Method and device for controlling cooling speed of core assembly casting

A technology of cooling speed and control method, which is applied in the direction of casting molding equipment, casting molds, mold cores, etc., can solve the problems of poor thermal conductivity of sand molds, difficult control, and difficulty in ensuring the internal compactness of local thick and large castings, so as to ensure the internal quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

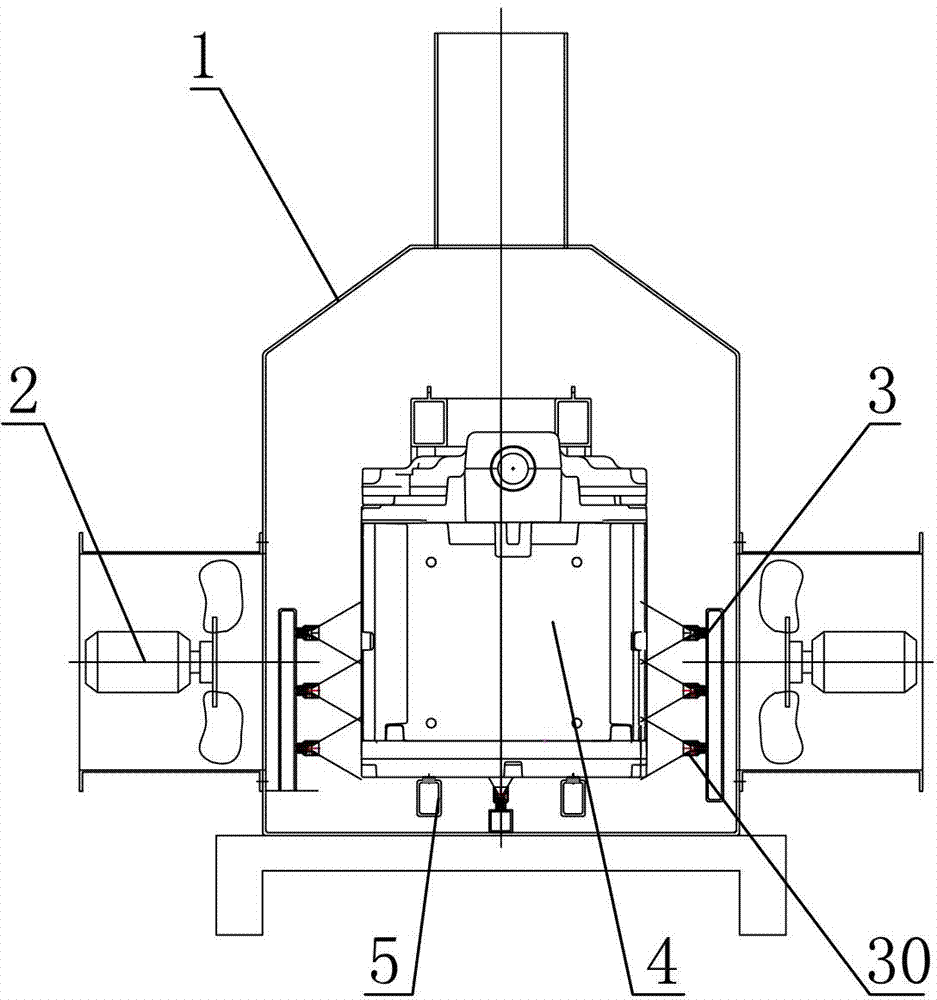

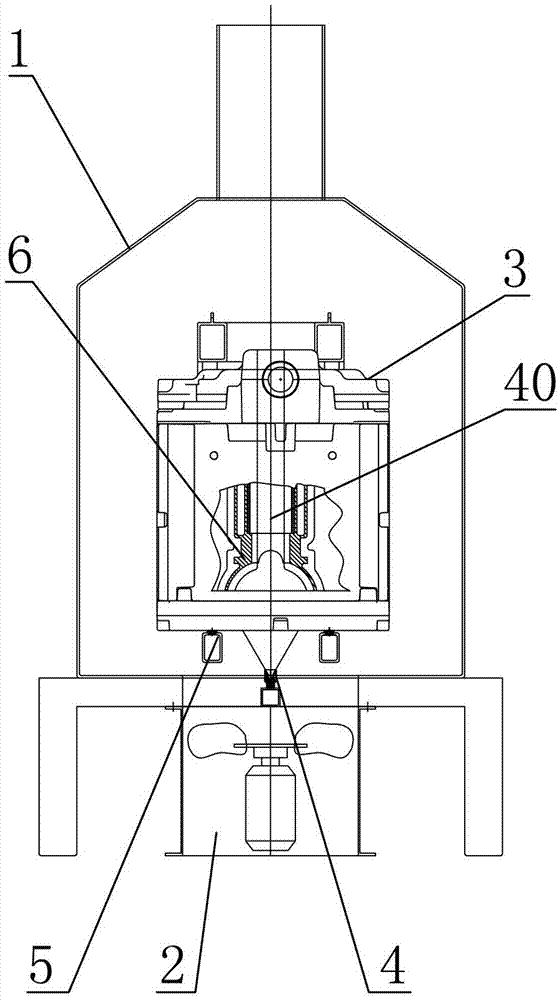

[0023] Below in conjunction with accompanying drawing and embodiment example, the present invention will be further described:

[0024] A method for controlling the cooling speed of core group casting. The molten metal is poured into the sand mold, and the