12Cr2Mo1R thick steel plate for equipment contacting hydrogen and method for producing the same

A technology of a hydrogen-prone equipment and a manufacturing method, which is applied to the 12Cr2Mo1R thick steel plate and its manufacturing field, can solve the problems that the use conditions of the hydrogen-prone equipment cannot be met, and the microstructure cannot be obtained, and achieves guaranteed performance, excellent mechanical properties, and microstructure. well organized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

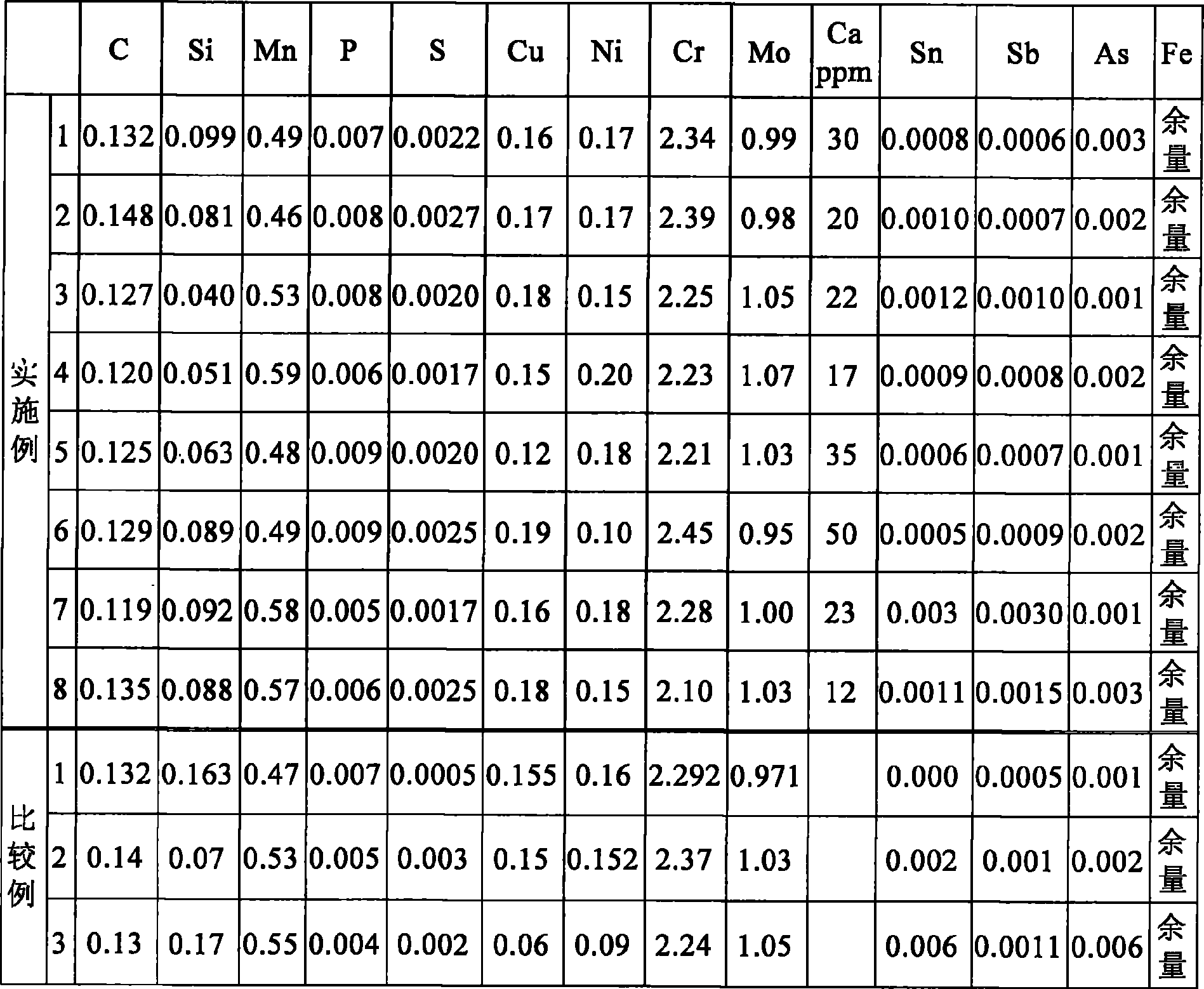

[0042] Refer to Table 1 for the embodiment of the present invention, refer to Tables 2 and 4 for the physical indicators of producing thick steel plates, and Table 3 is the comparison of the heat treatment processes.

