Piezoelectric buried damage self-diagnosis asphalt concrete pavement structure

A technology of asphalt concrete and pavement structure, which is applied to the coagulation pavement, roads, roads and other directions of on-site paving, can solve the problems of increased axle load of trucks, increased maintenance cost, early damage of asphalt concrete pavement, etc., and achieves a reasonable size effect on strength, good road performance and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

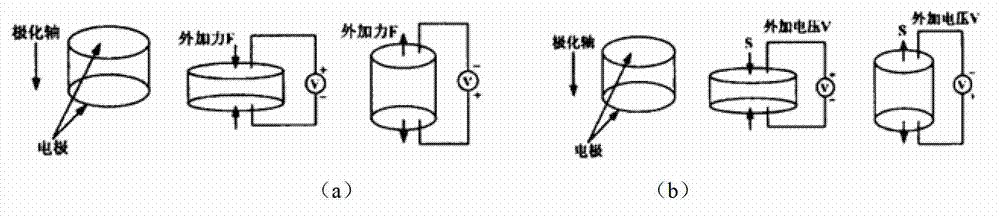

Method used

Image

Examples

Embodiment 1-5

[0026] In following embodiment 1-5:

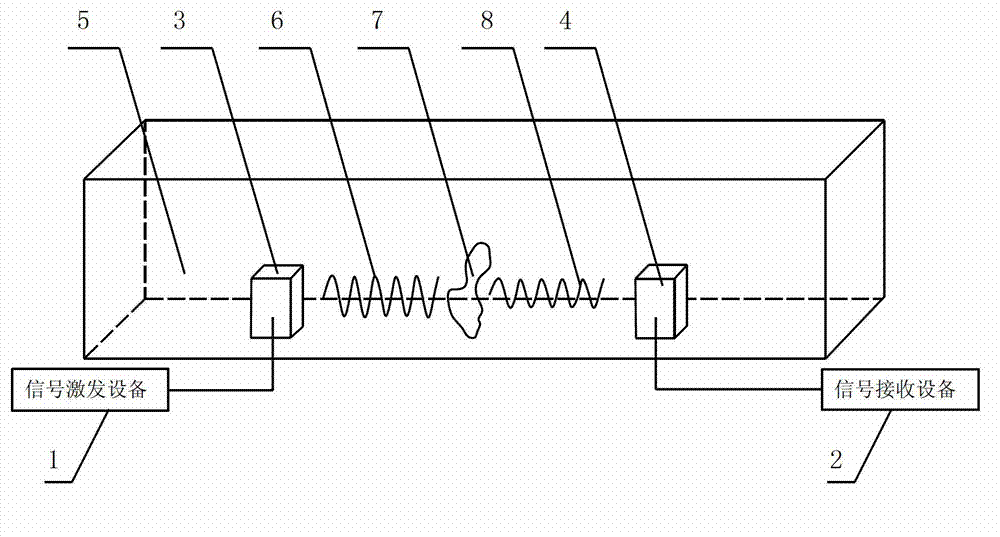

[0027] Such as image 3 As shown, the piezoelectric embedded damage self-diagnosis asphalt concrete pavement structure includes: an asphalt concrete pavement structure 5 formed by pouring asphalt concrete, at least two piezoelectric self-diagnosis units (one piezoelectric self-diagnostic unit 3 and another piezoelectric self-diagnostic unit 4), and an auxiliary diagnostic device electrically connected to the piezoelectric self-diagnostic unit.

[0028] In accordance with the relevant provisions of "Technical Specifications for Asphalt Construction on Highway" (JTG F40-2004), select coarse aggregate, fine aggregate, asphalt and mineral powder that meet the requirements. Fully combine the existing gradation AC, SMA, Superpave and other structures with gradation design theories, optimize and improve the original gradation, find out the best gradation, and make its composition meet the requirements of the piezoelectric self-diagnostic unit tha...

Embodiment 1

[0059] The mass ratio of common asphalt concrete (being bituminous concrete) in embodiment 1: coarse aggregate 56%, fine aggregate 40%, slag powder 4% (the weight percentage sum of coarse aggregate, fine aggregate and slag powder is 100 %, the same as in the following examples); the asphalt ratio is 4.8% (that is, the amount of asphalt added is 4.8% of the mass of coarse aggregate, fine aggregate and mineral powder), and the embedded length L=2cm, width W=2cm, thickness T = 3cm piezoelectric self-diagnostic unit. Other see above. Example 1 According to the compaction method T0702-2011 in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTGE20-2011), the Marshall test piece is formed, and the piezoelectric self-diagnosis unit is embedded during the forming. Its piezoelectric performance index is shown in Table 1. It can be seen from the table that the piezoelectric damage self-diagnosis asphalt concrete prepared by the present invention has excel...

Embodiment 2 and Embodiment 3

[0061] The mass ratio of ordinary asphalt concrete (i.e. asphalt concrete) in embodiment 2: coarse aggregate 56%, fine aggregate 40%, mineral powder 4%; Asphalt ratio is 4.8% (namely the addition of asphalt is coarse aggregate, fine aggregate 4.8% of the mass of aggregate and mineral powder), without embedded piezoelectric self-diagnostic unit, as a comparative example.

[0062] The mass ratio of ordinary asphalt concrete (i.e. asphalt concrete) in embodiment 3: coarse aggregate 56%, fine aggregate 40%, mineral powder 4%; The asphalt ratio is 4.8% (i.e. the addition of asphalt is coarse aggregate, fine aggregate 4.8% of the mass of aggregate and mineral powder), but a piezoelectric self-diagnosis unit with length L=2cm, width W=2cm, and thickness T=3cm is embedded in it. Examples 2 and 3 were formed according to the wheel rolling method of T0703-2011 in the "Test Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTG E20-2011), and the piezoelectric self-dia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com