Novel PCB linear expansion control method

A control method and PCB board technology, applied in printed circuit manufacturing, circuit inspection/monitoring/correction, instruments, etc., can solve problems such as the inability to prevent PCB core board expansion and shrinkage in advance, waste of production costs and labor costs, etc., to improve data Compare accuracy and production efficiency, save production cost, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A novel PCB linear expansion and contraction control method, comprising the following steps:

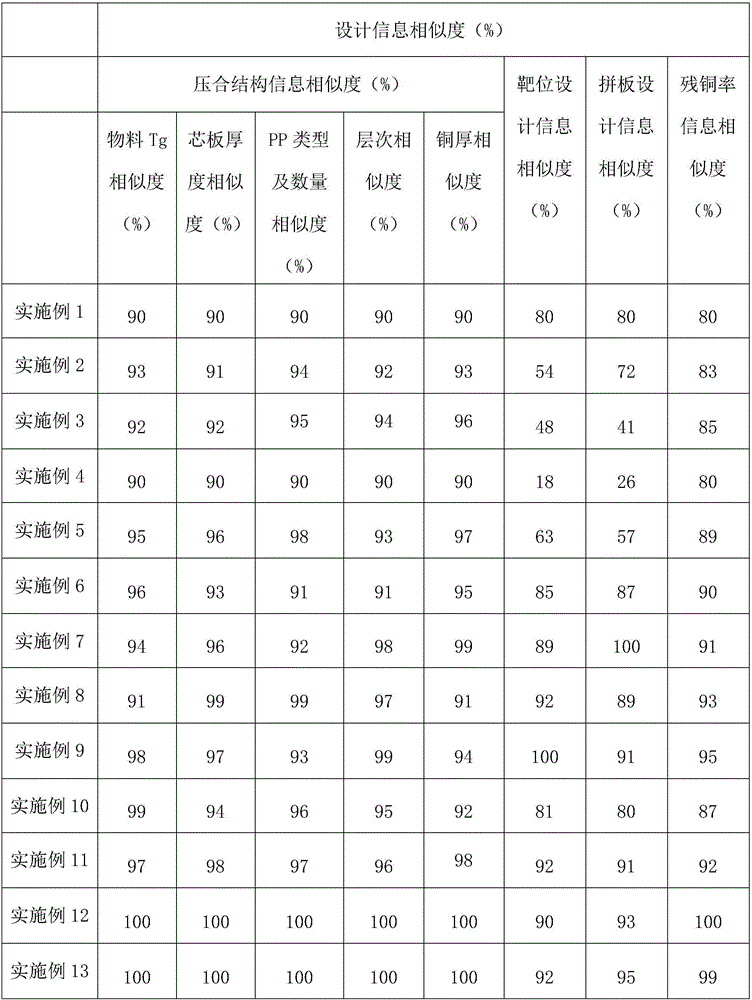

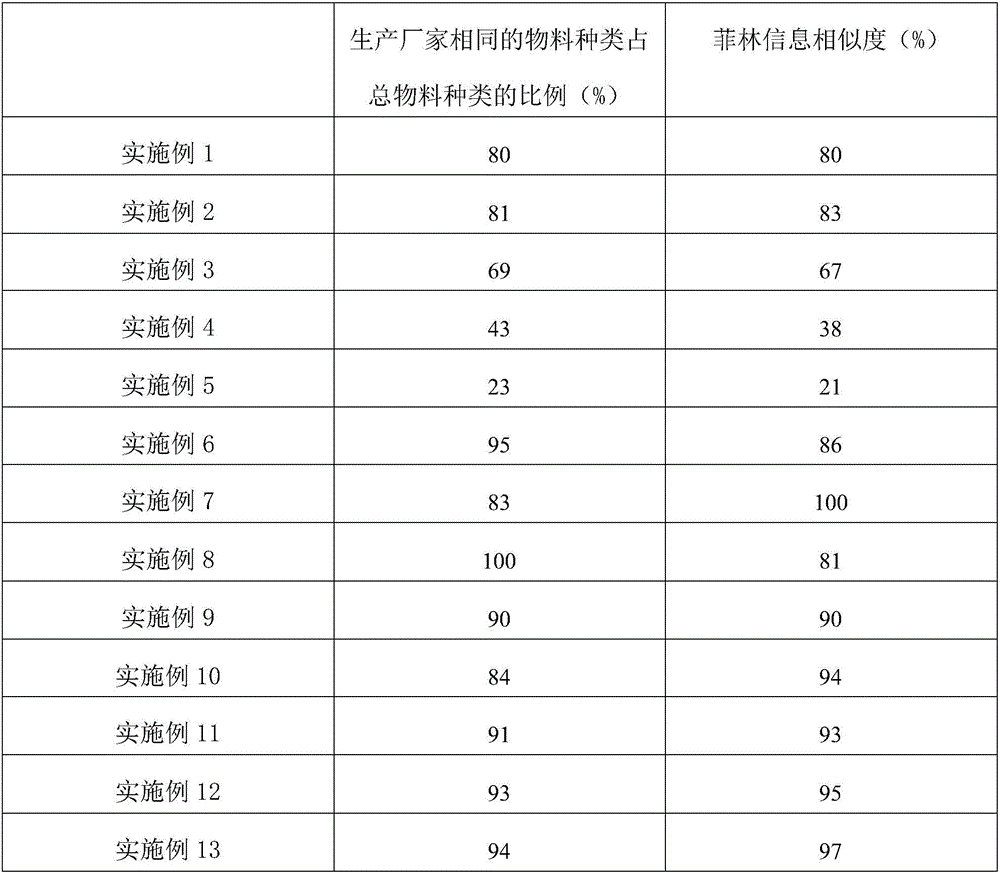

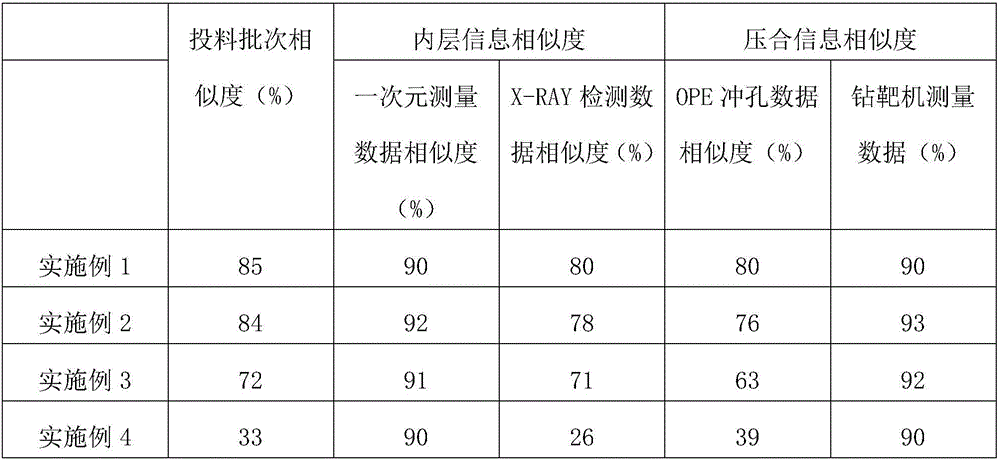

[0035] Engineering design, making engineering data according to the customer's drawing requirements, the engineering data is based on the customer's data, using the established expansion and contraction database, through the information comparison principle to find out the expansion and contraction value of the historical PCB board that meets the information comparison principle, so The information that needs to be compared in the information comparison principle includes design information, material information, and station data information. The design information includes lamination structure information, target design information, jigsaw design information, and residual copper rate information. Structural information includes material Tg, core board thickness, PP type and quantity, layer, and copper thickness. The material information includes material supplier information a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com