Monitoring method for aligning degree of laser drilling

A technology of laser drilling and alignment, applied in circuit inspection/monitoring/correction, printed circuits, electrical components, etc., can solve the problems of selection, leakage, and low efficiency that cannot be laser drilled and drilled

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

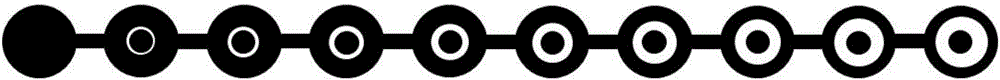

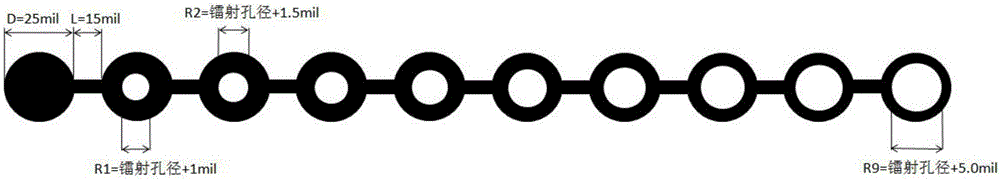

[0026] Design laser drilling alignment monitoring Coupon (module), such as figure 1 As shown, this module is set on the process side and has no functional impact on the contents of the board.

[0027] The module design content is as follows:

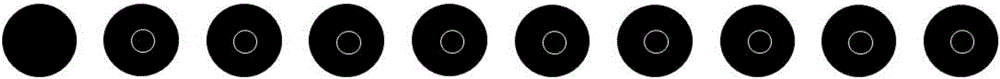

[0028] 1. In the laser drilling Target (the pad layer at the bottom of the laser drilling hole, it can also be called the bottom pad of the blind hole, with the attached Figure 5 -Laser drilling) layer design a row of series Pad*10 (such as figure 2 -Laser drilling Target layer module design), Pad size D = 25mil, distance between Pad and Pad L = 15mil, the first Pad is solid, the middle of the second Pad is etched and isolated, the isolation size R1 = laser drilling aperture + 1mil ( For example, the laser drilling aperture is 4.0mil, R1=5mil), the middle etching isolation of the third Pad, the isolation size R2=laser drilling aperture+1.5mil, the fourth Pad etching isolation in the middle, the isolation size R3=laser drilling apertu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com