Outline printing

A contour and layout technology, applied in printing, printed circuit, printed circuit manufacturing, etc., can solve the problems of occupying printed circuit board production, long time interval of production time, time-consuming inspection and processing, etc., to achieve accurate external dimensions and reduce impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0115] Various embodiments of the present invention are described using FIGS. 1-7 .

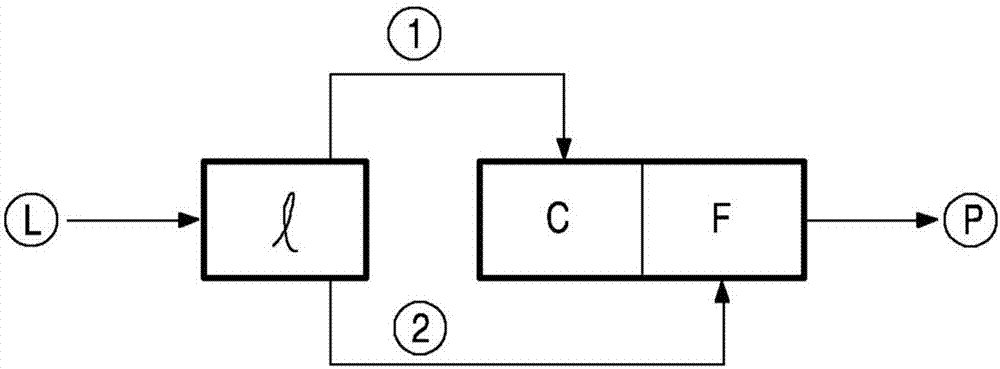

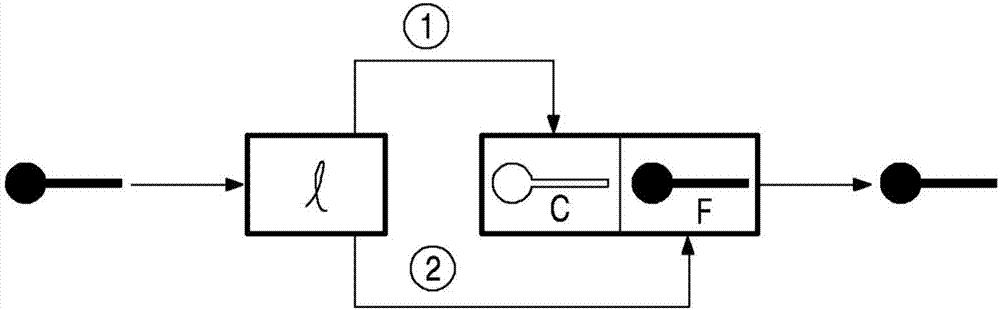

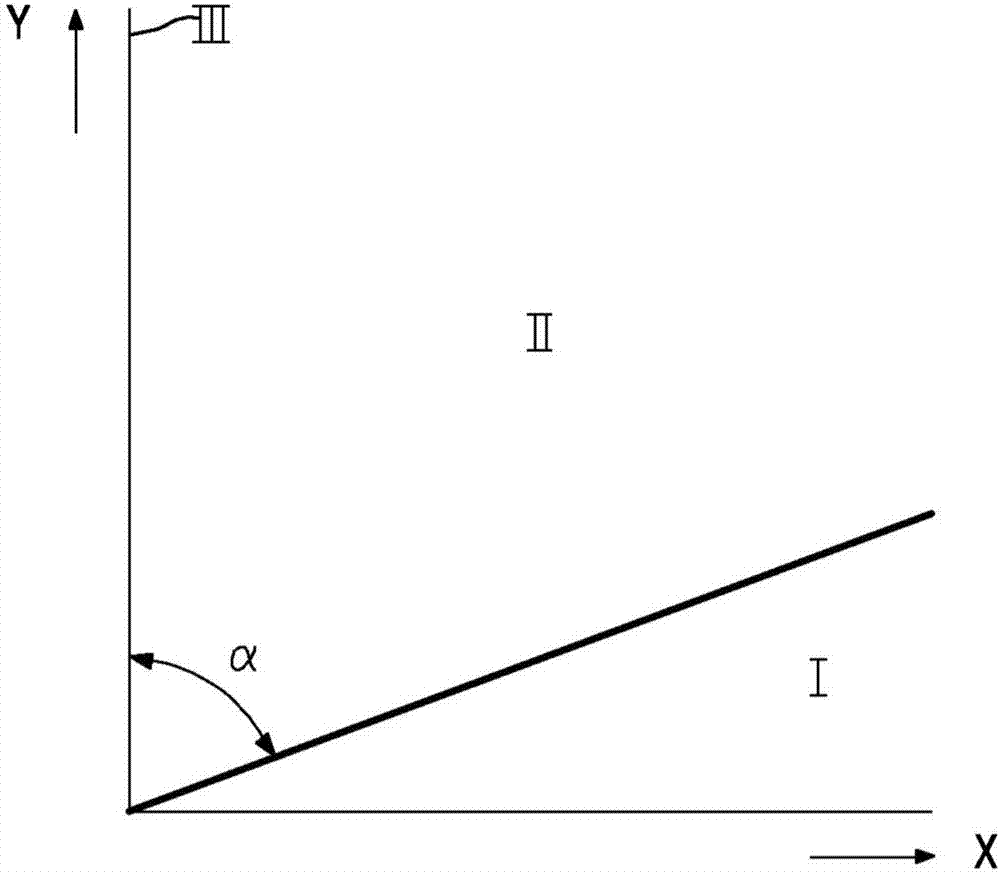

[0116] Figure 1A A flow diagram of the method according to the invention is shown. In this method, the pattern layout L is received by the control electronics of the inkjet system. The control electronics contain software to convert the pattern layout into ink patterns. The software contains logic L to convert the received pattern layout L into a single contour layer comprising at least one contour portion and a single inner region layer comprising at least one inner region portion of the pattern layout. Logic L provides output data used to control at least one printhead of the inkjet system. Logic L provides first output data 1 and second output data 2 . The first output data 1 comprises contour data for printing the contour defined in the contour layer. The second output data 2 comprises inner region data for printing the inner region defined by the inner region layer. The outer outli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com