Inspect method and inspect device

A technology of inspection device and inspection method, which is applied in measurement devices, circuit inspection/monitoring/correction, material analysis by optical means, etc., can solve the problems of long time required for inversion and complex structure, and achieve efficient inspection and simplification. Structure, easy to flip effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

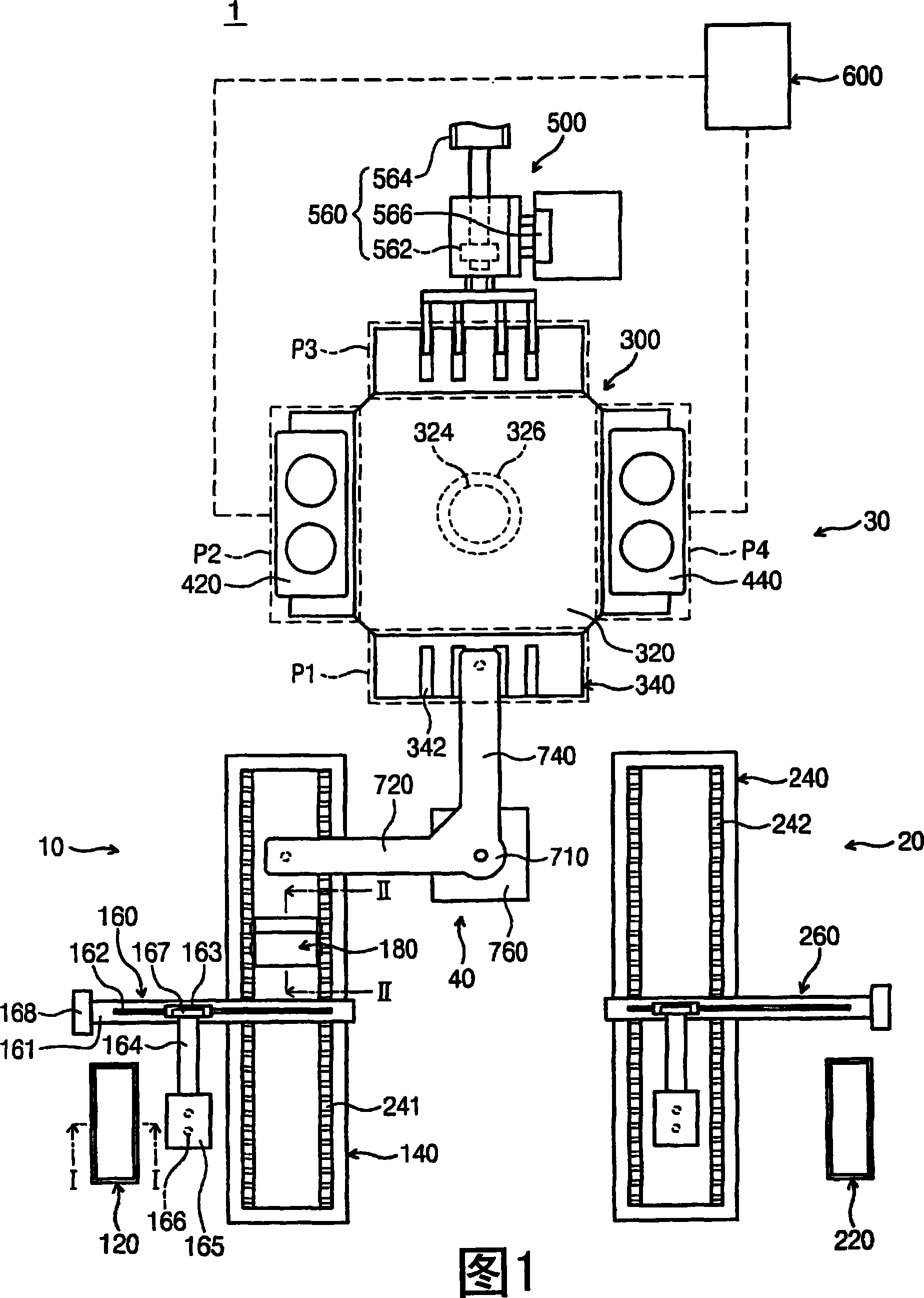

[0048] Hereinafter, the embodiment of the present invention will be described in more detail based on FIGS. 1 to 10 .

[0049] Various modifications can be made to the embodiments of the present invention, and the scope of the present invention should not be interpreted as being limited to the following embodiments. This embodiment mode is for those having ordinary technical knowledge in the art to fully understand the present invention. Therefore, the shapes of elements in the drawings are emphasized for clarity.

