Patents

Literature

112results about "Circuit inspection/monitoring/aligning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

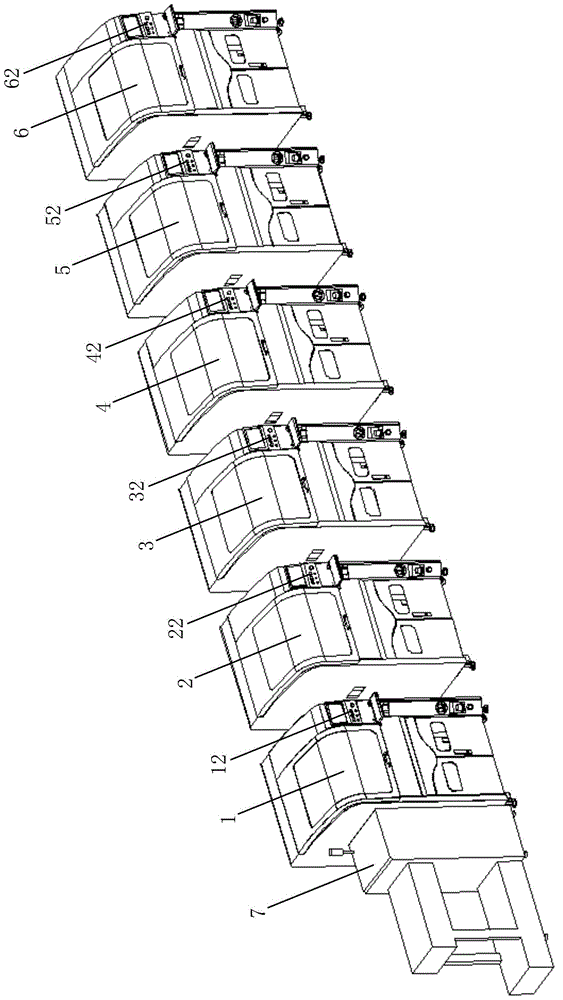

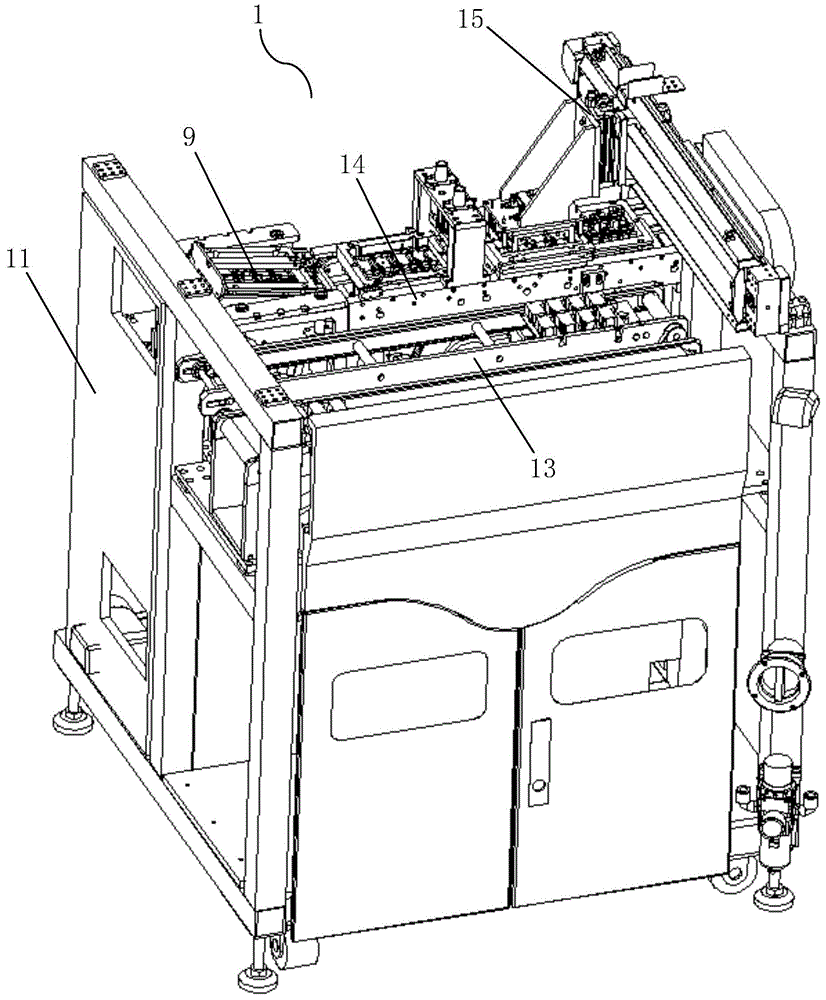

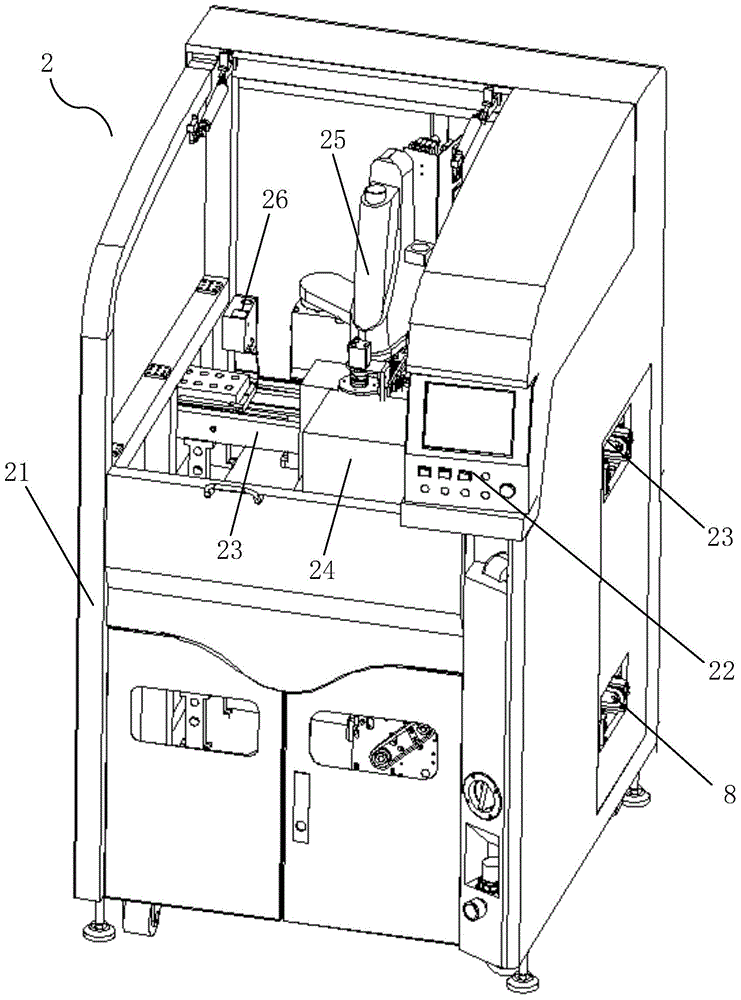

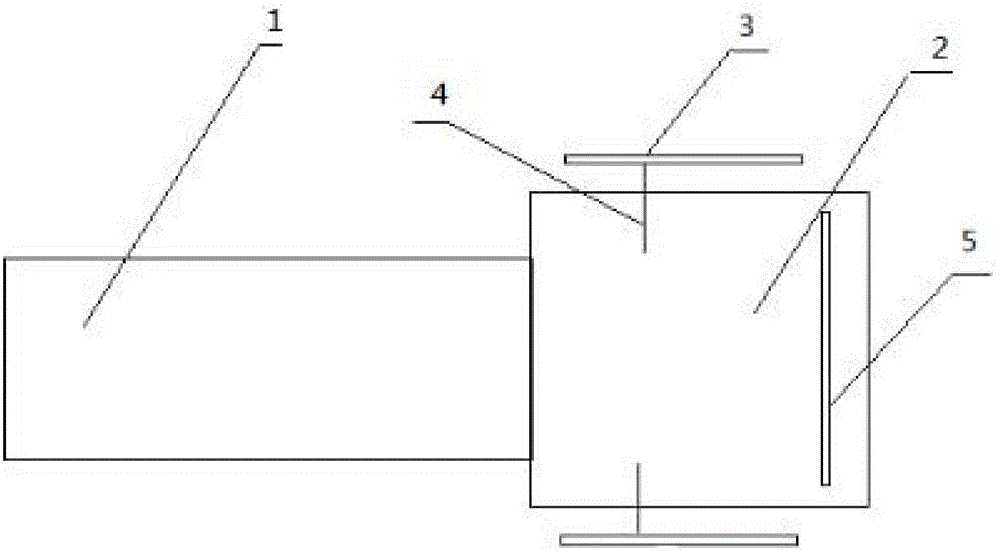

Novel multifunctional PCB production automation system

ActiveCN104822230AReduce labor intensityReduce in quantityLiquid surface applicatorsInsulating layers/substrates workingAdhesiveEngineering

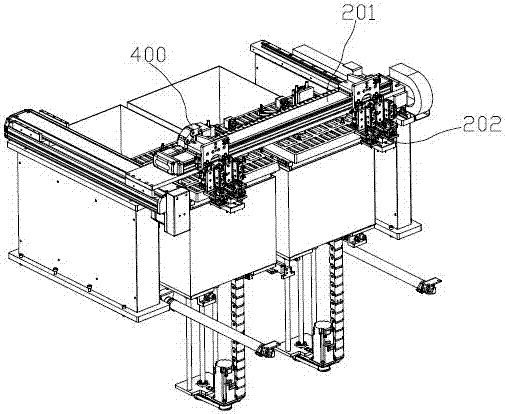

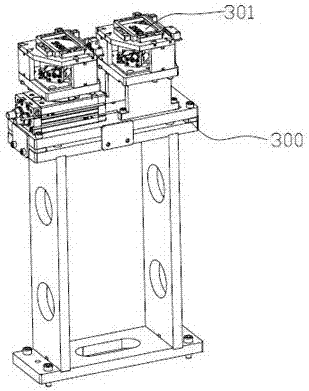

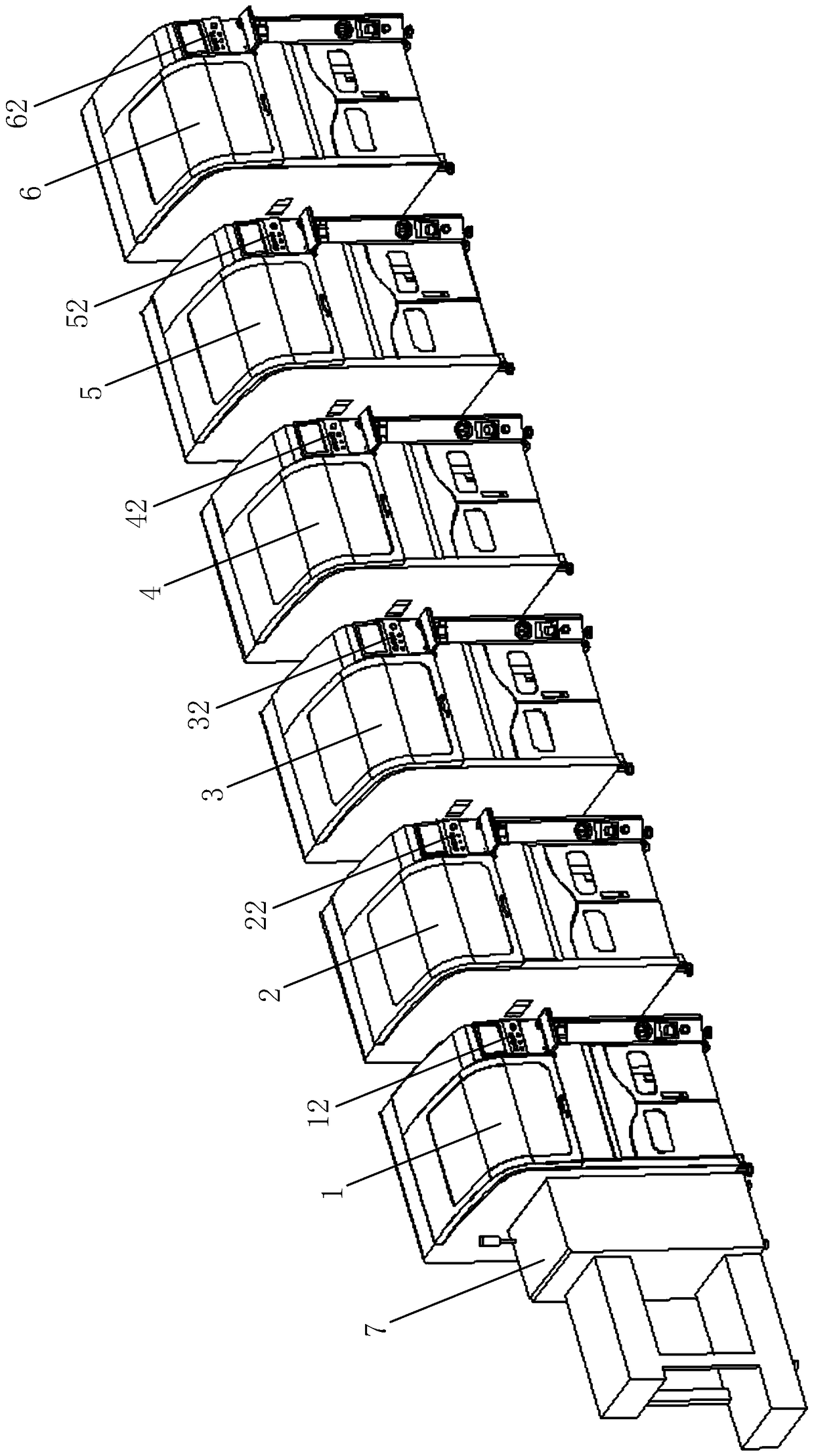

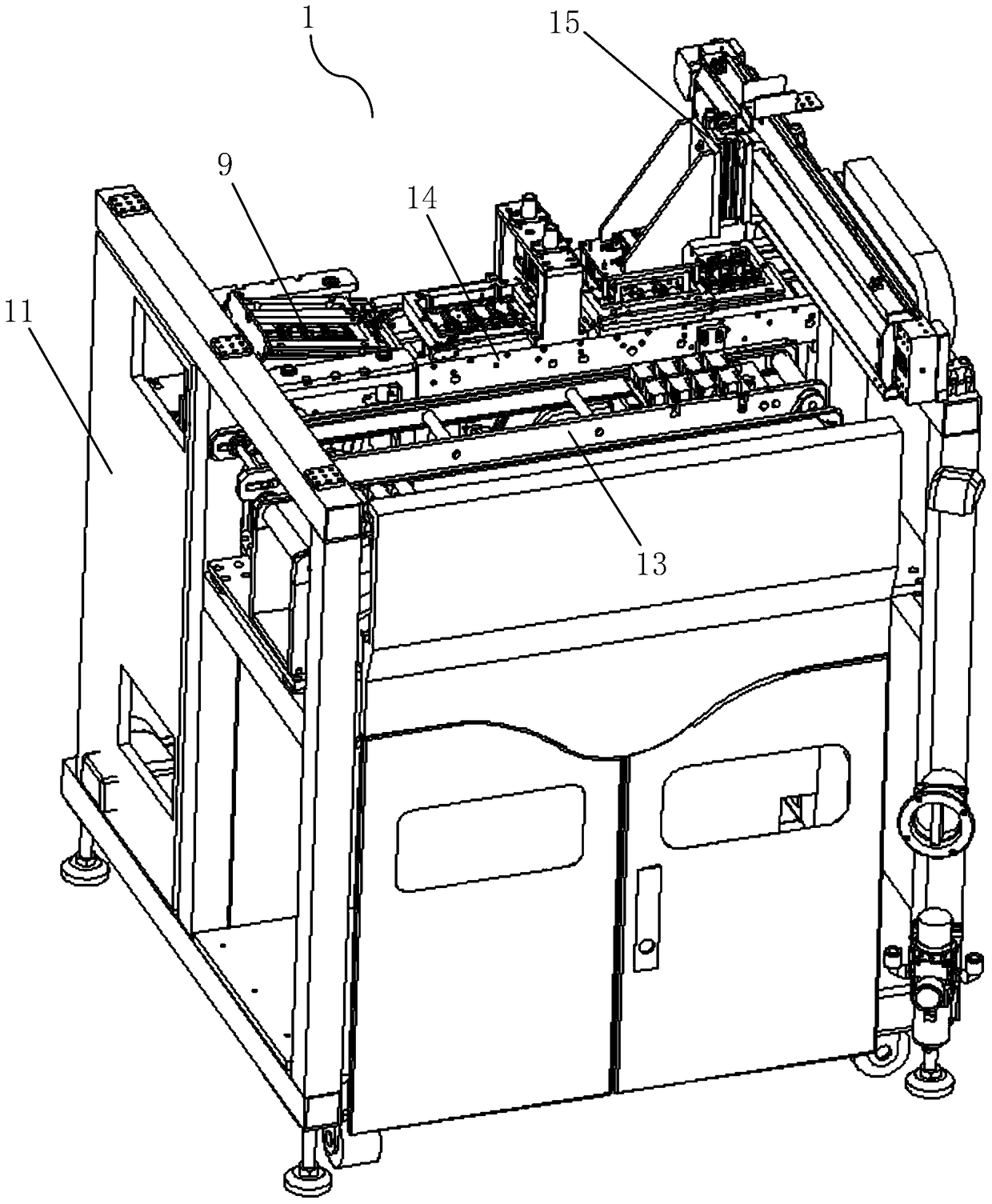

The invention relates to a novel multifunctional PCB production automation system, comprising an automatic feeding system, a fully-automatic two-dimensional code sticking system, a height measuring system, an automatic adhesive dispensing curing system, an online automatic board-splitting cutting system, and a finished product sorting recovery system. The input ends and output ends of the above systems are connected in sequence. Control centers disposed on the above systems are connected with each other. The input end of the automatic feeding system is also provided with a large PCB feeding device. The large PCB feeding device is connected with the control center of the automatic feeding system. Thus, two-dimensional code marking on each PCB unit on a large PCB can be automatically completed, and good product detection, and cutting of the large PCBs can be automatically completed. The system can automatically complete finished products of PCB units, and the system is powerful in functions, high in automation degree, high in production efficiency, low in labor intensity, low in production cost, and high in qualified rate, and has assurance in product quality. A reversed design is used, thereby effectively preventing dusts generated in a cutting process from falling on the PCB, so the finished products are clean.

