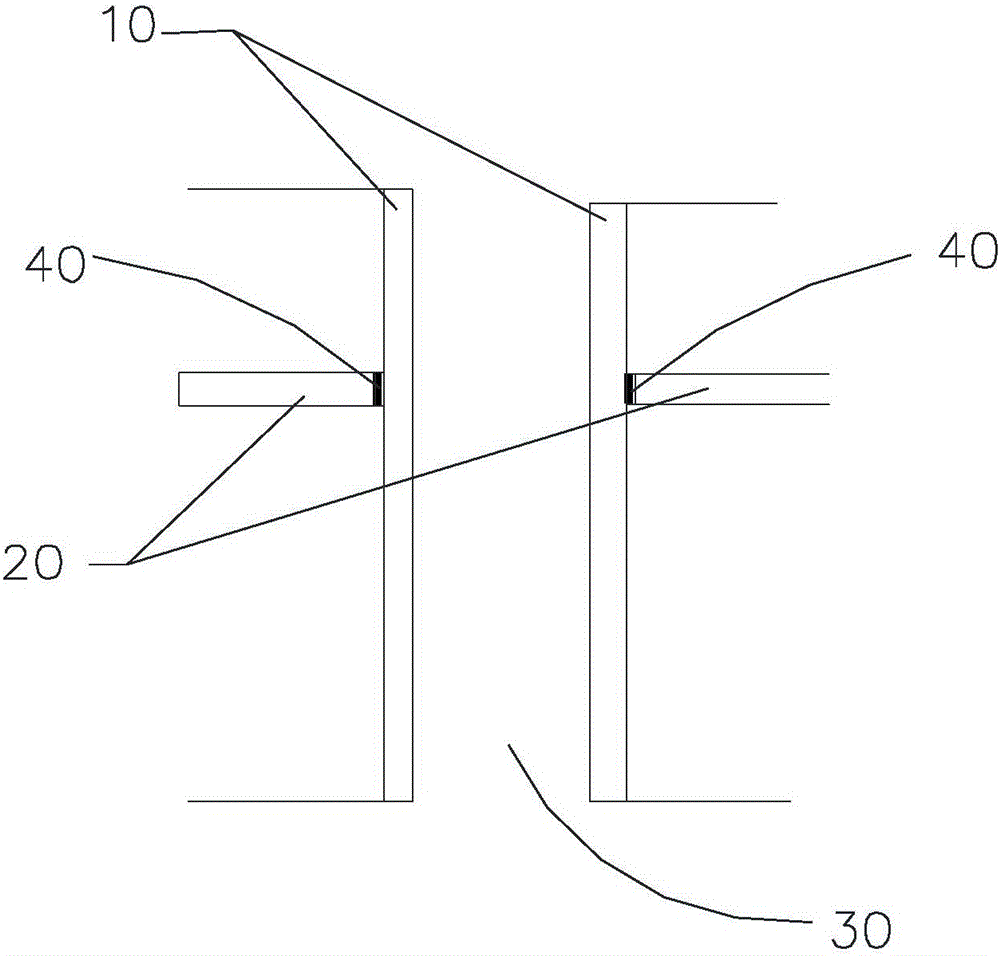

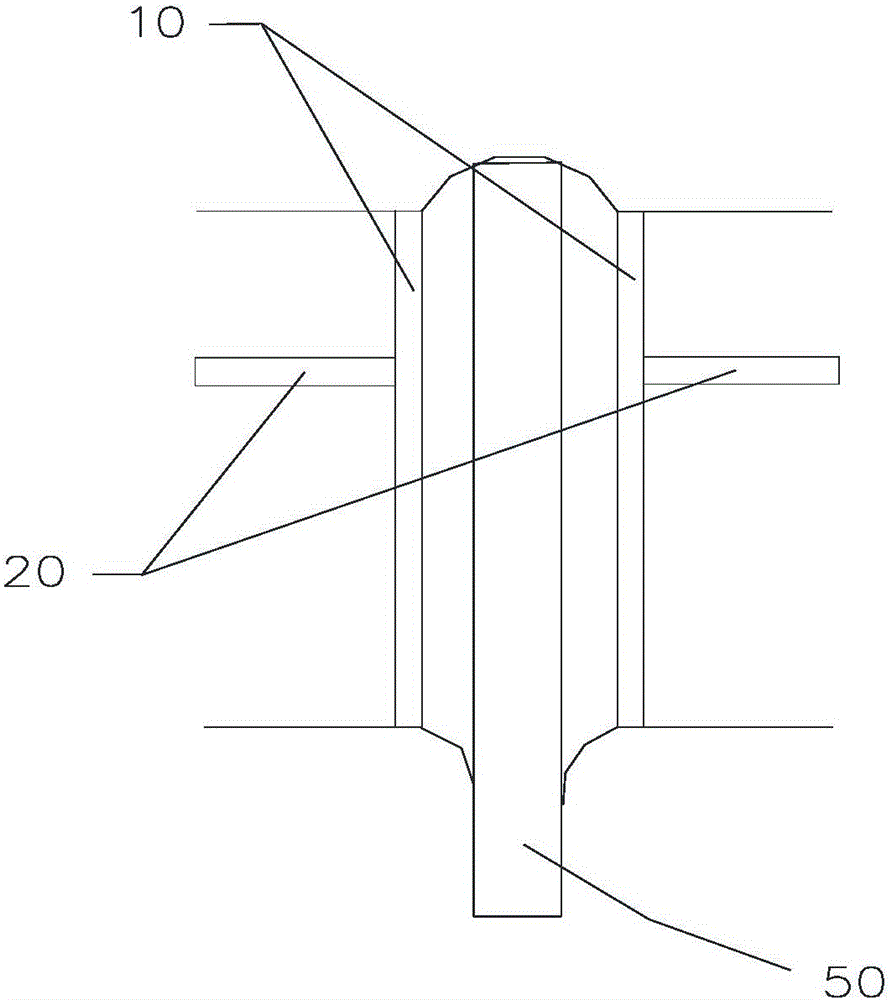

ICD (Internal Connection Defect) detection method for PCB

ActiveCN105682378AImprove detection efficiencyAccurate and effective detectionCircuit inspection/monitoring/aligningPrinted element electric connection formationCopper wireMicroscopic observation

The invention discloses an ICD detection method for a PCB. The method comprises the flowing steps that a vertical slice of a PCB sample is made, and a metallographic microscope is used to observe whether there is a crack between an electro-coppering layer and an internal copper ring in the vertical slice; if there is, an outside force is used to separate the whole electro-coppering layer from the internal copper ring, an unthreaded hole is formed in the PCB; if there is not, it is shown that no residual glue exists between the electro-coppering layer and the internal copper ring, and no detection is needed any longer; and a scanning electron microscope is used to detect the internal copper ring to observe whether residual glue exists on the internal copper ring. Vertical slicing and copper wire pulling are carried out on the circuit board sample, the electro-coppering layer is directly separated from the internal copper ring, and the scanning electron microscope is used to directly observe whether residual glue exists on the electro-coppering layer; and thus, the detection method can be used to detect whether cracks and residual glue exist between the electro-coppering layer and the internal copper ring is a more direct, effectively and accurate manner, and the ICD detection efficiency of the PCB is greatly improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

