700 MPa level automobile beam steel belt and preparation method thereof

A technology of automobile beam steel and steel strip, applied in the field of high-strength steel production, can solve the problems of low tensile strength, reduced benefit per ton of steel, limitation of beam thickness reduction, etc., achieves good forming performance, improves strength, and reduces overheating sensitivity effect of brittleness and temper brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

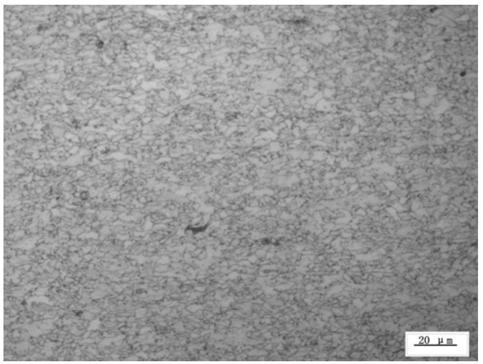

Image

Examples

preparation example Construction

[0025] In the second embodiment of the present invention, the present invention also provides a method for preparing the above-mentioned 700MPa grade automobile frame steel strip, comprising the steps of continuous casting, continuous casting slab heating, rough rolling, finish rolling, cooling and coiling.

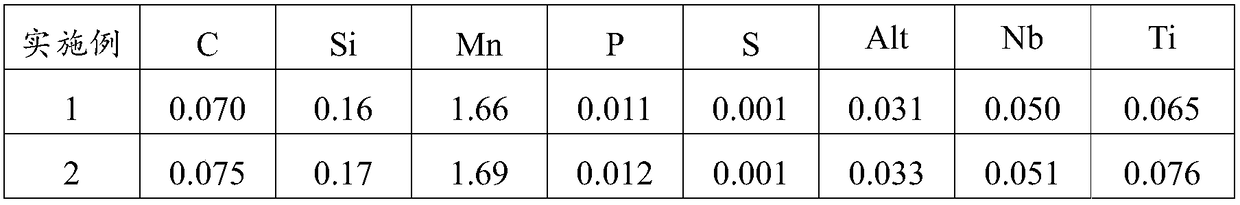

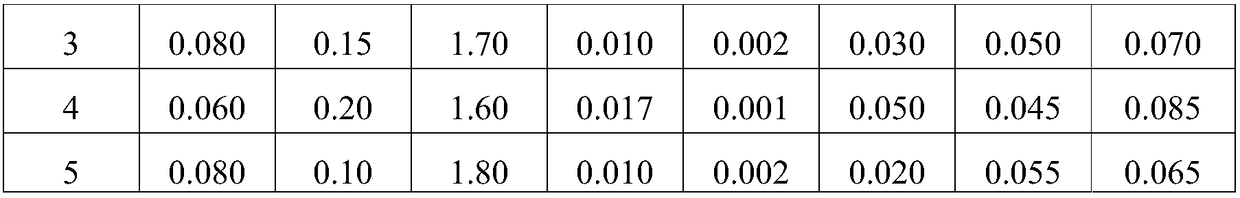

[0026]In a preferred embodiment, the above-mentioned continuous casting step includes the following steps: molten iron pretreatment, converter combined blowing, RH refining and casting machine; specifically, the molten iron is subjected to desulfurization pretreatment, and the molten iron is decarburized by top-bottom combined blowing converter smelting , Dephosphorization to obtain molten steel, the obtained molten steel is added to the converter, and the tapping temperature of the converter is ≥1620 °C; then the molten steel after converter smelting is subjected to the LF refining process, and ferromanganese, ferrosilicon, ferroniobium and other alloys are added according...

Embodiment 1

[0033] Embodiment 1: the preparation of the 700MPa grade automobile frame steel strip of the present invention

[0034] The molten iron is subjected to desulfurization pretreatment, and the molten iron is decarburized and dephosphorized by top-bottom combined blowing converter smelting to obtain molten steel. Scrap steel is added to the converter, and the tapping temperature of the converter is ≥1620°C. Then, the molten steel after converter smelting is subjected to the LF refining process, and alloys such as ferromanganese, ferrosilicon, and ferro-niobium are added according to the composition of the molten steel to adjust to the target composition. After LF refining, the molten steel is subjected to RH operation. After the RH vacuum treatment, adjust the argon flow to make the molten steel in a soft blowing state, and feed the Si-Ca wire for calcium treatment. After feeding the wire, ensure that the soft blowing time is greater than 8 minutes to prevent the molten steel from ...

Embodiment 2

[0035] Embodiment 2: the preparation of the 700MPa grade automobile frame steel strip of the present invention

[0036] The molten iron is subjected to desulfurization pretreatment, and the molten iron is decarburized and dephosphorized by top-bottom combined blowing converter smelting to obtain molten steel. Scrap steel is added to the converter, and the tapping temperature of the converter is ≥1620°C. Then, the molten steel after converter smelting is subjected to the LF refining process, and alloys such as ferromanganese, ferrosilicon, and ferro-niobium are added according to the composition of the molten steel to adjust to the target composition. After LF refining, the molten steel is subjected to RH operation. After the RH vacuum treatment, adjust the argon flow to make the molten steel in a soft blowing state, and feed the Si-Ca wire for calcium treatment. After feeding the wire, ensure that the soft blowing time is greater than 8 minutes to prevent the molten steel from ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com