High-toughness synthetic cast iron cylinder-sleeve material and manufacturing process

A technology of synthetic cast iron and manufacturing process, which is applied in the field of cylinder liner material preparation, can solve problems such as unproposed product application and casting process method, unsuitable for large-scale industrial production, complex inoculation process, etc., to achieve increased rigidity, Good processing performance and uniform hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

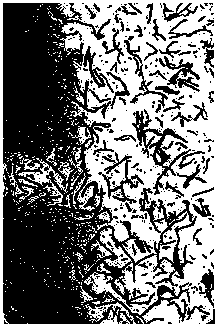

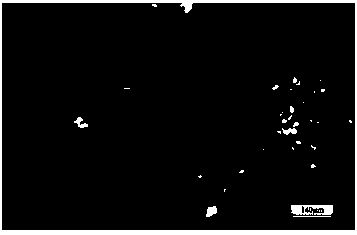

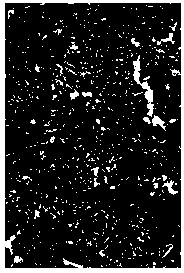

Image

Examples

Embodiment 1

[0031] 1. Selection of scrap steel: scrap steel has low carbon content, and the control of harmful substances within the composition range is strict. Based on the characteristics of scrap steel with stable carbon content and less impurities, scrap steel is selected as the primary raw material for high-strength cylinder liners, and pig iron is directly eliminated. raw materials.

[0032] Because scrap steel kind is a lot, and the scrap steel carbon content of different kinds is different, and the kind and the content of the alloy element in the steel also have very big difference, the scrap steel that the present invention selects is low-carbon steel (A3 ship plate shearing material, thread cutting head, Channel steel, angle steel cut head, etc.).

[0033] Table 1 Chemical composition requirements of steel scrap

[0034]

[0035] 2. Carbon-increasing and silicon-increasing, carbon-reducing inoculation treatment

[0036]Add 800kg of steel scrap into the intermediate frequ...

Embodiment 2

[0045] 1. Selection of scrap steel: scrap steel has low carbon content and strict control of harmful substances within the composition range. Based on the characteristics of scrap steel with stable carbon content and less impurities, scrap steel is selected as the primary raw material for high-strength cylinder liners, and pig iron is directly eliminated. raw materials.

[0046] Because scrap steel kind is a lot, and the scrap steel carbon content of different kinds is different, and the kind and the content of the alloy element in the steel also have very big difference, the scrap steel that the present invention selects is low carbon steel (A3 ship plate shearing material, thread cutting head, Channel steel, angle steel cut head, etc.).

[0047] Table 3 Chemical Composition Requirements of Steel Scrap

[0048]

[0049] 2. Carbon-increasing and silicon-increasing, carbon-reducing inoculation treatment

[0050] Add 700kg of scrap steel into the intermediate frequency el...

Embodiment 3

[0059] 1. Selection of scrap steel: scrap steel has low carbon content and strict control of harmful substances within the composition range. Based on the characteristics of scrap steel with stable carbon content and less impurities, scrap steel is selected as the primary raw material for high-strength cylinder liners, and pig iron is directly eliminated. raw materials.

[0060] Because scrap steel kind is a lot, and the scrap steel carbon content of different kinds is different, and the kind and the content of the alloy element in the steel also have very big difference, the scrap steel that the present invention selects is low carbon steel (A3 ship plate shearing material, thread cutting head, Channel steel, angle steel cut head, etc.).

[0061] Table 5 Chemical Composition Requirements of Steel Scrap

[0062]

[0063] 2. Carbon-increasing and silicon-increasing, carbon-reducing inoculation treatment

[0064] Add 600kg of steel scrap into the intermediate frequency el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com