Owner:ZHUHAI ZHIXIN AUTOMATIC TECH CO LTD

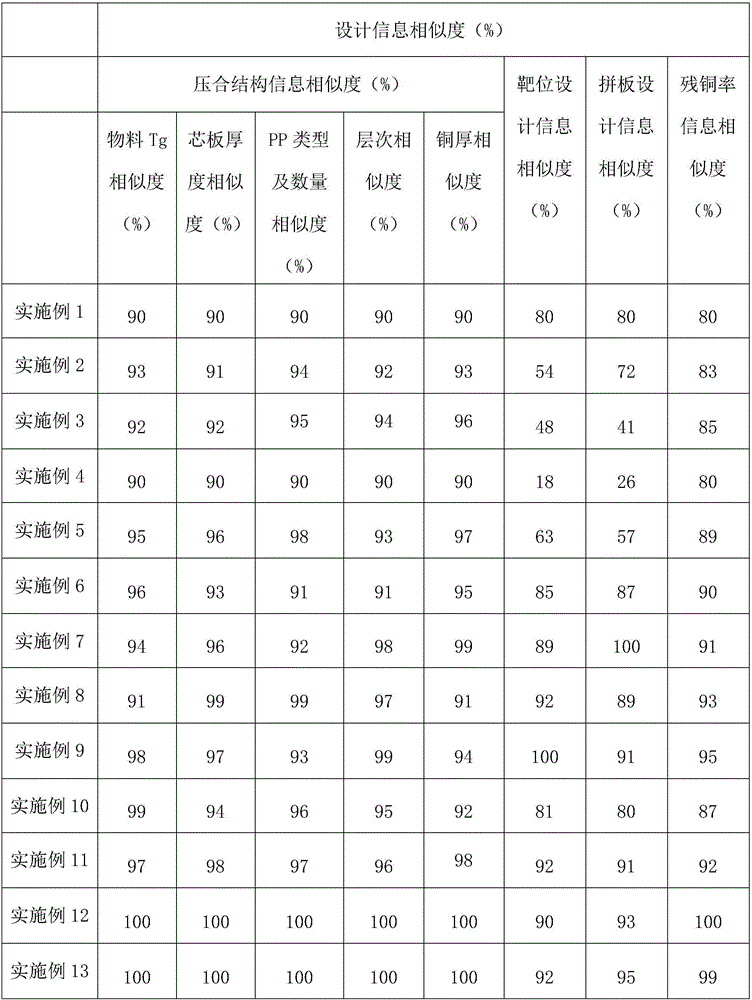

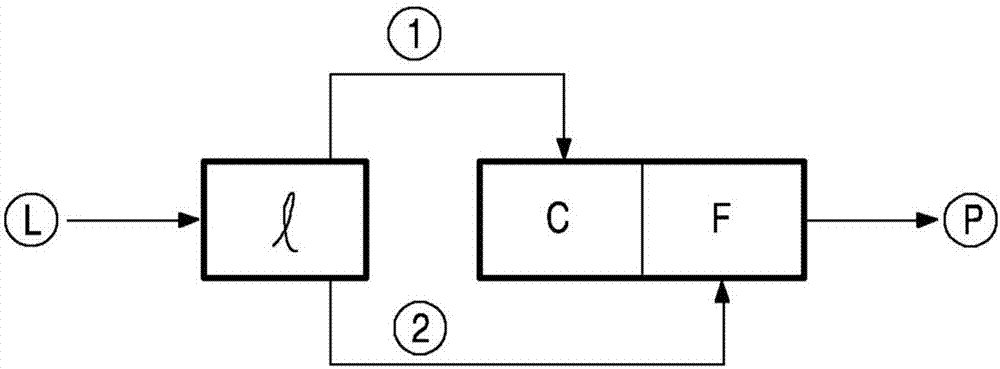

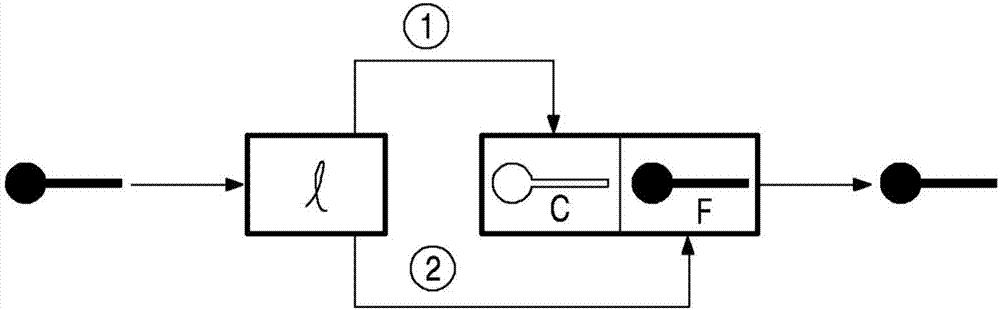

Novel PCB linear expansion control method

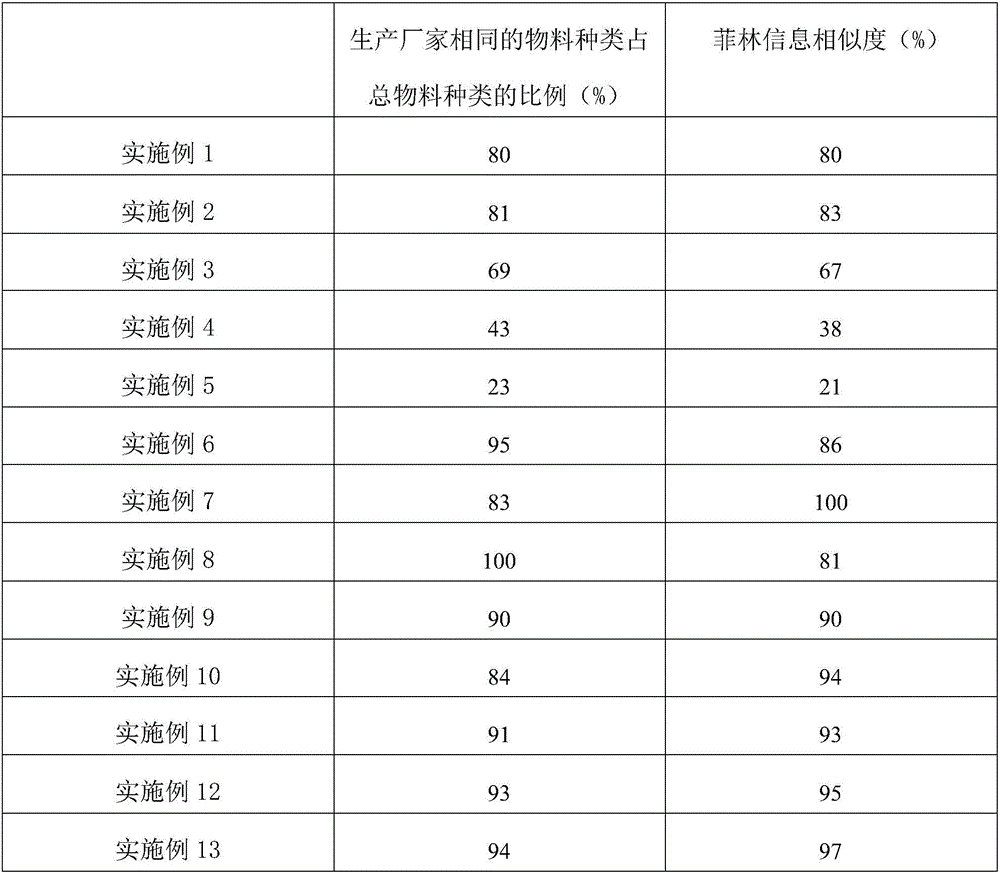

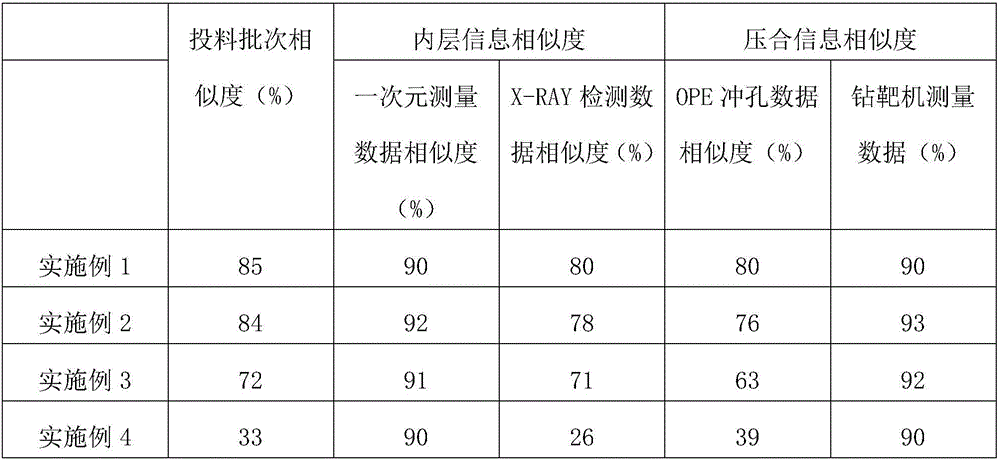

ActiveCN106572600APrevention and control of expansion and contraction in advanceExpansion prevention and controlCircuit inspection/monitoring/aligningSpecial data processing applicationsData informationDesign information

The invention discloses a novel PCB linear expansion control method. The method comprises the steps of engineering design: manufacturing engineering data according to the drawing requirements of a customer, finding out the historical expansion values of a PCB coincident with the information comparison principle out of the engineering data based on the information comparison principle by using an established expansion database according to customer data, and applying the expansion values to the manufacturing engineering data of existing PCB manufacture and design; PCB manufacture: manufacturing PCBs according to the engineering data obtained through the engineering manufacturing and designing process, collecting the workstation data information and the expansion values of currently manufactured PCBs, and storing the workstation data information, the expansion values, the design information and the material information of currently manufactured PCBs in an expansion database, wherein the workstation data information, the expansion values, the design information and the material information of currently manufactured PCBs are adopted as a reference for the subsequent design and comparison of PCBs; detection: detecting manufactured PCBs, judging whether the finished products of PCBs are qualified or not, and performing the batch manufacture of PCBs on the condition that the finished products of PCBs are qualified. According to the technical scheme of the invention, the expansion of PCB core boards can be prevented in advance and controlled. Therefore, a large amount of template production cost is saved and the production efficiency is improved.

