Lightweight, heat-insulation and fire-proof castable composition, and application and preparation method thereof

A technology for refractory castables and compositions, which is applied in the field of refractory materials, can solve the problems of large environmental hazards, impact on the health of construction workers, and short lifespan, and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

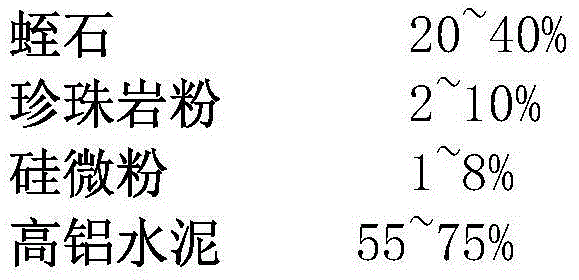

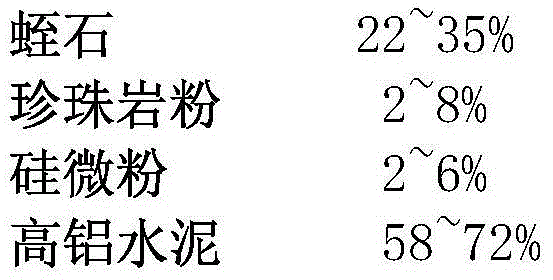

[0025] Example 1 Take by weight the vermiculite with a particle size of 4-10 mesh, 12 parts; the vermiculite with a particle size of 10-28 mesh, 13 parts; the perlite powder with a particle size of 0.425-3mm, 5 parts; the silicon micropowder, 3 parts ; High-alumina cement, 67 parts; a total of 100 parts of solid, plus water, 95 parts.

[0026] The production method is: weigh various raw materials according to the above weight ratio, first add 4-10 mesh and 10-28 mesh vermiculite particles and perlite powder particles and mix evenly, stir in a mixer for 2 to 3 minutes, and then add other Stir the powder for 6-8 minutes. After mixing evenly, add 95 parts of water gradually, and stir while adding water, so that the solid and liquid are fully mixed. Stir for 3-5 minutes to form a castable with good fluidity.

Embodiment 2

[0027] Example 2 Weigh 13 parts of vermiculite with a particle size of 4-10 mesh according to the weight ratio; 16 parts of vermiculite with a particle size of 10-28 mesh; 3 parts of perlite powder with a particle size of 0.425-3mm; silicon micropowder, 4 parts ; High-alumina cement, 64 parts; Additional water, 95 parts, the preparation method is the same as in Example 1.

Embodiment 3

[0028] Example 3 Weigh 11 parts of vermiculite with a particle size of 4-10 mesh according to the weight ratio; 17 parts of vermiculite with a particle size of 10-28 mesh; 7 parts of perlite powder with a particle size of 0.425-3mm; microsilica powder, 5 parts ; A high alumina cement, 60 parts; add water, 95 parts, the preparation method is the same as in Example 1.

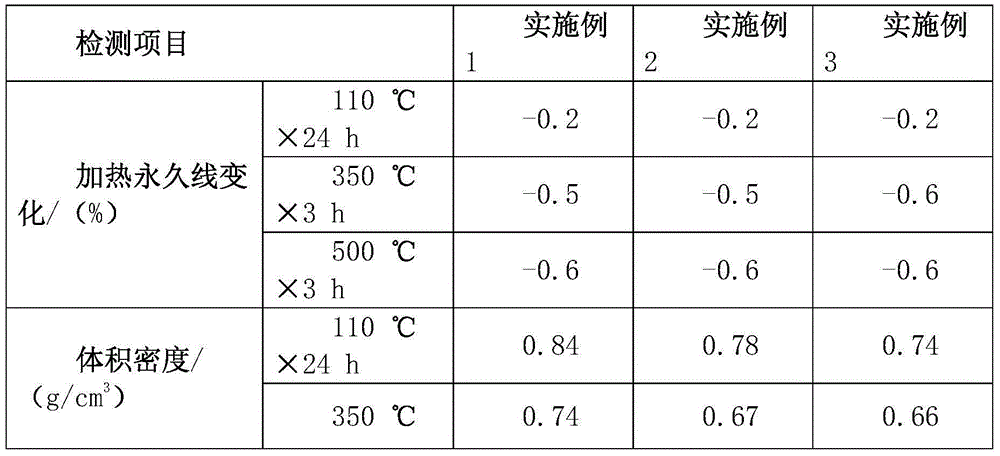

[0029] Table 1 shows the physical properties of the lightweight, heat-insulating and refractory castable compositions prepared in the above examples.

[0030] Table 1

[0031]

[0032]

[0033] The physical and chemical performance parameters in the table were measured according to the following standards:

[0034] The heating permanent line change is determined according to GB / T5988-2007 test method for heating permanent line change of refractory materials;

[0035] Bulk density is measured according to YB / T5200-1993 dense refractory castable apparent porosity and bulk density test method;

[0036] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com