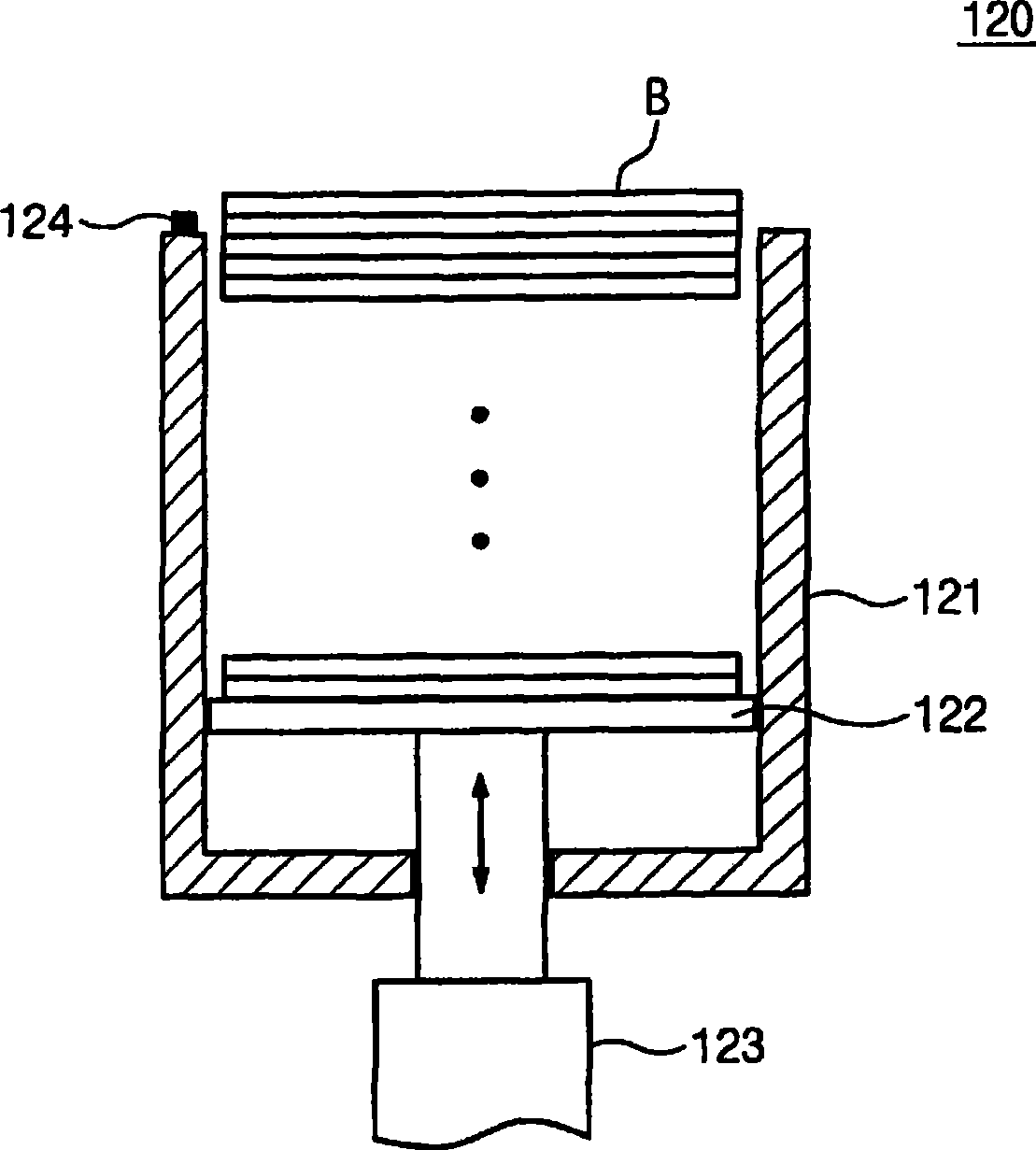

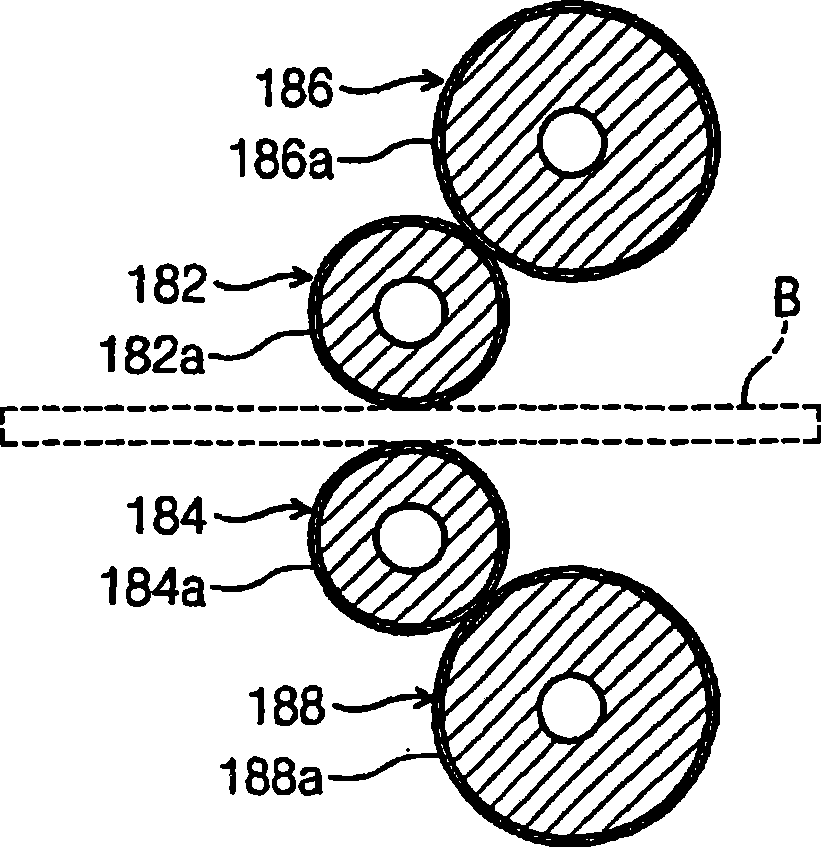

[0050] In this embodiment, a case where the inspection target object is a printed circuit board B that is a substantially thin plate will be described as an example. However, the technical idea of the present invention can also be applied to inspection items other than the printed circuit board B in addition to this.

[0051] FIG. 1 is a plan view schematically showing an embodiment of an inspection device 1 of the present invention. As shown in FIG. 1 , the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com