Method for preparing alumina catalyst carrier

A technology of catalyst carrier and alumina, which is applied in the direction of catalyst carrier, catalyst activation/preparation, physical/chemical process catalyst, etc., and can solve the problems that cannot be made

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described in detail below through examples, but the present invention is not limited only to the following examples.

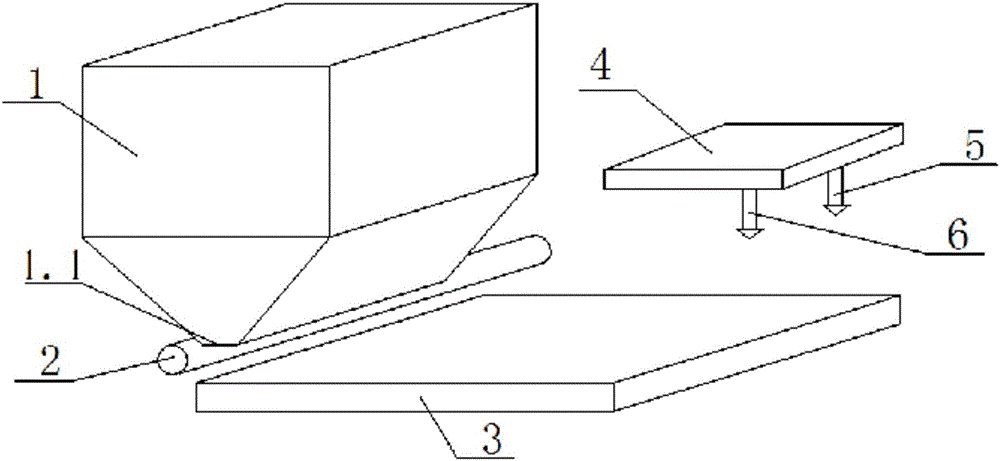

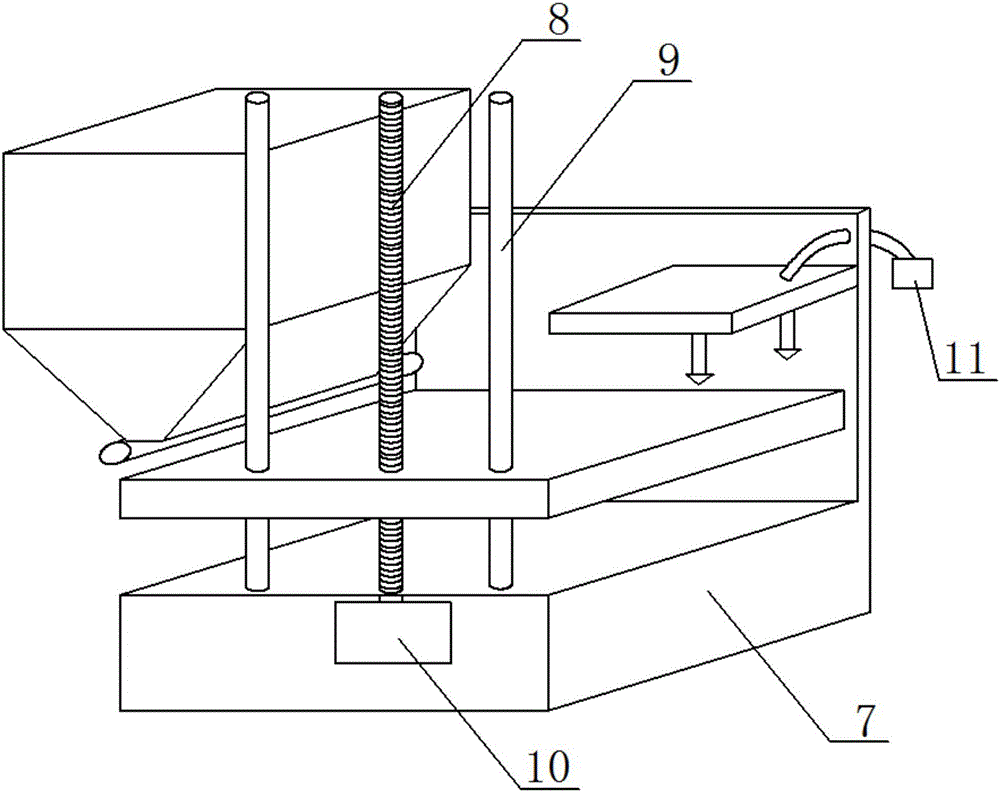

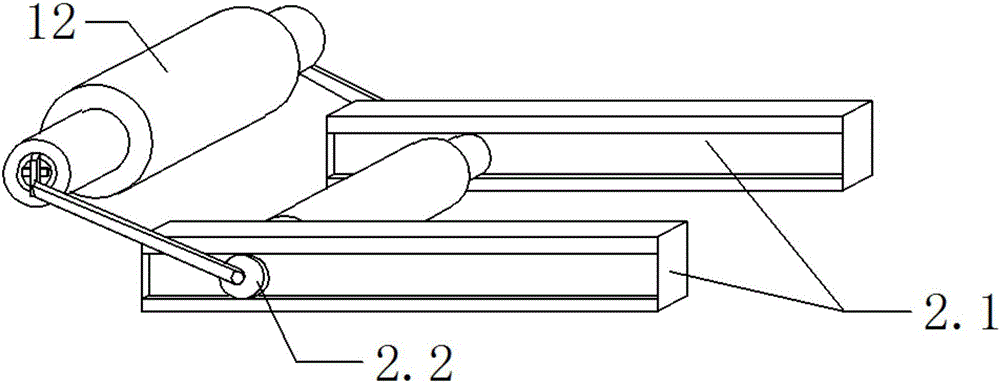

[0024] The 3d printing mechanism of the present invention, as attached figure 1 Shown: including a feeding container 1, a nozzle 1.1 is arranged below the feeding container, a roller 2 capable of running along the X axis is arranged under the nozzle; a lifting platform 3 is arranged below the roller, and the lifting platform 3 is arranged below the roller. A controller 4 is arranged above, and a glue nozzle 5 and a laser 6 are arranged at the lower end of the controller 4; details are as attached figure 2 A base 7 is arranged below the lift platform 3 of the present invention, the base is provided with a lead screw 8 that drives the lift platform to move up and down, guide rods 9 are provided on both sides of the lead screw, and the bottom of the base is provided with a first motor 10 for driving the lead screw The lif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com