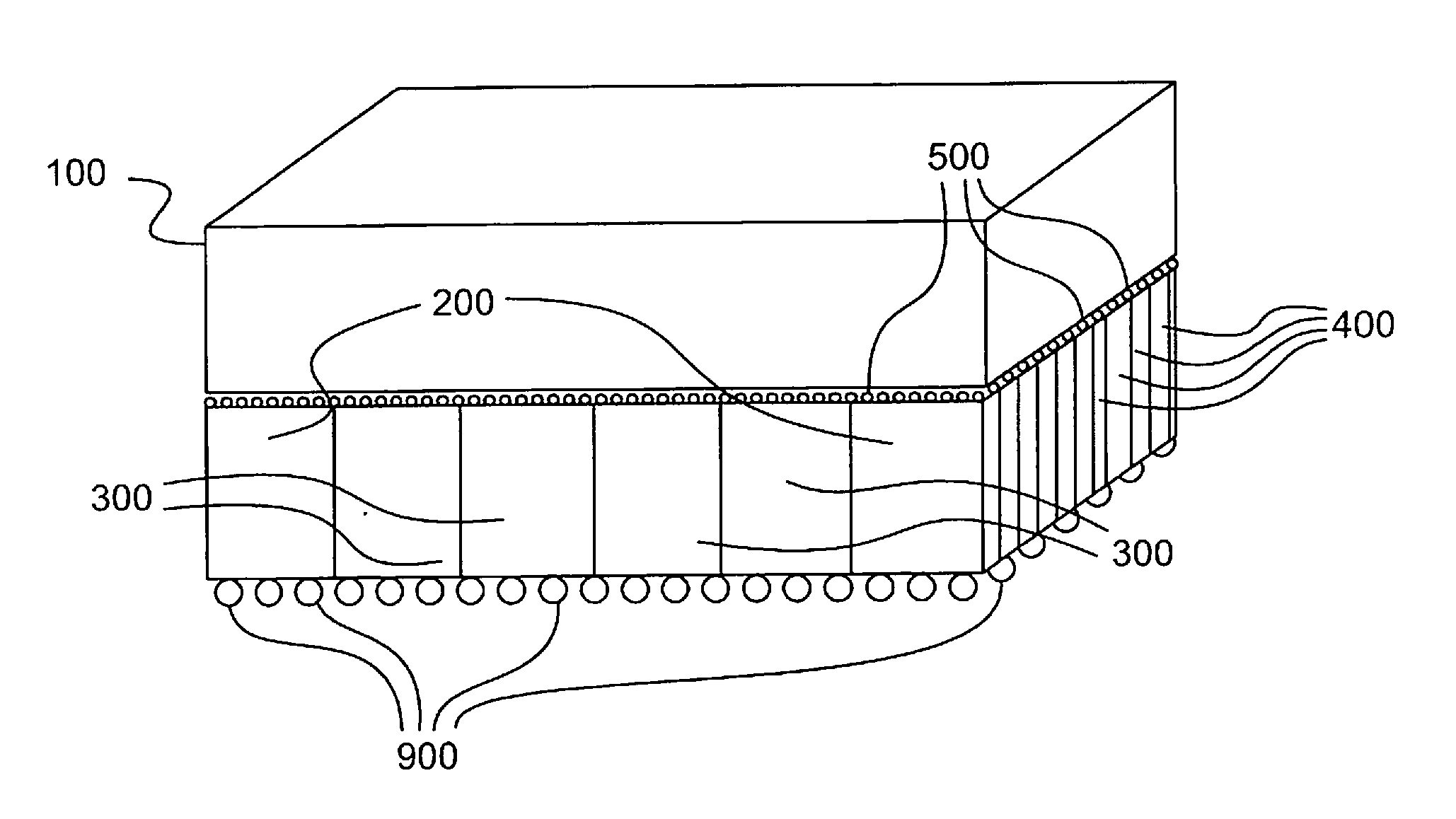

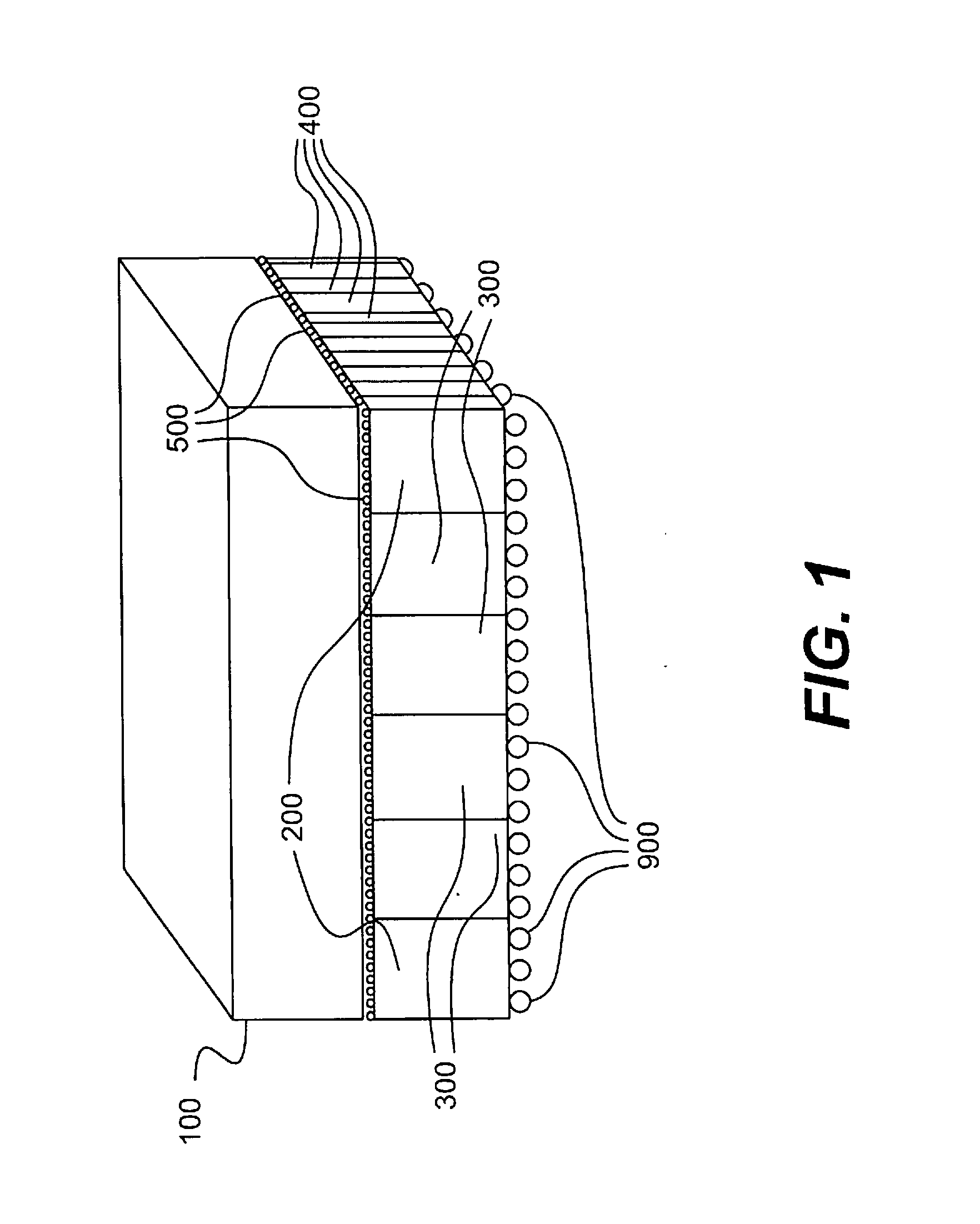

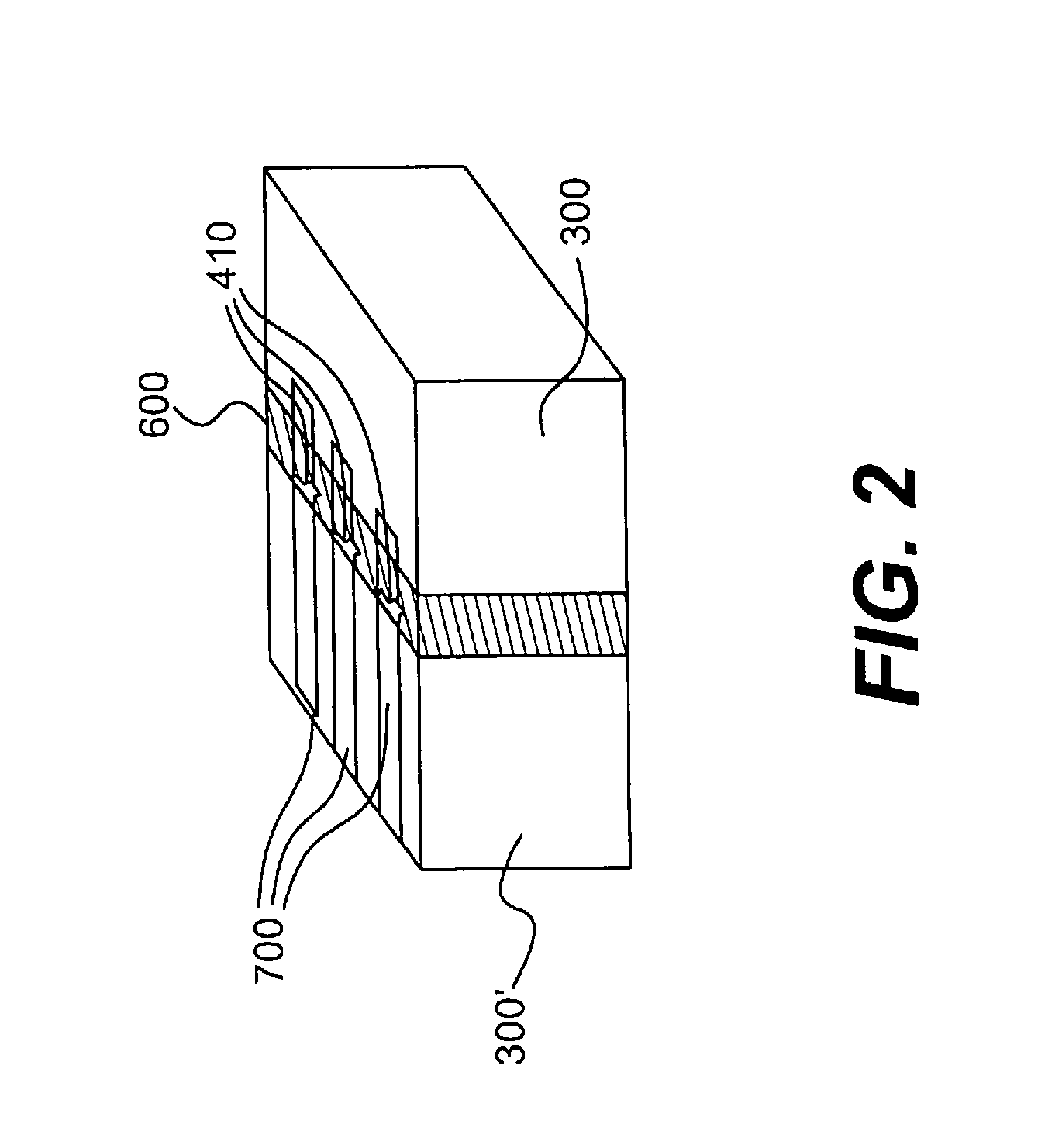

Process for Enhanced 3D Integration and Structures Generated Using the Same

a technology structures, applied in the direction of electrical apparatus construction details, electromagnetic transmission, transmission, etc., can solve the problems of low input/output density, signal delay, and difficulty in powering the system through edge connections, and achieve the effect of enhanced 3d integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0002]1. Field of the Invention

[0003]The field of the invention comprises integrated electronic 3D system devices and a process for building integrated 3D system devices that enables a higher level of system integration than possible with current 3D integration processes and structures, but does not employ through silicon vias.

[0004]2. Background of the Invention and Related Art

[0005]Various processes and structures described in the related art address high level system integration such as Hoffman, et al., U.S. Pat. No. 6,033,931, one of a class of so-called “cube patents.” Hoffman, et al. discloses a three-dimensional microchip circuit assembly process that employs a three-layer dry film sandwich to prepare a stacked circuit cube. Bertin, et al. U.S. Pat. No. 5,563,086 discloses an integrated memory cube structure and method of fabrication in which stacked semiconductor memory chips are integrated by a controlling logic chip such that a more powerful memory architecture is defined ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com