Thin film resistor inner layer etching method

A technology of thin film resistors and inner layers, which is applied in directions including printed resistors, removal of conductive materials by chemical/electrolytic methods, electrical components, etc., can solve problems such as affecting production efficiency, increasing equipment and potion costs, and complex technological processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following will be described in detail in conjunction with the embodiments.

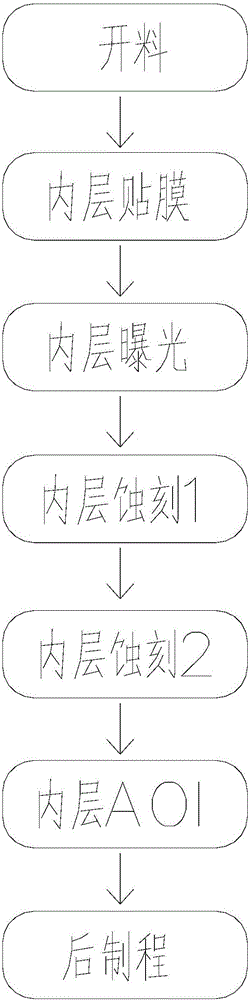

[0012] combine figure 1 , This solution relates to a method for etching the inner layer of a thin-film resistor, which includes the following processes in sequence: material cutting → inner layer film attachment → inner layer exposure → inner layer etching 1 → inner layer etching 2 → inner layer AOI → post-processing.

[0013] Cutting, that is, the process of cutting the original circuit board core board into the required size specifications with a cutting machine according to the process requirements and size specifications. The cutting process is mostly the initial process of circuit board production. In this process, the core board of the circuit board can be cut out according to the size of the panel for subsequent process production.

[0014] Inner layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com