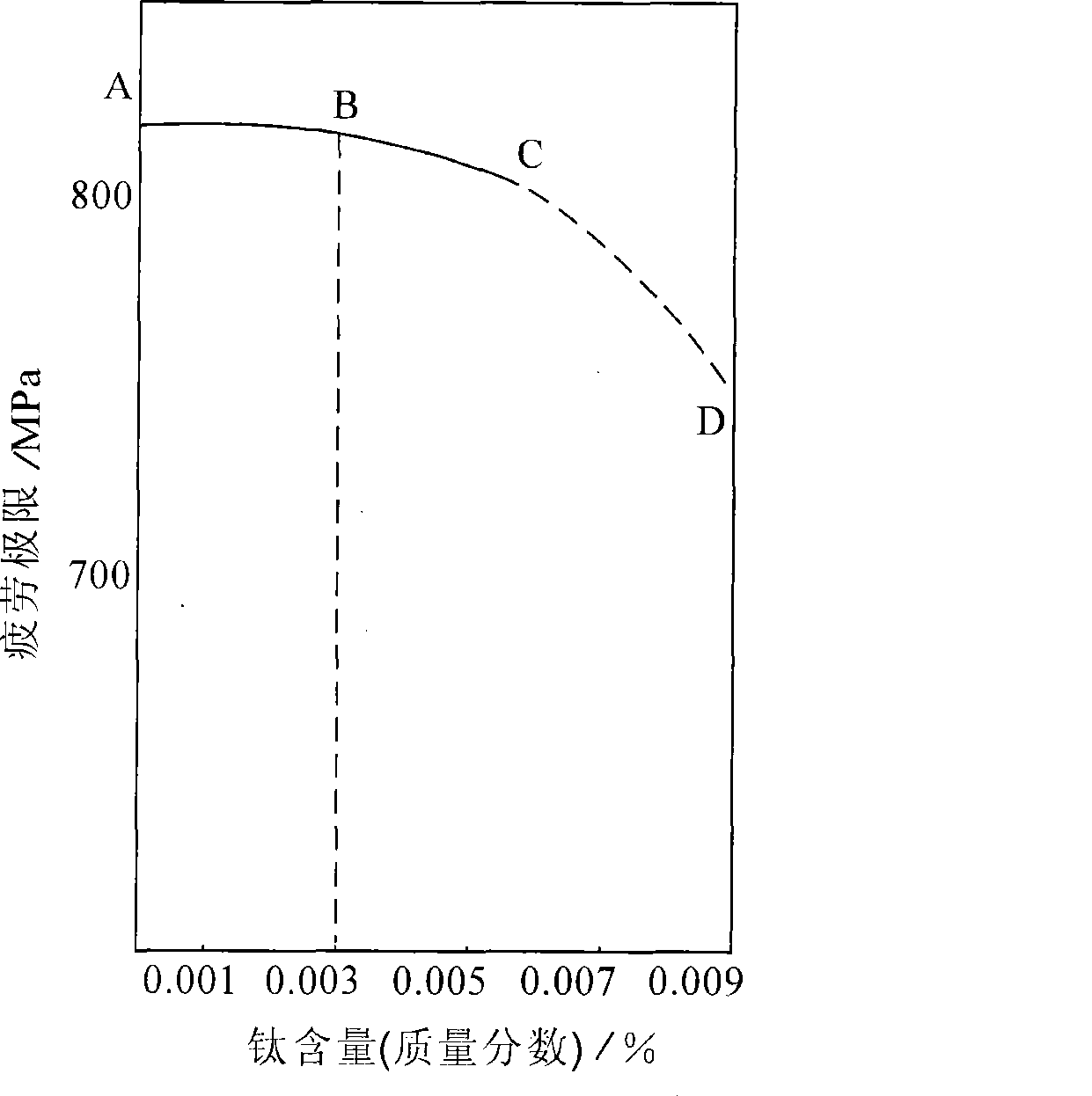

Low-cost high-purity medium carbon bearing steel for automobile hub and manufacturing method thereof

A technology for automobile wheel hubs and medium carbon bearings, which is applied in the direction of temperature control, etc., can solve the problems of reducing fatigue life, low lower limit composition, and unreachable hardness, and achieves good wear resistance and fatigue life, less oxide inclusions, Production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