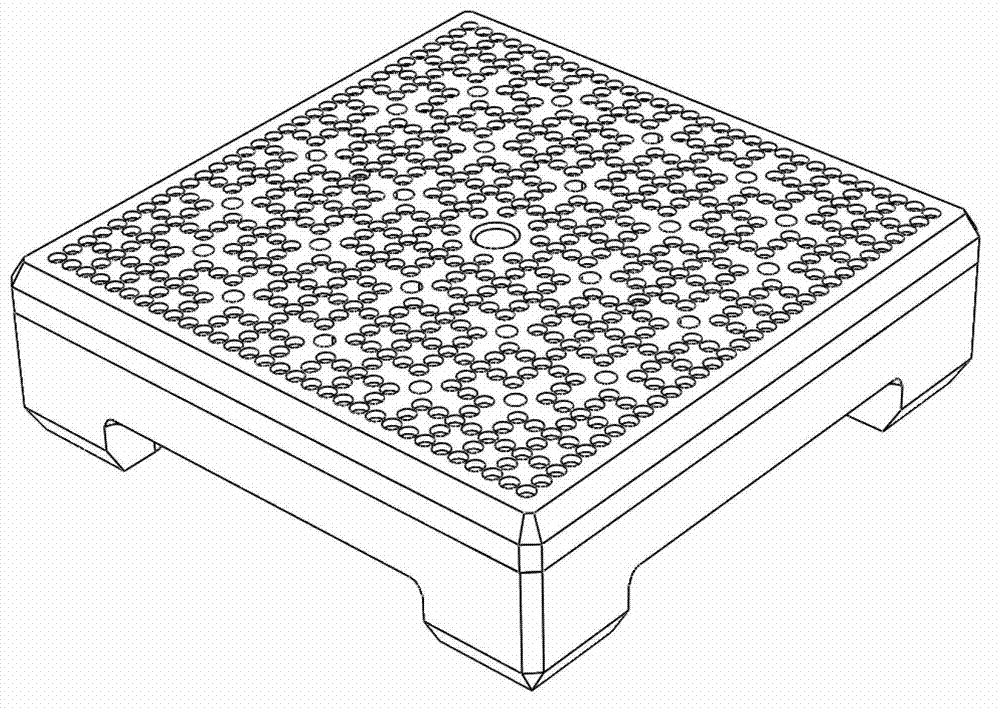

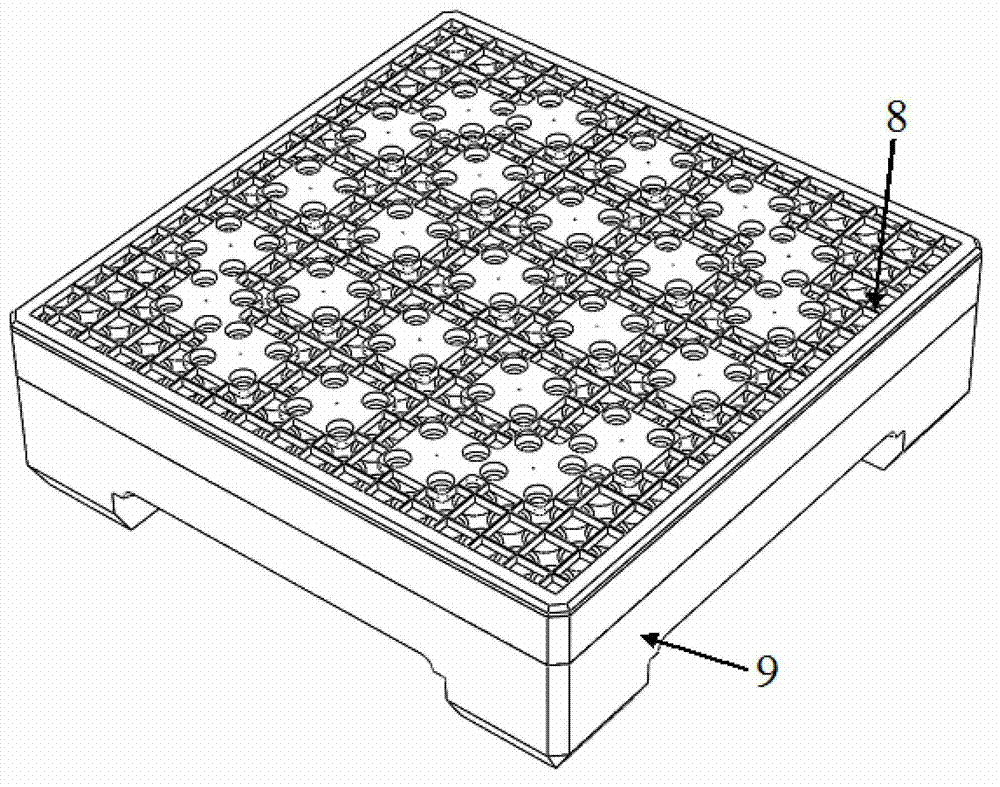

Method for inspecting a region of interest

An inspection method utilizing vertical slice imaging. A number of horizontal slice images, extending through an object of interest, are acquired. A vertical region of interest is defined from the data representing the horizontal slice images. A vertical slice image is constructed based upon the horizontal slice image data falling within the vertical region of interest. The vertical slice image data may be analyzed to detect defects. In addition, a method is provided to detect defects in a BGA joint. The method includes locating a center of the joint. The method may further include measuring a number of diameters through the center of the joint and applying a rule to compare the measured diameters to an expected diameter.

