Patents

Literature

34results about How to "Quick drying and curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

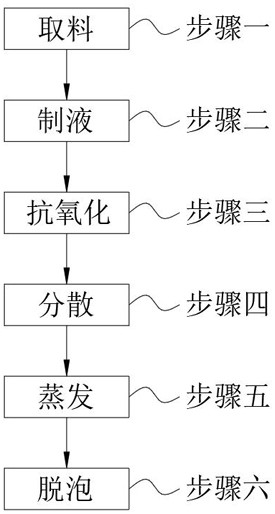

Photocuring double-component polyurea waterproof coating and preparation method thereof

ActiveCN112778886AGood weather resistanceFlexiblePolyurea/polyurethane coatingsPolymer scienceAntioxidant

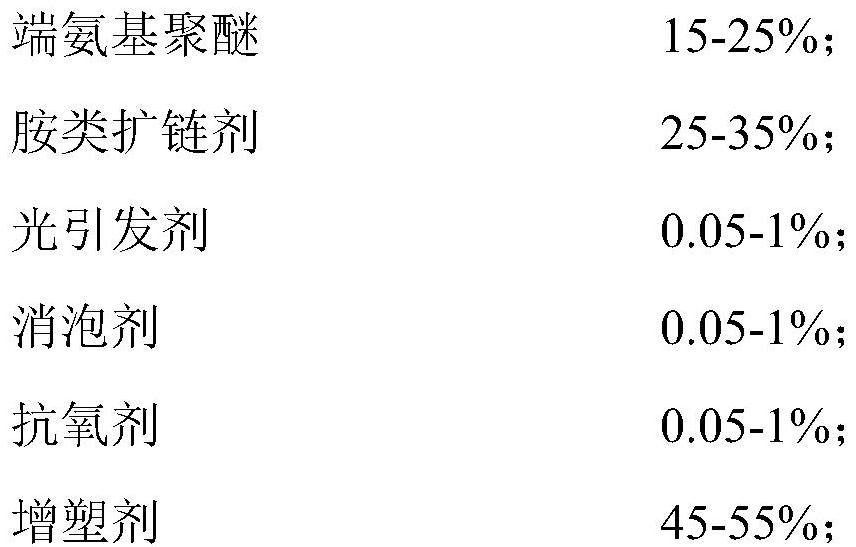

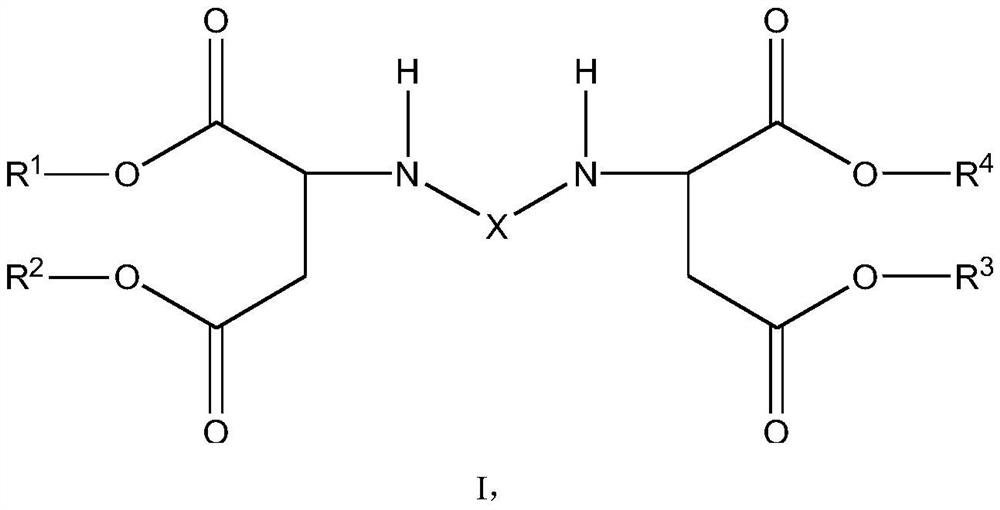

The invention relates to a photocuring double-component polyurea waterproof coating and a preparation method thereof. The photocuring double-component polyurea waterproof coating is composed of a component A and a component B. The raw material formula of the component A comprises a polyurea prepolymer and an acrylic acid modified polyurea prepolymer, and the polyurea prepolymer is prepared through a reaction of isocyanate and steric hindrance secondary amine. The raw material formula of the component B comprises amino-terminated polyether, an amine chain extender, a photoinitiator, a defoaming agent, an antioxidant and a plasticizer. The steric hindrance secondary amine and the amine chain extender are respectively selected from asparaginic acid ester steric hindrance type secondary amine. An asparaginic acid ester compound is introduced into the component A and the component B at the same time, the photoinitiator is used in cooperation, the coating can be rapidly and deeply dried and cured to form a film after being irradiated by ultraviolet rays, and the weather resistance is good. Acrylic acid is introduced for modification, so that the coating has the flexibility of polyurethane and the hardness of acrylic acid at the same time, and the coating also has excellent cohesiveness, excellent self-repairing and self-healing performance and long opening time.