Owner:江西景旺精密电路有限公司

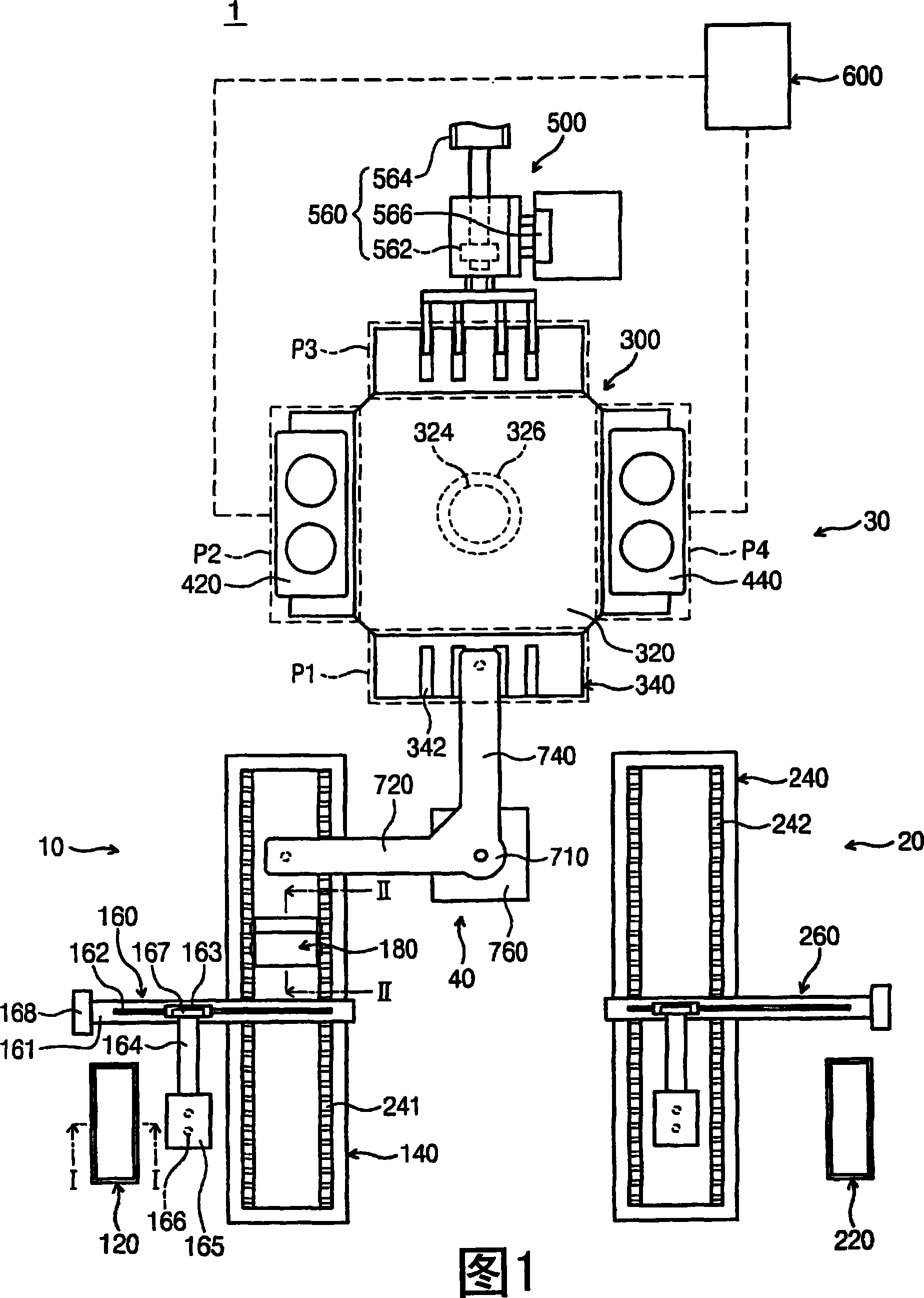

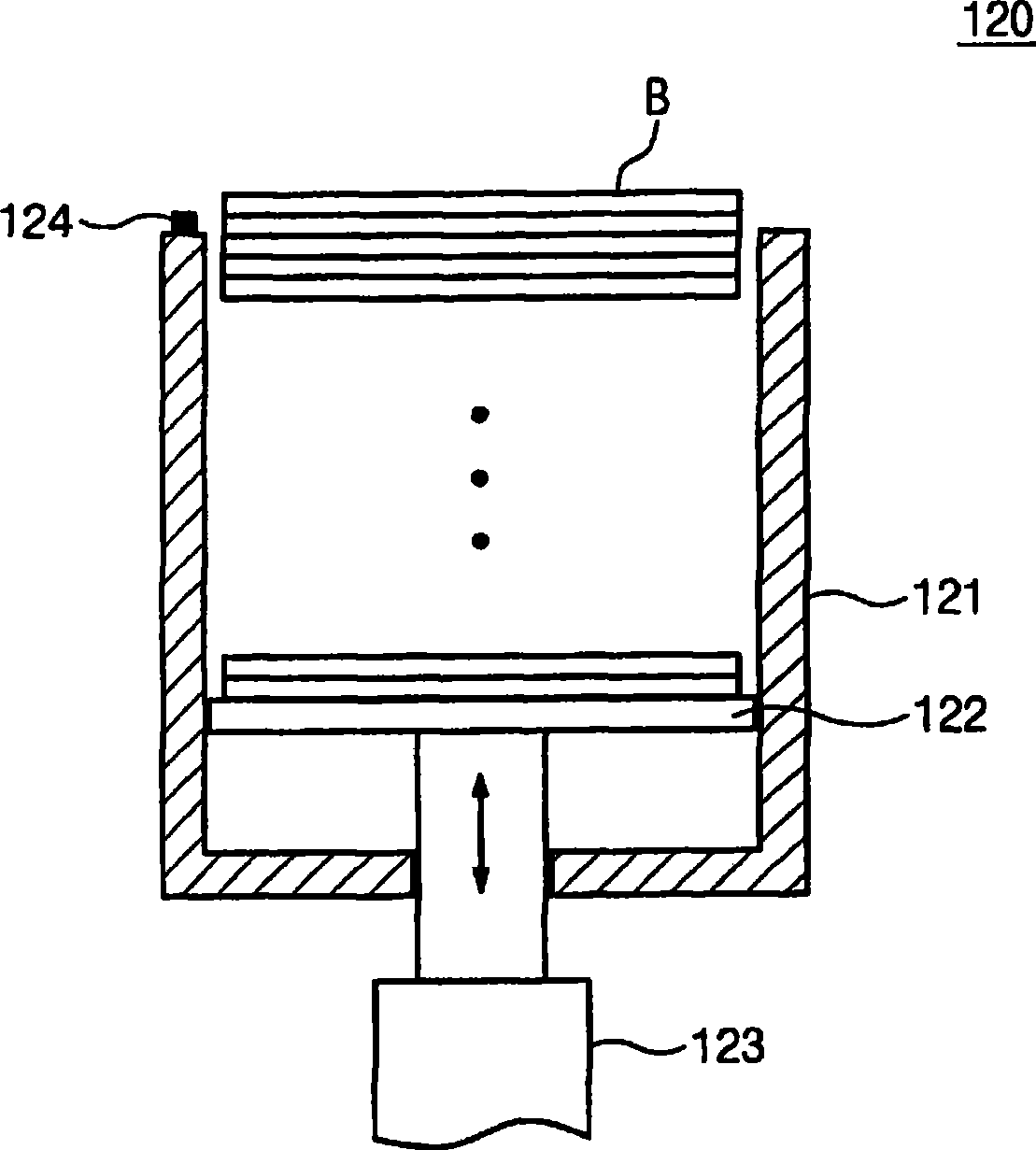

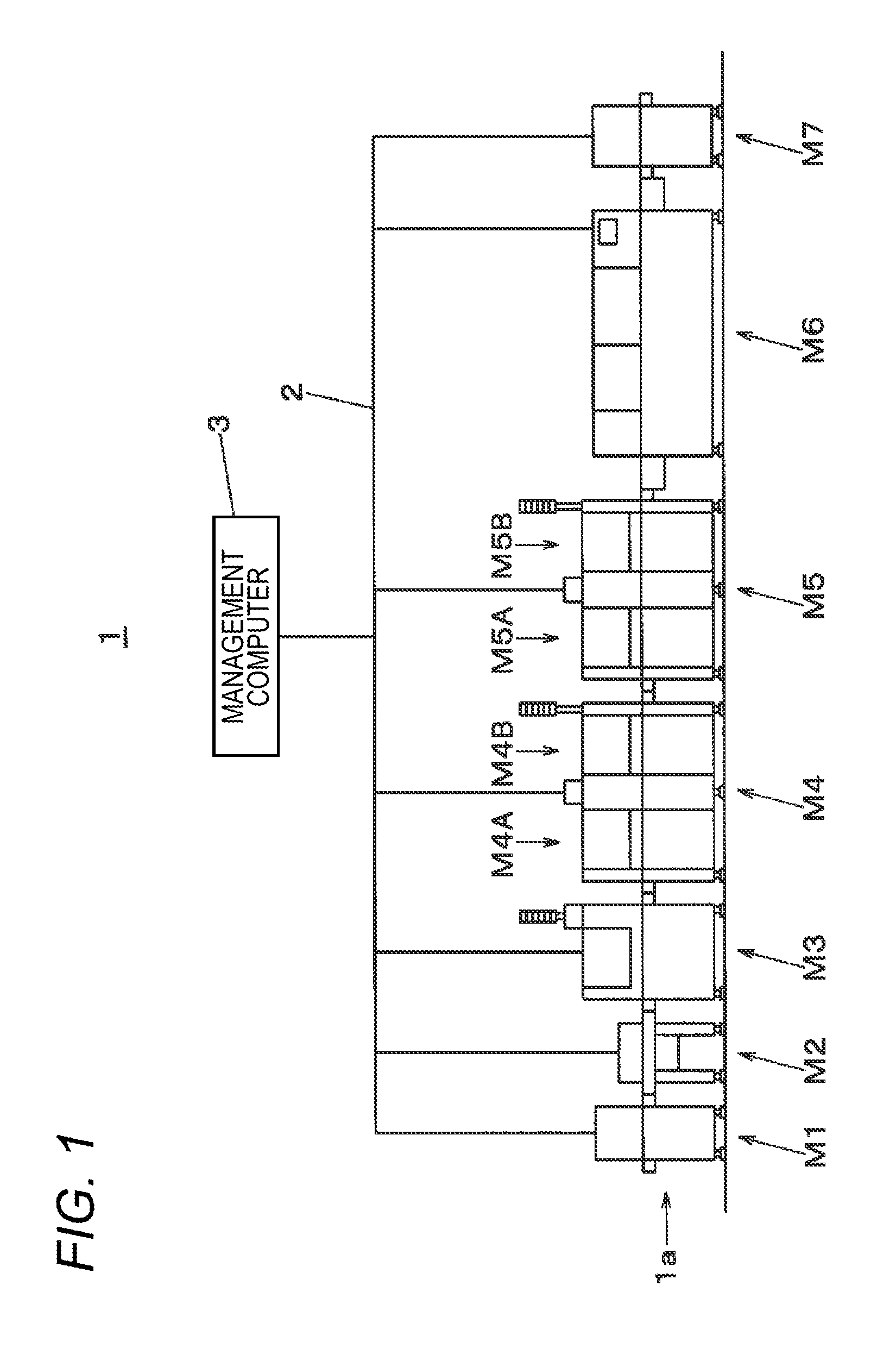

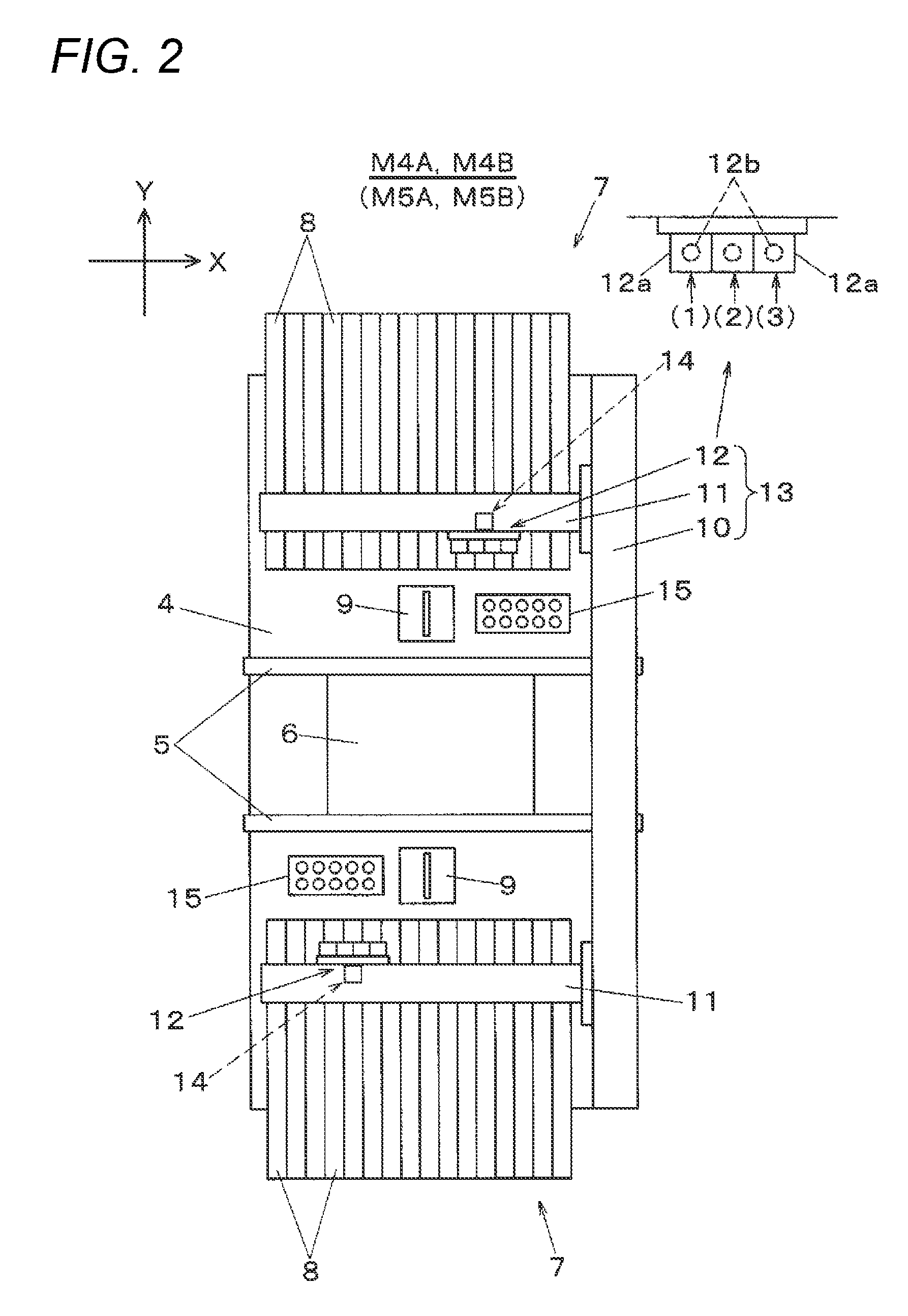

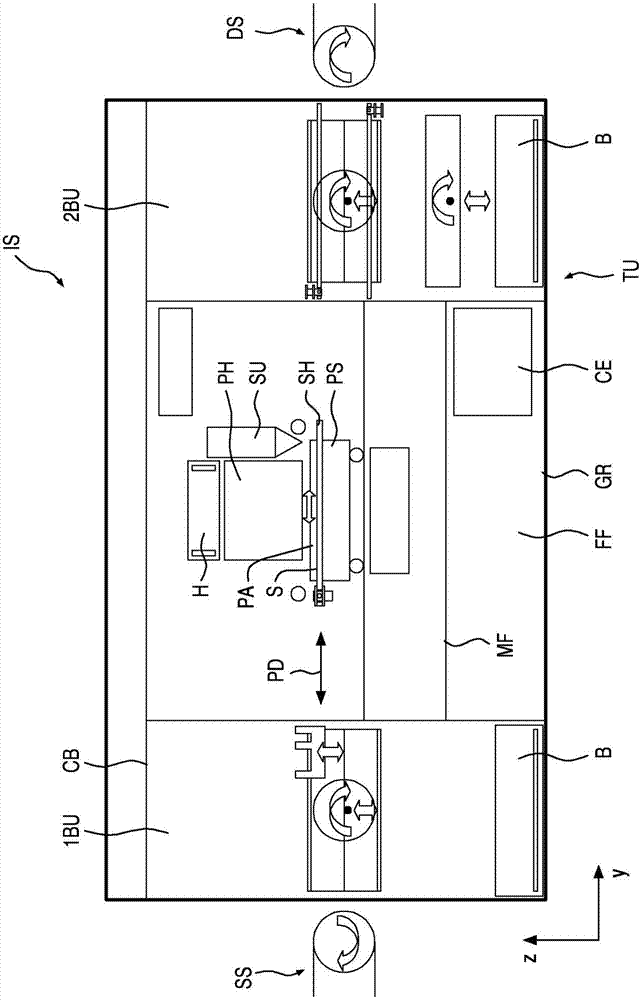

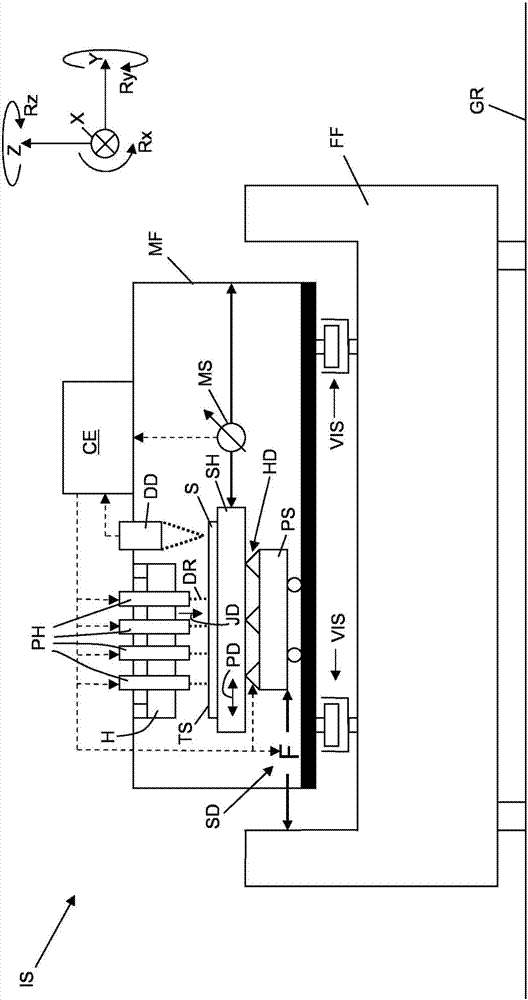

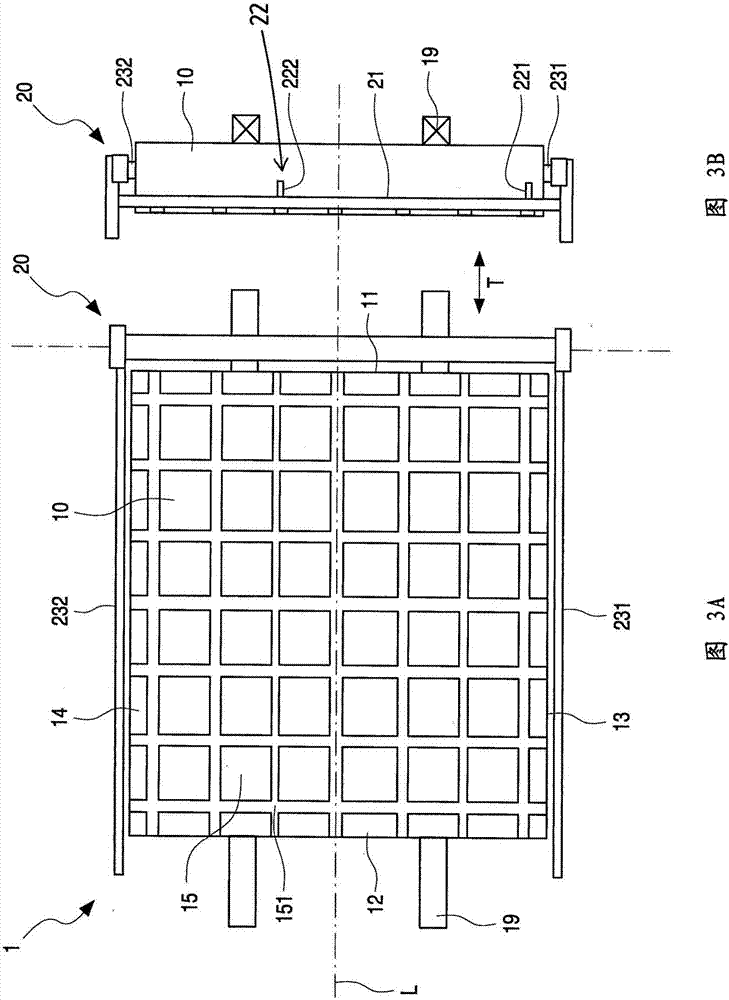

Inspect method and inspect device

InactiveCN101393142AEfficient inspectionShorten the timeMaterial analysis by optical meansCircuit inspection/monitoring/aligningPrinted circuit boardInspection method

The invention provides an inspection device and inspection method for efficiently inspecting an object to be inspected, such as an printed circuit board, etc. The printed circuit board moves from a move-in unit (10) to an inspection unit (30), performs orderly shooting, turning for upper surface, shooting for lower surface, then moves to a move-out unit (20). The printed circuit board moves between the move-in unit (10), the inspection unit (30) and the move-out unit (20), by using two arms (720, 740) configured to be a right angle, simultaneously the printed circuit board moves from the move-in unit (10) to the inspection unit (30), and from the inspection unit (30) to the move-out unit (20). Groove, formed on a carrier (340) for carrying the printed circuit board in the inspection unit (30), is used for inserting a finger part (510) for turning the printed circuit board, therefore the printed circuit board is lifted from the carrier (340) or carried on the carrier (340) by the movement of the finger part (510) in the groove.

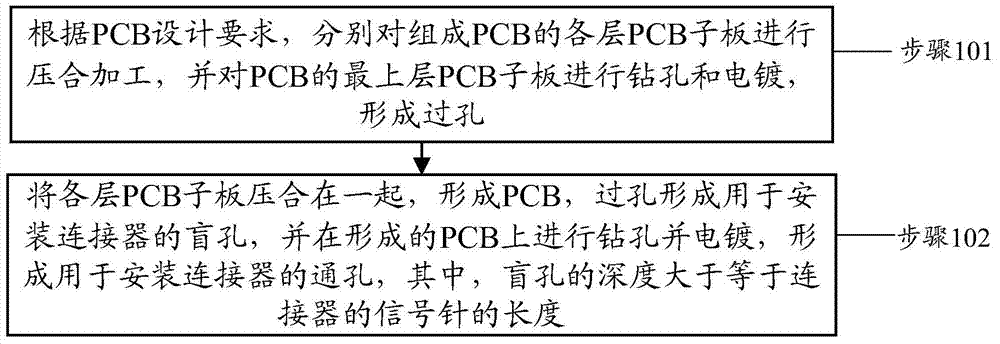

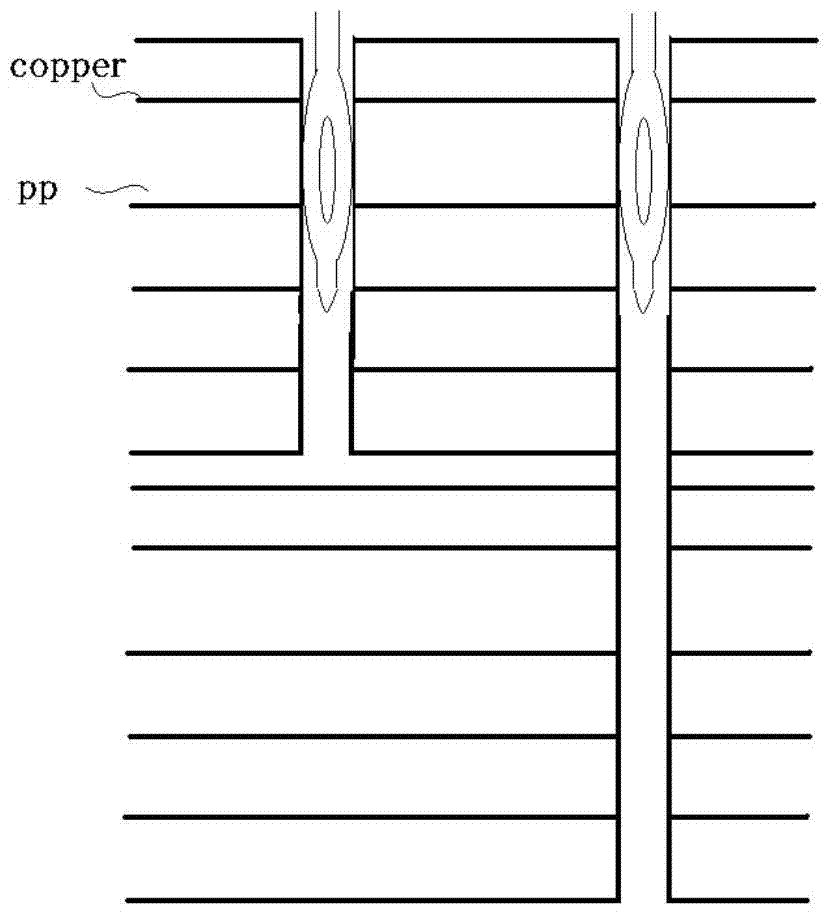

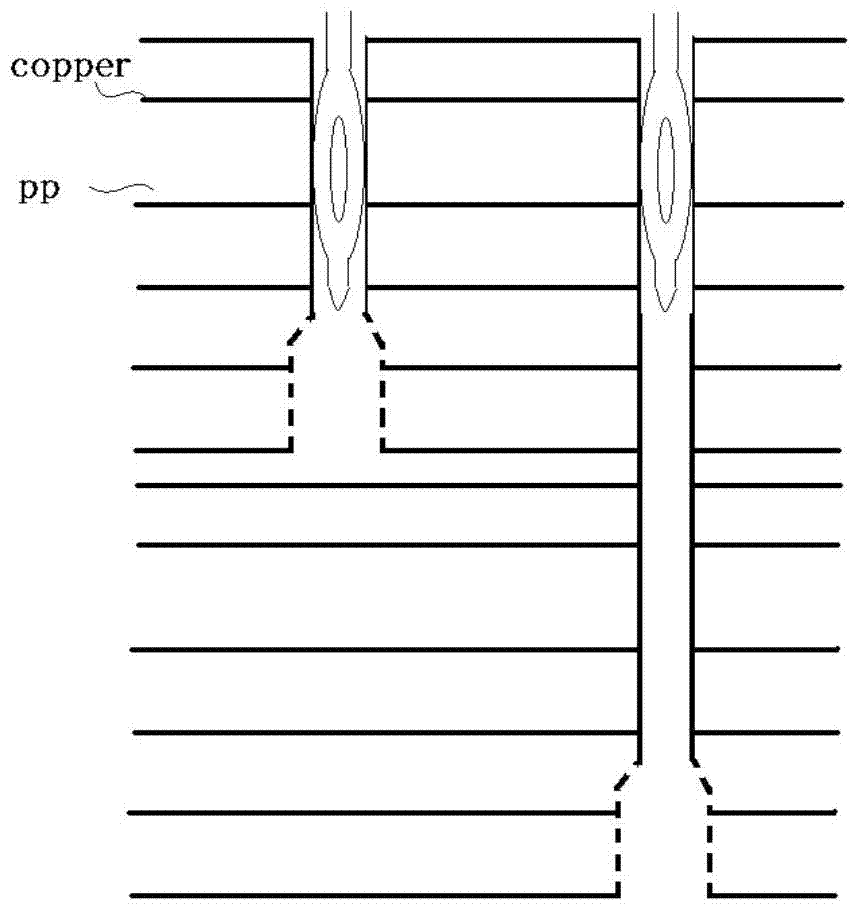

PCB processing method and PCB

ActiveCN104754886AIncrease spacingIncrease outlet spacePrinted circuit aspectsCircuit inspection/monitoring/aligningEngineeringElectroplating

Disclosed are a PCB processing method and a PCB. The method comprises: conducting lamination processing on various layers of PCB sub-boards respectively forming a PCB according to PCB design requirements, and conducting hole drilling and electroplating on the PCB sub-boards of the uppermost layer of the PCB to form a via hole; and laminating the various layers of PCB sub-boards together to form the PCB, the via hole forming a blind hole used for installing a connector, and conducting hole drilling and electroplating on the formed PCB to form a through hole used for installing the connector, wherein the depth of the blind hole is greater than or equal to the length of a signal pin of the connector. By means of the technical solution of the present invention, the spacing between wafers among the lower layers of the PCBs can be doubled, so that the line outlet space between the wafers can be doubled.

Owner:ZTE CORP

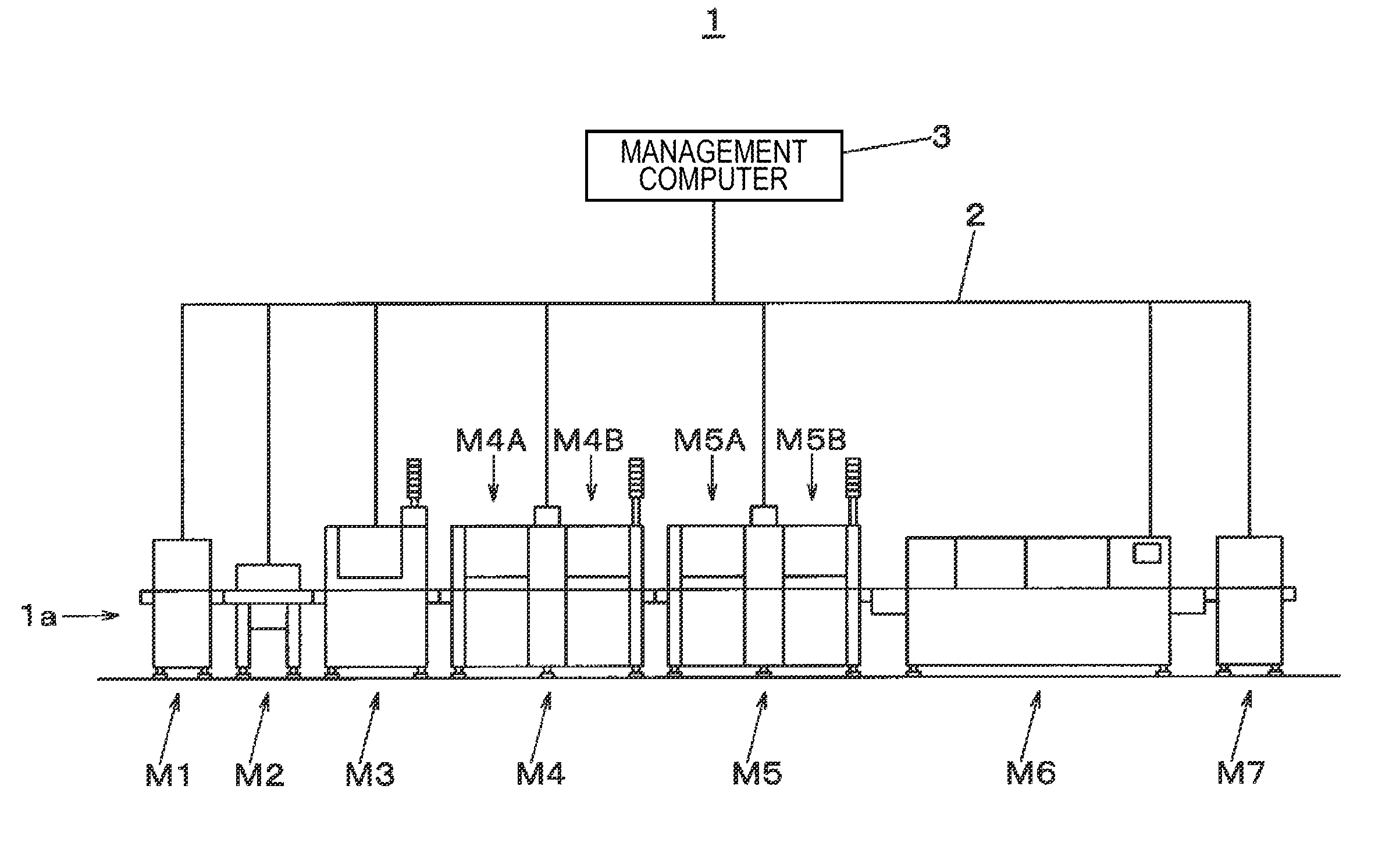

Component mounting method and component mounting system

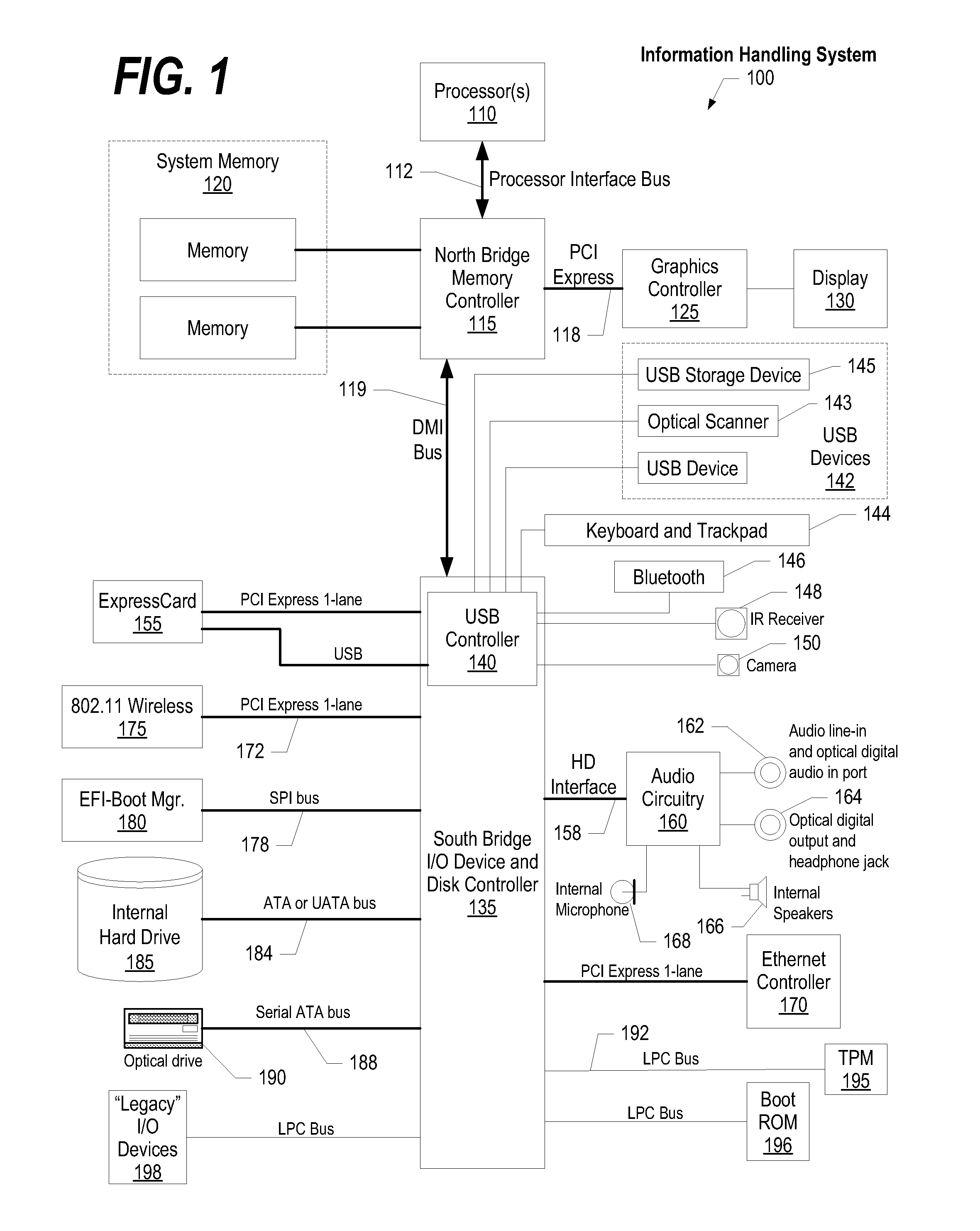

InactiveUS20160021803A1Increase production capacityPrinted circuit assemblingAutomatic control devicesEngineeringData link

A component mounting method is provided in a component mounting apparatus that mounts a component onto a board using a plurality of pieces of production data linked to component data. The method includes executing, when the component data is changed, a simulation of a production cycle time based on the production data, and making an improvement plan for the production cycle time as a target based on a simulation result after change of the component data, and outputting the improvement plan.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

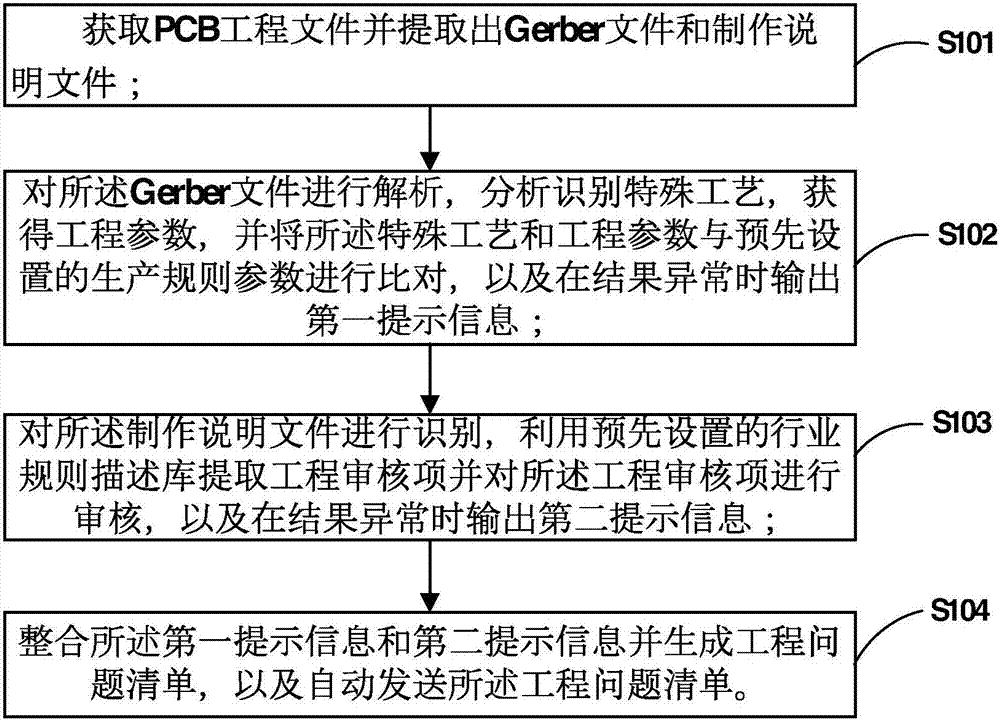

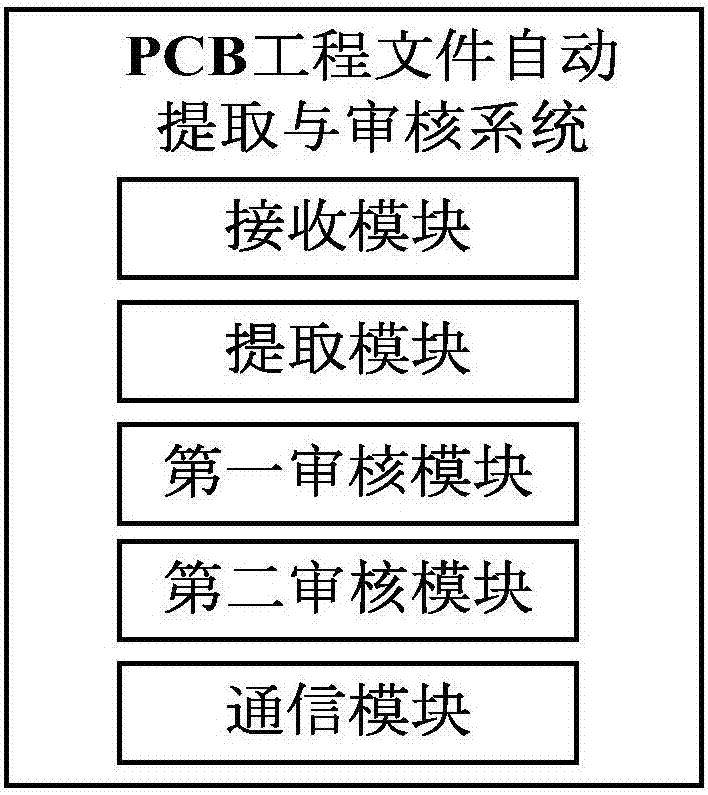

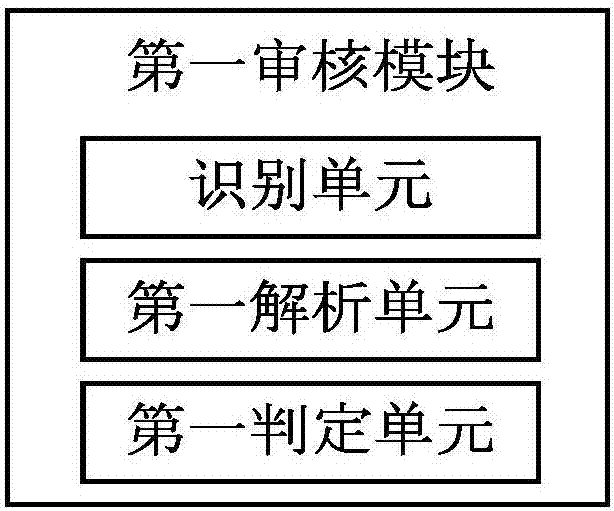

Method and system for automatically extracting and reviewing PCB engineering associated problems

InactiveCN106912162AAccelerate the pre-production processImprove search efficiencyCircuit inspection/monitoring/aligningComputer designed circuitsProblem listComputer science

The invention provides a method and a system for automatically extracting and reviewing PCB engineering associated problems. The method comprises: obtaining the PCB engineering files and extracting the Gerber file and the manufacturing specification file; decoding the Gerber file; analyzing and recognizing the special techniques; obtaining the engineering parameters; comparing the special techniques and the engineering parameters with the preset production rule parameters and outputting the first prompting message when the comparison result is an abnormal one; recognizing the manufacturing specification file; utilizing the preset industrial rule describing base to extract the engineering reviewing items and reviewing the engineering reviewing items; outputting the second prompting message when the result is an abnormal one; integrating the first prompting message and the second prompting message so as to generate an engineering problem list and automatically transmitting the engineering problem list. According to the method for automatically extracting and reviewing PCB engineering associated problems, it is possible to automatically extract and review the PCB engineering files so as to reduce the PCB check time and to increase the working efficiency.

