Method for improving corrosion resistance of magnesium alloy through laser shock peening and magnetron sputtering

A laser shock strengthening, magnetron sputtering technology, applied in sputtering coating, metal material coating process, ion implantation coating and other directions, can solve the poor adhesion between the substrate and the metal glass film, the atomic diffusivity of metal glass film It can improve the corrosion resistance, improve the hardness, and reduce the hardness difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

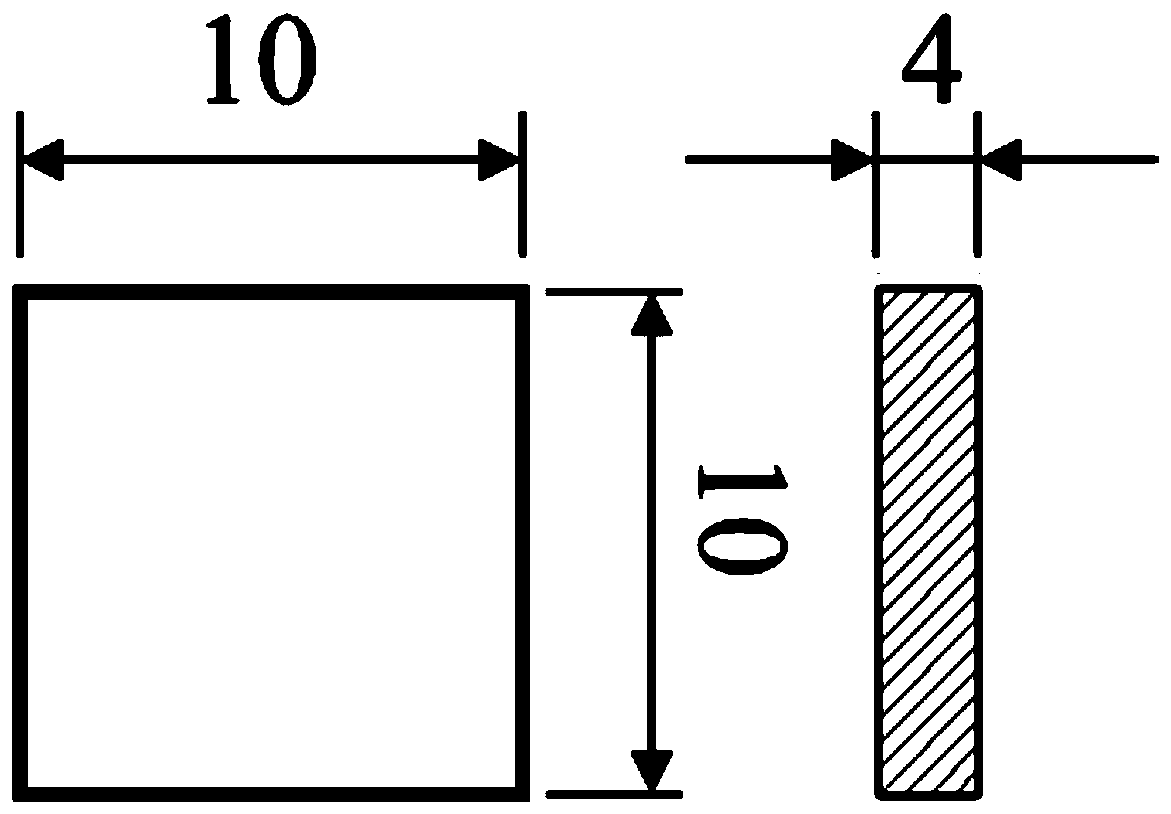

[0025] (1) Select three magnesium alloy samples with a size of 10mm×10mm×4mm (length×width×thickness) for the test, which are respectively recorded as samples A, B and C. The schematic diagram of the sample size is as follows figure 1 . Use metallographic sandpaper with sandpaper meshes of P400, P800, P1500, P2000, and P3000 to grind samples A, B, and C step by step, and then polish the workpiece with diamond spray polishing agent and polishing cloth;

[0026] (2) Set the relevant process parameters of laser shock strengthening: wavelength 1064nm, pulse width 12ns, single pulse energy 10J, frequency 1Hz, spot diameter 2mm, spot overlap rate between rows and columns 50%, constrained layer 2mm thick running water;

[0027] (3) The magnesium alloy samples B and C are controlled by the manipulator to move them to the focus point of the laser beam, and the magnesium alloy surface is subjected to large-area laser lap impact strengthening by the method of line-by-line processing;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com