Flint clay based unshaped refractory material for rocket launching stand

A technology for rocket launch and refractory materials, which is applied in the field of coke-based amorphous refractory materials for rocket launch pads and amorphous refractory materials for rocket launch pads. It can solve the problems of heavy weight, inability to move the launch pad, and thick thickness. Achieve the effects of reducing porosity, good resistance to rocket plume gas flow erosion, and increasing bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] According to the weight ratio, take 30 parts of burnt gemstone with a particle size of 6-35M; 30 parts of burnt gemstone powder with a particle size of 100-325M; 15 parts of cordierite particles with a particle size of 0.5-1mm; high alumina cement, 20 parts ; Silica fume, 5 parts; Water, 18 parts (additional).

[0012] The preparation method is as follows: weighing various raw materials according to the above-mentioned weight ratio, firstly adding particles with a size of 0.5-1mm or more and mixing evenly, stirring in a mixer for 2-3 minutes, and then adding other powder materials and stirring for 10-15 minutes. Finally, add water and stir for 3-5 minutes.

[0013] The coke gem-based amorphous refractory materials for rocket launch pads prepared by adopting the above raw material weight ratio and production method, the main aggregate uses raw materials of different particle size grades, wherein the raw materials with larger particle sizes play the role of skeleton, and ...

Embodiment 2

[0015] According to the weight ratio, take 32 parts of burnt gemstone with a particle size of 6-35M; 32 parts of burnt gemstone powder with a particle size of 100-325M; 10 parts of cordierite particles with a particle size of 0.5-1mm; high alumina cement, 19 parts parts; silica fume, 7 parts; water, 17 parts (additional). The production process and effect are the same as above.

Embodiment 3

[0017] According to the weight ratio, take 28 parts of burnt gemstone with a particle size of 6-35M; 29 parts of burnt gemstone powder with a particle size of 100-325M; 17 parts of cordierite particles with a particle size of 0.5-1mm; high alumina cement, 22 parts parts; silica fume, 4 parts; water, 17.5 parts (additional). The production process and effect are the same as above.

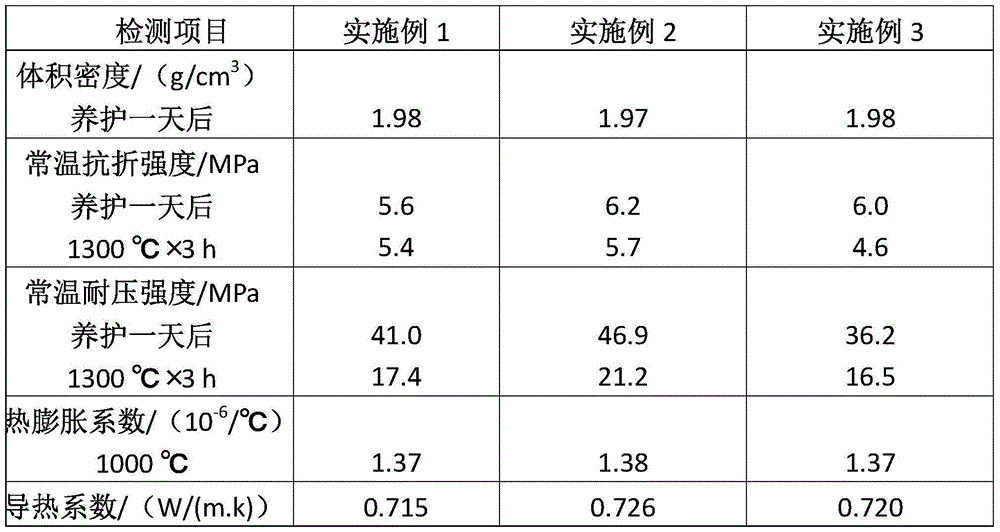

[0018] The following table shows the physical properties of the coke gem-based monolithic refractory materials used in the rocket launch pads prepared in the above examples.

[0019]

[0020] The physical and chemical performance parameters in the table were measured according to the following standards:

[0021] Bulk density is measured according to YB / T5200-1993 dense refractory castable apparent porosity and bulk density test method;

[0022] The room temperature flexural strength is determined according to GB / T3001-2007 test method for room temperature flexural strength of refractory materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com