Preparation method of alloyed hot-galvanized dual-phase steel

A dual-phase steel and alloying technology, applied in hot-dip plating process, metal material coating process, coating, etc., can solve the problems of poor hole expansion of dual-phase steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

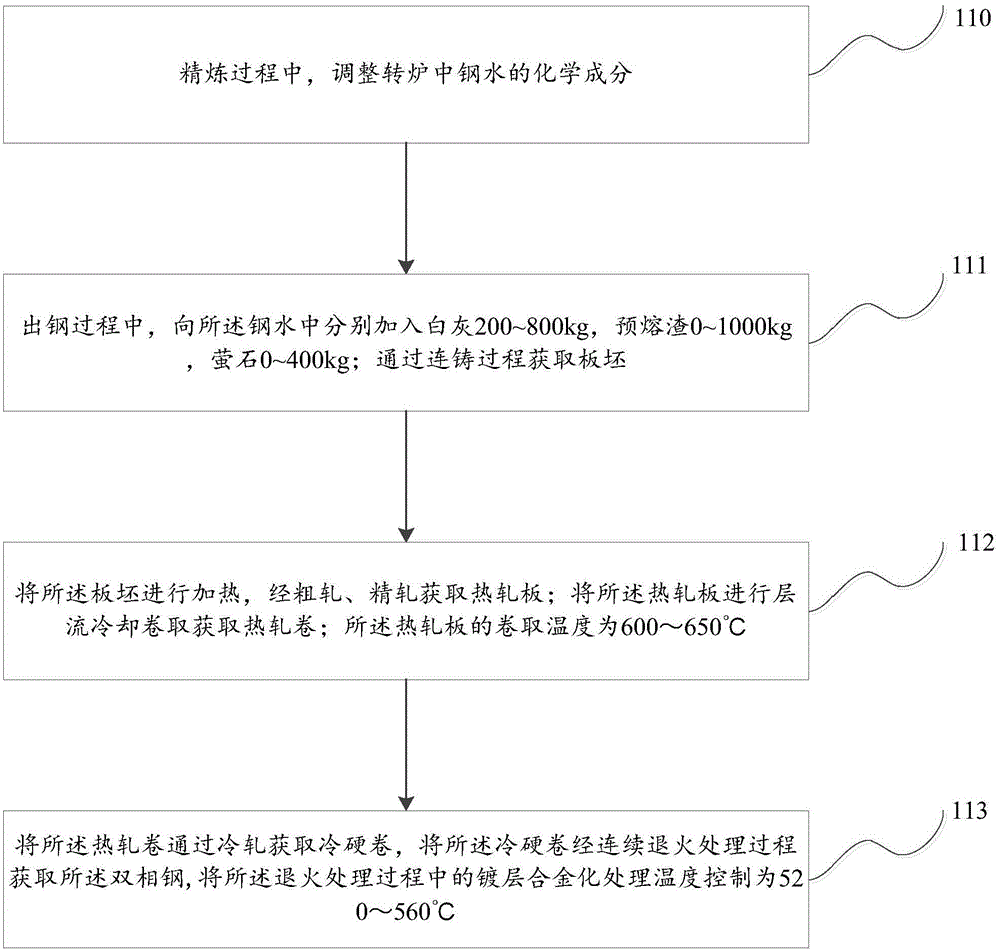

Method used

Image

Examples

Embodiment 2

[0066] In order to verify the preparation method of the dual-phase steel provided by the present invention, the experiment was carried out at different coiling temperature, second heating temperature and galvanizing alloying temperature in this embodiment.

[0067] Specifically, the chemical composition table of the molten steel is shown in Table 1:

[0068] Table 1

[0069] C

[0070] As shown in Table 1, the weight percentage of C is 0.09%; the weight percentage of Si is 0.2%; the weight percentage of Mn is 1.5%; the weight percentage of Als is 0.036%; the weight percentage of P The percentage is 0.002%; the weight percentage of S is 0.002%; the weight percentage of Cr is 0.2%; the weight percentage of Mo is 0.22%; the weight percentage of Nb is 0.03%.

[0071] Test the molten steel under four different test conditions to test the hole expansion rate and yield strength of dual-phase steel;

[0072] The first test includes: setting the coiling temperature to 690°C, the second heati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com