Aggregates used for preparing tin bath bottom bricks and preparation method thereof and tin bath bottom bricks

A tin bath bottom brick and aggregate technology, which is applied in the field of refractory materials, can solve the problems of low bulk density, high apparent porosity, nephrite petrochemical of tin bath bottom bricks, etc., and achieves uniform pore distribution, simple process and good thermal insulation effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

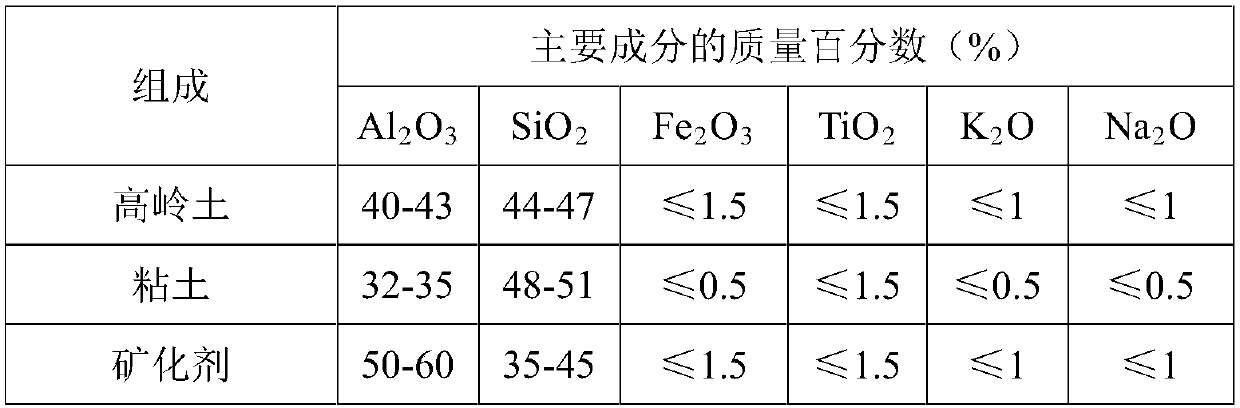

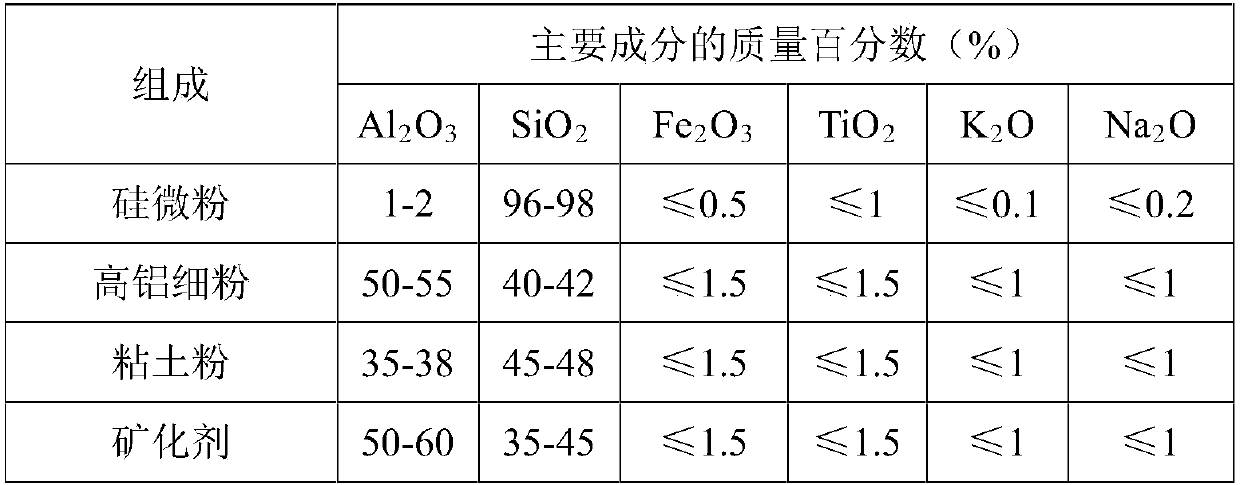

[0028] The preparation method of the aggregate used to prepare tin bath bottom bricks provided by the present invention comprises the following steps: mixing kaolin, clay, alumina powder and mineralizer with water to make a billet, then curing and drying, and then drying at 1600~ It is fired at 1700°C and crushed to obtain it.

[0029] Preferably, Al in the kaolin 2 o 3 The mass fraction is not less than 40%, Fe 2 o 3 The mass fraction is not more than 2.0%. Further preferably, Fe in the kaolin 2 o 3 The mass fraction is not more than 1.5%. The fineness of the kaolin is not more than 250 mesh.

