Manufacture method of bamboo curtain sheets

A production method and technology for curtain sheets, which are applied in the joining of wooden veneers, manufacturing tools, wood processing appliances, etc., can solve problems such as blade side bending, improve the ability to resist side bending, improve the utilization rate, strength and toughness reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

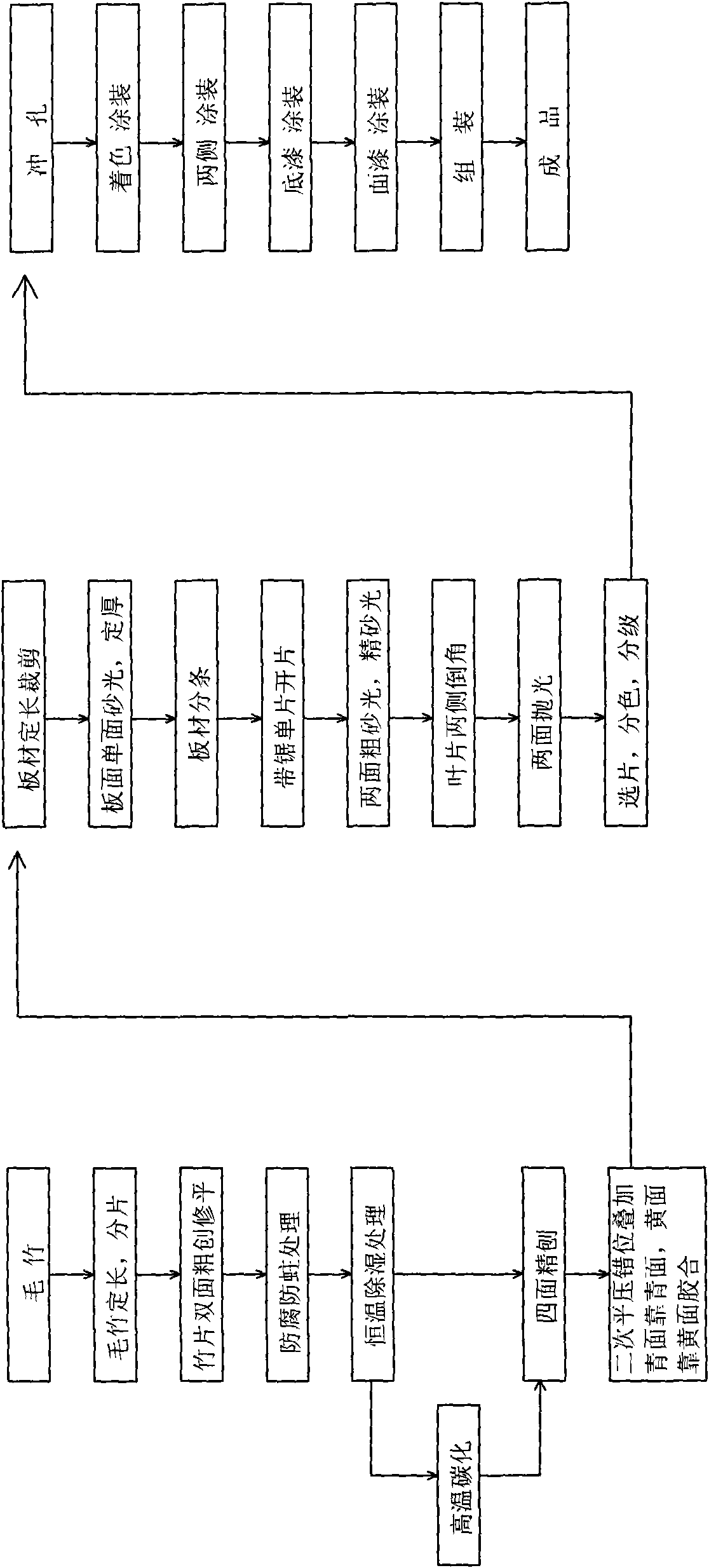

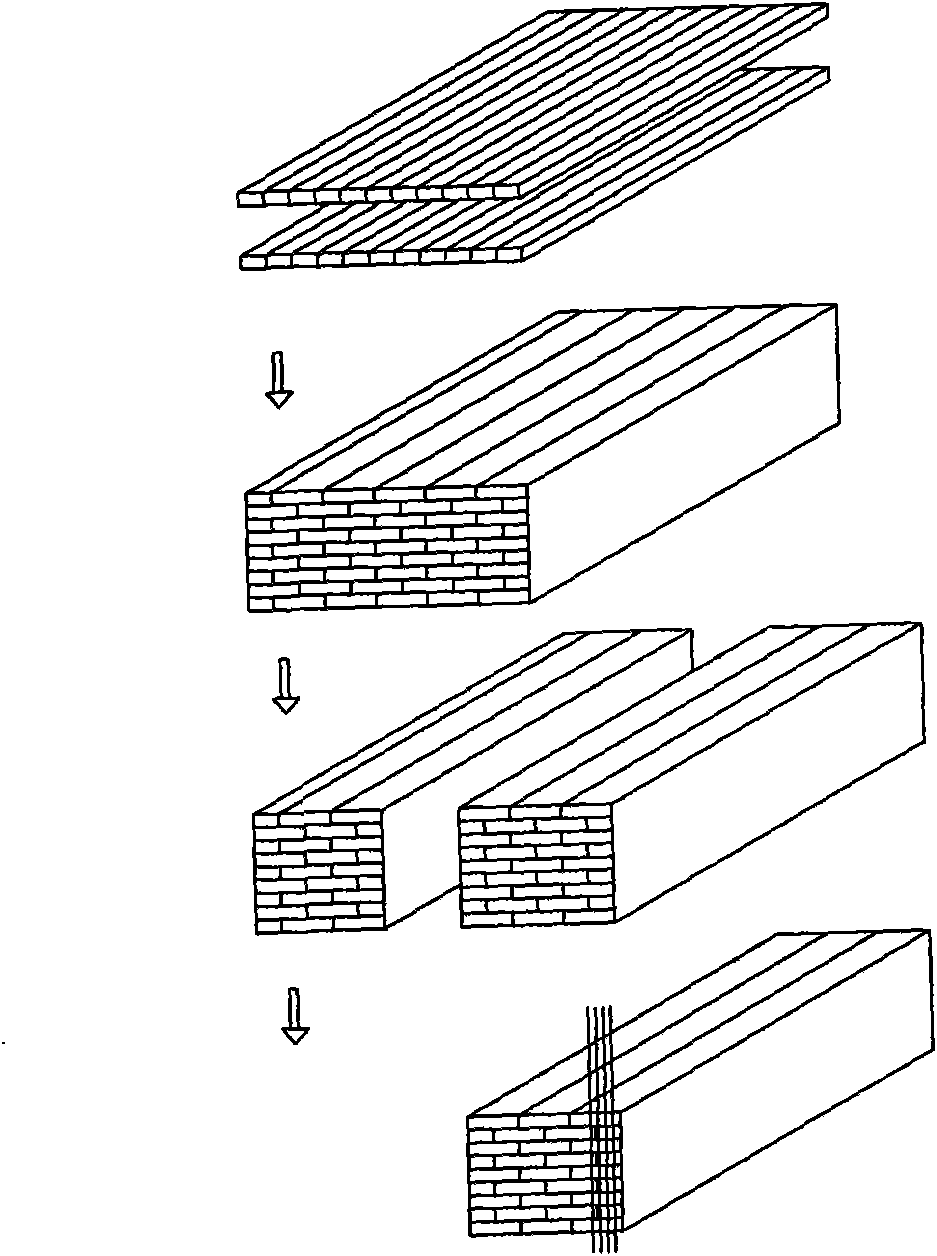

[0022] Embodiment: present embodiment selects suitable moso bamboo, mainly with the moso bamboo more than four years bamboo age, and moso bamboo diameter is 5~14 inches, and thickness is 6 millimeters~28 millimeters, and technological process sees figure 1 shown. First, fix the length of moso bamboo according to the required size, adjust the size of the bamboo slices, collide with the machine to open the bamboo strips, remove the bamboo inner nodes, bamboo yellow, and bamboo green, and at the same time flatten the four sides of the bamboo slices, take the fine and flat parts, and cut them out. Obtaining the bamboo strips with a width of 12mm-32mm and doing anti-corrosion and anti-moth treatment (boiling for 6.5 hours with diluted industrial hydrogen peroxide), then drying at a constant temperature, and doing four-sided fine planing to the required size, such as figure 2 As shown, the glued bamboo strips are pressed into curtain panels by dislocation, superposition and flat pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com