Owner:TERADYNE

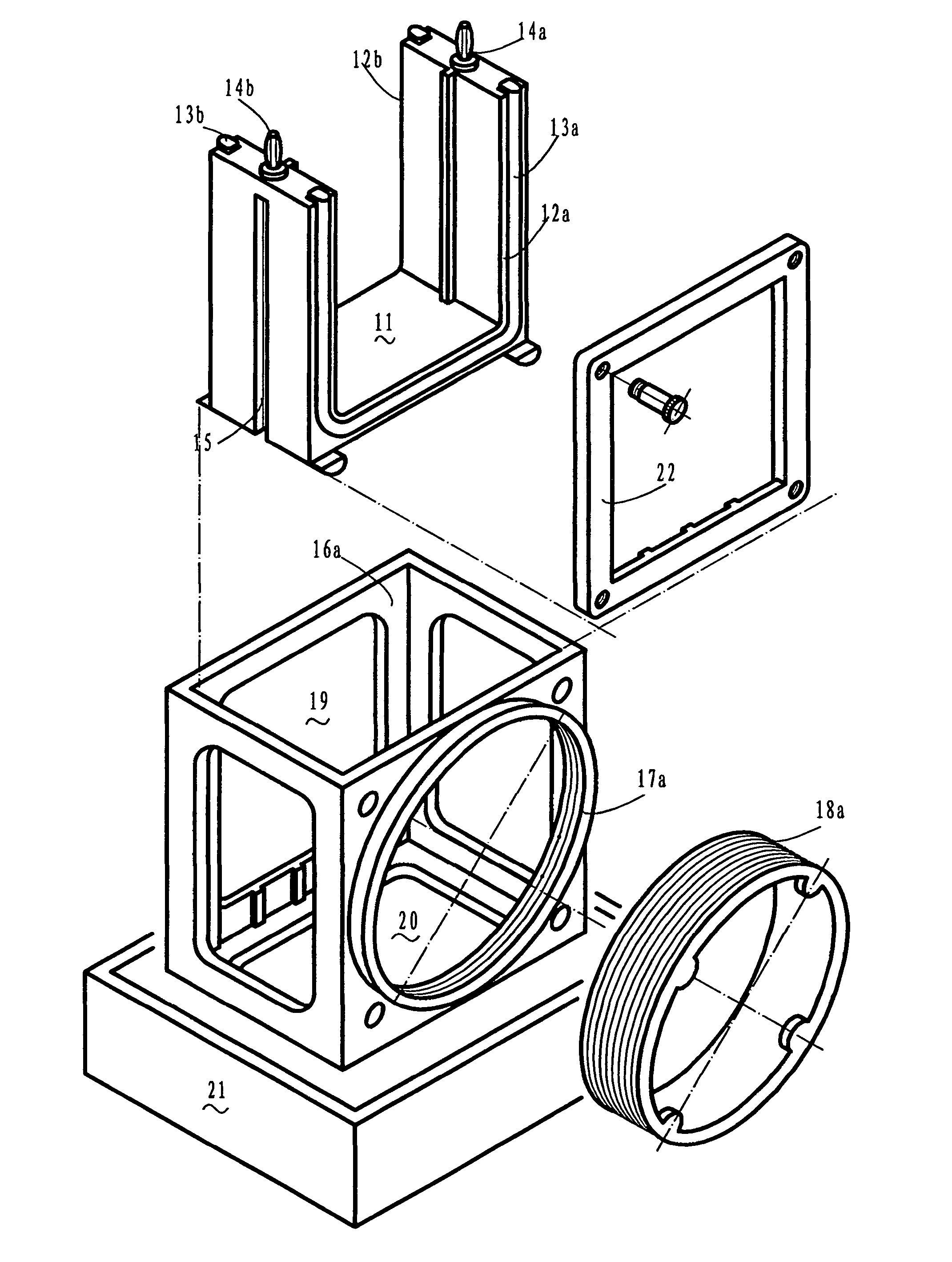

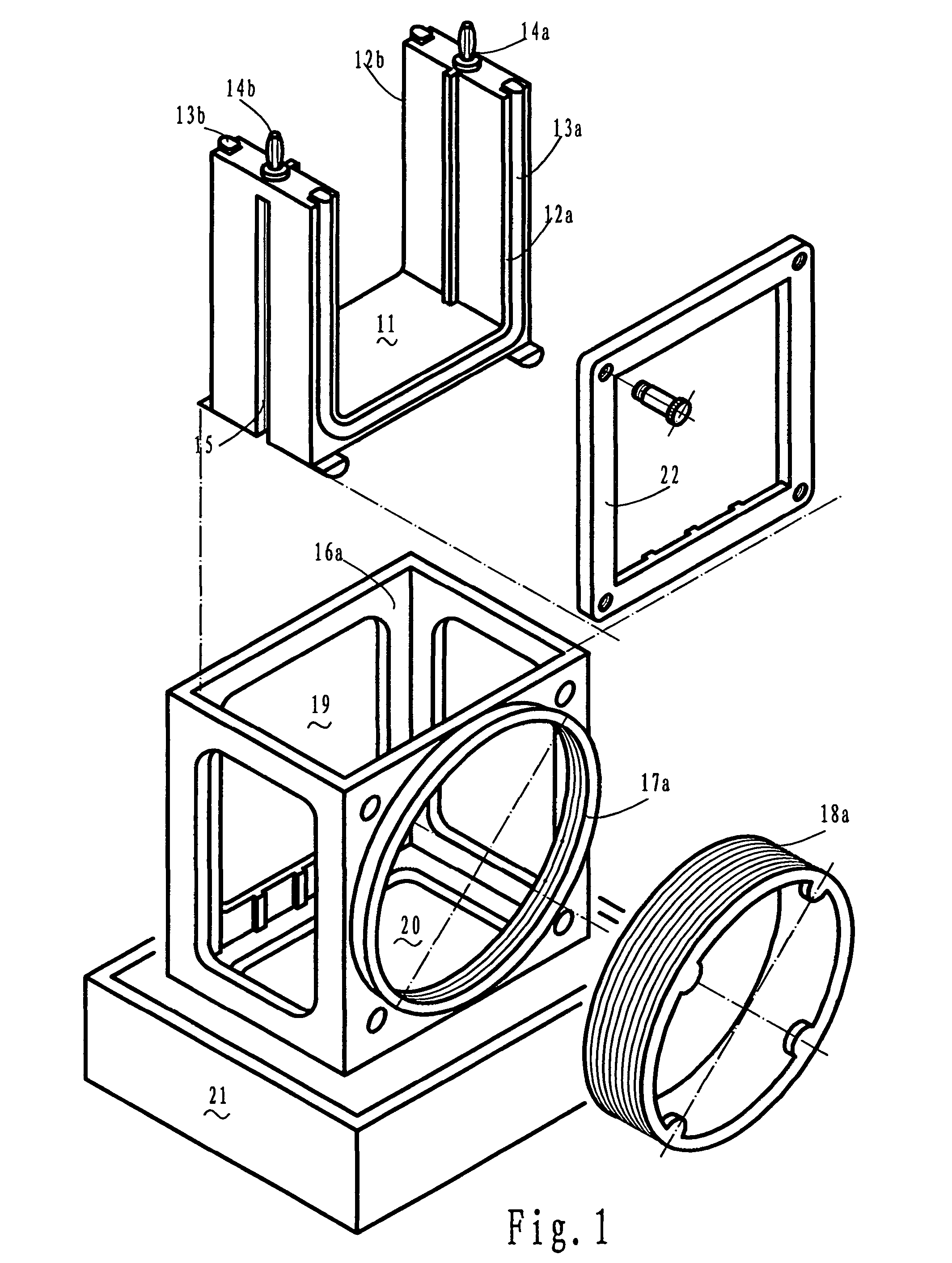

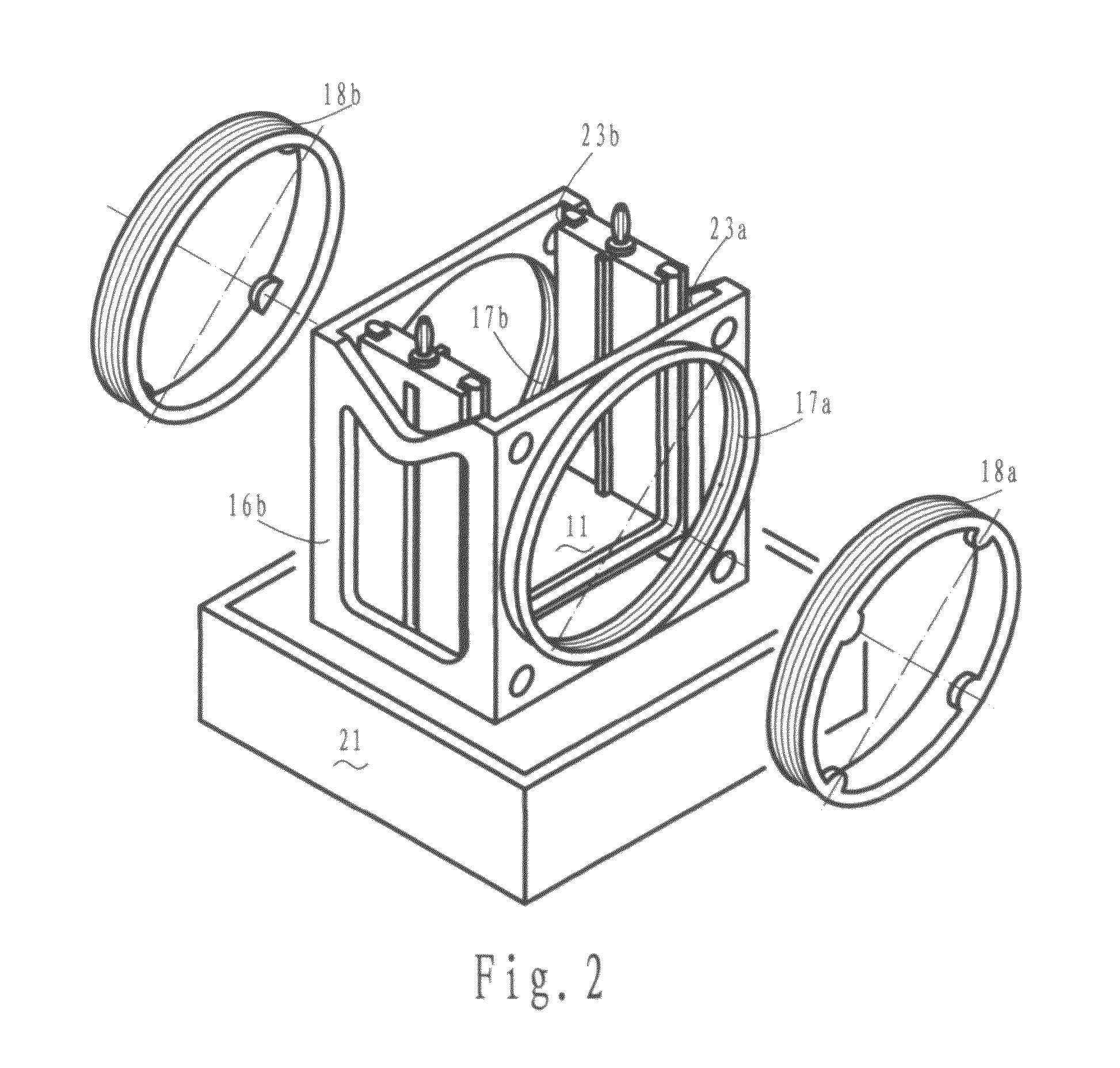

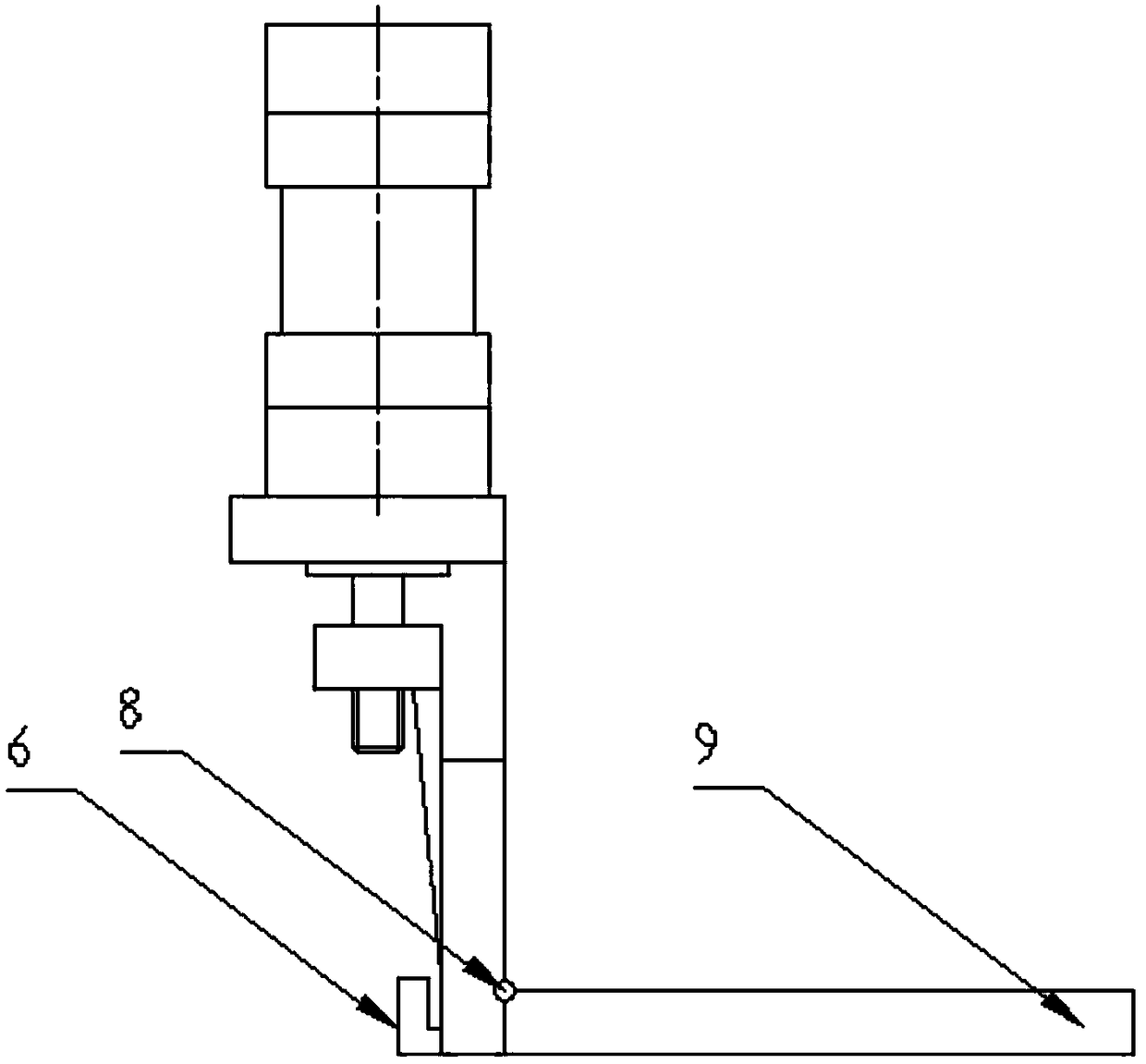

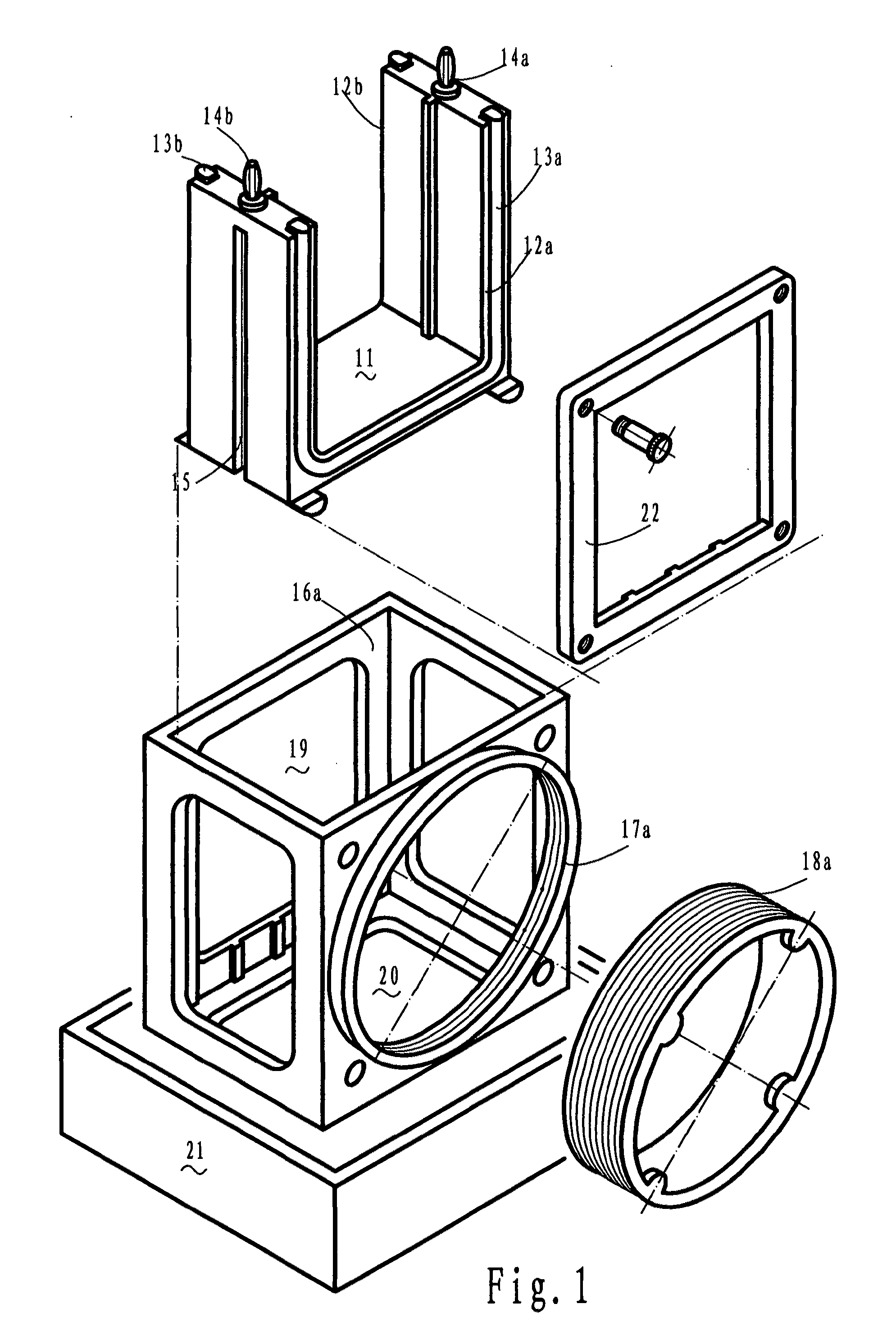

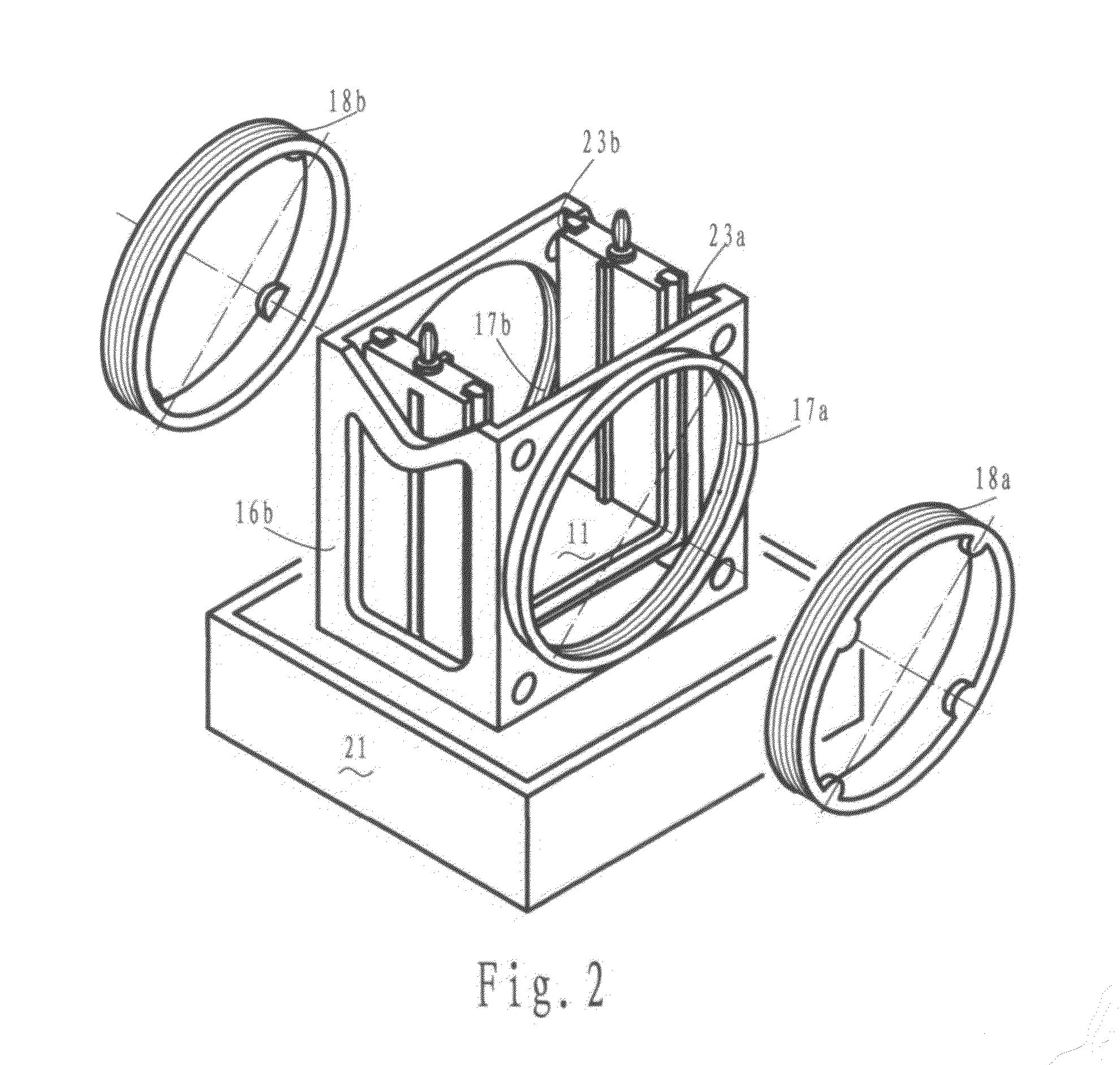

Vertical slice gel electrophoresis cell

In the present innovated vertical slice gel electrophoresis cell, at least one piece of large diameter screw urging ring is held to face to one U-shaped side opening of an upper buffer chamber, but an interval is left therebetween. After inserting a gel cassette into the interval, turning tight the screw urging ring can force at least one piece of gel cassette to join the upper buffer chamber tightly, no matter how thick the cassette is. In addition, some other materials are found also suitable for absorbing the Joule-heat after sealing them into dielectric shells respectively.