Owner:JIANGSU CANLON BUILDING MATERIALS

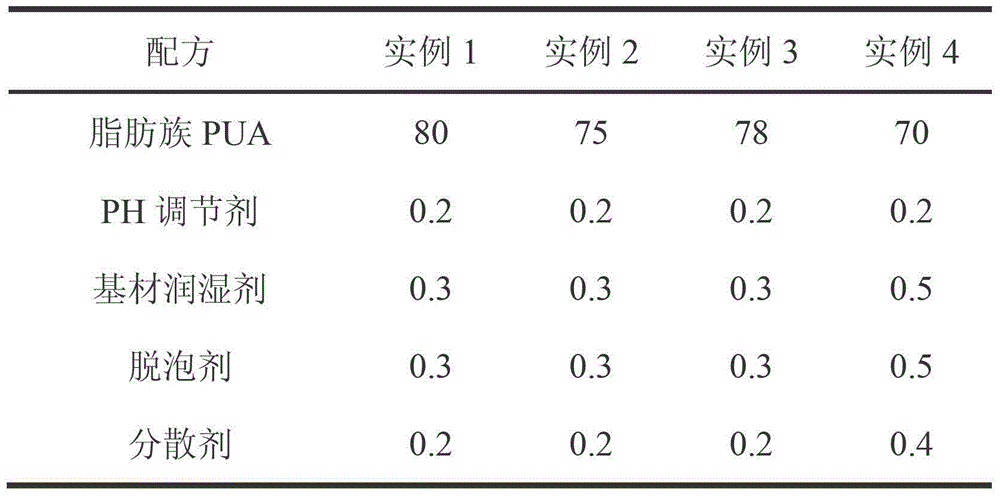

Dual-cured scratch-resistant wear-resistant water-based black luster finish coat

ActiveCN103333602AFast drying and curing paint film mechanical propertiesExcellent mechanical properties of paint filmPolyurea/polyurethane coatingsDual cureWax

