Manufacturing method for circuit board capable of detecting inner-layer pore ring

A manufacturing method and circuit board technology, applied in the direction of multi-layer circuit manufacturing, circuit inspection/monitoring/correction, etc., can solve the problems of circuit board inflow, customer claims, circuit board defects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

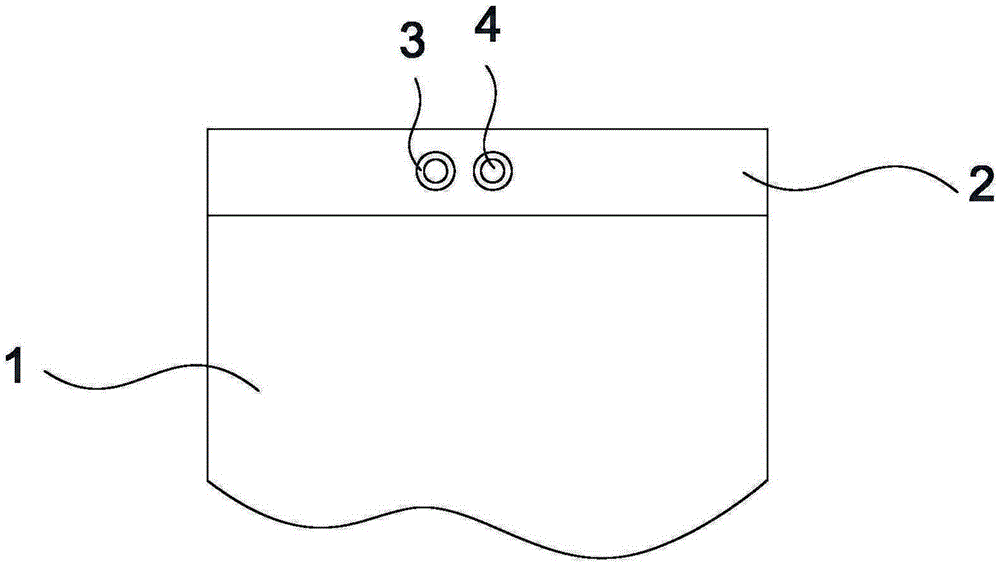

[0020] Such as figure 1 As shown, the circuit board includes a PCB unit 1 and a process side 2, and the inner annular ring in the PCB unit 1 is required to be ≥0.025mm. The minimum annular ring width in PCB unit 1 is 0.125mm, corresponding to the drilling aperture diameter of the smallest annular ring is 0.1mm (that is, the annular ring surrounds the drill hole, and the outer diameter of the annular ring is 0.35mm. Two windows 3 are provided on the process side 2, and the window There is no copper at position 3, the hole diameter of window 3 is 0.3mm, the window position is provided with auxiliary hole 4, and the hole diameter of auxiliary hole 4 is 0.1mm; The layer is not connected to the copper lines in PCB unit 1.