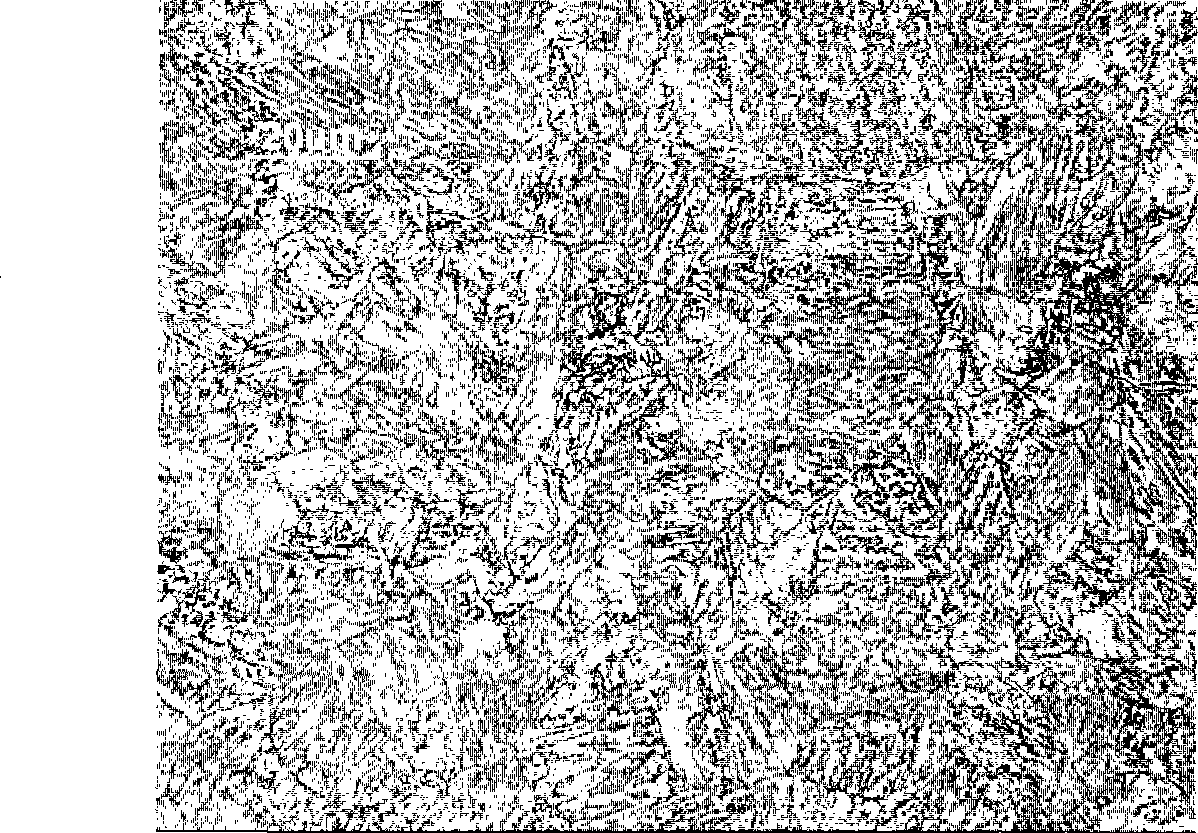

[0043] The present invention utilizes a pressure quenching machine to ensure that the microstructure of the 12Cr2Mo1R finished steel plate is tempered bainite through normalizing + accelerated cooling + tempering process, see figure 1 .

[0044] It can be seen from Table 1 that the Si content of the embodiment is lower than that of Comparative Examples 1 and 3; the contents of Sn, Sb and As are lower than that of Comparative Example 3.

[0045] As can be seen from Table 2, the J coefficient of the embodiment is higher than that of Comparative Examples 1 and 2, but much lower than that of Comparative Example 3. Example of v Tr55+2.5Δ v Tr55 was substantially equivalent to the comparative example.

[0046] It can be seen from Table 4 that the intensity of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com