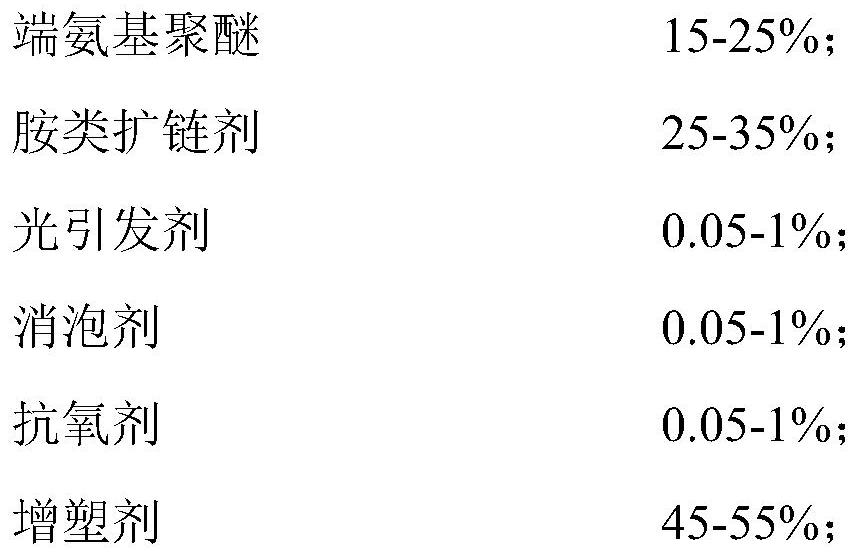

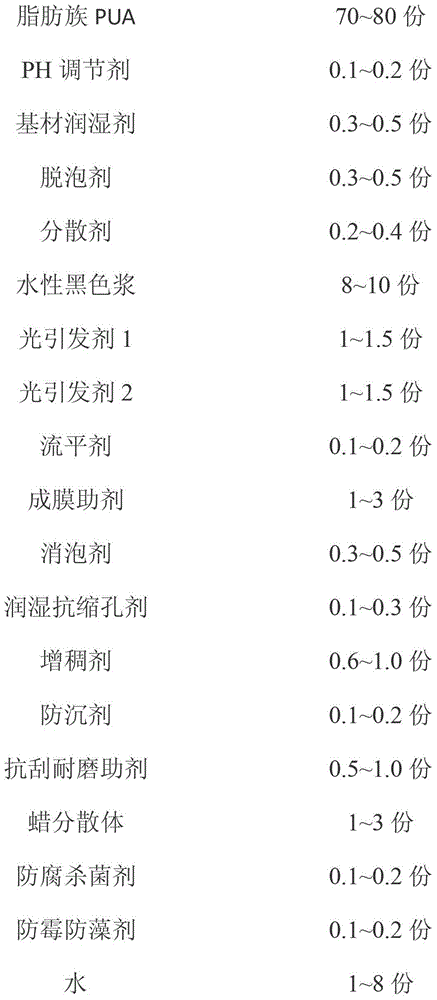

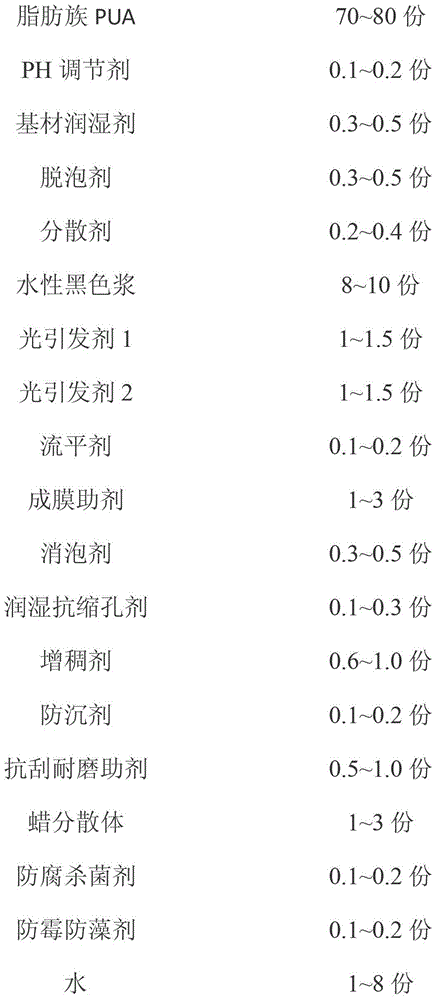

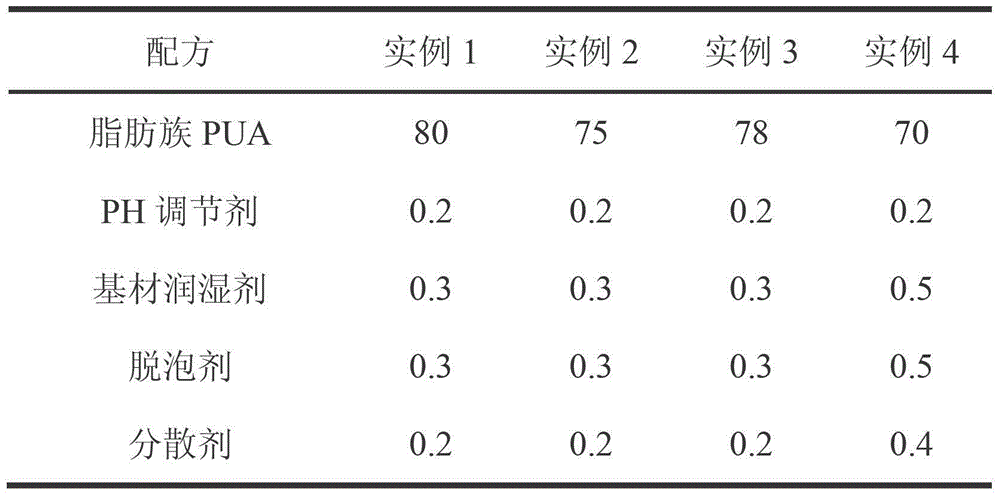

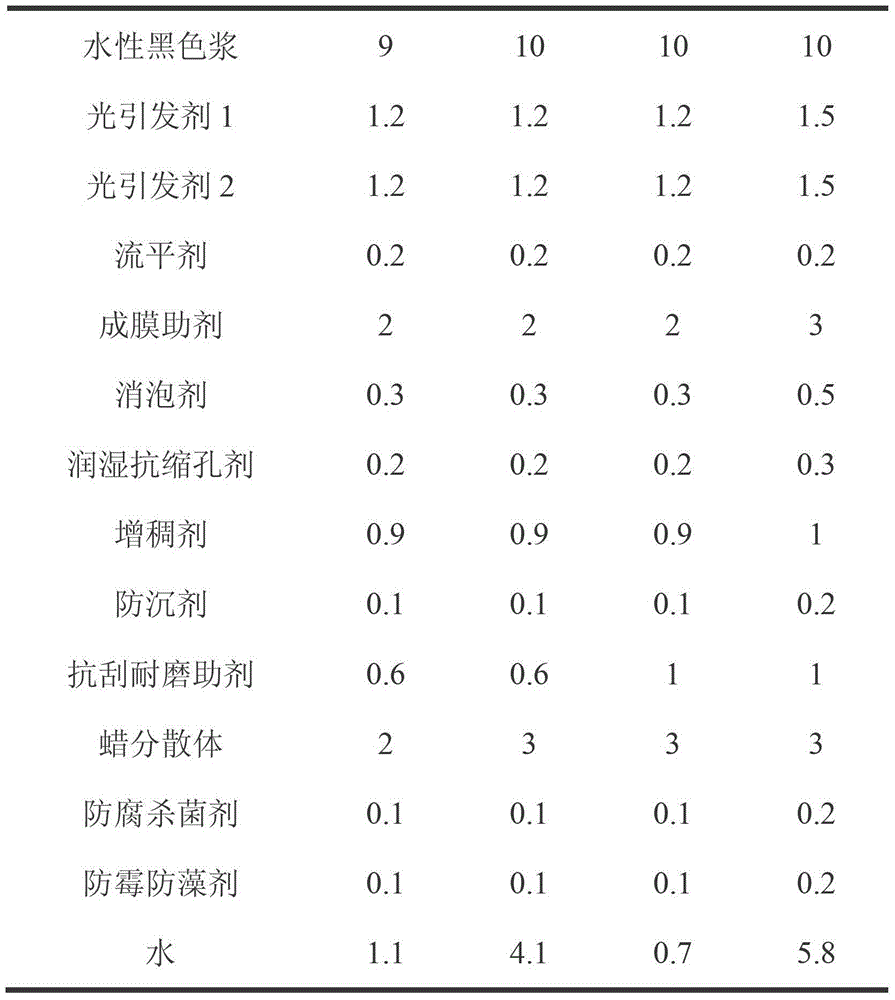

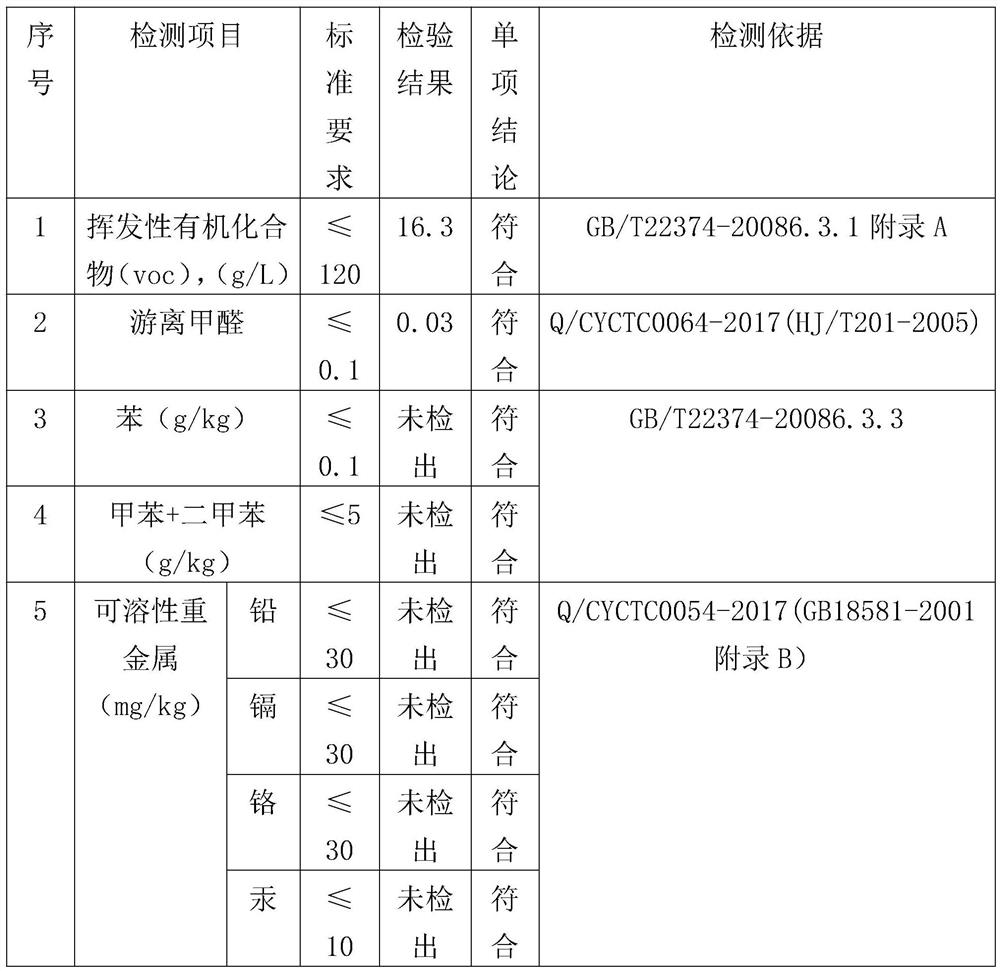

The invention discloses a dual-cured scratch-resistant wear-resistant water-based black luster finish coat which is prepared from the following components in parts by weight: 70-80 parts of aliphatic PUV (polyurethane acrylate), 0.1-0.2 part of pH regulator, 0.3-0.5 part of substrate wetting agent, 0.3-0.5 part of defoamer, 0.2-0.4 part of dispersing agent, 8-10 parts of water-based black paste, 1-1.5 parts of photoinitiator 1, 1-1.5 parts of photoinitiator 2, 0.1-0.2 part of leveling agent, 1-3 parts of film-forming assistant, 0.3-0.5 part of antifoamer, 0.1-0.3 part of wetting and anti-shrinkage agent, 0.6-1.0 part of thickener, 0.1-0.2 part of anti-settling agent, 0.5-1.0 part of scratch-resistant wear-resistant agent, 1-3 parts of wax dispersion, 0.1-0.2 part of anticorrosive bactericide, 0.1-0.2 part of moldproof algaecide and 1-8 parts of water. The black luster finish coat disclosed by the invention is prepared from dual-cured aliphatic PUV, has excellent scratch resistance and wear resistance, and has both the environment-friendly property of the water-based wood paint and the high drying and curing speed and excellent paint film mechanical properties of the oil-based UV paint. The invention is a favorable substitute for both the oil-based UV solid color paint and the water-based single-component solid color paint.

