Circuit board shielding case component inserter

A shielding cover, plug-in machine technology, applied in electrical components, printed circuits, electrical components and other directions, can solve the problems affecting quality and efficiency, unable to mount production, expensive and other problems, to improve production efficiency, low manufacturing cost, equipment Flexible and strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

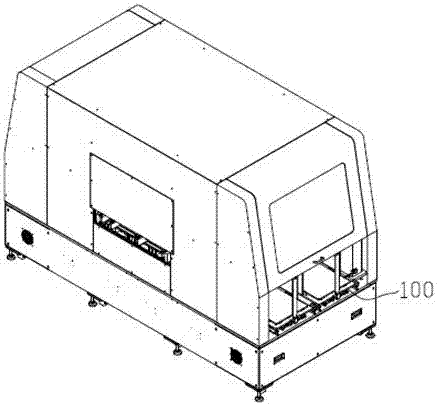

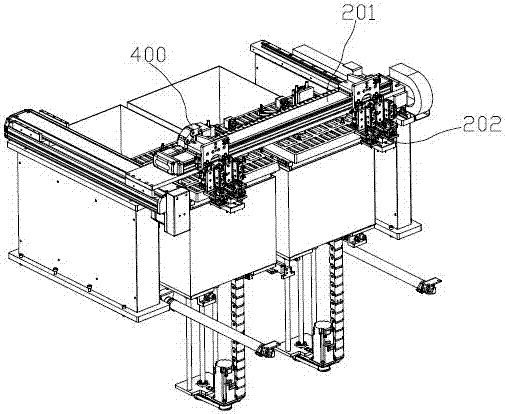

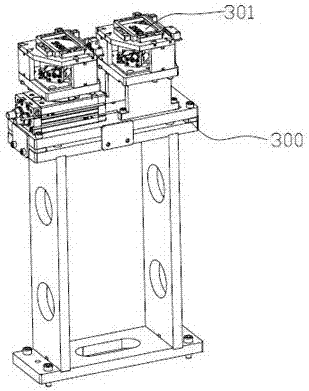

[0027] refer to Figure 1-4 , a circuit board shielding cover plug-in machine, including a feeder 100, a reclaimer, a detection table 300, a horizontal multi-joint robot 400 and a PCB circuit board moving assembly; The reclaimer is composed of a linear module 201 and an electromagnetic suction head 202. The electromagnetic suction head 202 is fixed on the slide table of the linear module 201. distribution and are all located below the linear module 201; the horizontal multi-joint robot 400 is provided with an electromagnetic chuck 401, and the PCB circuit board moving assembly is composed of a guide rail and an electric gripper 500 movably arranged on the guide rail. After the horizontal multi-joint robot 400 rotates at a certain angle, the electromagnetic chuck 401 corresponds to the detection table 300 , and after rotating at a certain angle, the electromagnetic chuck 401 corresponds to the electric gripper 500 .

[0028] When working, the whole box of material trays with p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com