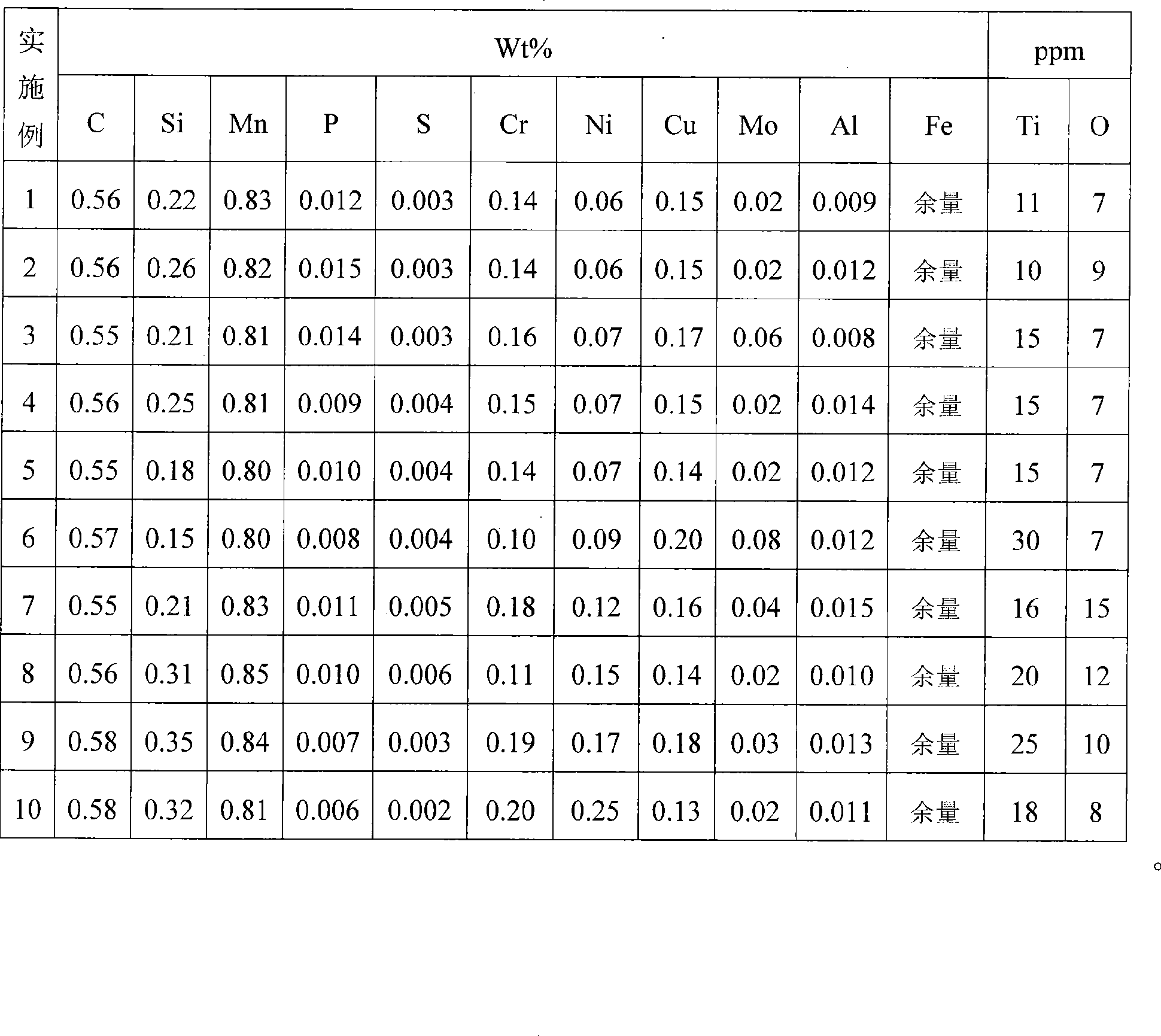

[0051] Implement the method of the present invention, adopt three-step production process: smelting (primary smelting in electric furnace+ladle furnace refining+vacuum degassing); continuous casting; continuous rolling, and successfully produced medium carbon bearing steel for automobile wheel hubs; see Table 2 for ingredients.

[0052] In the first step, the molten steel is initially smelted in an EBT (EBT, eccentric bottom tapping technology) electric furnace (EAF), followed by argon blowing refining in a ladle furnace with a matching capacity, and vacuum refining in a ladle furnace with a matching capacity. Degassing treatment:

[0053] The batching, smelting and tapping of the primary smelting furnace follow the conventional process; during the refining process of the ladle furnace, ensure that the molten steel does not expose the slag surface; when the temperature rises to melt the slag, and when the top slag melts into a liquid state, add lime 2-4Kg / t in 1-2 batches, At ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com