Owner:SHENZHEN PARTNER INFORMATION TECH

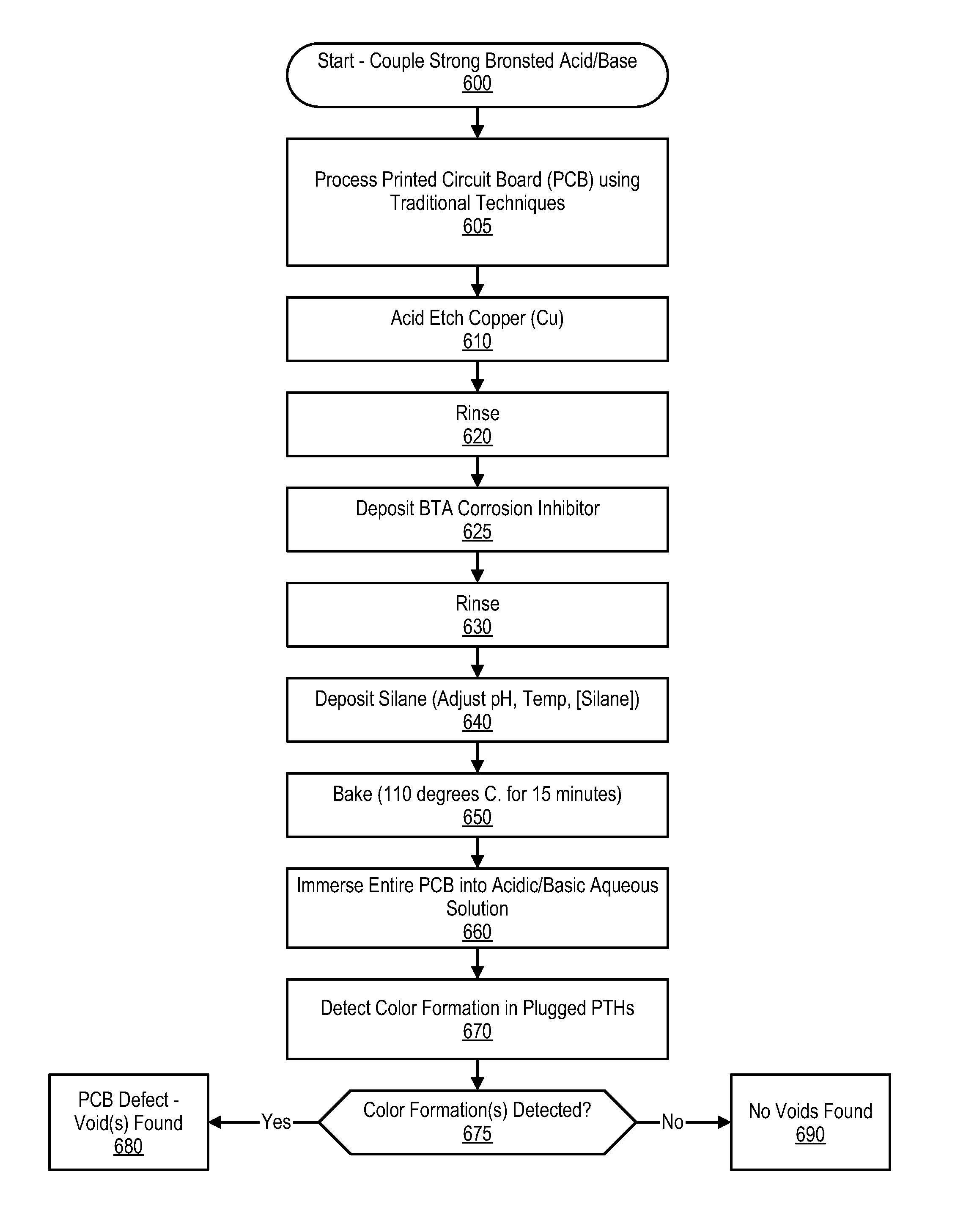

Plated Through Hole Void Detection in Printed Circuit Boards by Detecting A pH-Sensitive Component

ActiveUS20130016465A1Material analysis by observing effect on chemical indicatorElectronic circuit testingEngineeringPrinted circuit board

An approach is provided in which a pH-indicating compound is incorporated in a printed circuit board. The printed circuit board includes a number of layers with the pH-sensitive indicator being incorporated in one of the layers. Conductive pathways are formed from a conductive sheet laminated onto an outer surface of the printed circuit board. The printed circuit board is exposed to a pH-activating solution. Plated-through hole defects in the printed circuit board are identified by detecting a color formation at a surface location of the printed circuit board that corresponds to the plated-through hole defect. Another approach is also provided where a pH-activating compound is incorporated in one of the layers of the printed circuit board which is then exposed to a pH-indicating solution to produce the color formation that identifies the location of the plated-through hole defect.

Owner:IBM CORP

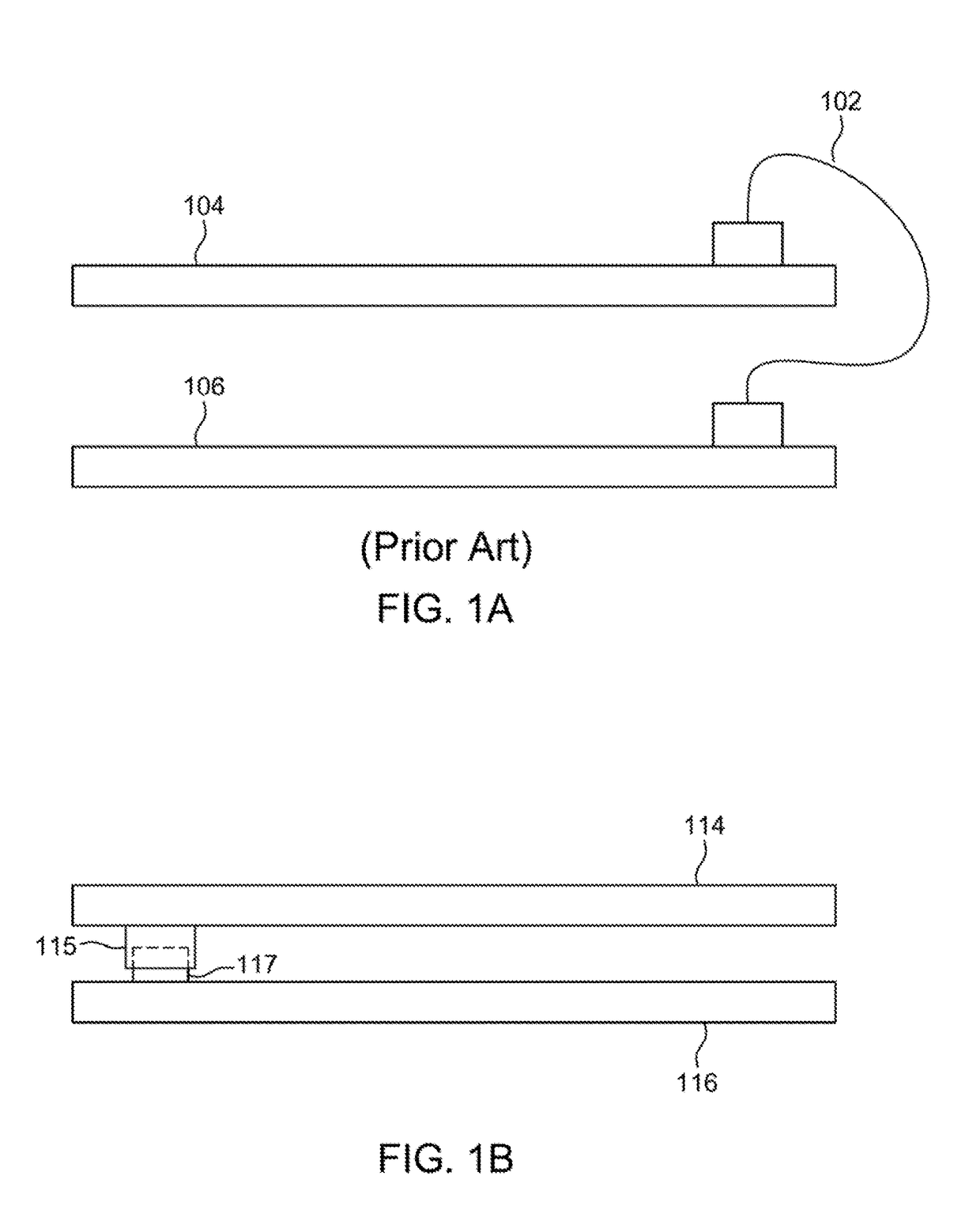

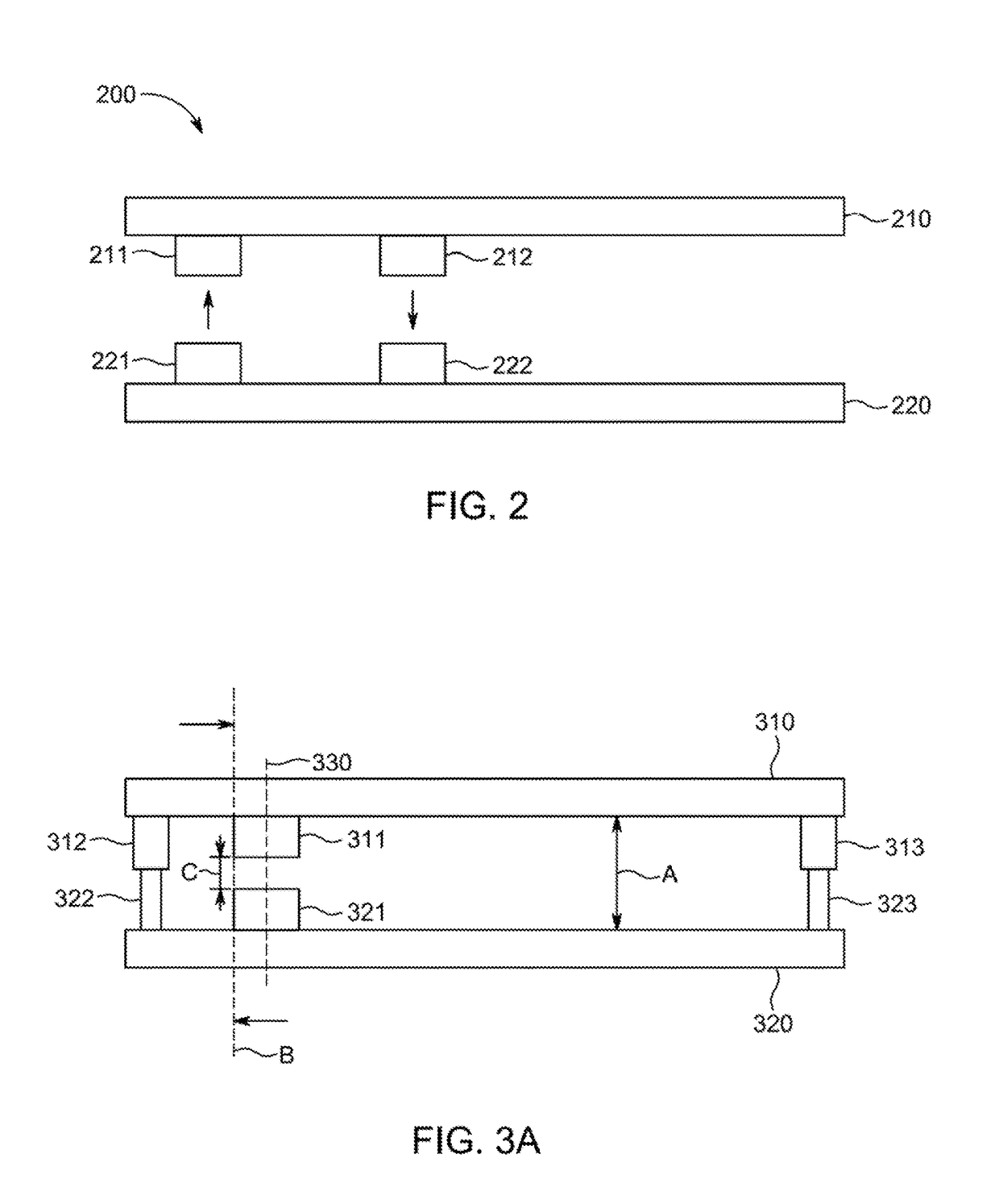

Board-to-board contactless connectors and methods for the assembly thereof

ActiveUS20170325328A1Simplify manufacturing line processHigh yieldPrinted circuit assemblingNear-field transmissionExtremely high frequencyBiomedical engineering

The present disclosure relates to extremely high frequency (“EHF”) systems and methods for the use thereof, and more particularly to board-to-board connections using contactless connectors.

Owner:KEYSSA +1

Manufacturing method for circuit board capable of detecting inner-layer pore ring

InactiveCN104918423AAvoid the risk of returning the whole batch for scrappingAvoid the risk of return scrappingCircuit inspection/monitoring/aligningMultilayer circuit manufactureShort-circuit testSmall hole

The present invention discloses a manufacturing method for a circuit board capable of detecting an inner-layer hole ring and relates to the technical field of production of circuit boards. The manufacturing method comprises: providing a secondary board for pressing and manufacturing the circuit board, wherein the secondary board comprises a PCB unit and a technical edge; manufacturing a circuit pattern in the PCB unit of each secondary board; meanwhile, etching at least two windows at a corresponding position on the technical edge of each secondary board, wherein the diameter of each window is 0.05mm smaller than the outer diameter of a smallest hole ring designed in the PCB unit; pressing each secondary board into the circuit board; drilling a borehole in the PCB unit and drilling an auxiliary hole at the central position of the window on the surface of the technical edge; manufacturing the borehole and the auxiliary hole in the PCB unit into metallized holes; and manufacturing a short-circuit test point of the auxiliary hole. The detection method provided by the present invention can ensure that the inner-layer hole ring of the manufactured circuit board has the diameter that is more than or equal to 0.025mm and meets IPC3 stage standard, is applicable to the circuit board that is particularly indicated that the diameter of the hole ring is required to be controlled to be more than or equal to 0.025mm, so as to effectively avoid complaints resulting from the defect of the inner-layer hole ring and the risk of the whole batch being returned and scrapped due to failure in a sample test.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

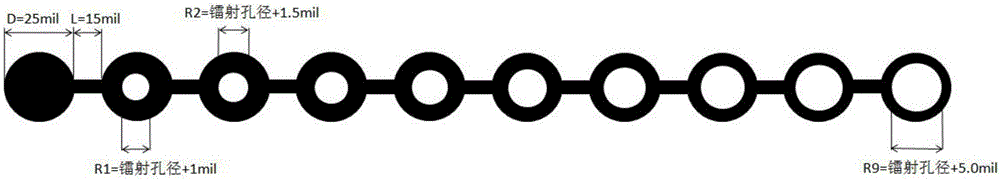

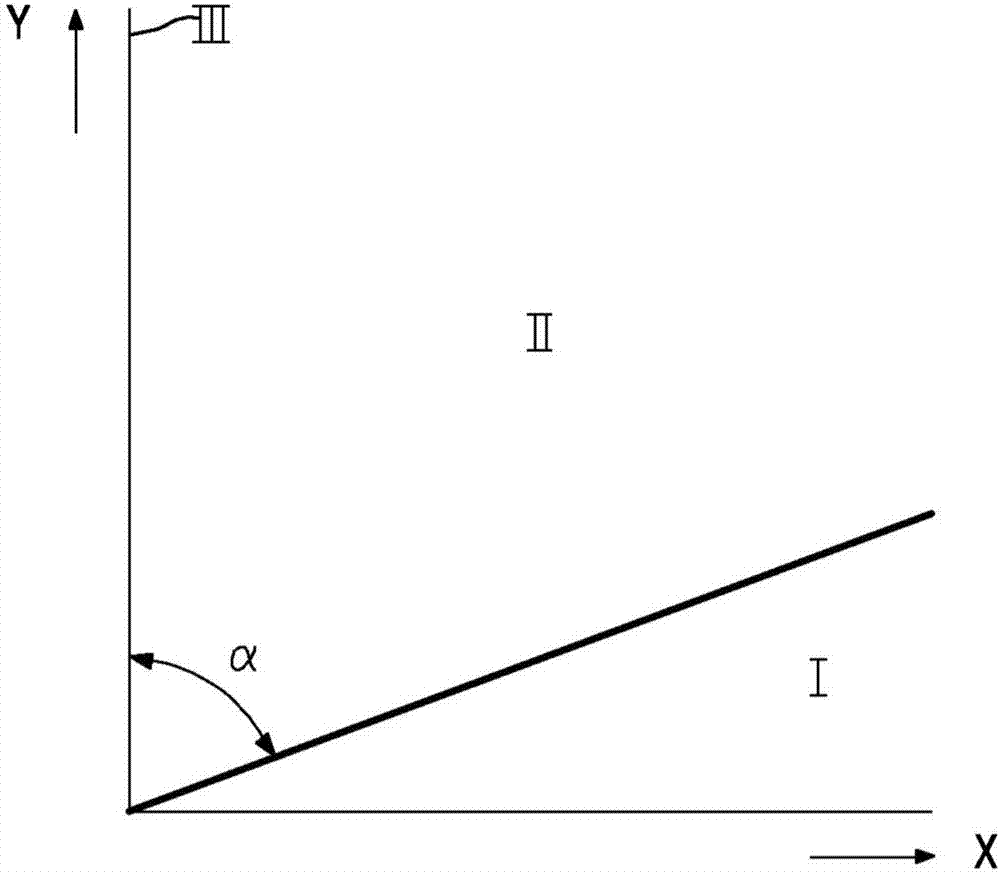

Monitoring method for aligning degree of laser drilling

InactiveCN106714457AEfficient and accurate drilling of abnormalitiesCircuit inspection/monitoring/aligningLaser drillingEnvironmental geology

The invention relates to a monitoring method for aligning degree of laser drilling. The monitoring method comprises the following steps of (1) according to the size of laser drilling Target Pad Ring, calculating the monitoring size of the aligning degree, wherein the calculation formula is monitoring of aligning degree=(Target Pad Ring-Target layer compensation) / 0.5; (2) testing method: after the monitoring value of the aligning degree of the laser drilling is calculated, arranging a testing needle under an electric measuring jig to the corresponding Pad; (3) judging method: if OPEN is tested out, the aligning degree is OK; if SHORT is tested out, the aligning degree is NG. The monitoring method has the advantage that the abnormal deviation of laser drilling is efficiently and accurately verified.

Owner:AOSHIKANG TECH CO LTD

Positioning and transferring of substrate

InactiveCN106973516AGood effectSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringSupport surface

The invention relates to positioning and transferring of a substrate. A substrate conveyer used for supporting a substrate in an ink jet system includes a conveyer main body, a conveyer supporting surface used for supporting the substrate and a substrate transferring unit used for conveying the substrate to the conveyer supporting surface and conveying the substrate back from the conveyor supporting surface. The substrate transferring unit includes at least one clamp used for clamping the substrate. Improvements of the substrate conveyer according to the invention are that a substrate transfer guiding device is fixed to the conveyer main body, so that in the process of movement of the substrate conveyer main body, the substrate transfer guiding device moves with the conveyer main body together. Favorably, conveying of the substrate can be executed with high precision and the substrate is then positioned on the conveyer supporting surface. Since the transfer guiding device is fixed to the conveyer main body, the substrate is more accurately placed on the conveyer supporting surface.

