Alloy steel, seamless steel pipe, manufacturing method thereof and well drilling water separating pipe

A technology of seamless steel pipe and manufacturing method, which is applied in earthwork drilling, drilling equipment, underwater drilling, etc., and can solve problems such as inability to meet the production demand of drilling risers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

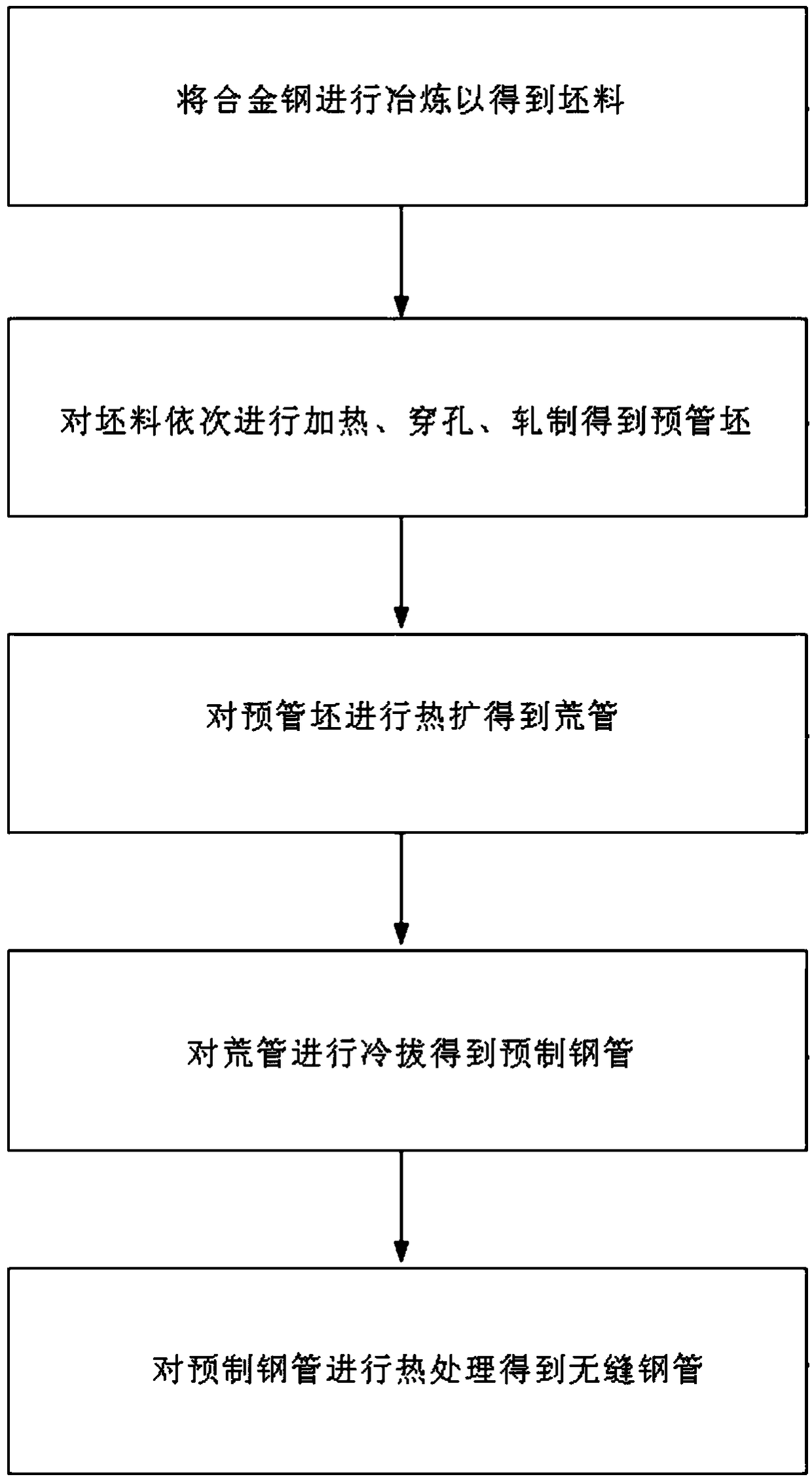

Method used

Image

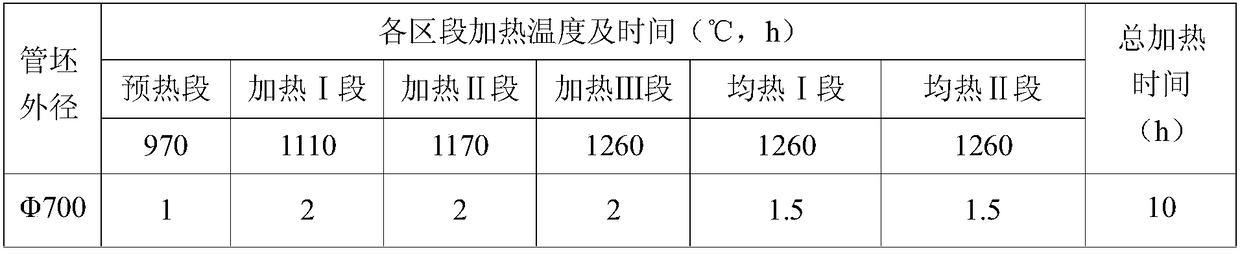

Examples

Embodiment 1

[0024] An alloy steel in Embodiment 1, calculated by weight percentage, the alloy steel includes: Fe, C, Si, Mn, Cr, Mo, Ni, Nb, P, S and Al. Among them, the content of each component is: 0.06%≤C≤0.12%, 0.20%≤Si≤0.50%, 1.30%≤Mn≤1.60%, 0.10%≤Cr≤0.50%, 0.10%≤Mo≤0.50, 0.15% ≤Ni≤0.30%, 0.01%≤Nb≤0.05%, 0.010%≤Al≤0.040%, P≤0.015%, S≤0.003%.

Embodiment 2

[0068] The manufacturing method of the seamless steel pipe of the second embodiment, wherein the difference between the second embodiment and the first embodiment is:

[0069] (1) Smelting of blanks

[0070] Add molten iron at a ratio of 500kg / t and scrap steel produced in the production of marine pipes at a ratio of 500kg / t as raw materials, smelt in a 45-ton electric furnace, refine in a 45-ton refining furnace, and add 2.5kg / t of silicon during the smelting process Iron, 17kg / t low-carbon ferromanganese, 2.0kg / t ferro-vanadium, 11kg / t micro-carbon ferrochromium, 9kg / t ferromolybdenum, and