Positioning and transferring of substrate

A positioning platform and transmission unit technology, applied in power transmission devices, conveyors, transportation and packaging, etc., can solve the problems of long intervals of production time, time-consuming inspection and processing, occupation of printed circuit board production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

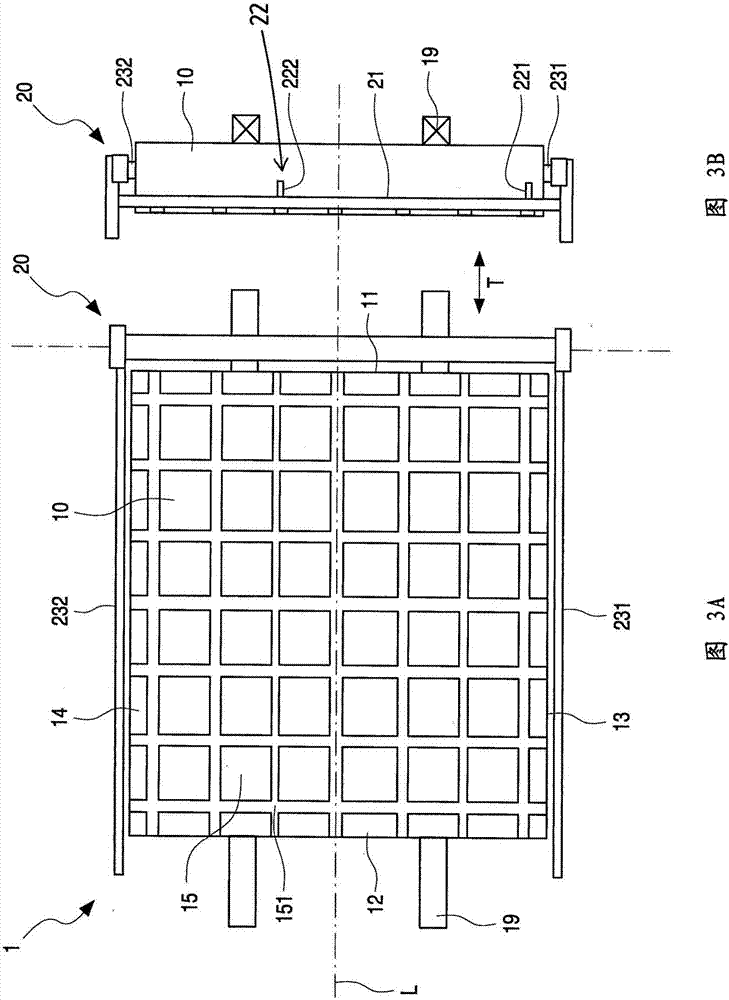

[0088] A printed circuit board, which is used to mechanically support and electrically connect electronic components, is called a PCB. A PCB is also known as a printed wiring board (PWB) or an etched wiring board. Printed circuit boards are used in nearly all of the simplest commercially manufactured electronic devices. The PCB includes a base including at least one conductive via layered etched from at least one copper sheet onto a non-conductive substrate. The base has a non-conductive substrate. The substrate typically includes resin-bonded fibers. The substrate is typically formed from a spacer insulator layered with epoxy. Boards are typically coated with a solder mask, most of which are green in color. A blank PCB, or simply called a "blank", is formed by layering a non-conductive substrate with at least one copper sheet. The blank form is used to manufacture the base product of the PCB.

[0089] Printed circuit boards can be manufactured in several ways. In order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com