Owner:MUTRACX INT

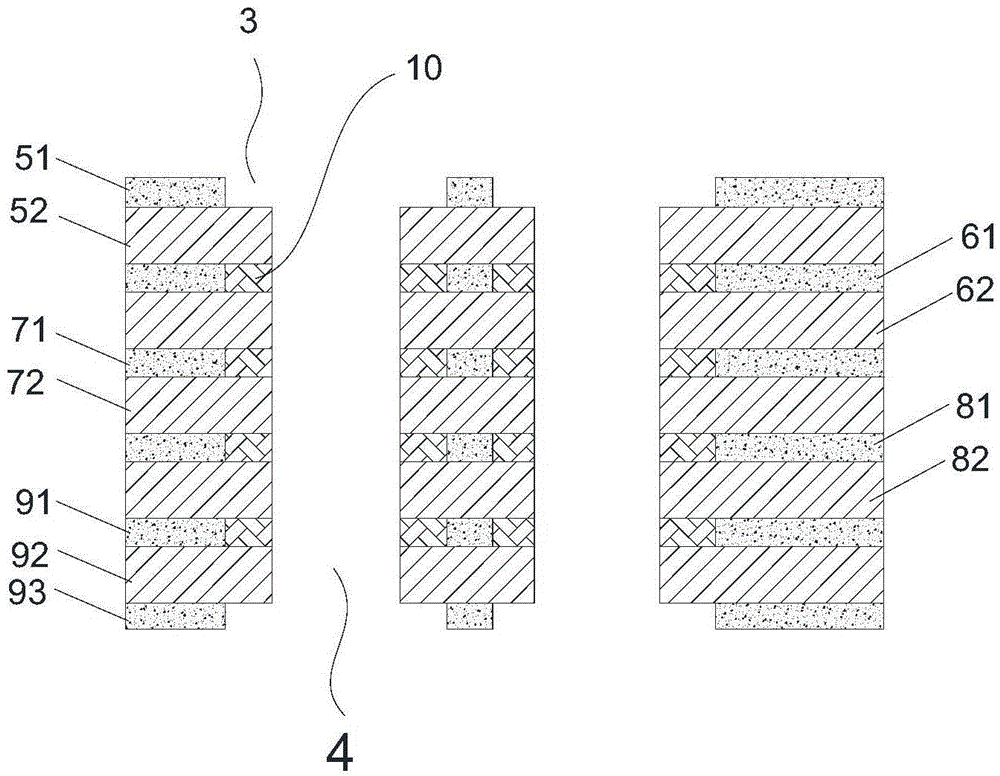

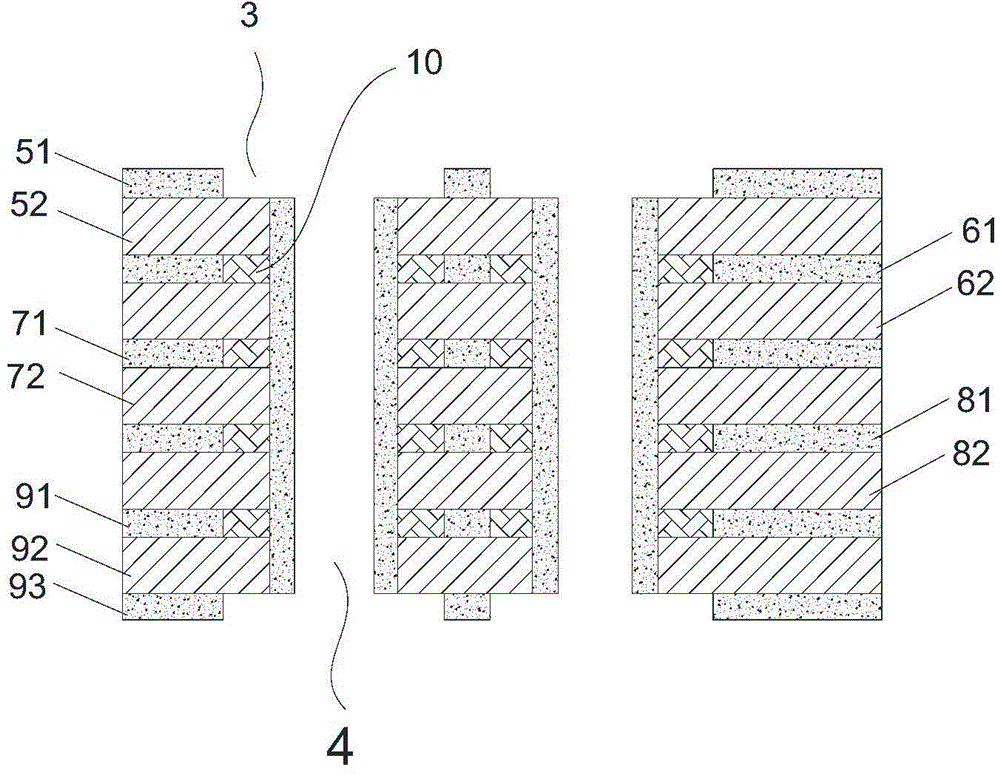

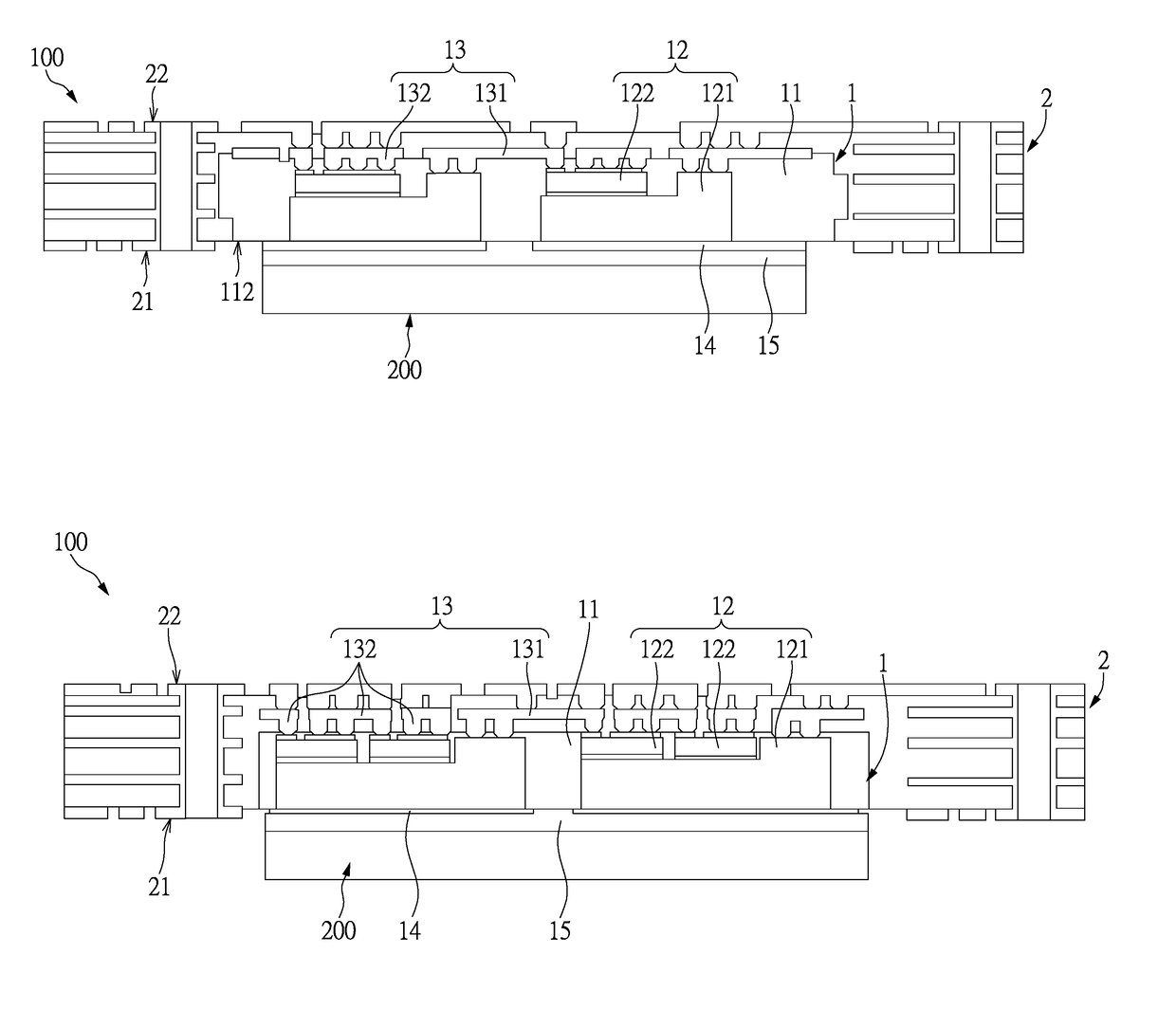

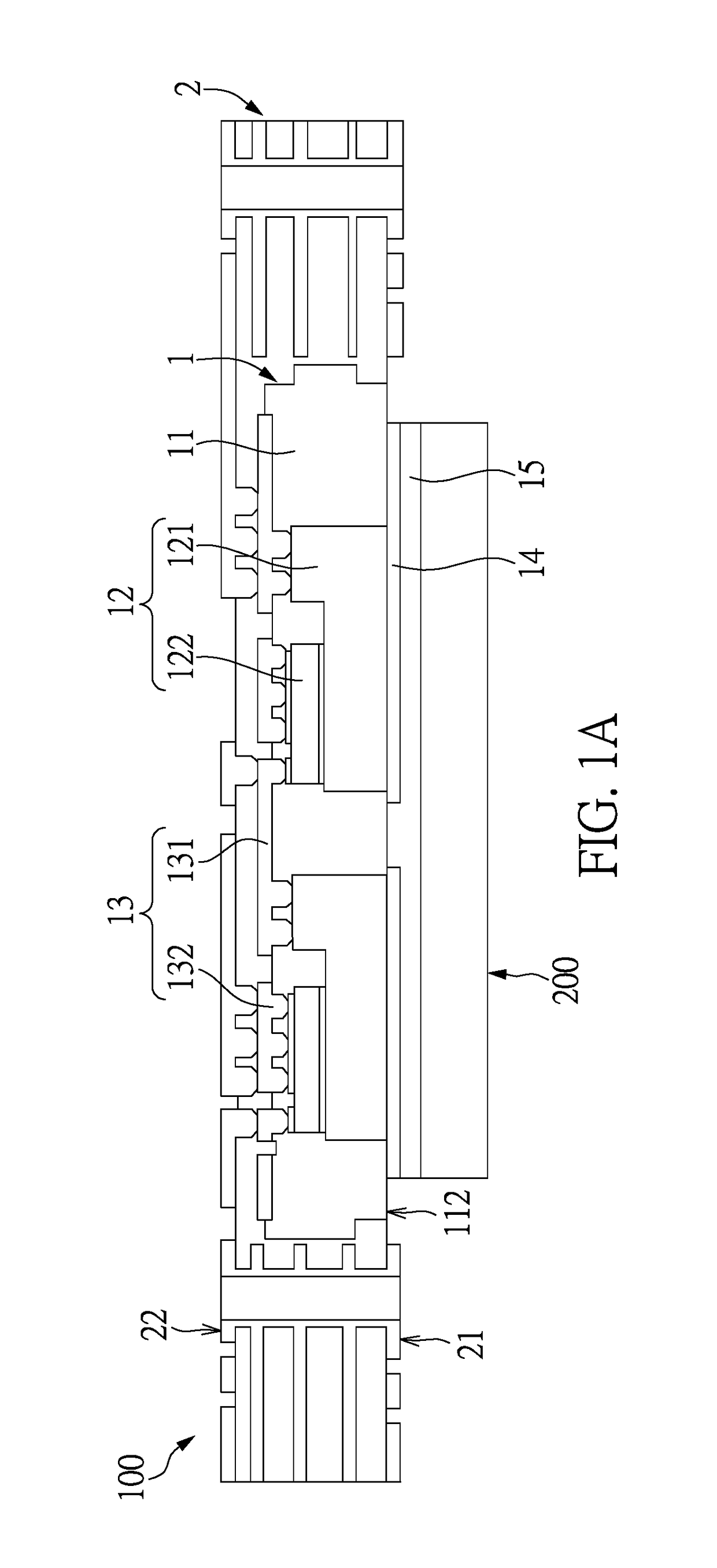

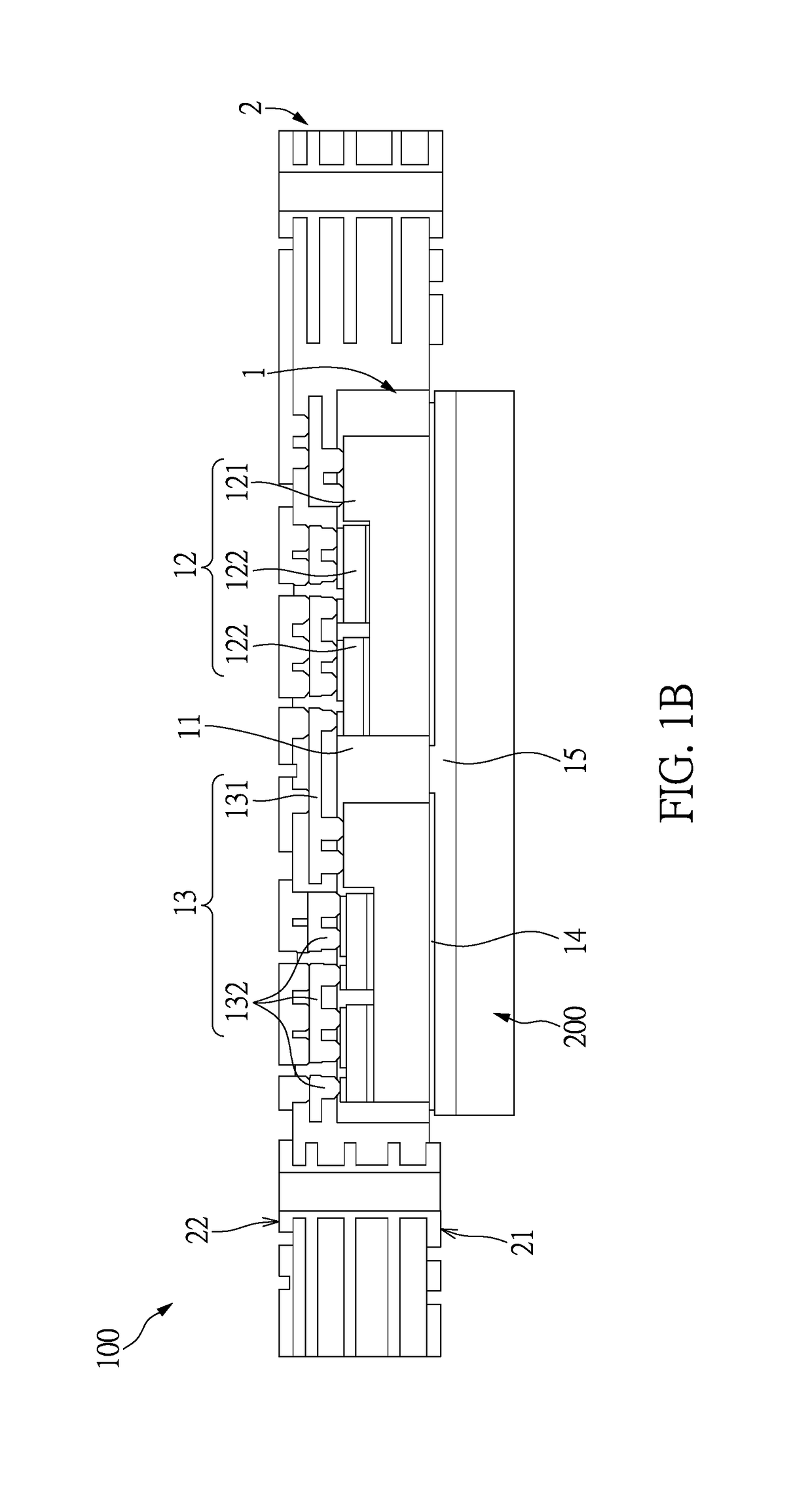

Circuit board structure with chips embedded therein and manufacturing method thereof

ActiveUS9860990B1Efficient solutionSolid-state devicesCircuit inspection/monitoring/aligningEngineeringBoard structure

A circuit board structure with chips embedded therein includes a multi-layer board and a power module embedded in the multi-layer board. The power module includes an insulating material, a power unit covered by the insulating material, and a circuit layer disposed on the insulating material. The power unit includes an electrically and thermally conductive carrier and a plurality of power chips. The electrically and thermally conductive carrier includes a transmitting portion and a carrying portion perpendicularly connected to the transmitting portion. Each power chip has a first electrode layer and an opposite second electrode layer. The first electrode layers are fixed on and electrically connected to the carrying portion in parallel, and the power chips are disposed at one side of the transmitting portion. The circuit layer is electrically connected to the electrically and thermally conductive carrier and the second electrode layers.

Owner:BOARDTEK ELECTRONICS CORP

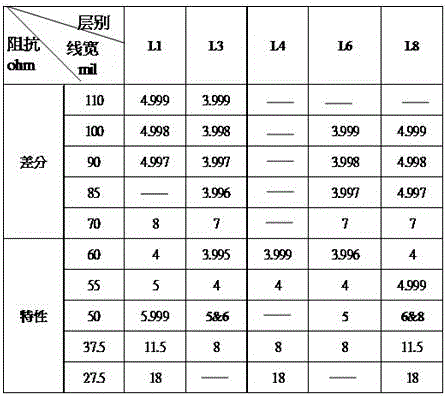

Impedance line width searching method

InactiveCN104955280AImprove current carrying capacityCircuit inspection/monitoring/aligningComputer designed circuitsLine widthPrinted circuit board

The invention provides an impedance line width searching method, and relates to the technical field of board card wiring. By utilizing a CAM (computer aided manufacturing) mode, various line widths of different spaces of the same line width requirement are formed by a genesis 2000 analysis function according to to-be-controlled impedance line width of each layer of a board card wiring part, and then needed data is obtained according to a line width and reality comparison result. By utilizing the method, a line width pole can be searched fast and effectively when the board card wiring is checked, and therefore the current carrying capability of a PCB (printed circuit board) is improved.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

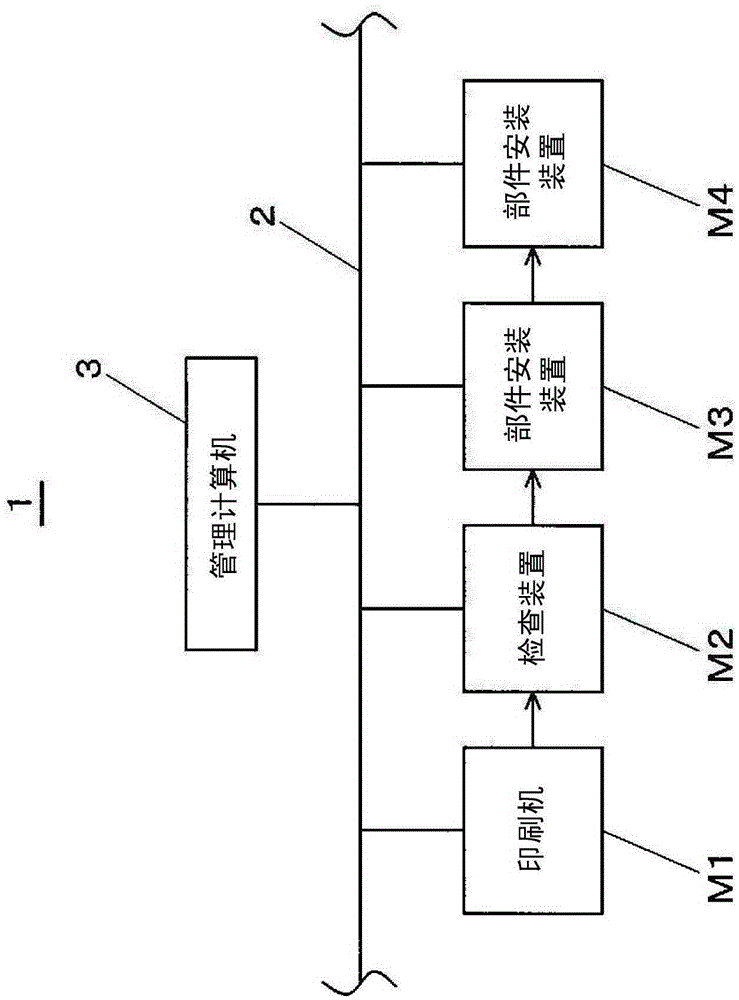

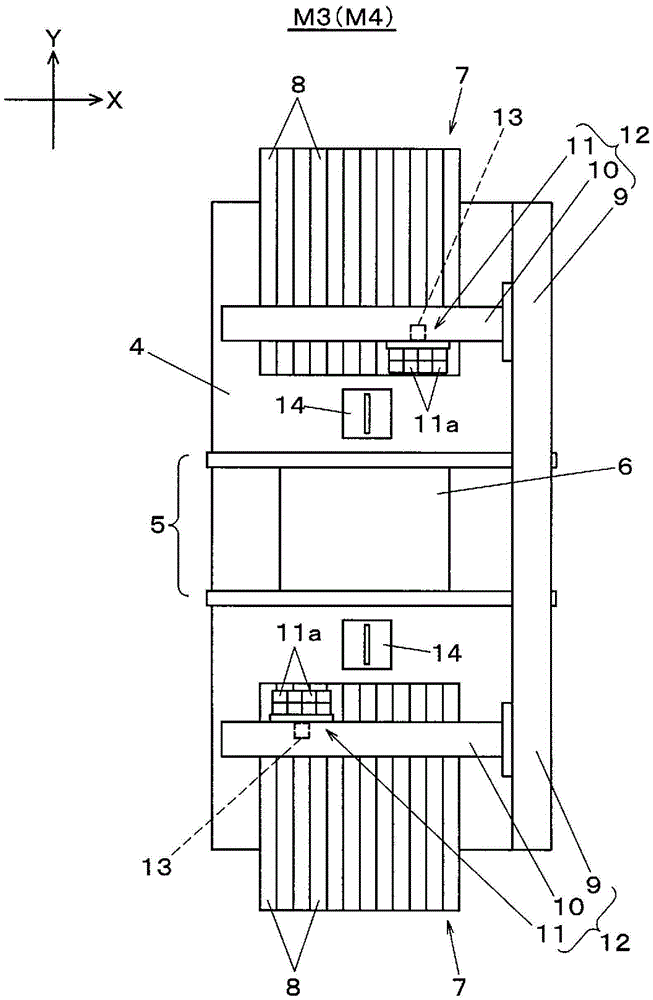

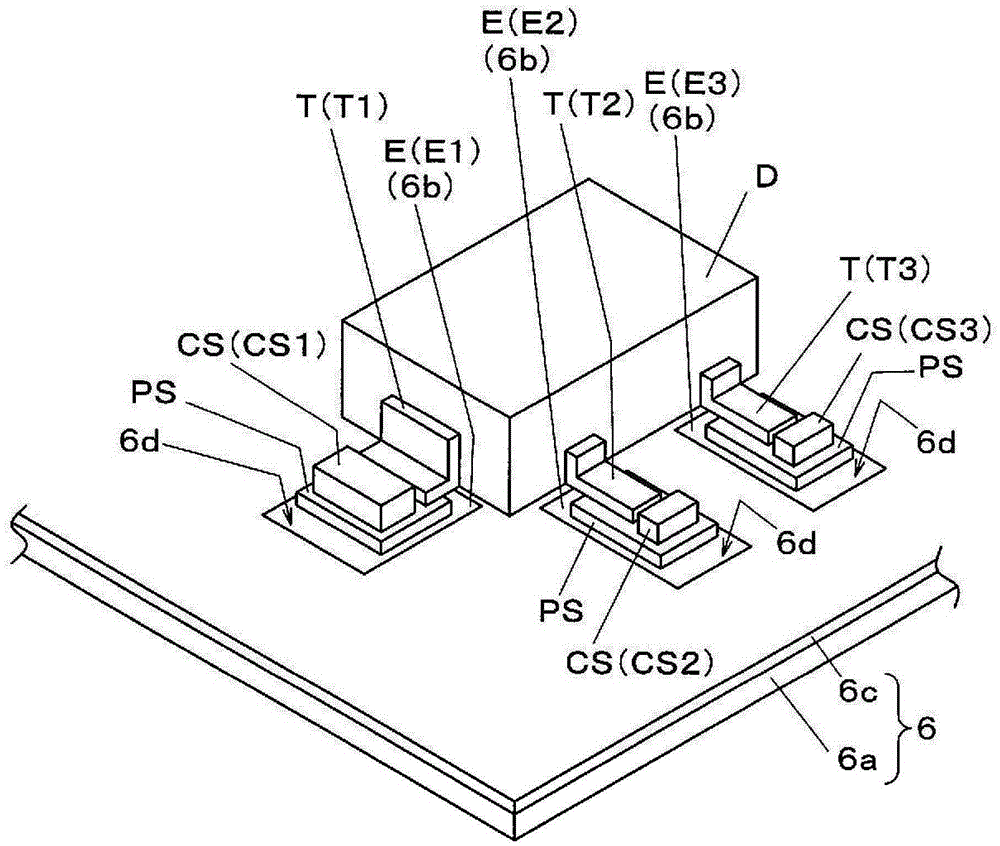

Component mounting line, component mounting method and component mounting apparatus

