Analysis method for opening of laser blind hole

An analysis method and blind hole technology, applied in the direction of material analysis, material analysis, measurement device, etc. by optical means, can solve the problems of inaccurate positioning, inability to improve, and inability to guarantee the reliability of HDI products, so as to improve reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

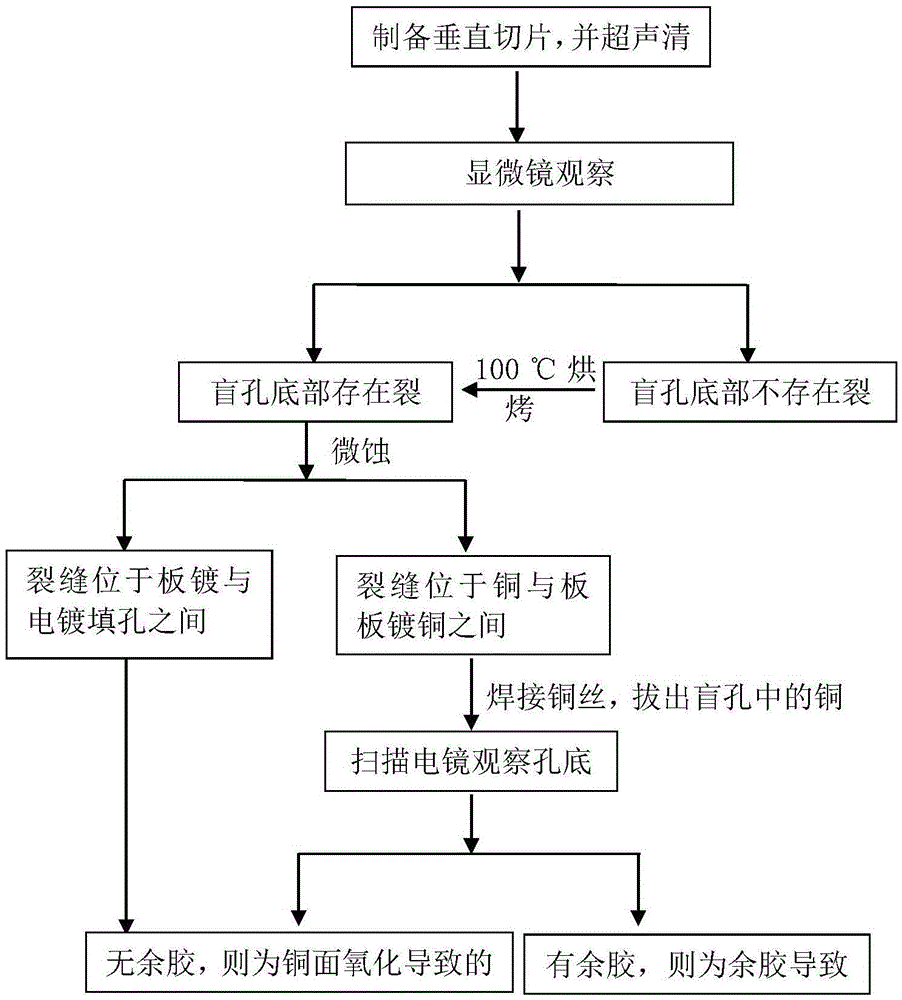

[0018] Such as figure 1 An analysis method for the open circuit of a laser blind hole is shown, comprising the following steps:

[0019] S1. Make vertical slices for laser blind holes with open circuit failure;

[0020] S2. Use a microscope to observe whether there are cracks at the bottom of the laser blind hole;

[0021] S3. If cracks are found by observation, use microetching solution to micro-etch the copper surface of the vertical slice, and observe the layer position where the crack is located;

[0022] S4. a. If the crack is located between the plate copper plating and the electroplating filled hole, and there is no glue at the bottom of the laser blind hole, it is judged that the laser blind hole is open due to the oxidation of the copper surface; b. If the crack is located between the base copper and the plate copper plating If there is no r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com