Owner:广东花王涂料有限公司

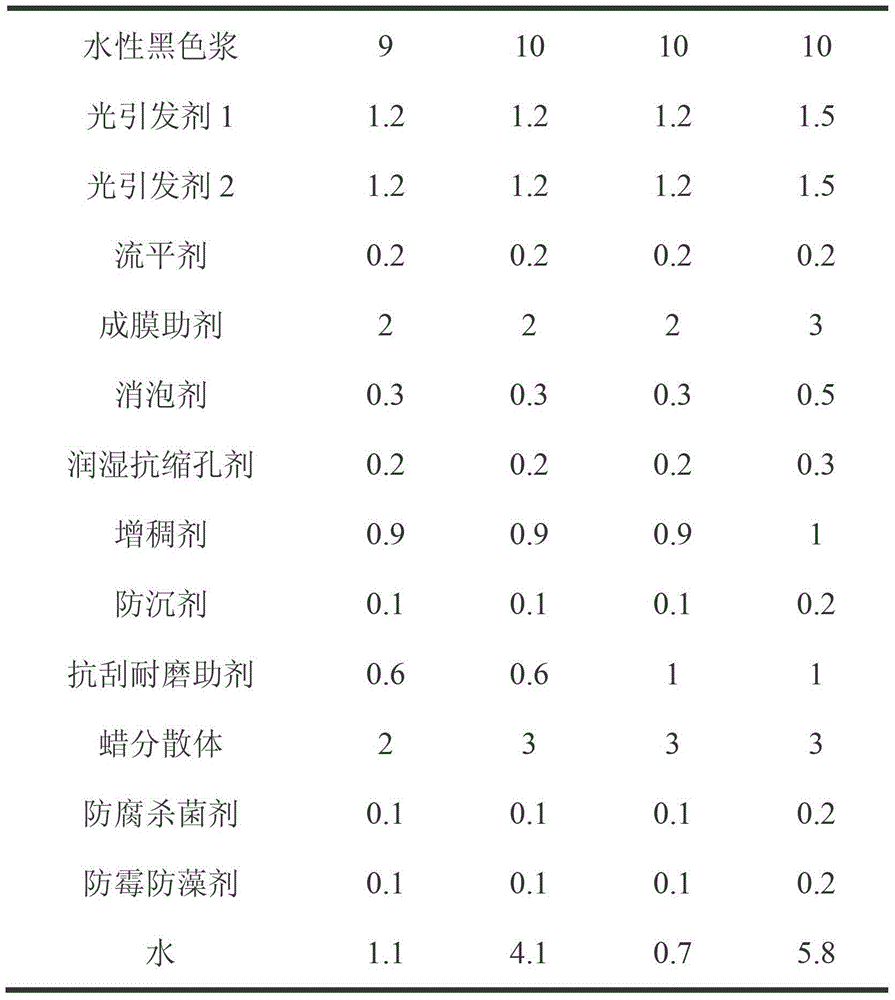

Method for preparing modified maize starch glue

InactiveCN102876255ASimple processGood adhesionNon-macromolecular adhesive additivesStarch derivtive adhesivesChemistryRenewable energy

The invention relates to a method for preparing a modified maize starch glue, comprising the following steps: (1) taking 85kg of maize starch, adding 9kg of oxidant, stirring uniformly, sealing, oxidizing for 10 hours, adding 6kg of quick-drying agent, stirring uniformly, and cooling for 10 hours to obtain the modified maize starch; and (2) adding 70kg of water, stirring uniformly, adding 3kg of sodium hydroxide, gelatinizing, adding 0.25kg of borax, stirring again, adding 15mg of defoaming agent, stirring uniformly, and barreling for use. The adopted maize starch is the environmentally-friendly product and the renewable energy. The modified maize starch glue is produced at the room temperature without heating, and the process for preparing the modified maize starch glue is easy. The materials adopted to produce the modified maize starch glue have good bonding strength, and the modified maize starch glue can be dried and cured quickly and is very suitable for producing honeycomb paperboards.

