Component mounting line, component mounting method and component mounting apparatus

A technology of installation device and installation method, applied in the direction of electrical components, electrical components, circuit inspection/monitoring/correction, etc., which can solve the problems of undisclosed, specified and mounted appropriateness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

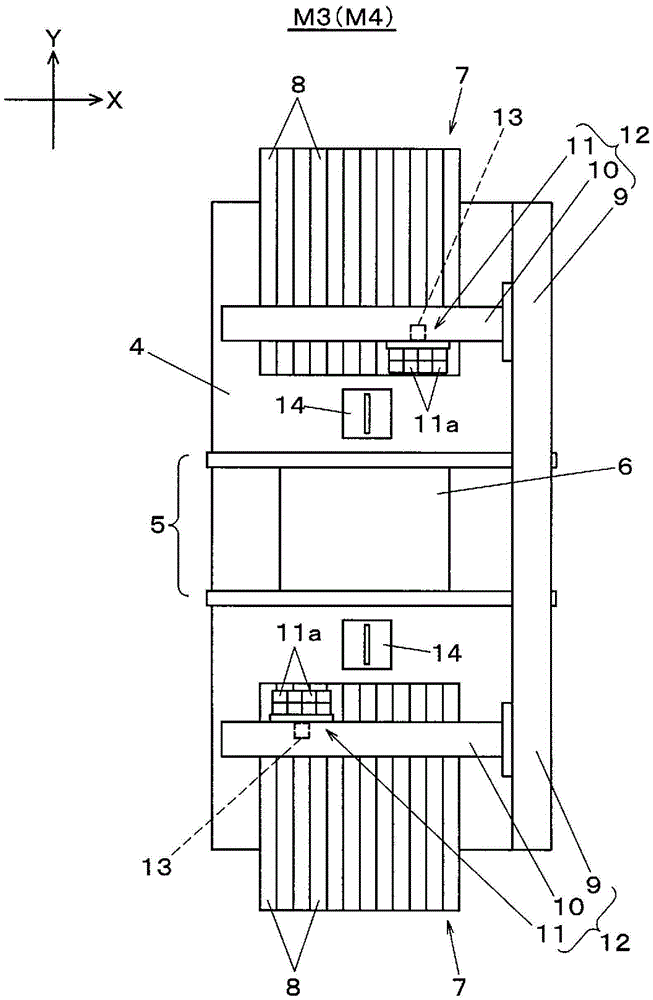

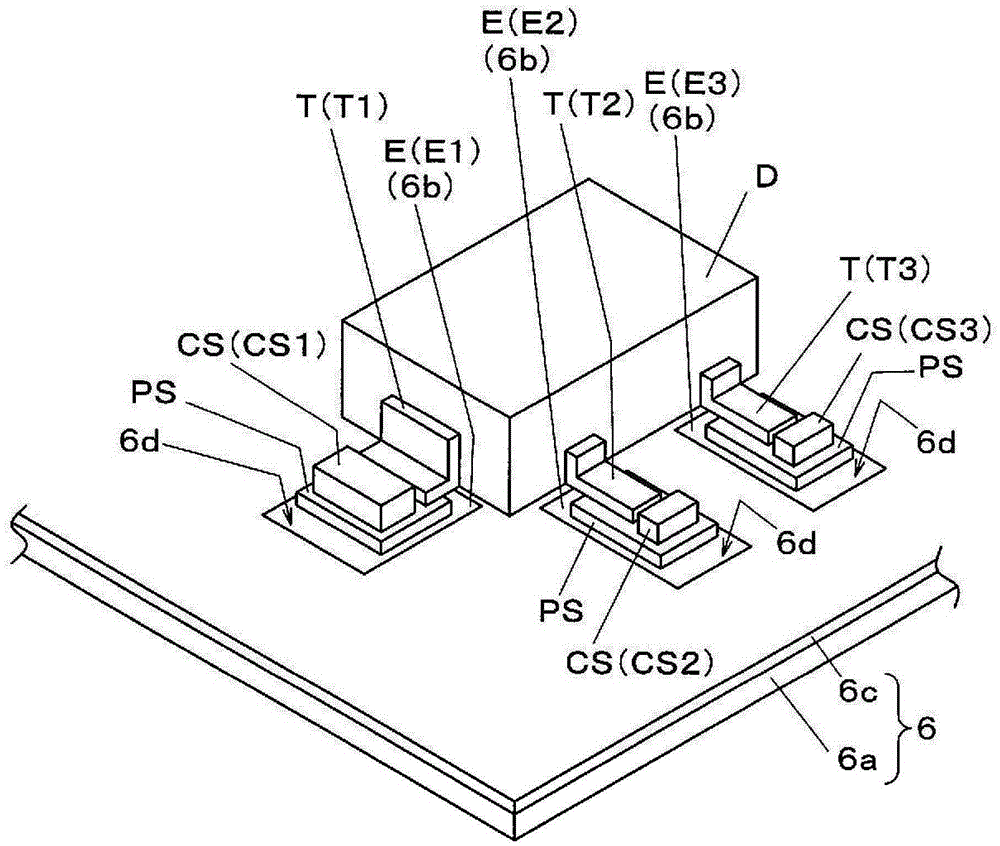

[0047] Next, embodiments of the present invention will be described with reference to the drawings. Below, the substrate transport direction ( figure 2 The left and right direction of the paper) is defined as the X direction, and the direction perpendicular to the X direction in the horizontal plane ( figure 2 The up and down direction of the paper) is defined as the Y direction.

