Mullite-based coating material for rocket launching pad and application of mullite-based coating material

A rocket launch, mullite-based technology, applied in the field of refractory materials, can solve the problems of heavy weight, inability to move the launch platform, thick thickness, etc., to achieve reduced porosity, good resistance to rocket tail flame simulation gas flow erosion, The effect of increasing bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

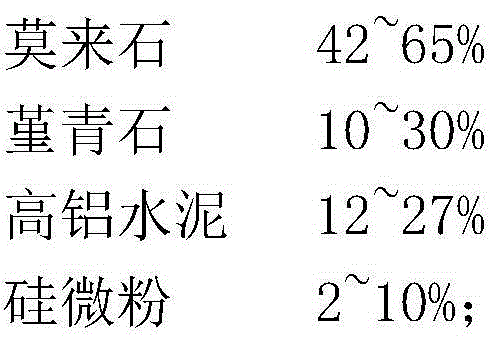

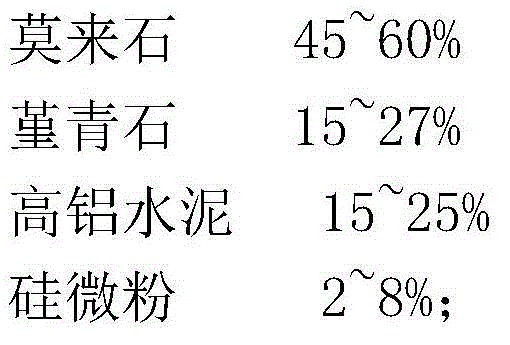

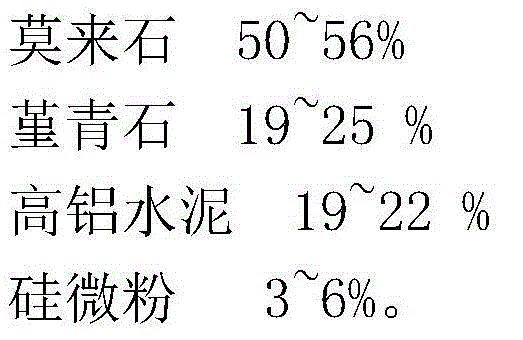

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Take by weight ratio mullite with a particle size of 5-3mm, 26 parts; mullite with a particle size of 3-1mm, 26 parts; cordierite particles with a particle size of 0.5-1mm, 24 parts; Secar71 cement, 20 parts; 970 type silica fume, 4 parts; water, 13 parts (additional).

Embodiment 2

[0028] Example 2 Weigh 24 parts of mullite with a particle size of 5-3mm according to the weight ratio; 26 parts of mullite with a particle size of 3-1mm; 25 parts of cordierite particles with a particle size of 0.5-1mm; Secar71 cement, 19 parts; 970 type silica fume, 6 parts; water, 12.5 parts (additional).

Embodiment 3

[0029] Example 3 Take 28 parts of mullite with a particle size of 5-3mm according to the weight ratio; 28 parts of mullite with a particle size of 3-1mm; 19 parts of cordierite particles with a particle size of 0.5-1mm; Secar71 cement, 22 parts; 970 type silica fume, 3 parts; water, 14 parts (additional).

[0030] The preparation method of embodiment 1-3 is: take various raw materials according to the weight ratio, first add 5-3mm and 3-1mm mullite particles and 0.5-1mm cordierite particles and mix evenly, stir in the mixer for 2-3 Minutes, then add other powder and stir for 6-8 minutes. Finally, add water and stir for 3-5 minutes.

[0031] The mullite smear for the rocket launch pad prepared by adopting the above-mentioned raw material weight ratio and production method, the main aggregate uses raw materials of different particle size grades, wherein the raw materials with larger particle sizes play the role of skeleton, and the raw materials with smaller particle sizes play...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com