Owner:ZUNYI HEXIN PACKAGE CO LTD

Method for preparing alumina catalyst carrier

ActiveCN106179520ASolve the problem of dry crackingHigh activityCatalyst carriersCatalyst activation/preparationMixed materials3d printer

The invention discloses a method for preparing an alumina catalyst carrier. The method comprises the following steps: uniformly mixing the following components in the ratio: 30-80 percent of pseudo-boehmite, 10-50 percent of superfine cellulose powder and 5-30 percent of quick-dehydrating powder; uniformly mixing, and grinding the mixed materials; preparing an acid solution in a weight ratio of acid to water being (0.5-30):100; adding the ground powder into a charging container; adding the prepared acid solution into a pressurized and flow-controllable container; printing the charging container filled with powder on a 3D printing mechanism under computer control layer by layer to obtain a finished product of a profiled large active alumina carrier. The method can be used for manufacturing mass integrated active alumina catalyst and preventing the phenomenon of dry cracking.

Owner:JIANGXI ACICHEMSHUN IND

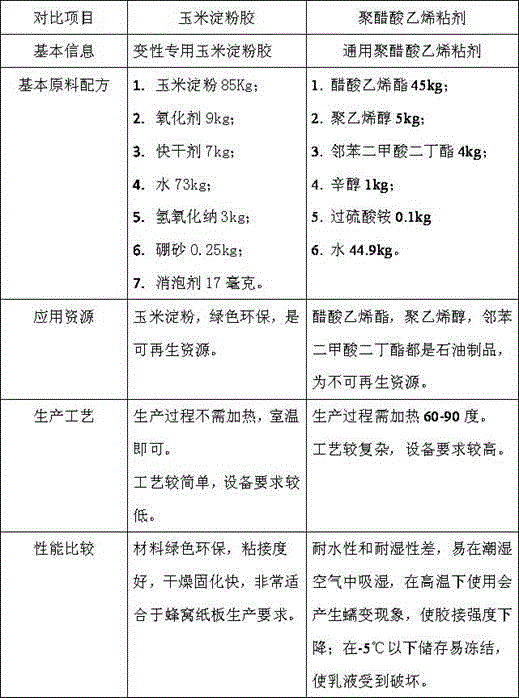

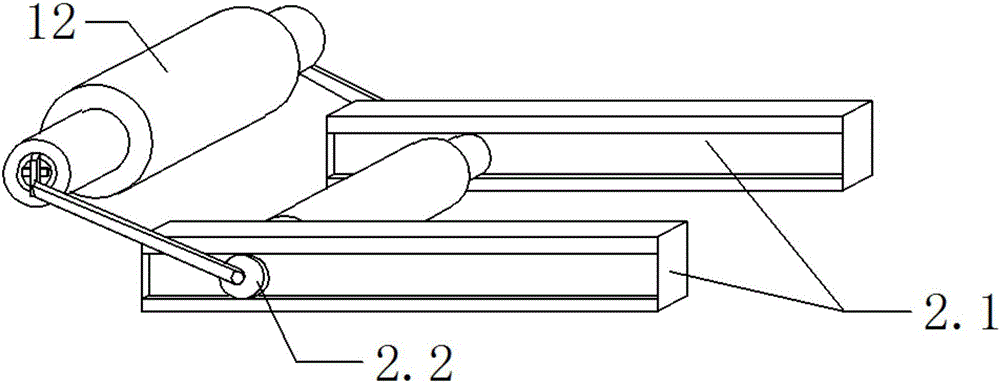

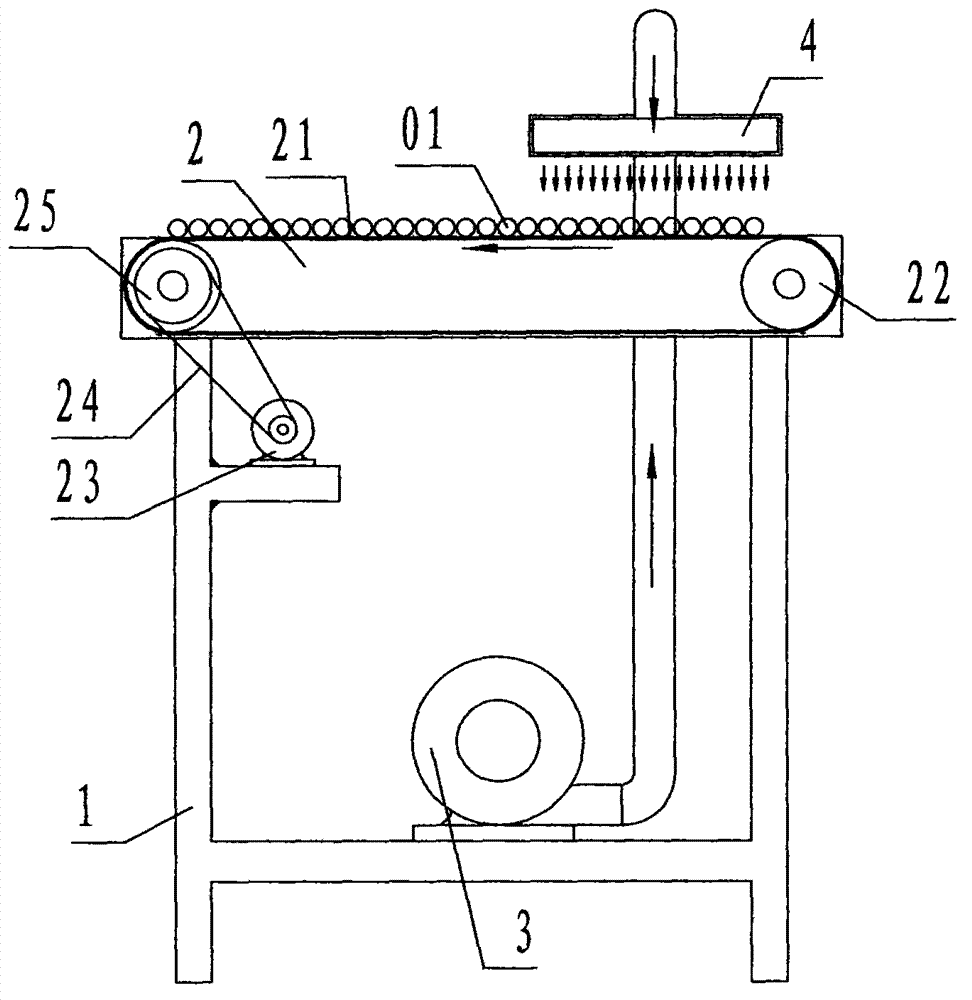