ActiveCN106028783ACircuit inspection/monitoring/aligningElectrical componentsEngineeringElectronic component

A component mounting line, a component mounting method, and a componetn mounting apparauts are provided for supporting a sheet soldering flux in proper size onto a substrate. The component mounting line includes an inspecting apparatus and a component mounting apparatus. The inspecting apparatus measures a solder volume of a printed solder on each electrode of a board. The component mounting apparatus includes a mounting unit that mounts an electronic component on the board, at least one component supply unit that supplies a chip solder, and a control unit that controls the mounting unit to mount the chip solder supplied from the component supply unit based on production data in which a size of the chip solder is instructed corresponding to the solder volume measured for each of component terminals corresponding to each electrode of the board.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Display module and manufacturing method thereof

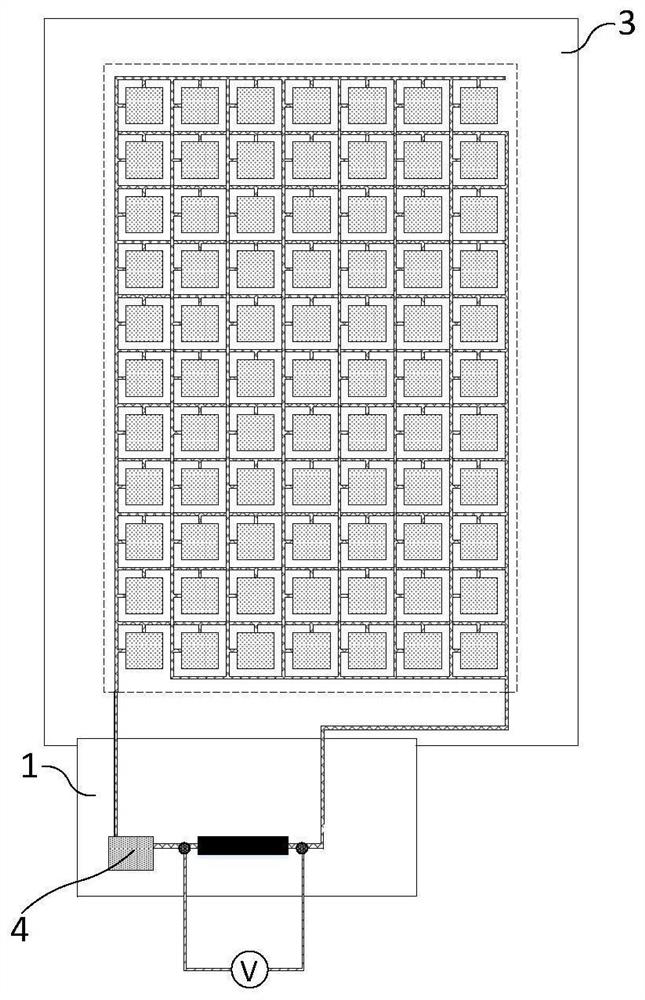

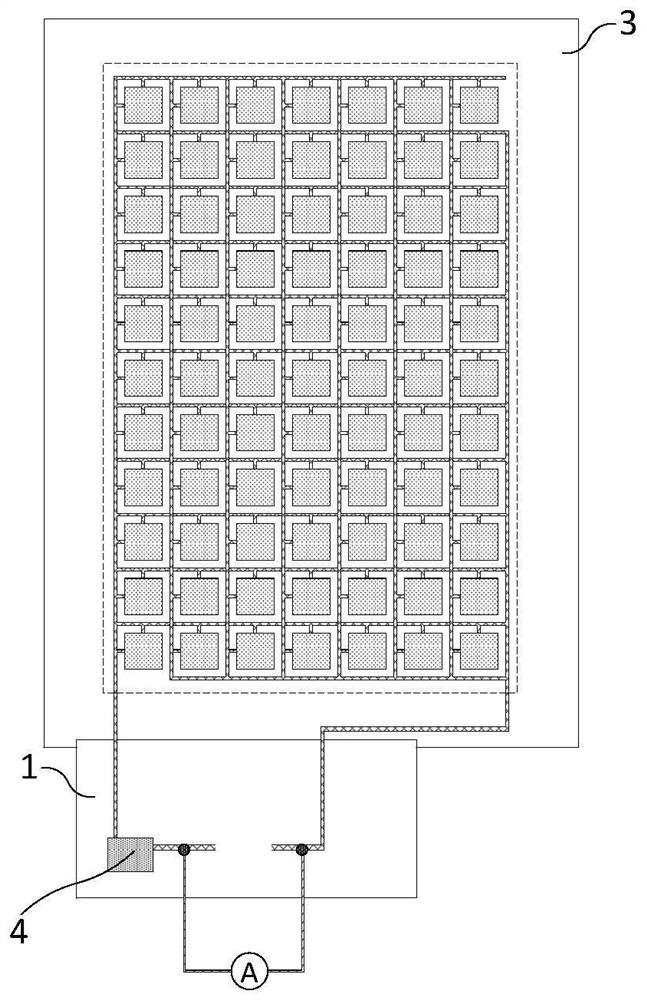

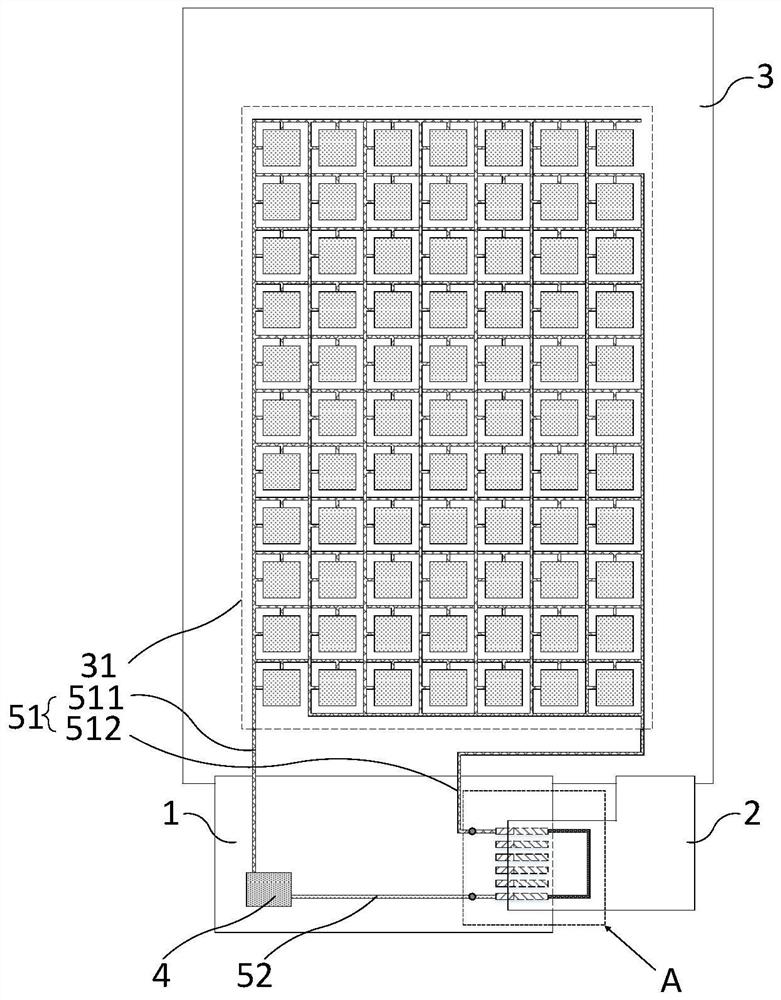

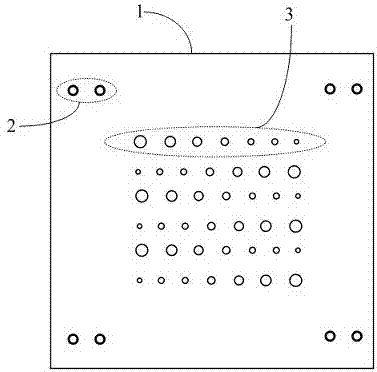

ActiveCN113079636AImplement parametric testingAvoid damagePrinted circuit aspectsInspection/indentification of circuitsFlexible circuitsHemt circuits

The invention discloses a display module and a manufacturing method thereof. The display module comprises a main flexible circuit board, wherein the main flexible circuit board comprises a first binding terminal, a second binding terminal, a first test point and a second test point; the first test point is electrically connected with the first binding terminal, and the second test point is electrically connected with the second binding terminal; the auxiliary flexible circuit board comprises a third binding terminal and a fourth binding terminal, and the third binding terminal is electrically connected with the fourth binding terminal; and the first binding terminal and the third binding terminal are correspondingly arranged, and the second binding terminal and the fourth binding terminal are correspondingly arranged. According to the display module disclosed by the invention, the first test point and the second test point can be directly connected through the test circuit to realize parameter test of the flexible circuit board, and during test, a circuit on the flexible circuit board is not cut off, and damage to the flexible circuit board caused by cutting off the circuit can be avoided.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

Black hole quality testing board for PCB, and quick examination method

InactiveCN107360666AAvoid wastingCircuit inspection/monitoring/aligningInspection/indentification of circuitsFilm resistanceElectrical resistance and conductance

Four corners and the central part of a copper-coated double-side plate are provided with the dedicated testing groups and through hole groups, so as to prepare a PCB black hole quality testing board. The method comprises the steps: carrying out the black hole direct electroplating of the PCB black hole quality testing board, detecting a resistance value R1 between two testing bonding pads in each testing group and a resistance value R3 between circuit bonding pads at two ends of he through holes, and comparing the resistance values R1 and R3 with a preset surface black hole film resistance standard value R2 and a preset in-hole black hole film resistance standard value R4, thereby achieving the purpose of quick examination. Before the black hole direct electroplating of a PCB product, the PCB black hole quality testing board can be used for testing and inspection, so as to pre-judge the machining quality of the black-hole direct electroplated surface black hole film and in-hole black hole, provide reference for the early finding of technological defects and the adjustment of the technological parameters, and prevent poor quality from causing waste during the black-hole direct electroplating of the PCB product.

Owner:VICTORY GIANT TECH HUIZHOU CO LTD

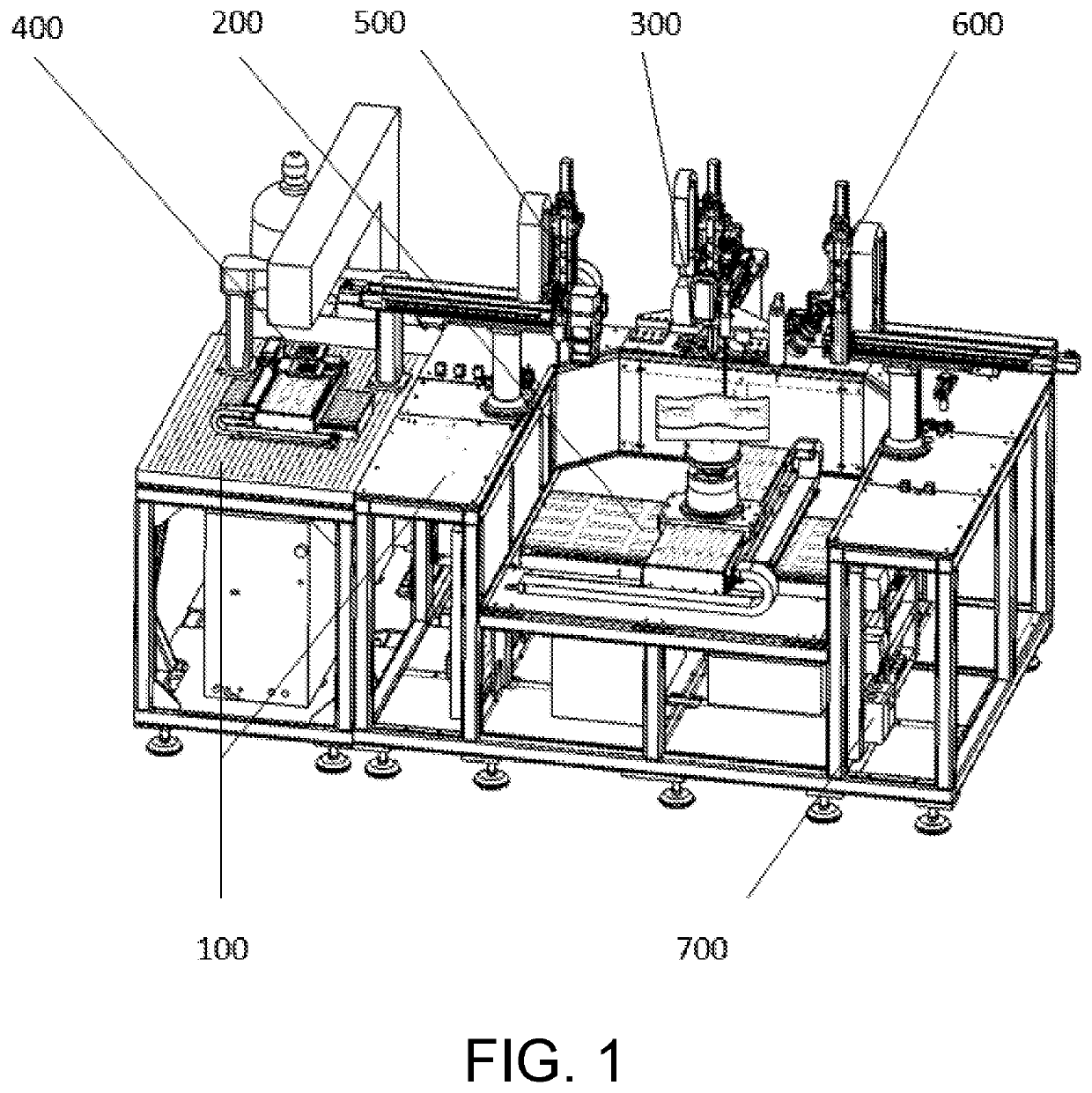

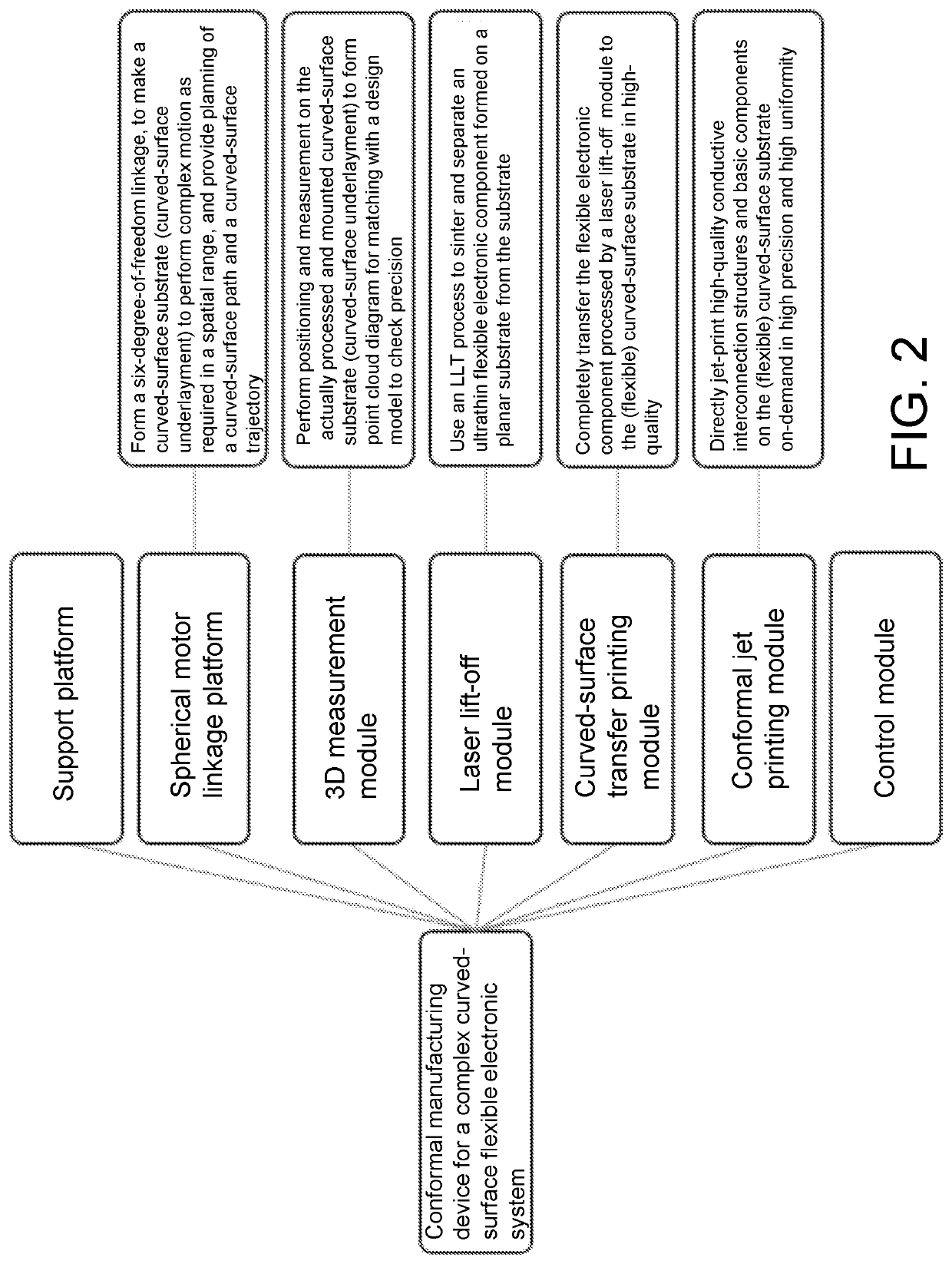

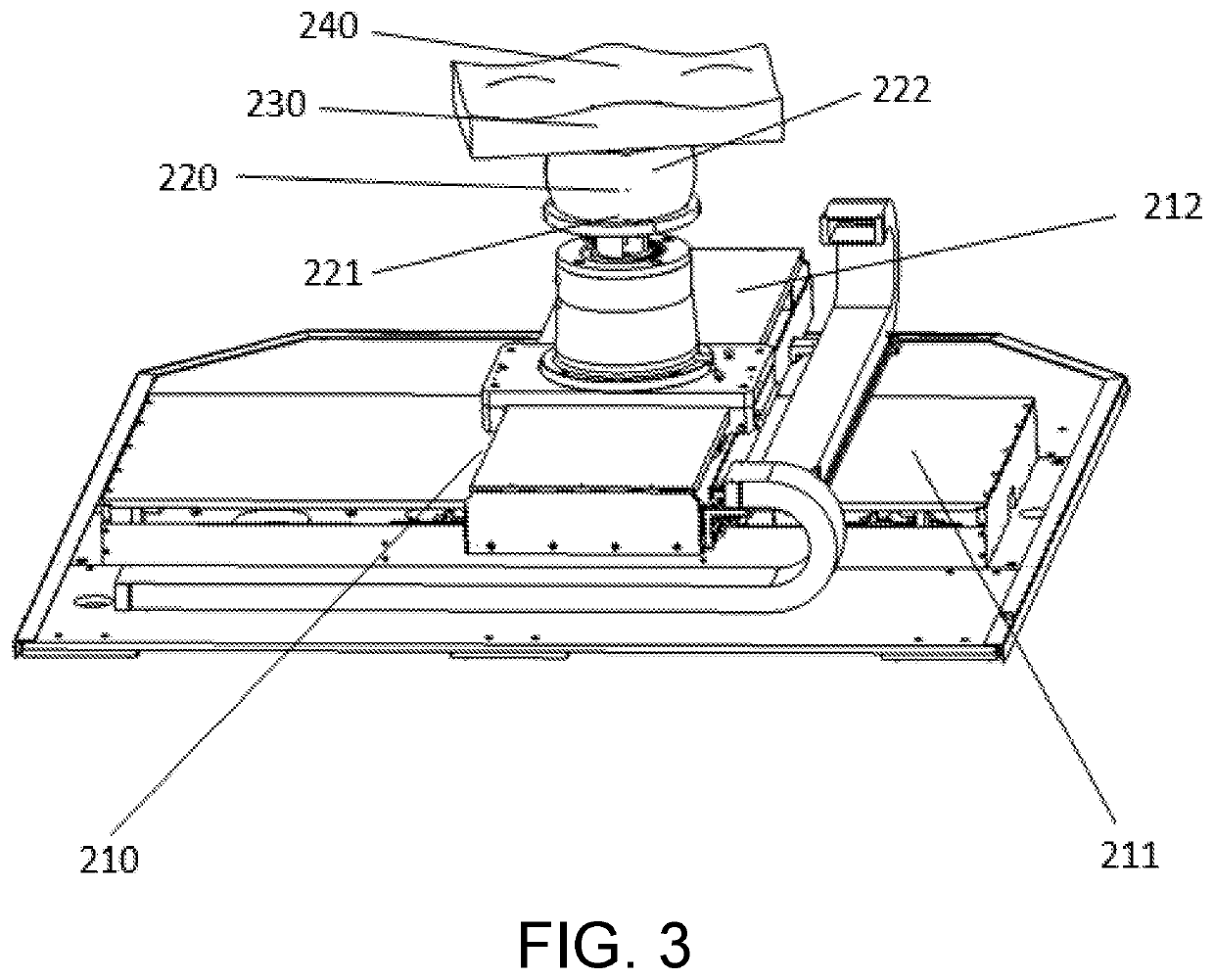

Conformal manufacturing device and method for complex curved-surface electronic system

ActiveUS20210076503A1Improving specific compositionImproving working modeManufacturing platforms/substrates3D rigid printed circuitsElectronic systemsManufacturing technology

The invention belongs to a related field of electronic manufacturing technology, and particularly relates to a conformal manufacturing device and a method for a complex curved-surface electronic system, the system includes a support platform and a six-degree-of-freedom spherical motor linkage platform, a 3D measurement module, a laser lift-off module, a curved-surface transfer printing module and a conformal jet printing module respectively mounted on the support platform and independently controllable, and specific structures and work modes of these key components are improved. The invention further discloses a corresponding manufacturing method. Through the invention, multiple process flows required in conformal manufacturing process of the complex curved-surface electronic system are effectively integrated into an integrated device, so as to realize conformal hybrid manufacturing of the rigid / flexible curved-surface electronic system with arbitrary area, and the invention has advantages of high precision, high efficiency and high automation, which greatly broadens the application scope of the curved-surface electronic manufacturing technology.