Owner:ZHOU DEMING

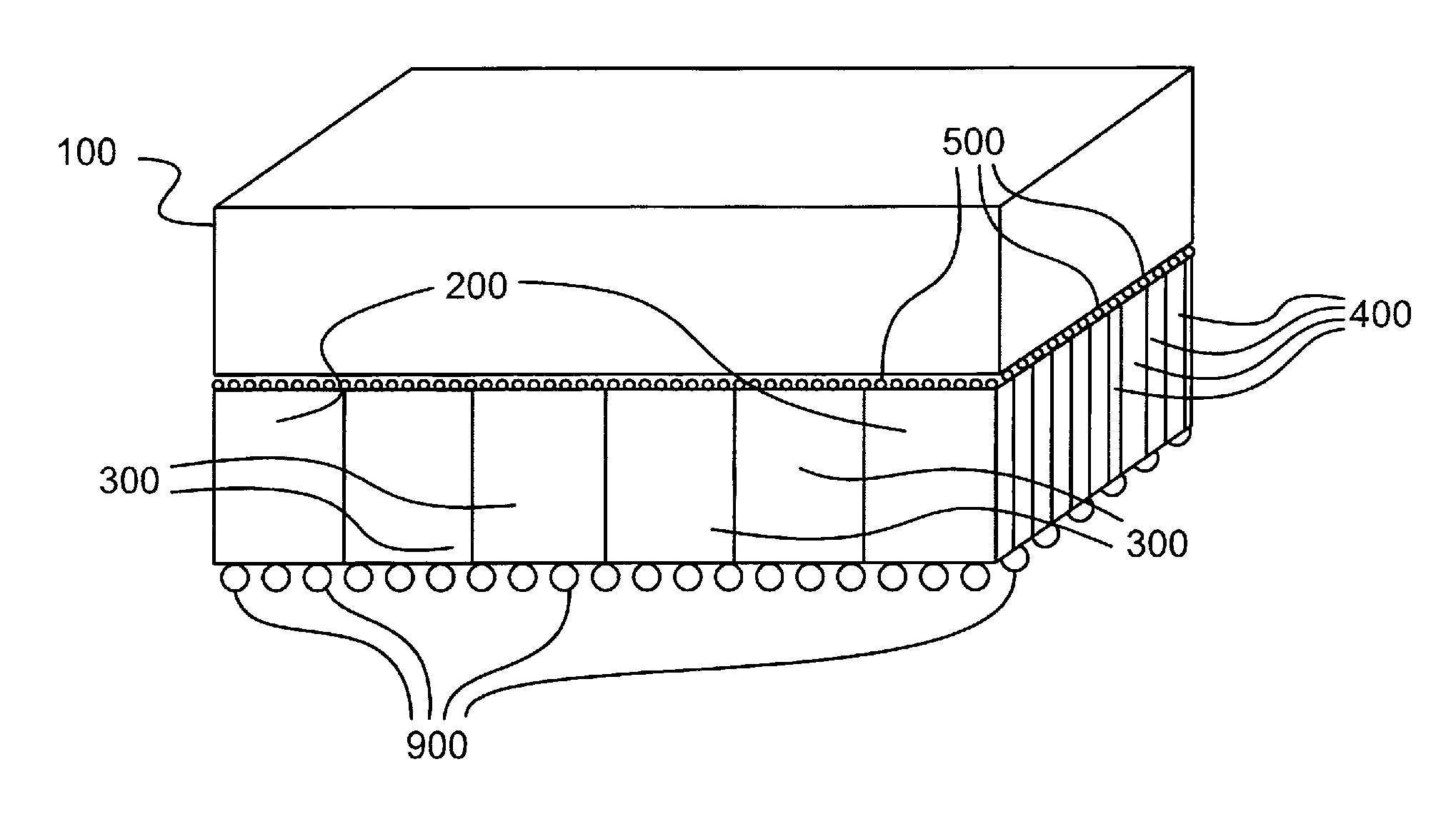

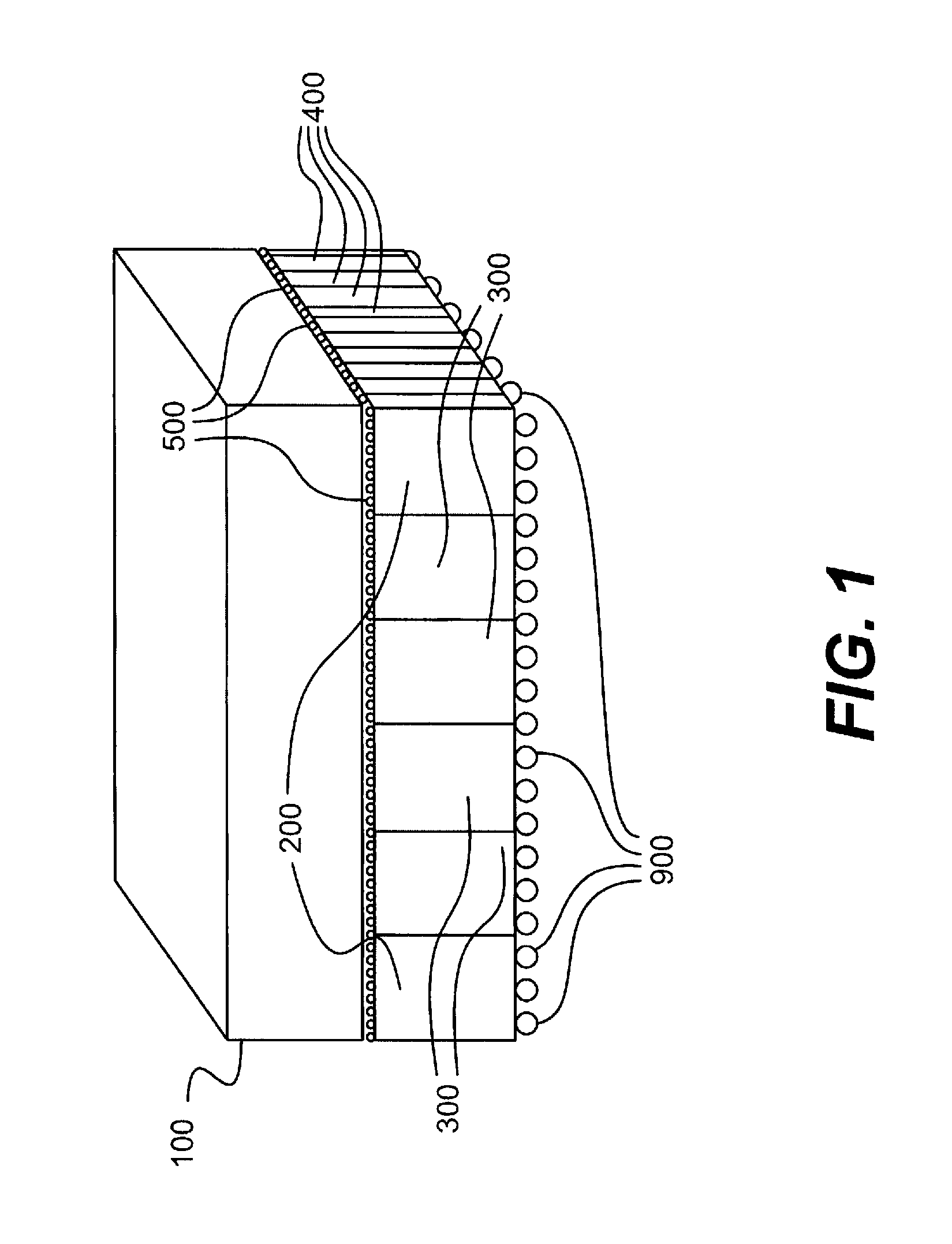

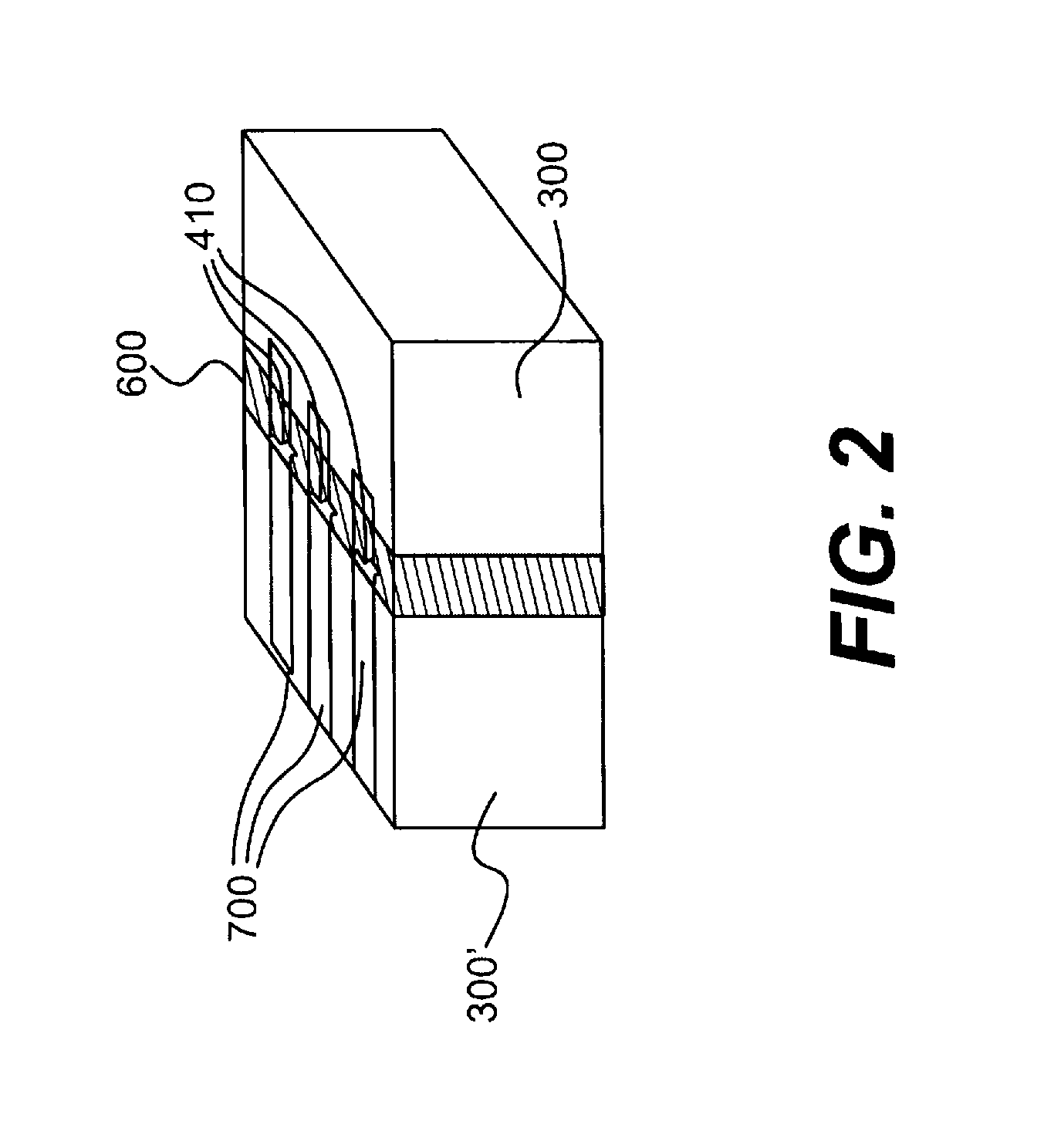

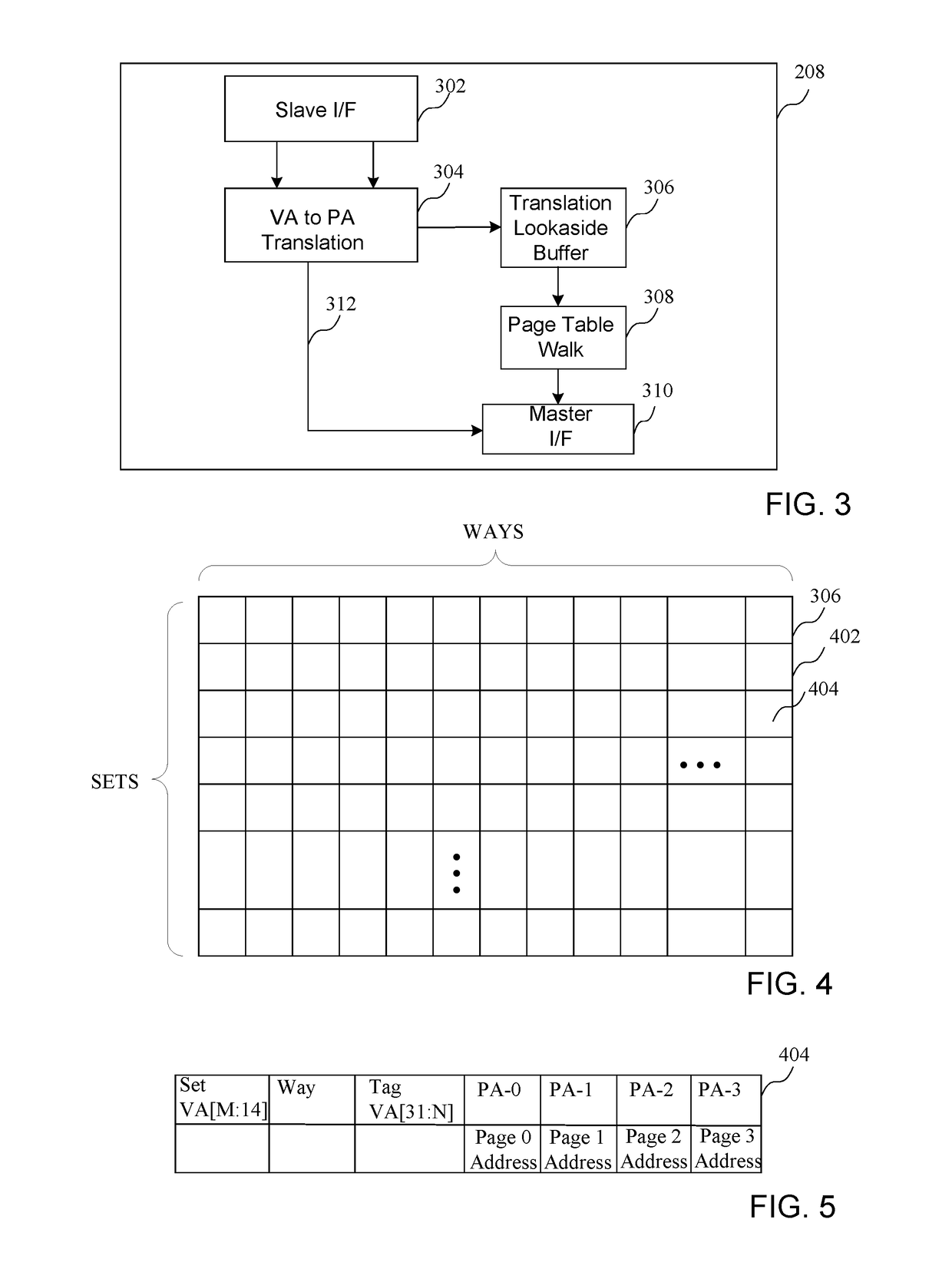

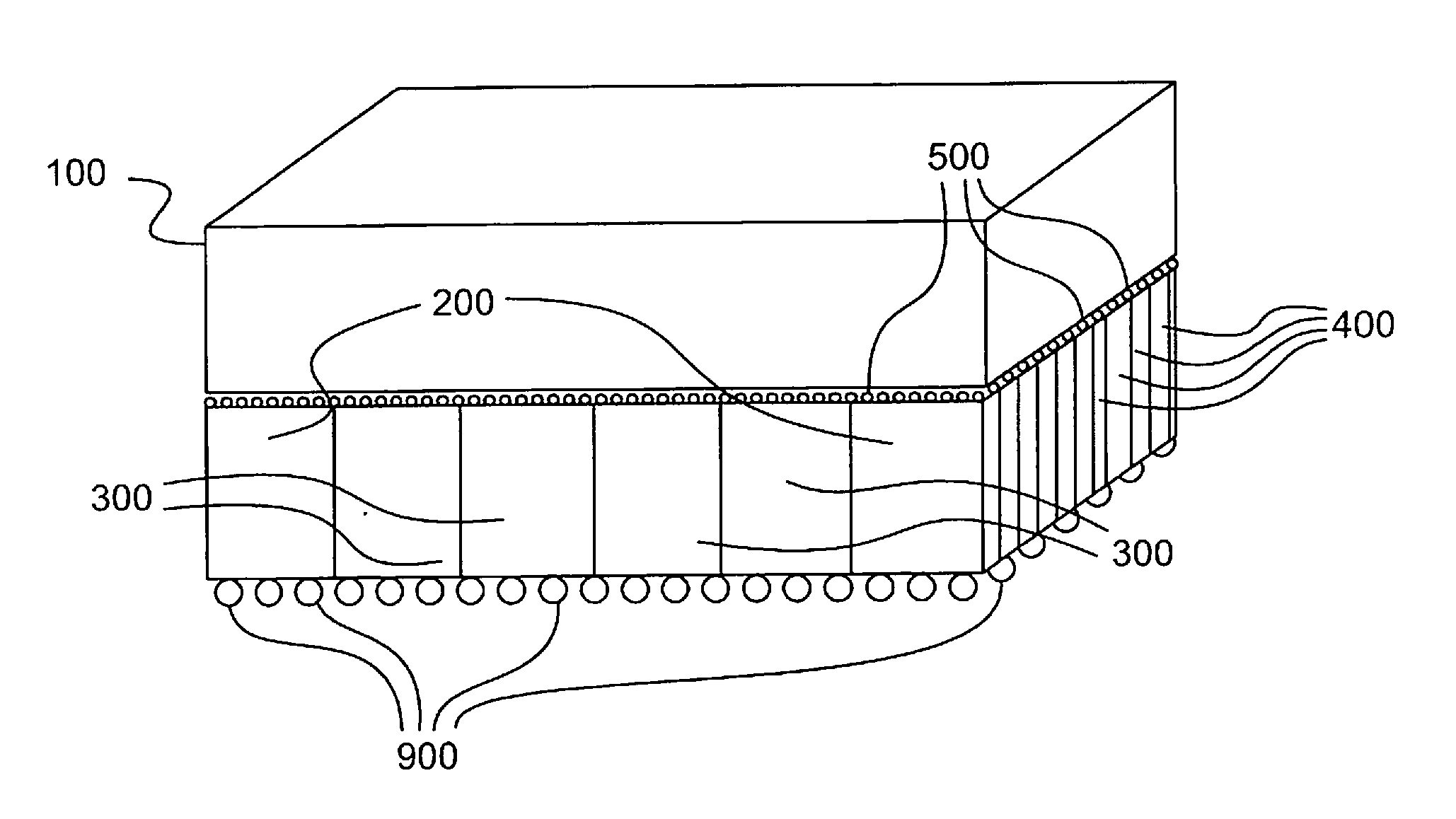

Processes for enhanced 3D integration and structures generated using the same

ActiveUS8330262B2Semiconductor/solid-state device detailsSolid-state devicesHigh bandwidthComputer module

An enhanced 3D integration structure comprises a logic microprocessor chip bonded to a collection of vertically stacked memory slices and an optional set of outer vertical slices comprising optoelectronic devices. Such a device enables both high memory content in close proximity to the logic circuits and a high bandwidth for logic to memory communication. Additionally, the provision of optoelectronic devices in the outer slices of the vertical slice stack enables high bandwidth direct communication between logic processor chips on adjacent enhanced 3D modules mounted next to each other or on adjacent packaging substrates. A method to fabricate such structures comprises using a template assembly which enables wafer format processing of vertical slice stacks.

Owner:INT BUSINESS MASCH CORP

Inspection method utilizing vertical slice image

An inspection method utilizing vertical slice imaging. A number of horizontal slice images, extending through an object of interest, are acquired. A vertical region of interest is defined from the data representing the horizontal slice images. A vertical slice image is constructed based upon the horizontal slice image data falling within the vertical region of interest. The vertical slice image data may be analyzed to detect defects. In addition, a method is provided to detect defects in a BGA joint. The method includes locating a center of the joint. The method may further include measuring a number of diameters through the center of the joint and applying a rule to compare the measured diameters to an expected diameter.

