High-low-voltage switch cabinet having dust removing function

A high and low voltage switch and switchgear technology, applied in the field of high and low voltage switchgear, can solve the problems of reducing the service life of high and low voltage switchgear, aging of switchgear lines, poor switch use environment, etc., to improve safety and reliability, durability Improved frictional performance and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

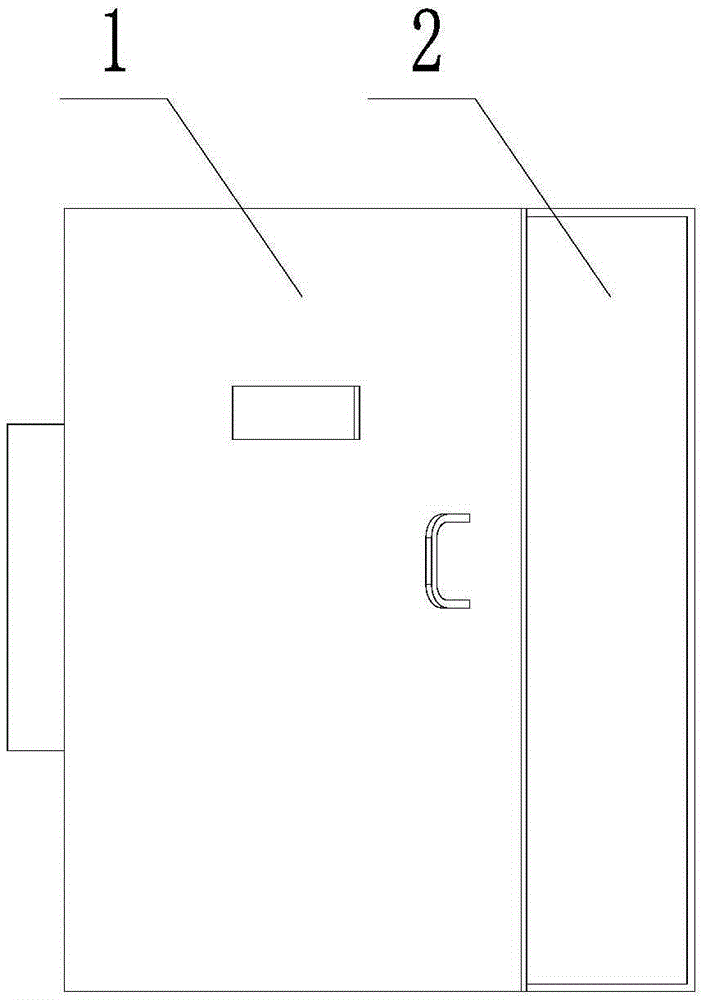

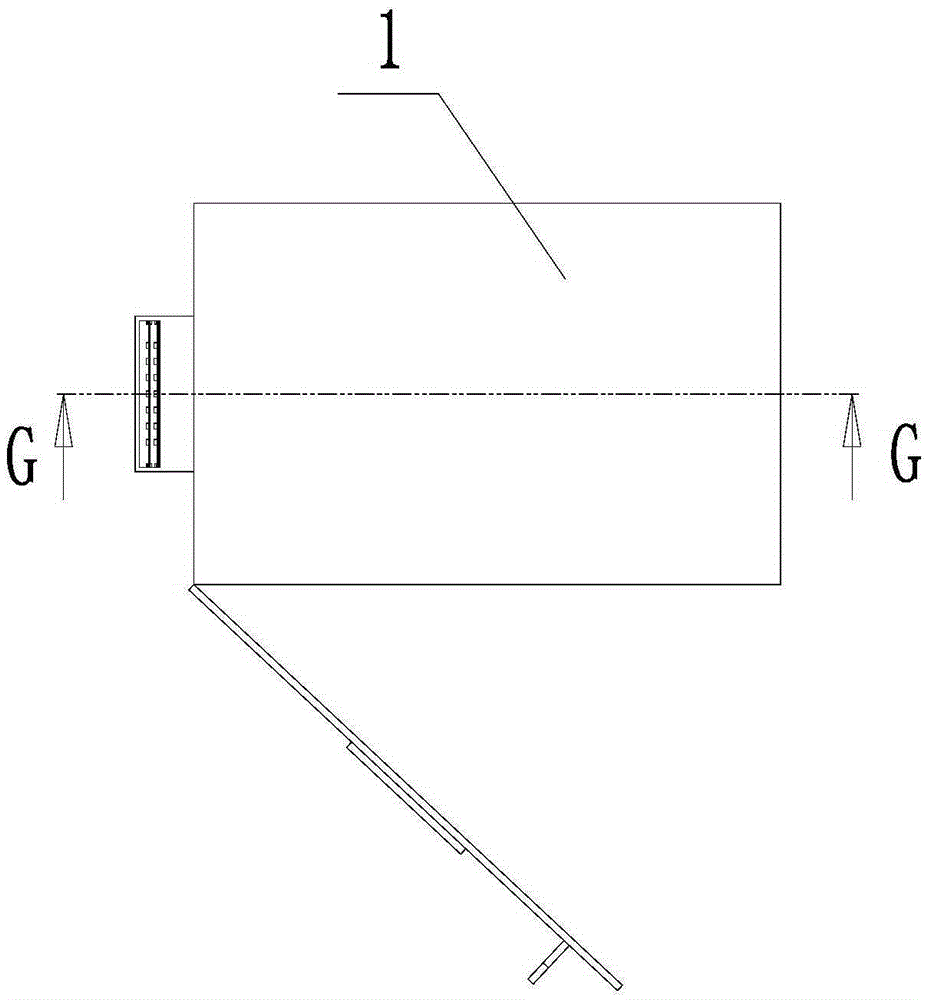

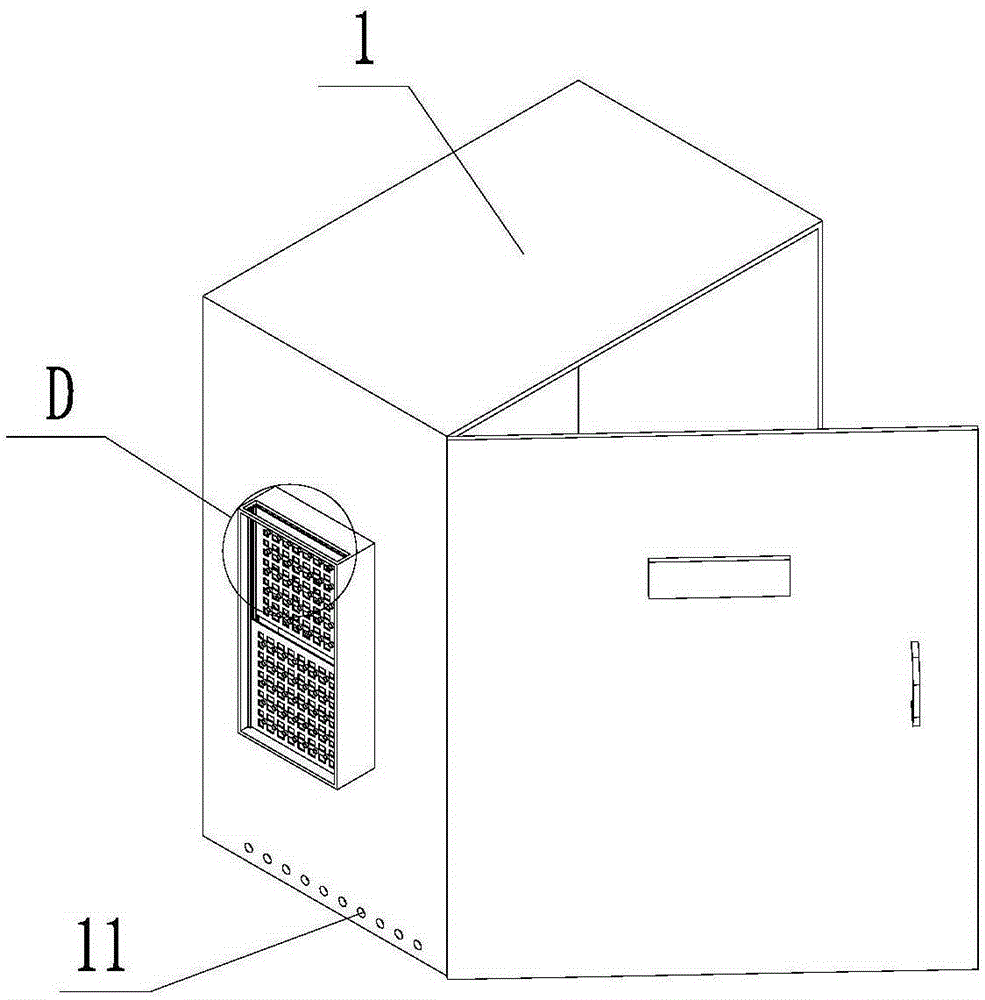

[0033]A high-voltage and low-voltage switchgear with dust removal function provided by this embodiment includes a switchgear 1 arranged horizontally. There is an installation cavity 2 inside the switchgear 1. A bracket 3 is arranged on the side wall of the switchgear 1. There is a support 4, an axial flow fan 5 is arranged on the support 4, a ventilation net 7 is arranged on the outside of the support 3 located at the axial flow fan 5, a magnet 8 is arranged on the surface of the ventilation net 7, and a magnet seat is extended outward from the ventilation net 7 10. The magnet 8 is set in the magnet seat 10, and the