Owner:HUAZHONG UNIV OF SCI & TECH

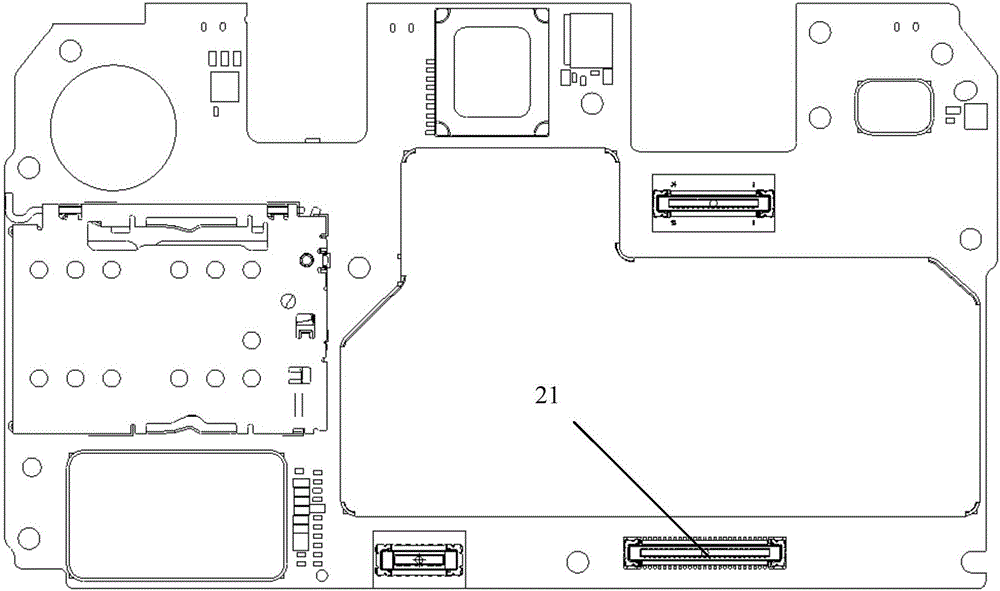

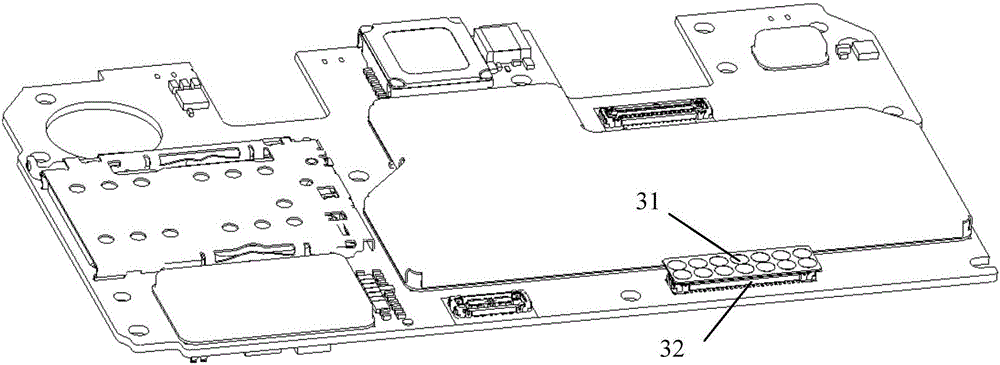

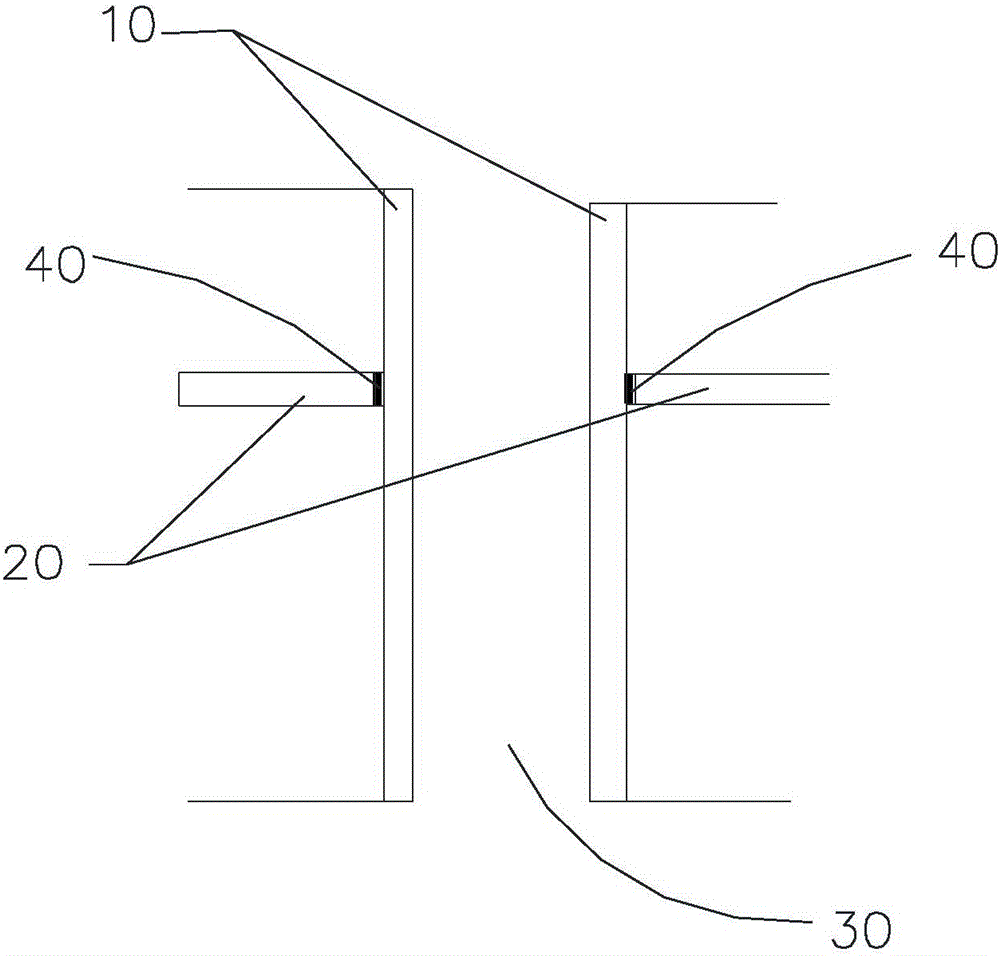

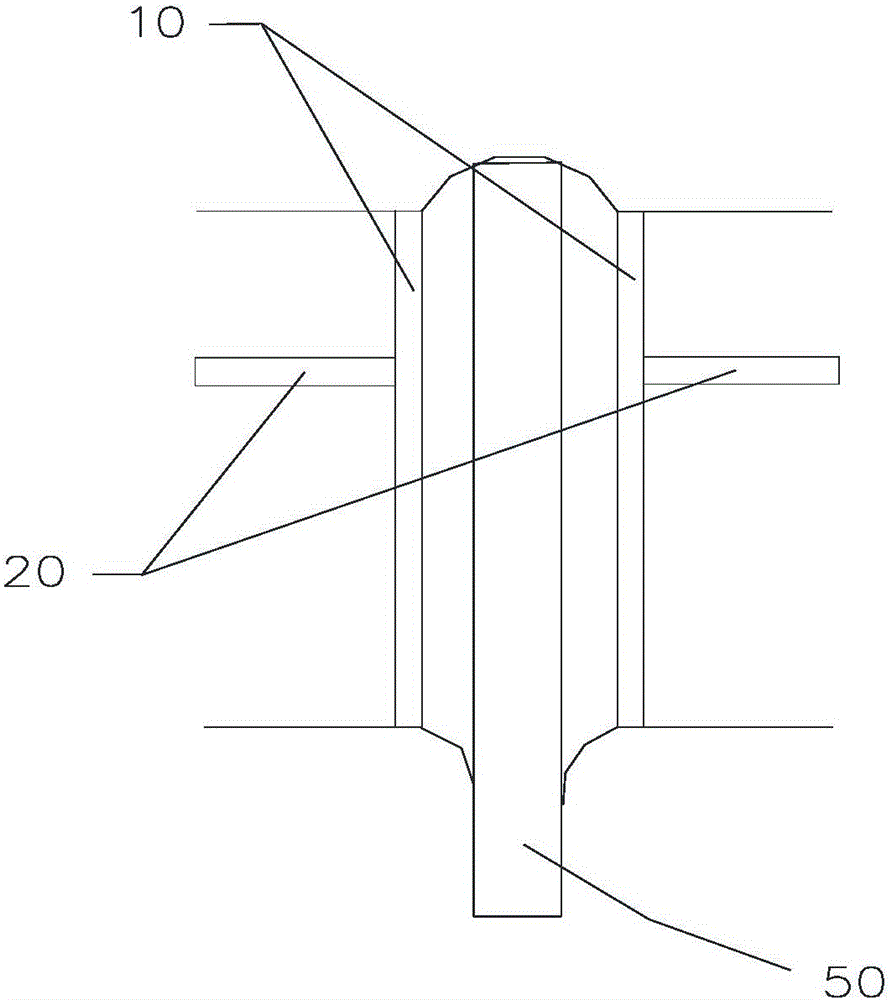

PCB and electronic device

PendingCN106802389AElectronic circuit testingCircuit inspection/monitoring/aligningElectrical and Electronics engineeringElectronic equipment

The invention provides a PCB and an electronic device, wherein the PCB includes a test point and a connector. The connector is a device on the PCB and that can be connected with an external cable. The connector is connected to a component to be tested on the PCB. The test point is connected with the component to be tested through the connector. The test point matches a first test tool. The first test tool tests the component via the test point. According to the PCB and the electronic device provided by the invention, the test point is set on the existing connector of the PCB so that it is not necessary to set the test point separately on the PCB, which reduces the PCB area occupied by the test point.

Owner:BLACKSHARK TECH NANCHANG CO LTD

ICD (Internal Connection Defect) detection method for PCB

ActiveCN105682378AImprove detection efficiencyAccurate and effective detectionCircuit inspection/monitoring/aligningPrinted element electric connection formationCopper wireMicroscopic observation

The invention discloses an ICD detection method for a PCB. The method comprises the flowing steps that a vertical slice of a PCB sample is made, and a metallographic microscope is used to observe whether there is a crack between an electro-coppering layer and an internal copper ring in the vertical slice; if there is, an outside force is used to separate the whole electro-coppering layer from the internal copper ring, an unthreaded hole is formed in the PCB; if there is not, it is shown that no residual glue exists between the electro-coppering layer and the internal copper ring, and no detection is needed any longer; and a scanning electron microscope is used to detect the internal copper ring to observe whether residual glue exists on the internal copper ring. Vertical slicing and copper wire pulling are carried out on the circuit board sample, the electro-coppering layer is directly separated from the internal copper ring, and the scanning electron microscope is used to directly observe whether residual glue exists on the electro-coppering layer; and thus, the detection method can be used to detect whether cracks and residual glue exist between the electro-coppering layer and the internal copper ring is a more direct, effectively and accurate manner, and the ICD detection efficiency of the PCB is greatly improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +2

Circuit board sign method based on bad mark two-dimensional codes

ActiveCN104411091AMethod with design optimizationNovel methodCircuit inspection/monitoring/aligningSurface mountingDimensional modeling

The invention discloses a circuit board sign method based on bad mark two-dimensional codes. The method comprises the following steps: (1), detecting and recording bad mark conditions of all sub circuit boards in a circuit board by use of a detection apparatus; (2), performing encoding through hexadecimal-system two-dimensional codes; (3), mounting the bad mark two-dimensional codes on the circuit board in a surface mounting mode or a laser mode; and (4), scanning the bad mark two-dimensional codes during application. Through such a mode, the circuit board sign method based on the bad mark two-dimensional codes has the advantages of optimized design, novel method, stable performance, lower cost, shorter identification time, higher production efficiency, convenient batch management and the like, thereby having wide market prospect on popularization of the circuit board sign method based on the bad mark two-dimensional codes.

Owner:苏州河图电子科技有限公司

Karst reservoir broken bead oil pool well point determining method and device

ActiveCN106028651AGuaranteed smoothnessImprove qualityCircuit inspection/monitoring/aligningPrinted element electric connection formationGeomorphologyKarst

The invention provides a karst reservoir broken bead oil pool well point determining method and device. The method comprises the steps that seismic data are used to identify an oil source fault from a karst reservoir to a source rock; the developmental interval of the karst reservoir and the distribution law of the developmental interval of the karst reservoir are determined; according to the distribution law and the seismic data, a number of fractured cavities which are communicated with the oil source fault are selected from the development interval of the karst reservoir; a seismic inversion method is used to carry out hydrocarbon detection on substances in the fractured cavities; the fractured cavities containing crude oil are used as broken bead oil pools; according to the distribution law and the seismic data, the oil pool size of the broken bead oil pools is determined; and according to the oil pool size of the broken bead oil pools, oil pool mining well points are determined. According to the invention, karst reservoir broken bead oil pool well points can be quickly and efficiently disposed.

Owner:广州广合科技股份有限公司

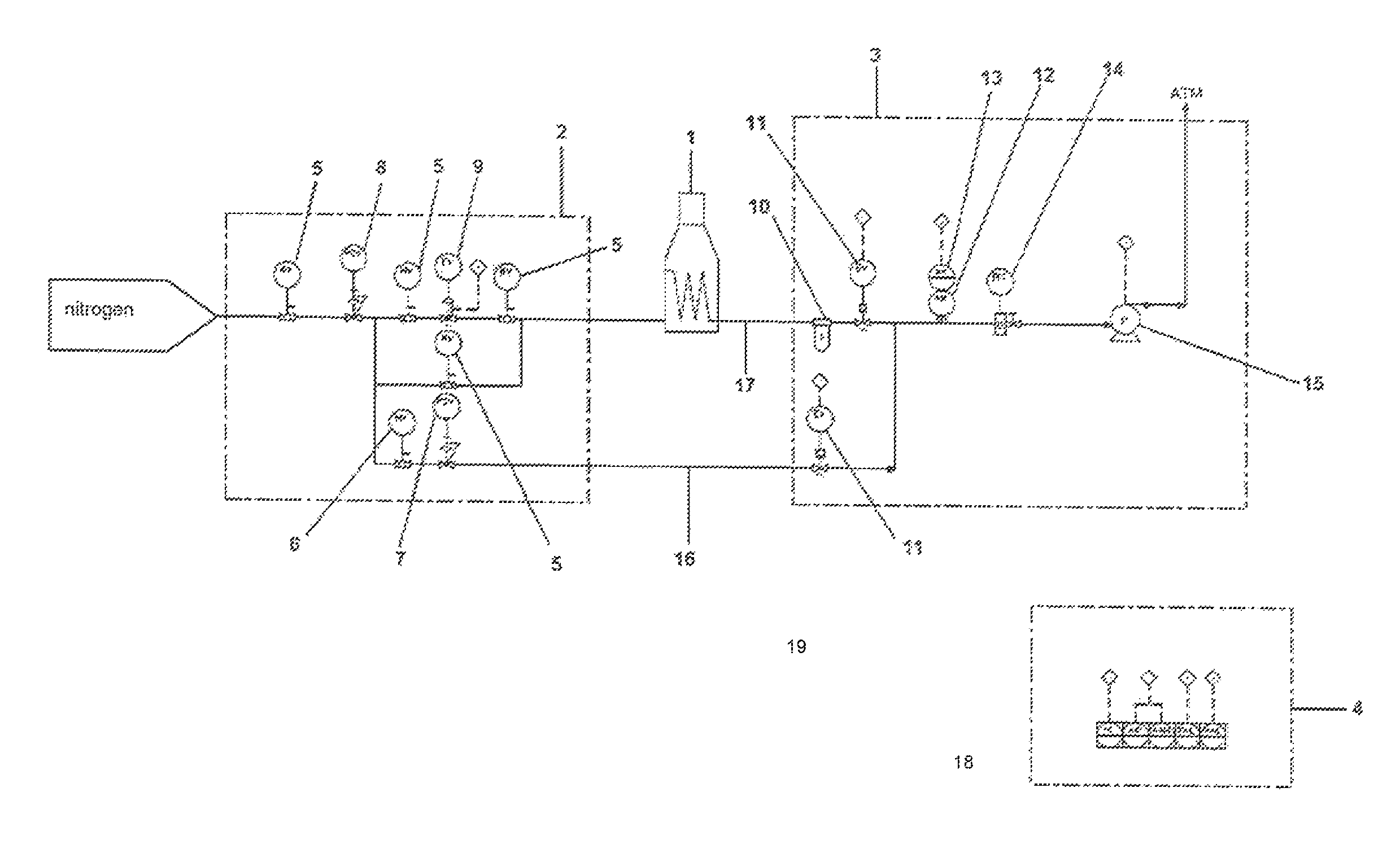

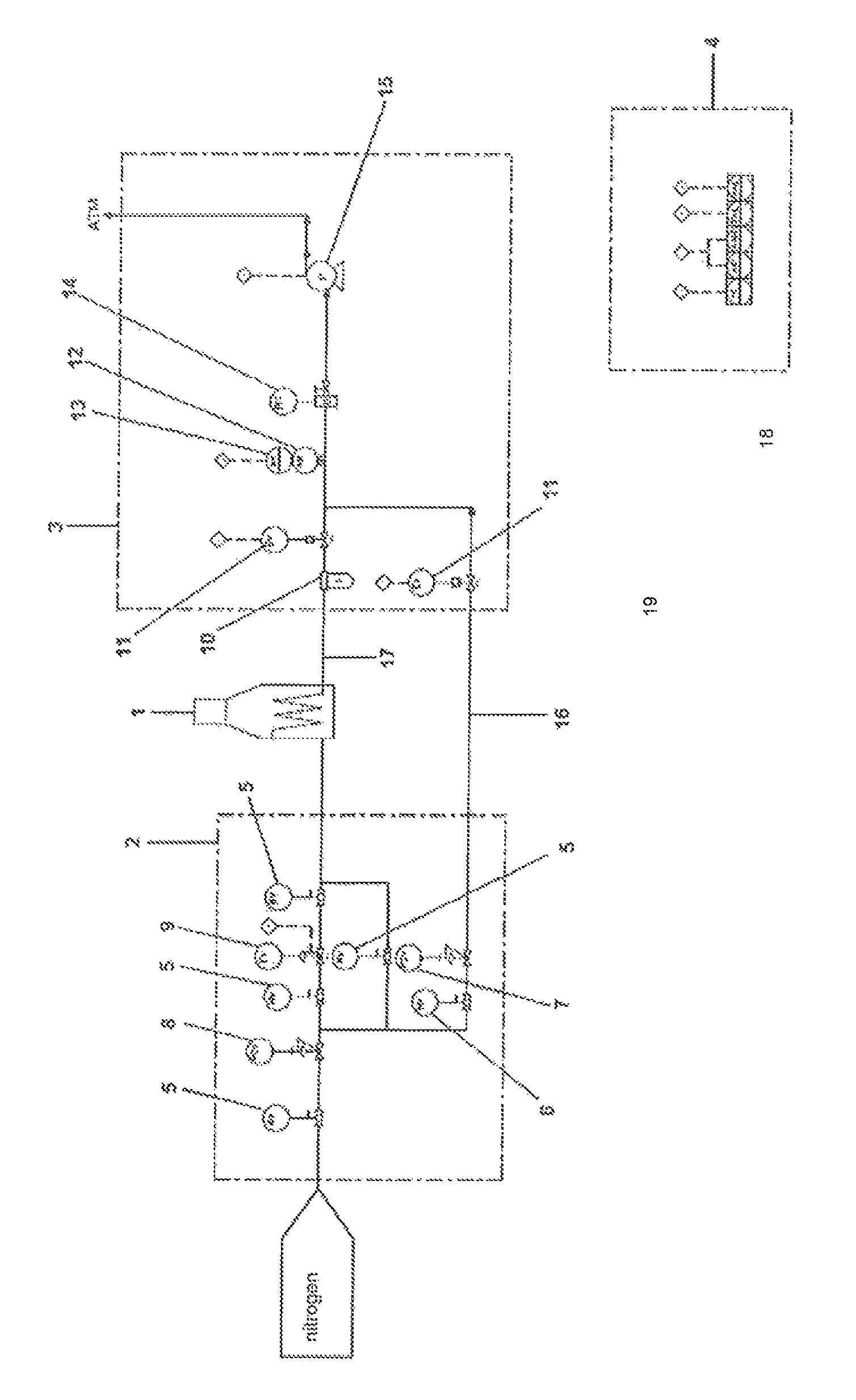

Portable equipment for monitoring and controlling the level of oxygen in reflow oven atmosphere

InactiveUS9539672B2Printed circuit assemblingWelding/cutting auxillary devicesMicrocontrollerProcess engineering