Owner:TERADYNE

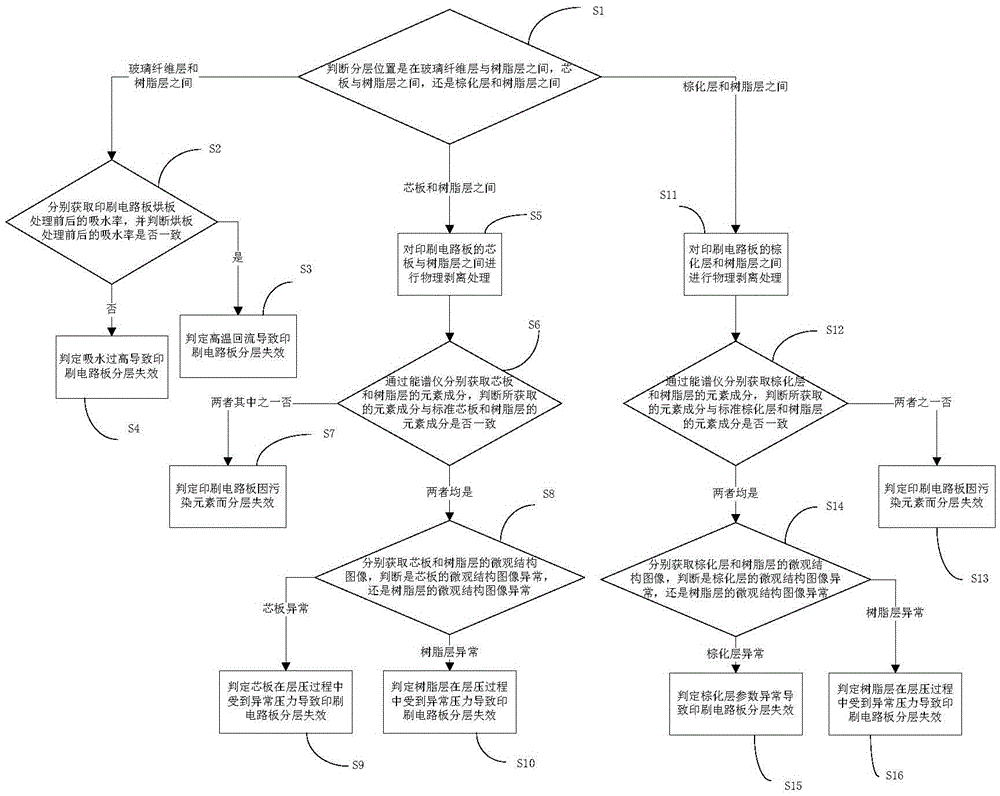

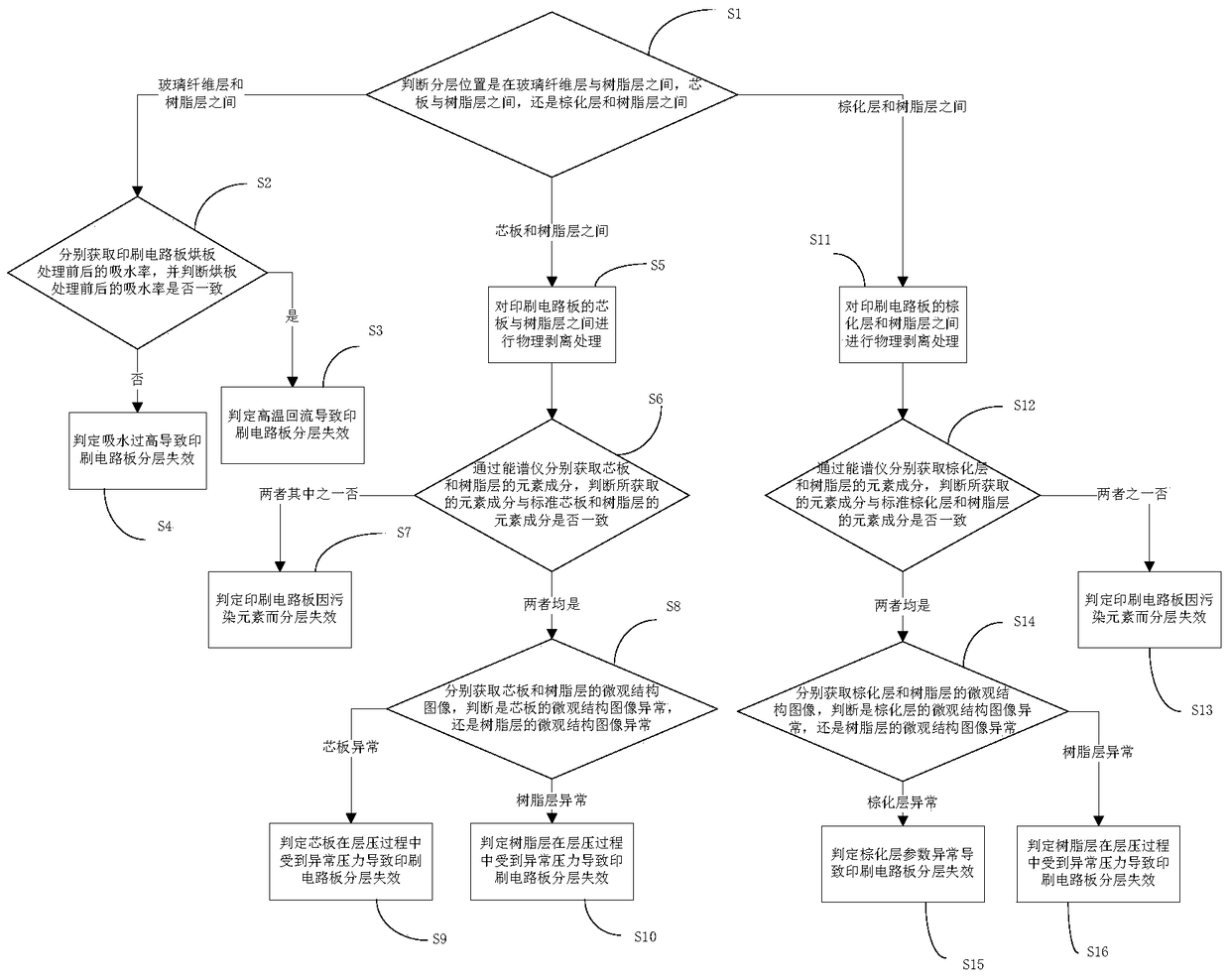

Printed circuit board layering failure detection method

ActiveCN105628716AConvenient placement processConvenience to improveMaterial weighingMaterial analysis by measuring secondary emissionAbsorption ratePrinted circuit board

The invention relates to a printed circuit board layering failure detection method, which comprises the following steps that a layering fracture printed circuit board is subjected to vertical slicing so as to judge whether the layering position is between a glass fiber layer and a resin layer or between a core plate and the resin layer or between a browning layer and the resin layer; if the layering position is between the glass fiber layer and the resin layer, the layering failure reason is judged according to the water absorption rate before and after the board baking treatment of the printed circuit board; if the layering position is between the core plate and the resin layer, the layering failure reason is judged according to the element ingredients and the microstructure image of the core plate and the resin layer; if the layering position is between the browning layer and the resin layer, the layering failure reason is judged according to the element ingredients and the microstructure image of the browning layer and the resin layer. The method provided by the invention can be used for detecting the layering reason by aiming at different layering positions of the printed circuit board, so that the subsequent pasting process can be improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