a small amount of aluminum wire and ferro-titanium, the above raw materials are used in a 45-ton vacuum degassing furnace process Carry out vacuum smelting of molten steel; then use round billet arc continuous casting machine for continuous casting; in the above process, control the refining furnace ladle hanging ladle molten steel temperature = liquidus temperature + (70 ~ 90) ± 10 ° C; t...

Embodiment 3

[0098] The manufacturing method of the seamless steel pipe of the third embodiment, wherein the difference between the third embodiment and the second embodiment is:

[0099] According to the ratio of 500kg / t to add molten iron and 500kg / t to add scrap steel produced by the production of marine pipe varieties, as raw materials, after smelting in a 45-ton electric furnace and refining in a 45-ton refining furnace, and adding 2.5kg / t during the smelting process Ferrosilicon, 17kg / t low-carbon ferromanganese, 2.0kg / t ferro-vanadium, 11kg / t micro-carbon ferrochrome, 9kg / t ferromolybdenum, and a small amount of aluminum wire and ferro-titanium, the above raw materials are used in a 45-ton vacuum degassing furnace The vacuum smelting of molten steel is carried out in the process; then the round billet arc continuous casting machine is used for continuous casting; Package baking for 3.5 hours, the baking temperature is above 1100°C; the casting speed is controlled at 0.610m / min; the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com