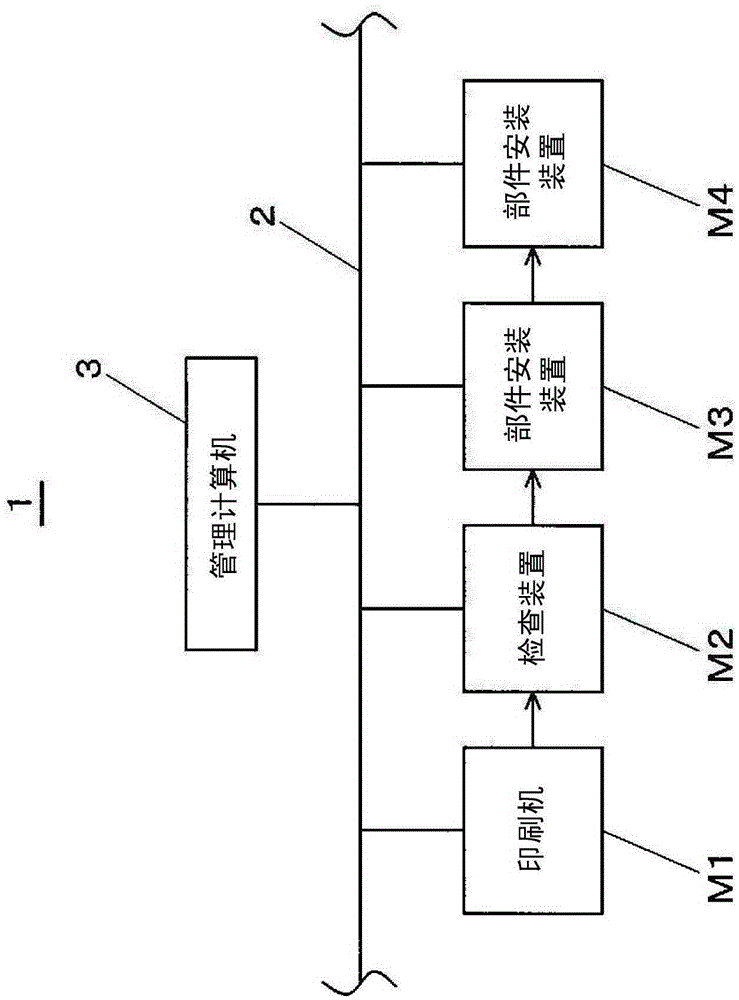

[0048] First, refer to figure 1 The component mounting line 1 will be described. exist figure 1 Among them, the component mounting production line 1 is configured by connecting a plurality of components mounting devices, that is, a printing machine M1, an inspection device M2, and a component mounting device M3, M4, and connecting the devices through a communication network 2 and controlling them by a management computer 3. overall.

[0049] The printer M1 has a function of transferring paste-like cream solder on pads formed on a substrate via a metal mask by screen printing. The inspection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com