[0030] Preferably, Al in the clay 2 o 3 The mass fraction is not less than 32%, Fe 2 o 3 The mass fraction is not more than 0.5%. Preferably, the fineness of the clay is not greater than 250 mesh.

[0031] Preferably, the fineness of the alumina powder is not greater than 120 mesh.

[0032] Preferably, the kaolin, clay and mineralizer used in the preparation of the aggreg...

Embodiment 1

[0059] The aggregate used to prepare tin bath bottom bricks in this embodiment is silicon-aluminum clinker, which includes the following components in mass percentage: Al 2 o 3 45.84%, SiO 2 48.95%, Fe 2 o 3 0.79%. The particle size of silicon-aluminum clinker is 0.1-5mm, and the bulk density is 2.30g / cm 3 , the apparent porosity is 5.66%, and the water absorption is 2.35%.

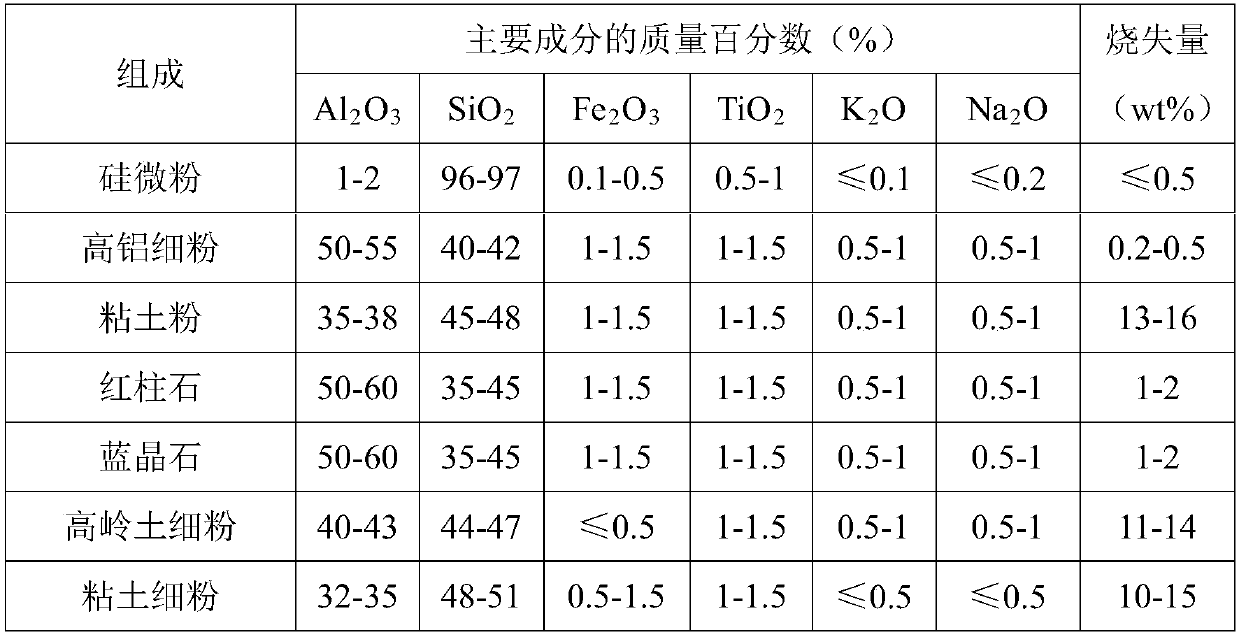

[0060] The aggregate used to prepare tin bath bottom bricks in this embodiment is mainly made of the following raw materials in parts by weight: 25 parts by weight of kaolin fine powder, 60 parts by weight of clay fine powder, 10 parts by weight of industrial alumina fine powder, mineralized Agent 5 parts by weight; The mineralizer that adopts is andalusite.

Embodiment 2

[0062] The aggregate used to prepare tin bath bottom bricks in this embodiment is silicon-aluminum clinker, which includes the following components in mass percentage: Al 2 o 3 45.75%, SiO 2 49.15%, Fe 2 o 3 0.78%. The particle size of silicon-aluminum clinker is 0.1-5mm, and the bulk density is 2.30g / cm 3 , the apparent porosity is 4.25%, and the water absorption is 2.1%.

[0063] The aggregate used to prepare tin bath bottom bricks in this embodiment is mainly made of the following raw materials in parts by weight: 20 parts by weight of kaolin fine powder, 65 parts by weight of clay fine powder, 8 parts by weight of industrial alumina fine powder, mineralized Agent 7 parts by weight; The mineralizer that adopts is kyanite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| cylinder compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com