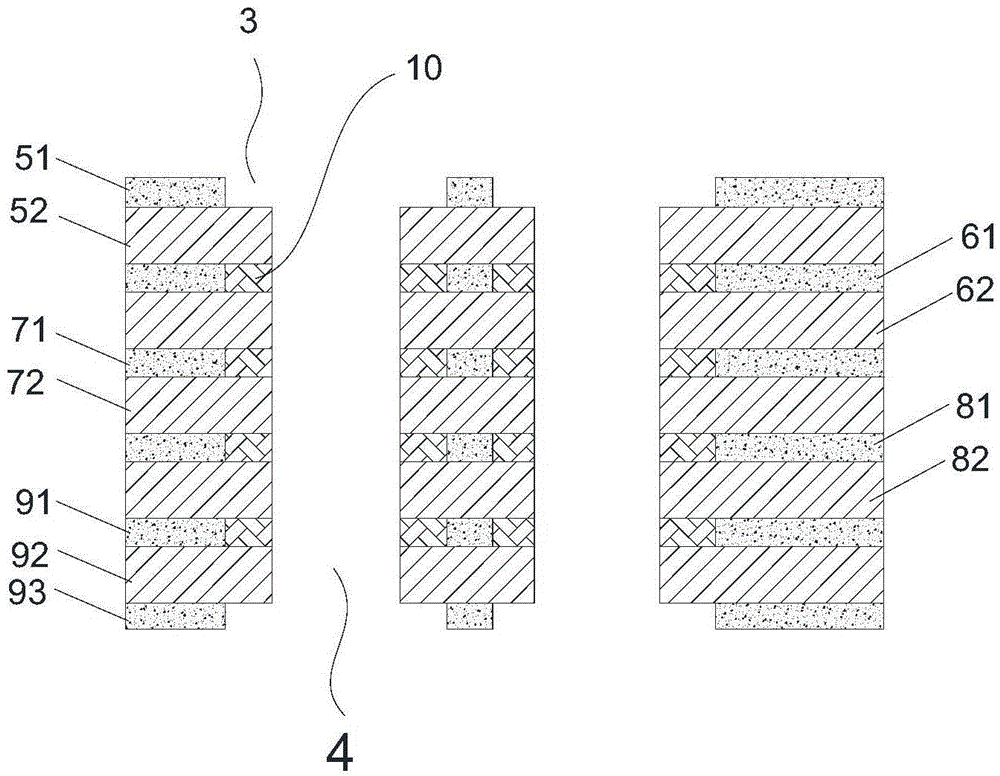

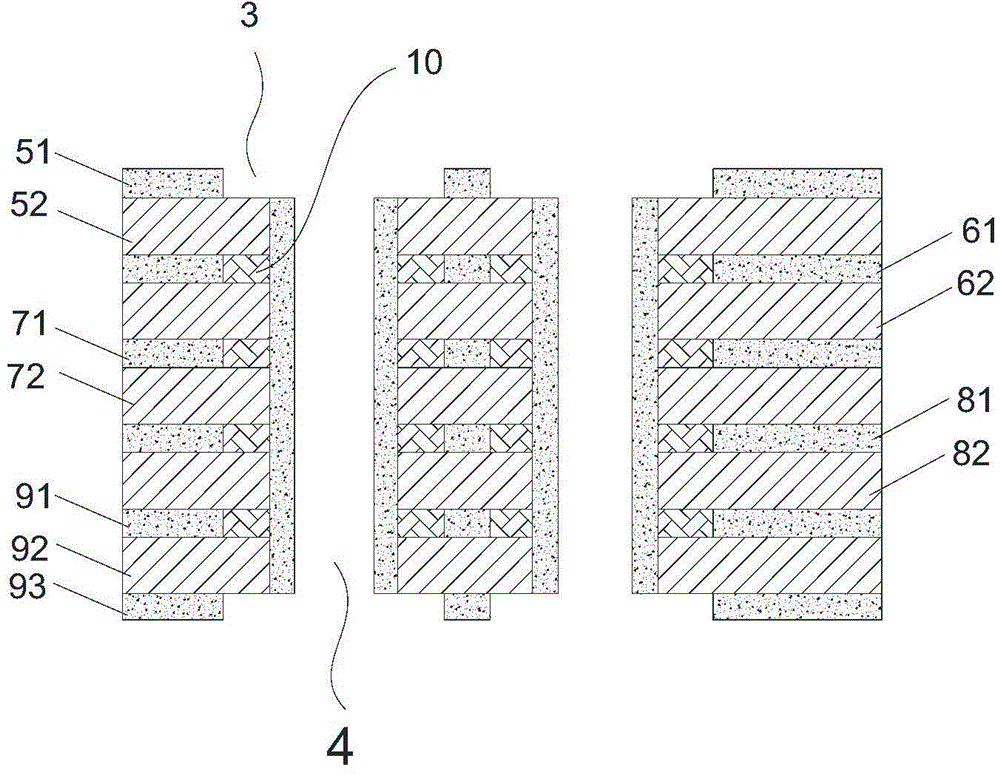

[0021] Such as figure 2 The circuit board is a six-layer circuit board, which is formed by pressing five sub-boards. The first sub-board includes the first copper layer 51 and the first core board 52, and the second sub-board includes the second copper layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com