airflow or water mist is sprayed on the part of the sand mold corresponding to the local thick hot spot of the casting, so as to accelerate the cooling and solidification of the casting inside the sand mold, and achieve local The effect of rapid cooling can avoid the casting pine defects caused by hot spots, and the cooling speed can be controlled by adjusting the air flow and water mist volume, among which: the air pressure of the air flow is 320~1500Pa, and the air flow volume is 10000~20000m 3 / h; the spray pressure of water mist is 5~7bar, and the spray volume of water mist is 10~30kg / min.

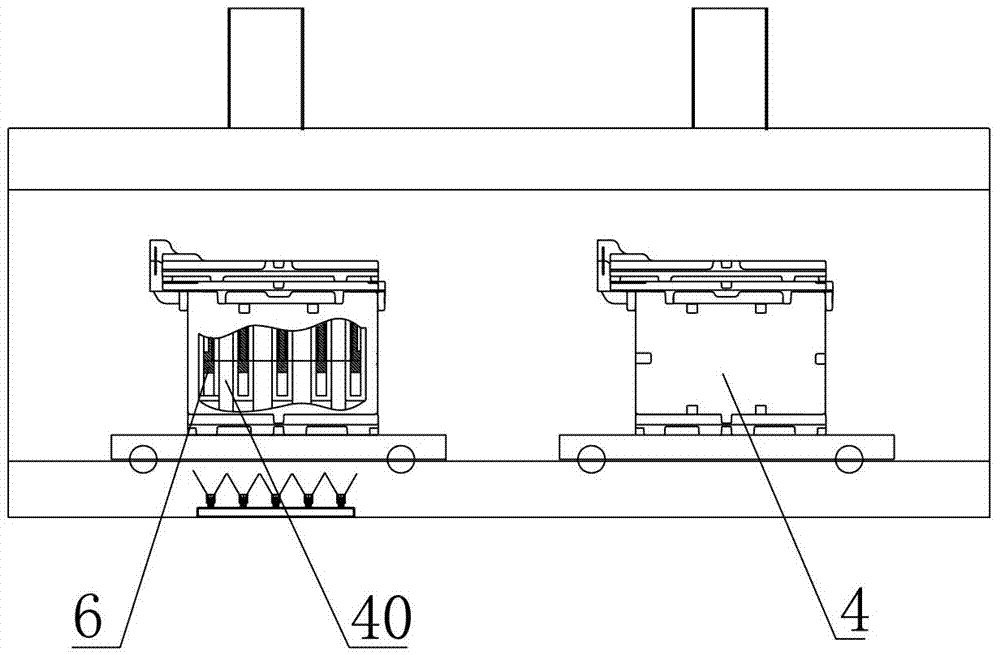

[0025] Such as figure 2 As shown: the sand mold 4 is provided with a cooling channel 40 at the part corresponding to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com