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

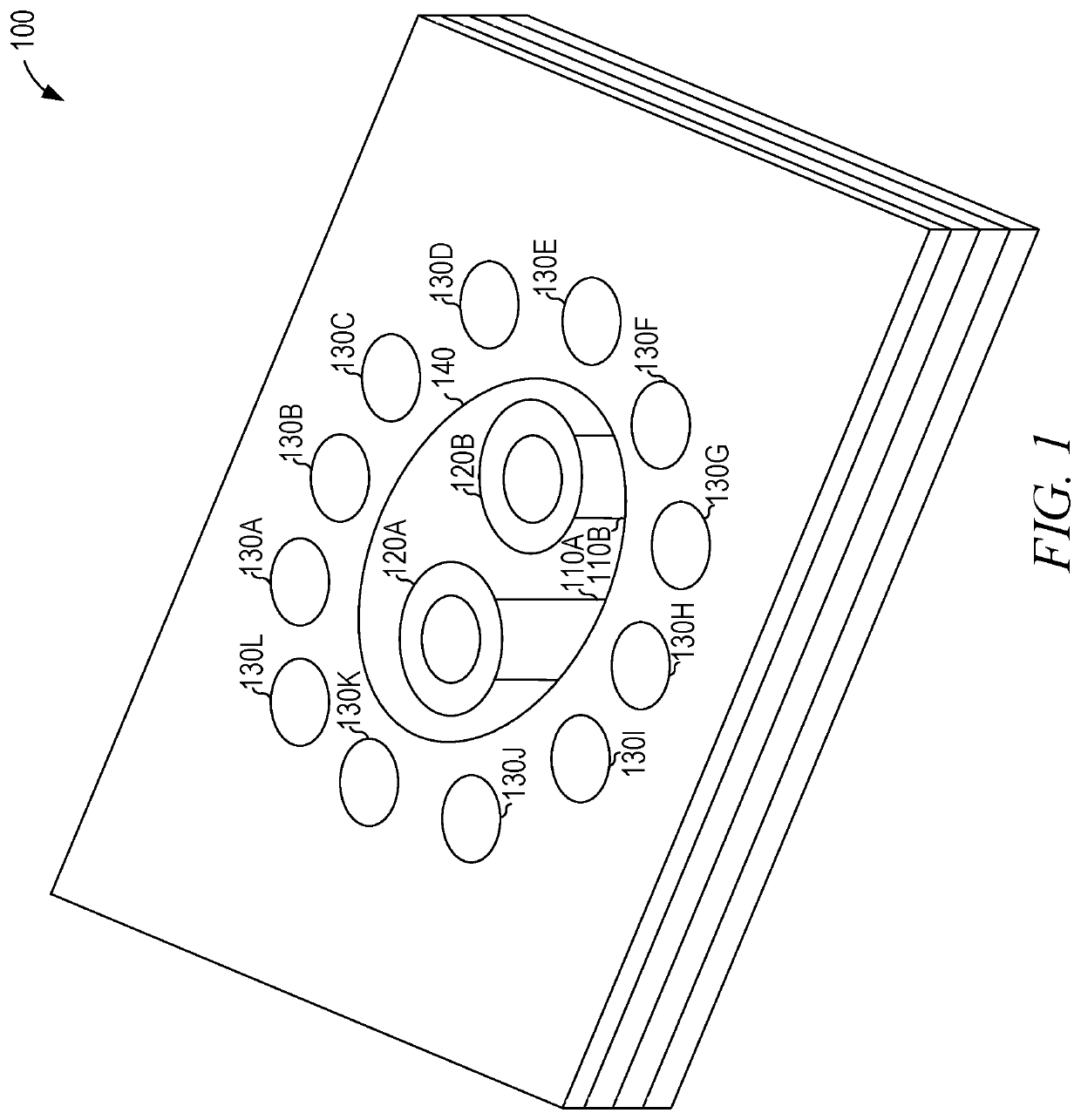

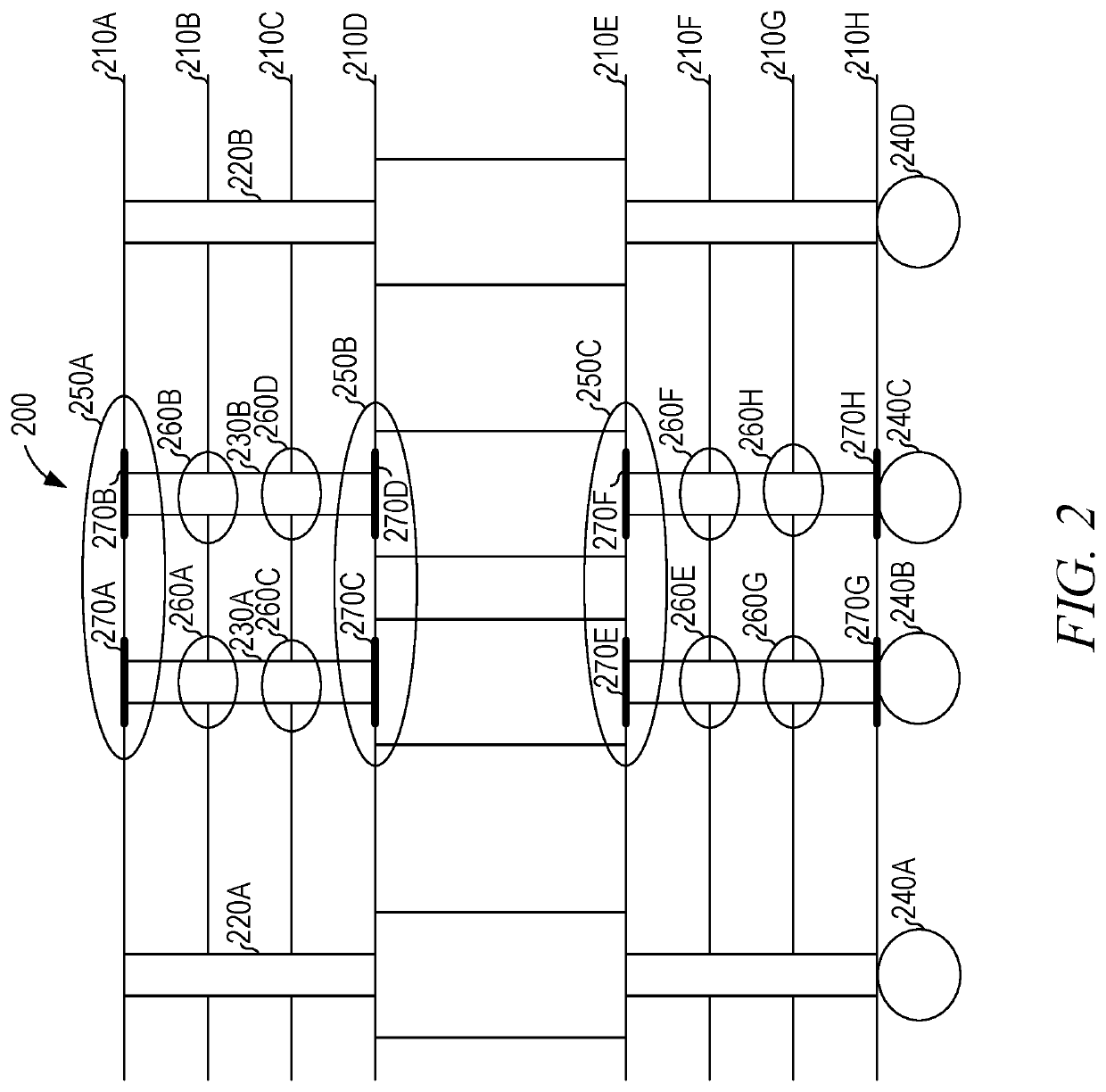

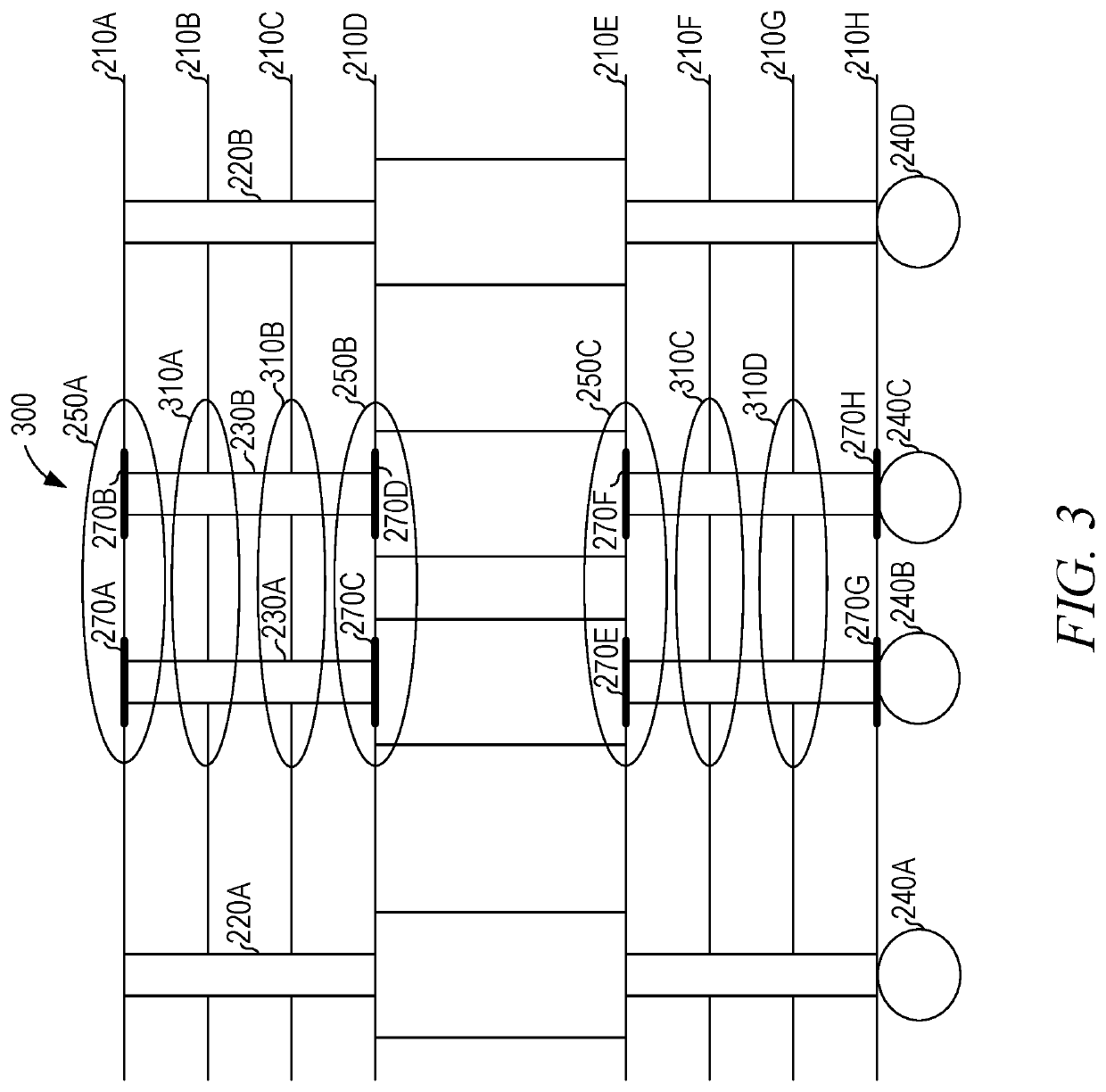

Capacitive compensation for vertical interconnect accesses

ActiveUS11324119B1Printed circuit aspectsHigh frequency circuit adaptationsCapacitanceImpedance distribution

Multiple designs for a multi-layer circuit may be simulated to determine impedance profiles of each design, allowing a circuit designer to select a design based on the impedance profiles. One feature that can be modified is the structure surrounding the barrels of a differential VIA on layers that are not connected to the differential VIA. Specifically, one antipad can be used that surrounds both barrels or two antipads can be used, with one antipad for each barrel. Additionally, the size of the antipad or antipads can be modified. These modifications affect the impedance of the differential VIA. Additionally, a conductive region may be placed that connects to the VIA barrel even though the circuit on the layer does not connect to the VIA. This unused pad, surrounded by a non-conductive region, also affects the impedance of the differential VIA.

Owner:ACHRONIX SEMICON CORP

Fine circuit printed board etching process

ActiveCN105007691AKeep aliveImprove etching effectCircuit inspection/monitoring/aligningConductive material chemical/electrolytical removalProduction lineSurface cleaning

The invention relates to a fine circuit printed board etching process, which comprises the steps of S1, opening a cylinder and preparing a solution; S2, carrying out startup checking; S3, starting up; S4, carrying out initial workpiece etching, wherein the initial workpiece etching is carried out on each model of printed board; wherein the specific operating steps of initial workpiece etching are as follows: S41, surface cleaning; S42, dry film attaching; S43, etching, that is, a printed board is placed in a stainless steel hanging basket with the upper part and the lower part being fixed, the stainless steel hanging basket is put in the etching bath prepared in the step 1, the temperature in the etching bath is controlled to be 45-53 DEG C, the nozzle pressure is 2.0-3.5kg / cm2, and the stainless steel hanging basket vibrates slightly for 3min-5min and is then taken out after a window is dissolved; S44, washing; S45, ink retreating; and S46, detection; and S5, carrying out mass production, that is, a plurality of printed boards with the same model are placed on a production line to carry out mass production according to the steps S41-S45 after the printed board is detected to be qualified in the step S46, and spot check is carried out in the mass production process. The advantages of the fine circuit printed board etching process lie in that occurrence of mass unqualified products can be avoided, and the etching effect is good.

Owner:SICHUAN HAIYING ELECTRONICS TECH

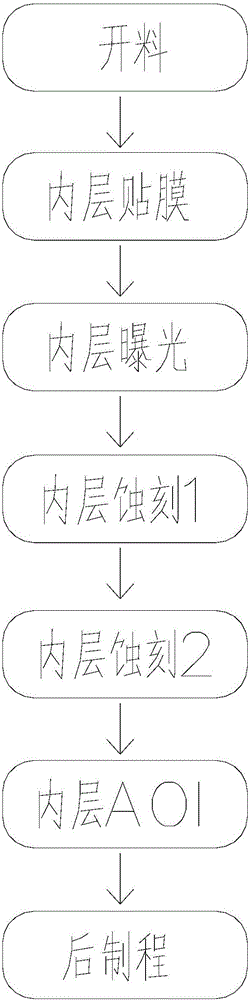

Thin film resistor inner layer etching method

ActiveCN106658966AReduce investmentOptimize process flowCircuit inspection/monitoring/aligningPrinted resistor incorporationTectorial membraneEtching

The present invention provides a thin film resistor inner layer etching method. The method includes the steps of rough shape cutting, inner layer film applying, inner layer exposure, inner layer etching 1, inner layer etching 2, inner layer AOI (Automatic Optic Inspection) and post treatment. According to the step of inner layer etching, it only needs to tear off a protection film of a surface provided with a resistor. According to the step of inner layer etching 2, a protection film of a surface with no resistor is torn off. According to the method provided by the technical schemes of the invention, the two steps of etching are both performed on the same etching line, and the different regions are protected by using the protection films during etching, and therefore, the first step of etching is only performed on the surface with the resistor, and the second step of etching is performed on two surfaces of a circuit board. With the etching method adopted, a process flow is optimized, equipment input and raw material input are decreased, production costs are effectively reduced, and production efficiency is improved.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

PCBA (Printed Circuit Board Assembly) manufacturability inspection method

ActiveCN105101650AReduce manufacturing costImprove review efficiencyCircuit inspection/monitoring/aligningComputer designed circuitsDatasheetPosition Number

The invention discloses a PCBA (Printed Circuit Board Assembly) manufacturability inspection method which utilizes a computer to generate a PCB package datasheet containing position number information in a PCB; checking if the position numbers are sole or not; outputting repetitive position numbers when the position numbers are not sole; utilizing a computer to generate a BOM datasheet containing position number information in an EBOM; checking if the position numbers in the PCB package datasheet are consistent with the position numbers in the BOM datasheet one to one; outputting inconsistent position numbers when inconsistency is found. According to the invention, full check can be conducted to the manufacturability of a PCBA. The method is capable of finding out errors such as repetition of position numbers in a PCB, inconsistency between position numbers in a PCB and an EBOM, non-use of standard package, mistaken use of standard package and the material height beyond technical requirements. With the method, the blind areas and difficult points in manual browsing inspection are overcome, high inspection efficiency can be achieved and the producing cost of a PCBA is reduced.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

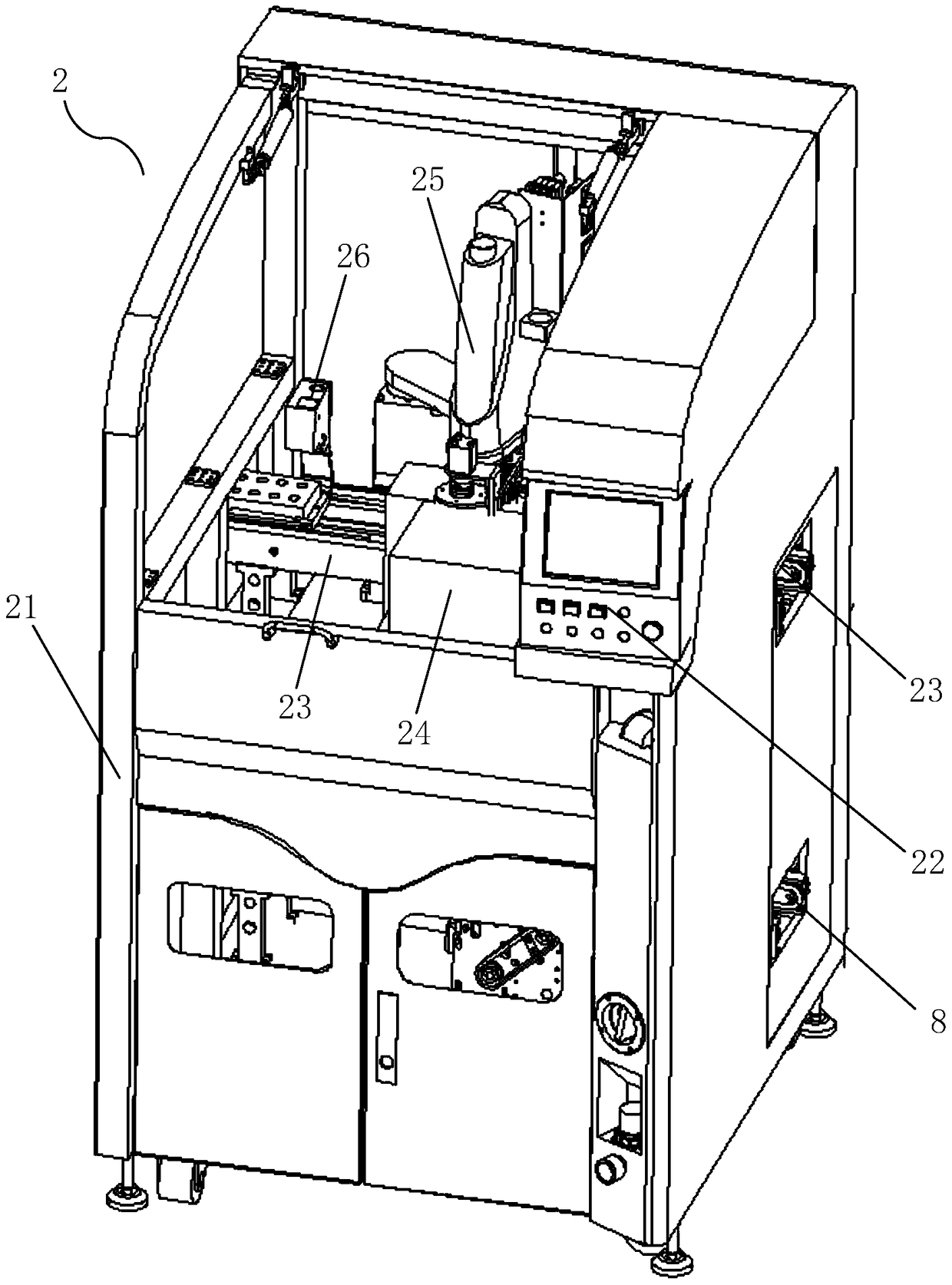

Circuit board shielding case component inserter

InactiveCN108012444AReduce labor costsIncrease productivityPrinted circuit assemblingPrinted circuit aspectsEngineeringElectrical and Electronics engineering

The present invention discloses a circuit board shielding case component inserter. The circuit board shielding case component inserter comprises a feeder, a material taking device, a detection bench,a horizontal articulated robot and a PCB mobile module. The feeder is formed by a lifting platform and a tray fixed on the lifting platform; the material taking device is formed by a linear module andan electromagnetic suction nozzle; the electromagnetic suction nozzle is fixed on a sliding bench of the linear module; the lifting platform and the detection bench are distributed in a direction ofthe linear module and are uniformly distributed below the linear module; the horizontal articulated robot is provided with an electromagnetic chuck; the PCB mobile module is formed by a guide rail andan electric clamping jaw movably arranged on the guide rail; when the horizontal articulated robot rotates at a certain angle, the electromagnetic chuck corresponds to the detection bench, and then the horizontal articulated robot further rotates at a certain angle, the electromagnetic chuck corresponds to the electric clamping jaw, and therefore, the manufacturing cost is low, the feeding by cases saves manpower, the compatibility is good, and the circuit board shielding case component inserter is suitable for parts with various sizes.

Owner:苏州泓舰自动化科技有限公司

A multi-functional pcb board production automation system

ActiveCN104822230BReduce labor intensityReduce in quantityLiquid surface applicatorsInsulating layers/substrates workingAdhesiveEngineering

The invention relates to a novel multifunctional PCB production automation system, comprising an automatic feeding system, a fully-automatic two-dimensional code sticking system, a height measuring system, an automatic adhesive dispensing curing system, an online automatic board-splitting cutting system, and a finished product sorting recovery system. The input ends and output ends of the above systems are connected in sequence. Control centers disposed on the above systems are connected with each other. The input end of the automatic feeding system is also provided with a large PCB feeding device. The large PCB feeding device is connected with the control center of the automatic feeding system. Thus, two-dimensional code marking on each PCB unit on a large PCB can be automatically completed, and good product detection, and cutting of the large PCBs can be automatically completed. The system can automatically complete finished products of PCB units, and the system is powerful in functions, high in automation degree, high in production efficiency, low in labor intensity, low in production cost, and high in qualified rate, and has assurance in product quality. A reversed design is used, thereby effectively preventing dusts generated in a cutting process from falling on the PCB, so the finished products are clean.

Owner:ZHUHAI ZHIXIN AUTOMATIC TECH CO LTD

PCB levelling apparatus

InactiveCN105704932ANo manual operation requiredCircuit inspection/monitoring/aligningEngineeringLevelling

Owner:广德英菲特电子有限公司

Outline printing

InactiveCN106965584ASemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringElectrical and Electronics engineering

The invention relates to outline printing. In a method of using a printing algorithm to print an ink pattern on a substrate in an ink jet system, a received pattern layout is divided into a discrete outline and a discrete inner area. The discrete outline is printed before the discrete inner area is printed. The printing algorithm may include converting the outline into a covering algorithm of a group of covering elements before generating a group of ink droplet positions. Apart from the printing algorithm, an ink flow algorithm used for considering ink flow influence before a group of ink droplet positions are generated may also be included.

Owner:MUTRACX INT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com