switch cabinet 1 is provided with an air outlet 11; the support 3 is rectangular, and the upper surface of the support 3 is provided with an opening 6 for replacing the ventilation net 7, which is parallel to the length direction inside the support 3 There are two guide rails 9, and the guide rails 9 are provided with ventilation nets 7 that can move along the guide...

Embodiment 2

[0047] This embodiment provides a high and low voltage switchgear with dust removal function, the structure of the high and low voltage switchgear with dust removal function in embodiment 2 is exactly the same as that in embodiment 1;

[0048] Wherein the outer surface of the switchgear is coated with a high-temperature-resistant metal coating, and the high-temperature-resistant metal coating includes by mass percentage: 40% of the metal mixture, 50% of the corrosion-resistant mixture, and the balance is additives;

[0049] The components of the metal mixture are: carbon: 0.15%, boron: 0.08%, chromium: 7.28%, titanium: 3.52%, gallium: 5.84%, scandium: 2.28%, niobium: 2.52%, cesium: 1.6% %, potassium: 0.4%, tungsten: 0.4%, zinc: 1.5%, germanium: 2.8%, neodymium: 3.7%, promethium: 0.35%, europium: 0.44%, gadolinium: 9.35%, lead: 0.8%, additives: 4.6%, the balance is iron;

[0050] The components of the corrosion-resistant mixture are calculated in parts by weight: water-based a...

Embodiment 3

[0061] This embodiment provides a high and low voltage switchgear with dust removal function, the structure of the high and low voltage switchgear with dust removal function in embodiment 3 is exactly the same as that in embodiment 1;

[0062] Among them, the high-temperature-resistant metal coating includes by mass percentage: 38% of metal mixture, 40% of corrosion-resistant mixture, and the balance is additives;

[0063] The outer surface of the switchgear is coated with a high-temperature-resistant metal coating, and the components of the metal coating are: carbon: 0.13%, boron: 0.07%, chromium: 7.26%, titanium: 3.28%, gallium: 5.58% , scandium: 2.26%, niobium: 2.29%, cesium: 1.5%, potassium: 0.3%, tungsten: 0.3%, zinc: 1.4%, germanium: 2.6%, neodymium: 3.5%, promethium: 0.34%, europium: 0.28% , gadolinium: 9.26%, lead: 0.5%, additives: 4.5%, and the balance is iron;

[0064] The components of the corrosion-resistant mixture are calculated in parts by weight: water-based a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com