Delamination failure detection method of printed circuit board

A printed circuit board and detection method technology, applied in the direction of measuring devices, analyzing materials, and using wave/particle radiation for material analysis, etc., can solve problems such as improving the placement process, PCB delamination and blistering, economic losses, etc., and achieve convenience Mounting process, convenience and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

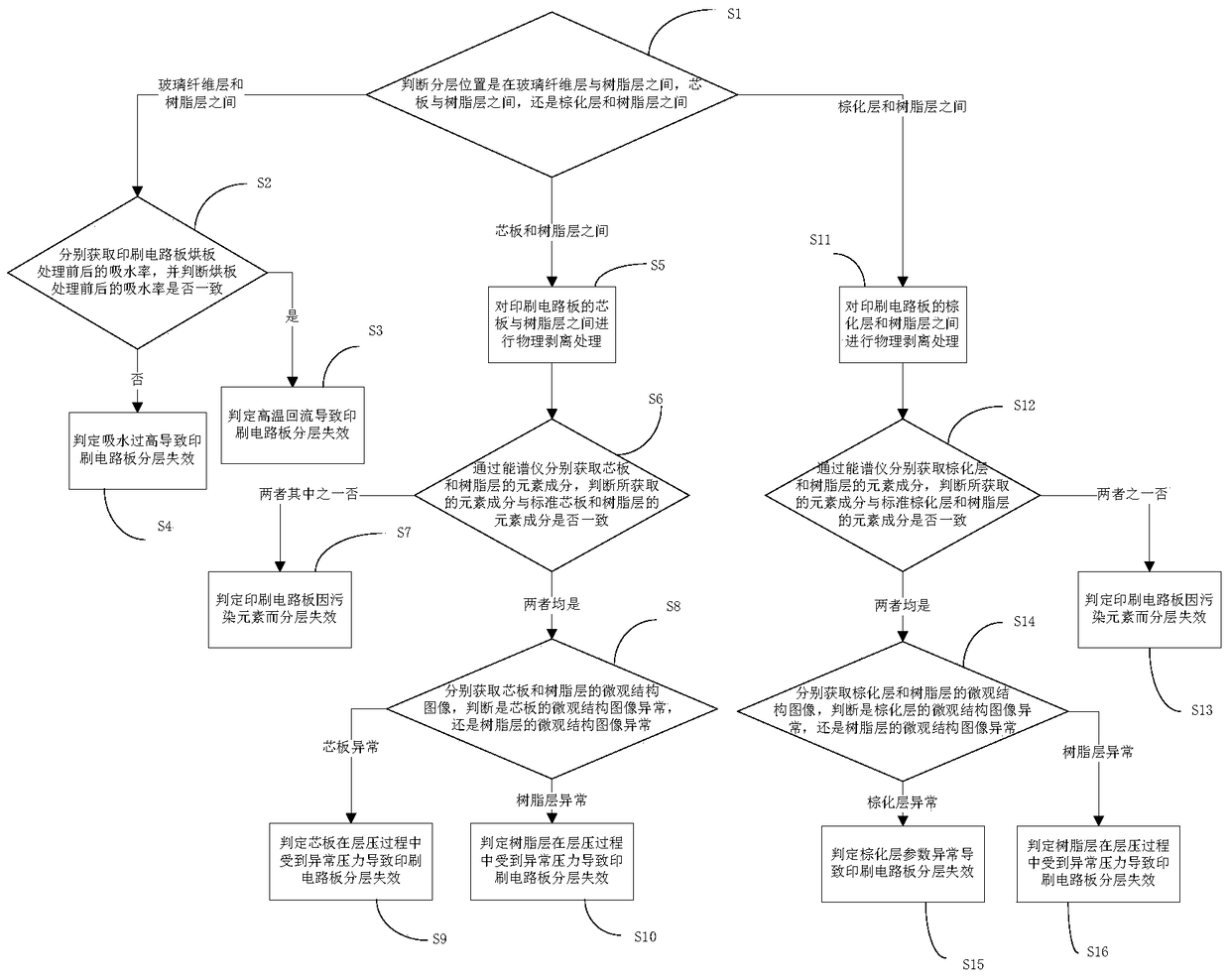

[0028] See figure 1 , the present invention relates to a kind of printed circuit board delamination failure detection method, and its preferred embodiment comprises the following steps:

[0029] Step S1: Vertically slice the delaminated printed circuit board to determine whether the delamination position is between the glass fiber layer and the resin layer, between the core board and the resin layer, or between the browning layer and the resin layer, if so Between the glass fiber layer and the resin layer, perform step S2; if it is between the core board and the resin layer, perform step S5; if it is between the browning layer and the resin layer, perform step S11;

[0030] Step S2: Obtain the water absorption rate of the printed circuit board before and after the drying plate treatment, and judge whether the water absorption rate before and after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com