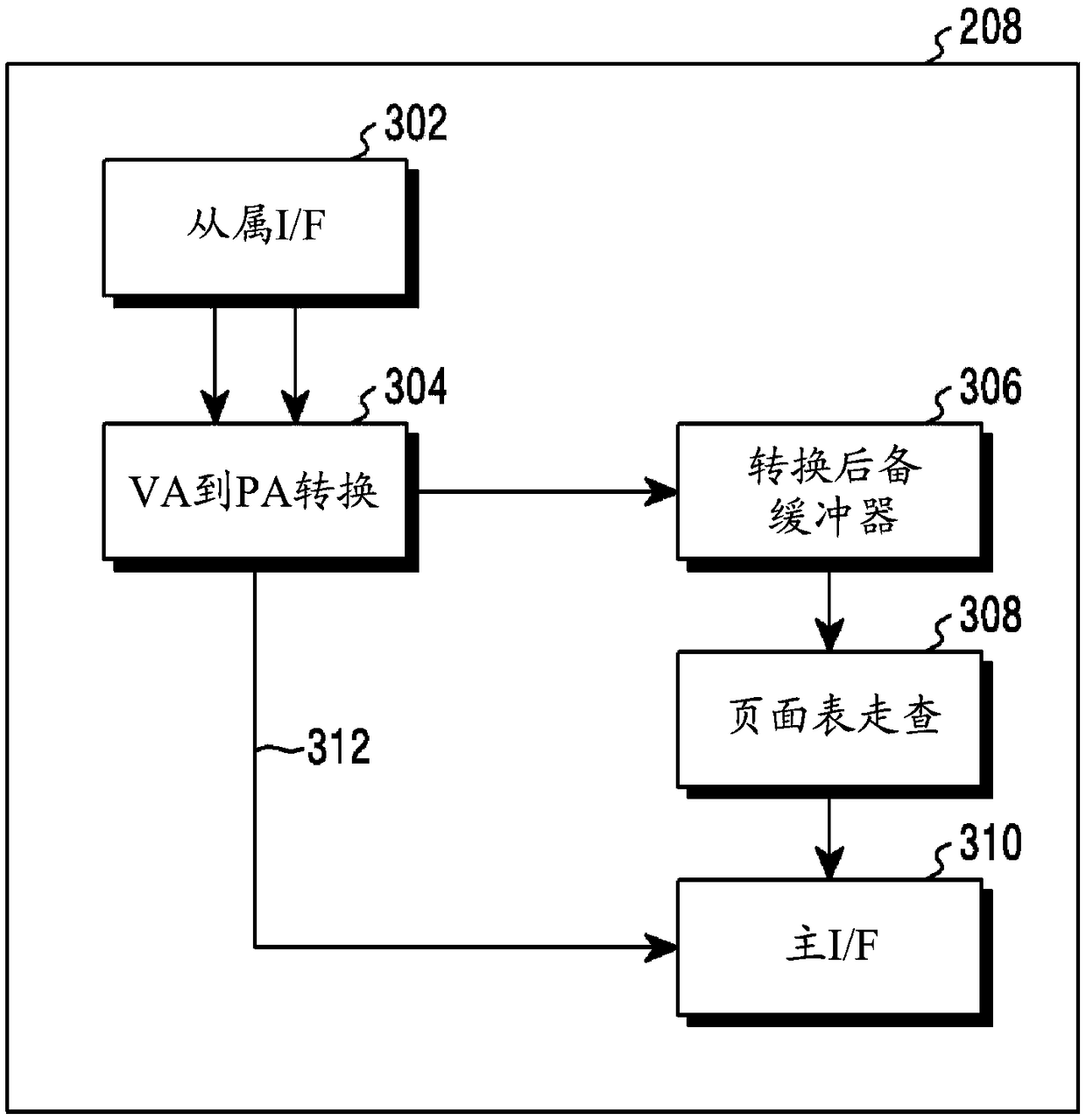

A method for enabling processing of a video stream and a device thereof

InactiveCN108886624AReduce cache missesReduce access latencyDigital video signal modificationSelective content distributionComputer hardwareComputer graphics (images)

A method for processing of a video stream is described. The method comprises receiving the video stream captured by a first sensor, dividing, for each of a plurality of frames of the video stream, into vertical slices having a slice width, and storing the divided each of the plurality of frames in a re-ordered slice based format. Computer-readable storage medium and a device for processing of a video stream are also described.

Owner:SAMSUNG ELECTRONICS CO LTD

An Analysis Method for Laser Blind Via Opening

The invention discloses an analysis method for opening of a laser blind hole. The analysis method comprises the following steps: S1) preparing a vertical slice for the laser blind hole with invalid opening; S2) observing by a microscope if a crack exists at the bottom of the laser blind hole; S3) if a crack is detected, using a micro-etching fluid for micro-etching a copper surface of the vertical slice and observing the position of the layer on which the crack is located; S4): a) confirming as opening of the laser blind hole caused by the oxidation of the copper surface if the crack is located between plating copper and an electroplate filling hole and no residual glue exists at the bottom of the laser blind hole, and b) confirming as opening of the laser blind hole caused by the oxidation of the copper surface if the crack is located between base copper and the plating copper and no residual glue exists at the bottom of the laser blind hole, and confirming as opening of the laser blind hole caused by the residual glue if the residual glue exists at the bottom of the laser blind hole. According to the analysis method provided by the invention, the reason of opening of the laser blind hole can be accurately acquired, so that the opening problem of the laser blind hole can be solved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

Device for and method of enabling the processing of a video stream

ActiveUS10034026B2Speed up the processReduce latencyTelevision system detailsColor television detailsComputer graphics (images)Vertical slice

Owner:SAMSUNG ELECTRONICS CO LTD

Process for Enhanced 3D Integration and Structures Generated Using the Same

InactiveUS20120308241A1Semiconductor/solid-state device detailsSolid-state devicesHigh bandwidthEngineering

An enhanced 3D integration structure comprises a logic microprocessor chip bonded to a collection of vertically stacked memory slices and an optional set of outer vertical slices comprising optoelectronic devices. Such a device enables both high memory content in close proximity to the logic circuits and a high bandwidth for logic to memory communication. Additionally, the provision of optoelectronic devices in the outer slices of the vertical slice stack enables high bandwidth direct communication between logic processor chips on adjacent enhanced 3D modules mounted next to each other or on adjacent packaging substrates. A method to fabricate such structures comprises using a template assembly which enables wafer format processing of vertical slice stacks.

Owner:INT BUSINESS MASCH CORP

Delamination failure detection method of printed circuit board

ActiveCN105628716BSubsequent placement process improvementMaterial weighingMaterial analysis by measuring secondary emissionVertical sliceMechanical engineering

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

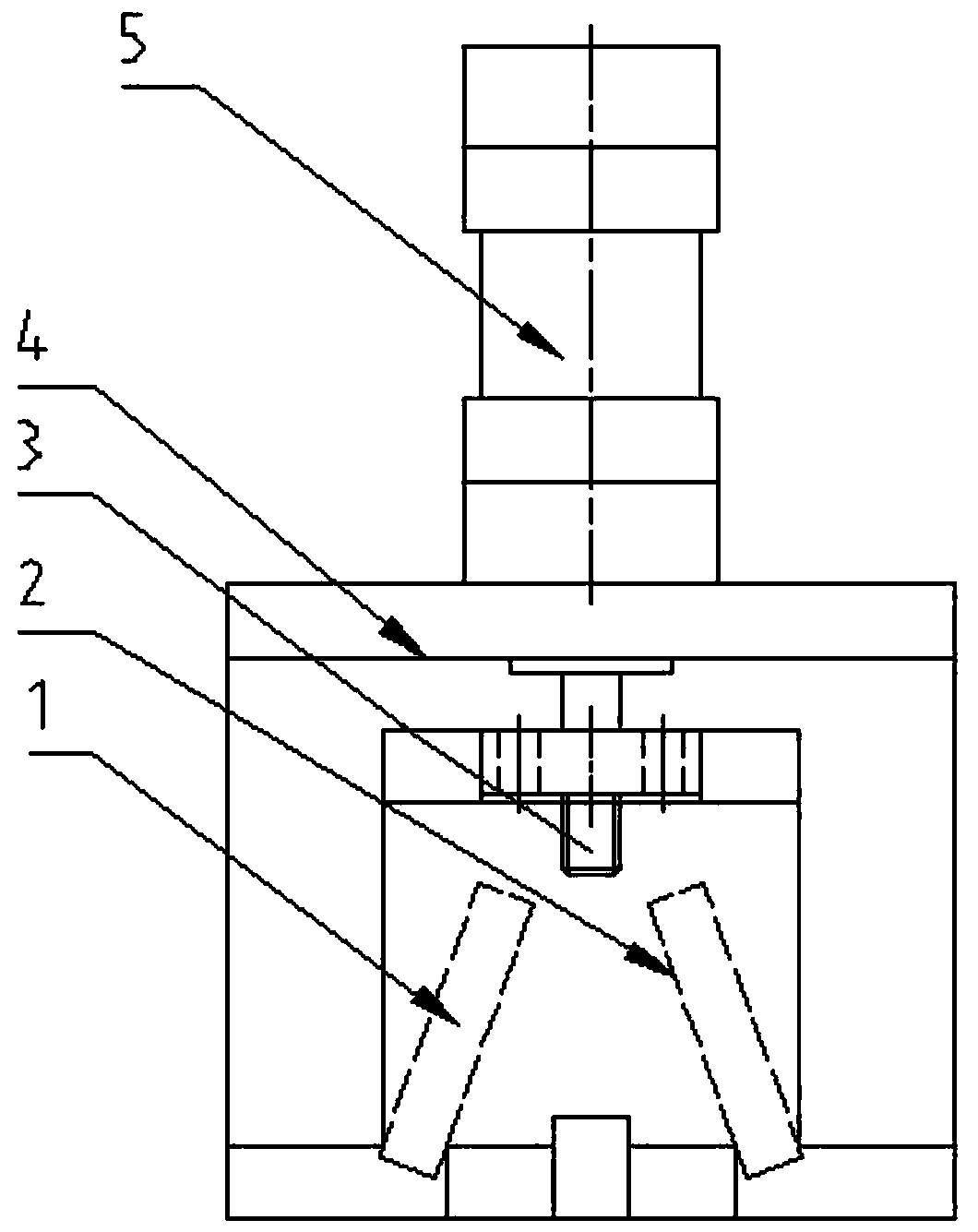

Device for V-belt sample slicing

InactiveCN109141958AMeet different sizesFulfil requirementsWithdrawing sample devicesPreparing sample for investigationHydraulic cylinderEngineering

The invention discloses a device for V-belt sample slicing. The device for the V-belt sample slicing is characterized in that the device comprises a underframe whose front end is provided with a cardslot; a left side compression adjustment plate is arranged on one side of the inner side of the card slot, while a right side compression adjustment plate is arranged on the other side of the inner portion of the card slot; a sample width adjustment plate is disposed on the front end of the card slot; a fixed rack provided with a hydraulic cylinder is arranged on the upper end of the underframe; aknife rest with the bottom provided with a cutting knife is arranged below the fixed rack; the hydraulic cylinder drives the cutting knife to operate; the bottom of the underframe is provided with anangle adjustment shaft for connecting the left side compression adjustment plate and the right side compression adjustment plate. Compared with the prior art,the device for the V-belt sample slicinghas the advantages of realizing slice width positioning, vertical slice, and slices with any angle from 0 to 180 degrees.

Owner:HENAN JINJIULONG IND

Vertical slice gel electrophoresis cell

In the present innovated vertical slice gel electrophoresis cell, at least one piece of large diameter screw urging ring is held to face to one U-shaped side opening of an upper buffer chamber, but an interval is left therebetween. After inserting a gel cassette into the interval, turning tight the screw urging ring can force at least one piece of gel cassette to join the upper buffer chamber tightly, no matter how thick the cassette is. In addition, some other materials are found also suitable for absorbing the Joule-heat after sealing them into dielectric shells respectively.

Owner:ZHOU DEMING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com