Black hole quality testing board for PCB, and quick examination method

A test board and black hole technology, which is applied in electronic circuit testing, printed circuit testing, circuit inspection/identification, etc., can solve the problems of black hole quality prevention and control, and achieve the effect of preventing poor quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to facilitate those skilled in the art to understand the technical content of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

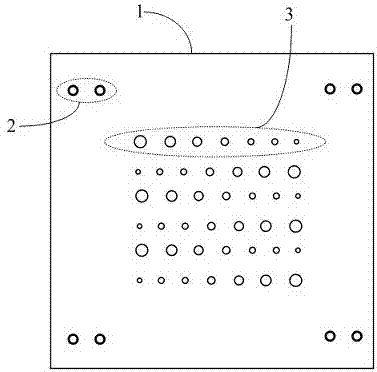

[0016] Such as figure 1 The PCB black hole quality test board shown includes a 60*60mm square copper-clad double-sided board 1, and a test group 2 is provided at the four corners of the copper-clad double-sided board 1. The test group includes two test pads, and the test pads are It is circular and has a diameter of 1mm, and the distance between the centers of the two test pads is 5mm; there are 6 through-hole groups 3 in the middle of the copper-clad double-sided board 1, and each through-hole group 3 includes 7 through-holes, with a diameter of 0.2 mm, 0.25mm, 0.3mm, 0.35mm, 0.4mm, 0.45mm, 0.5mm, lined up in order of diameter, and the center distance between adjacent through holes is 5mm. The upper and lower sides of the copper-clad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Center distance | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com