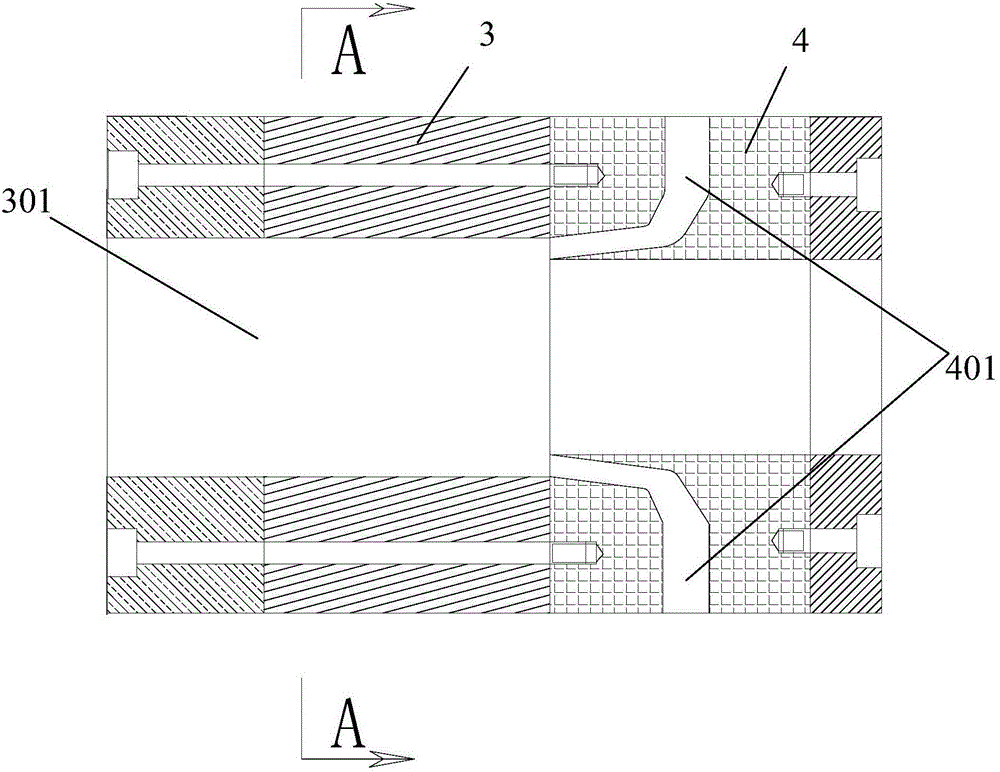

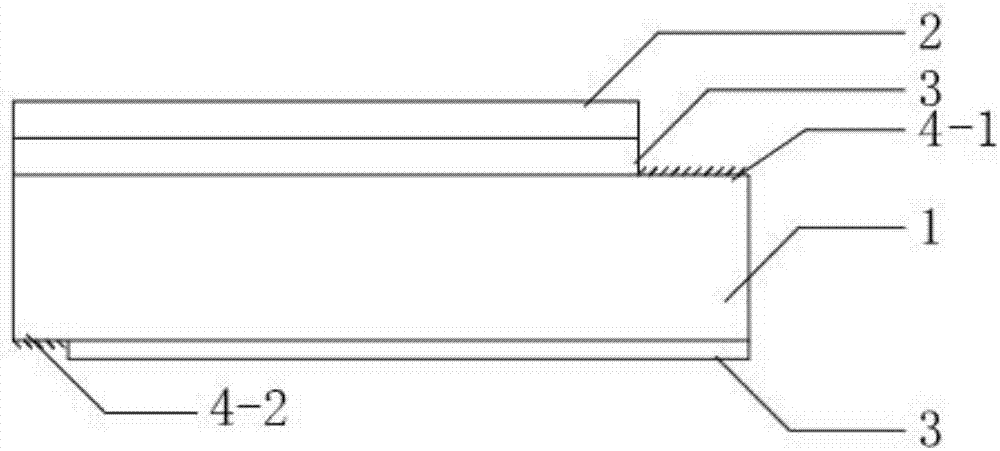

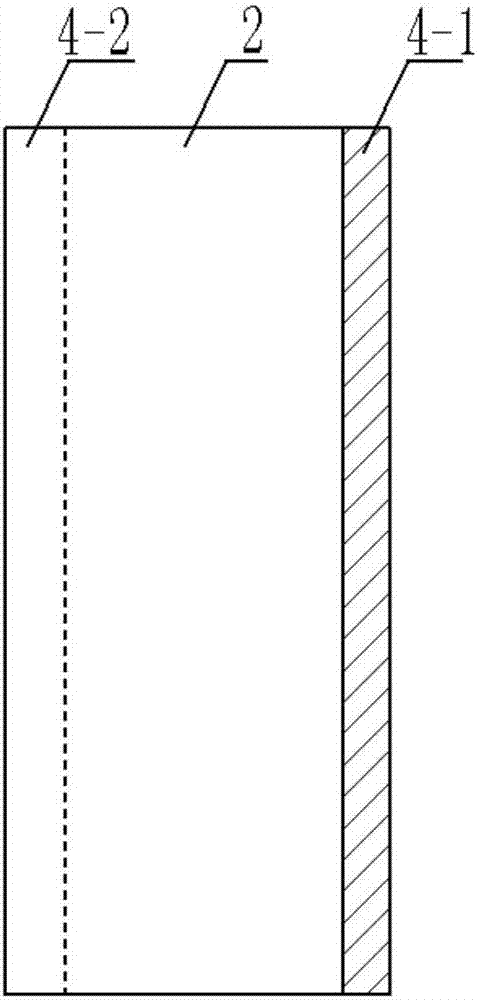

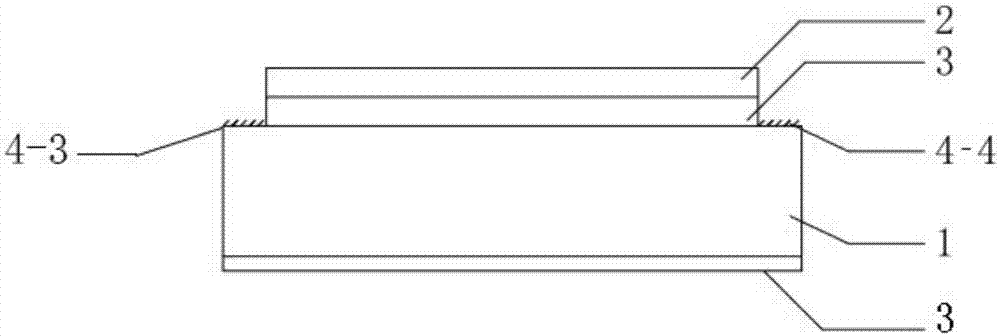

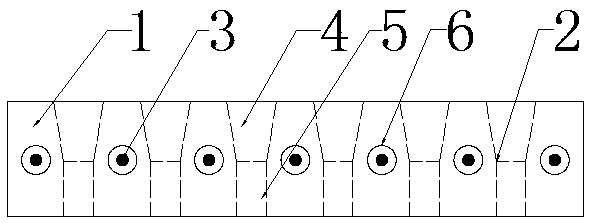

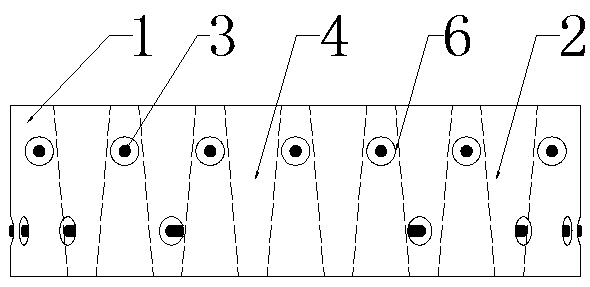

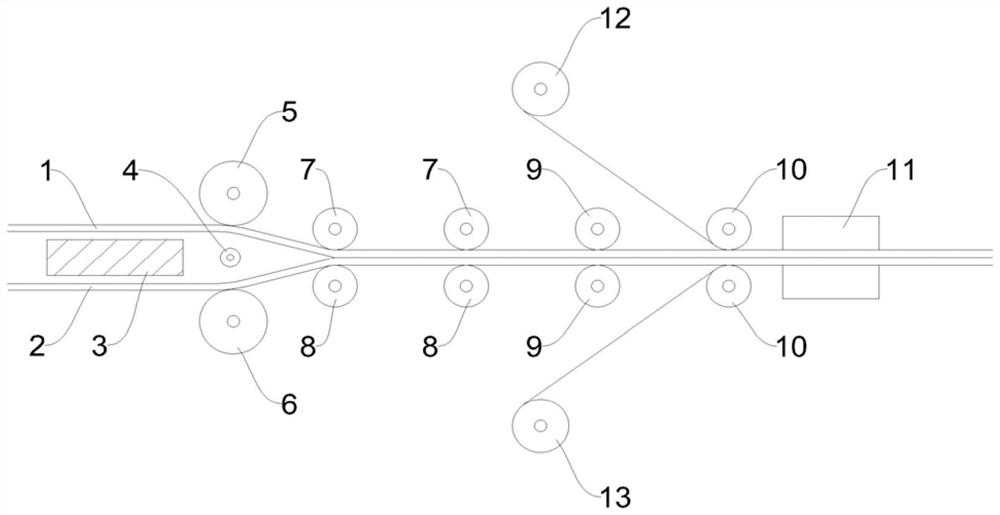

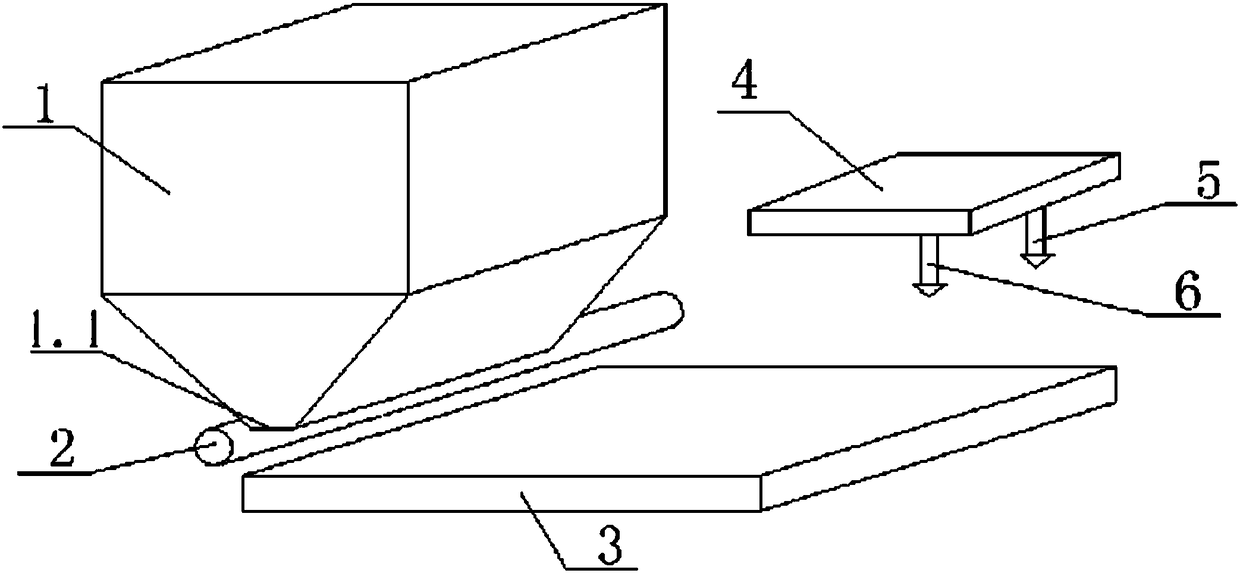

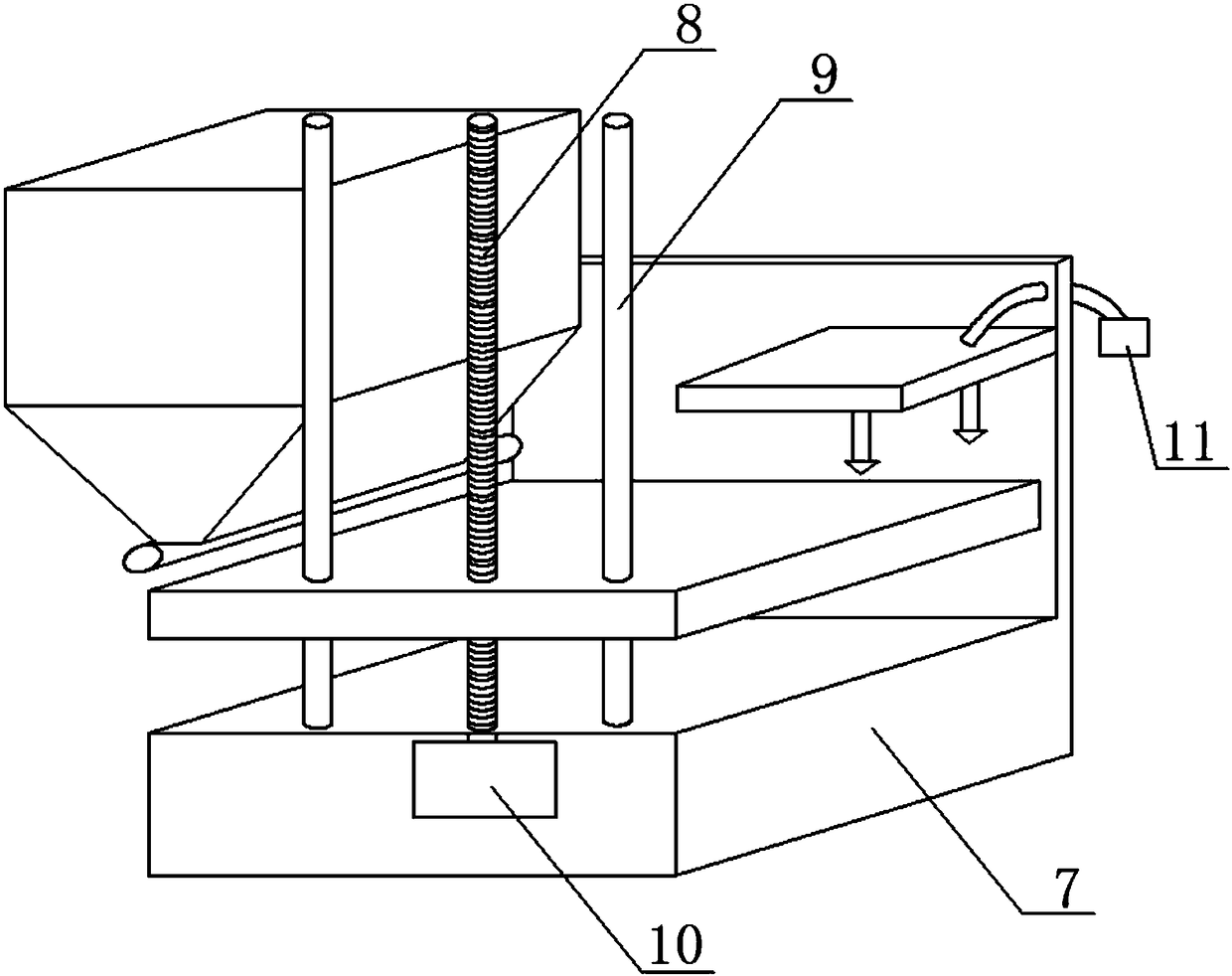

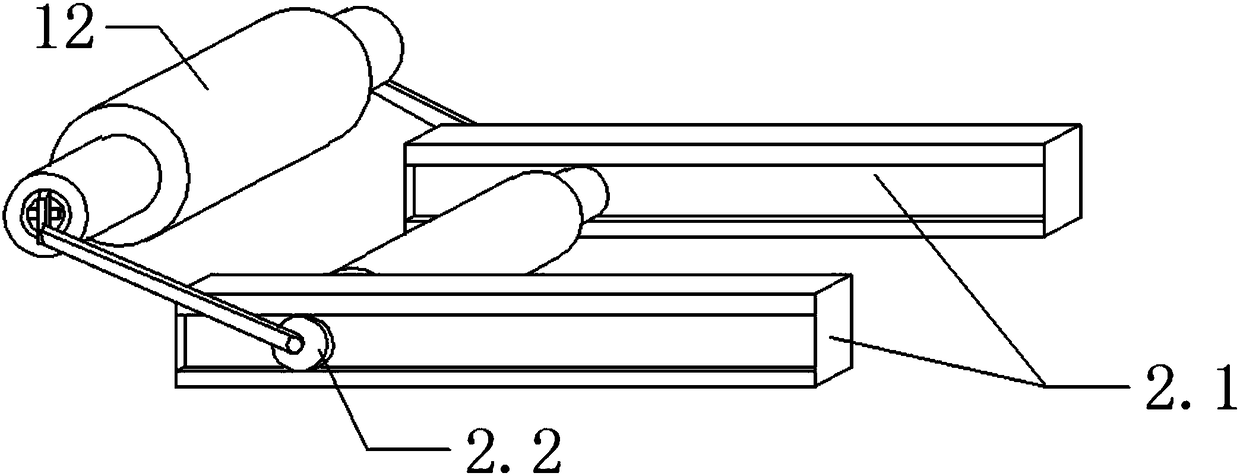

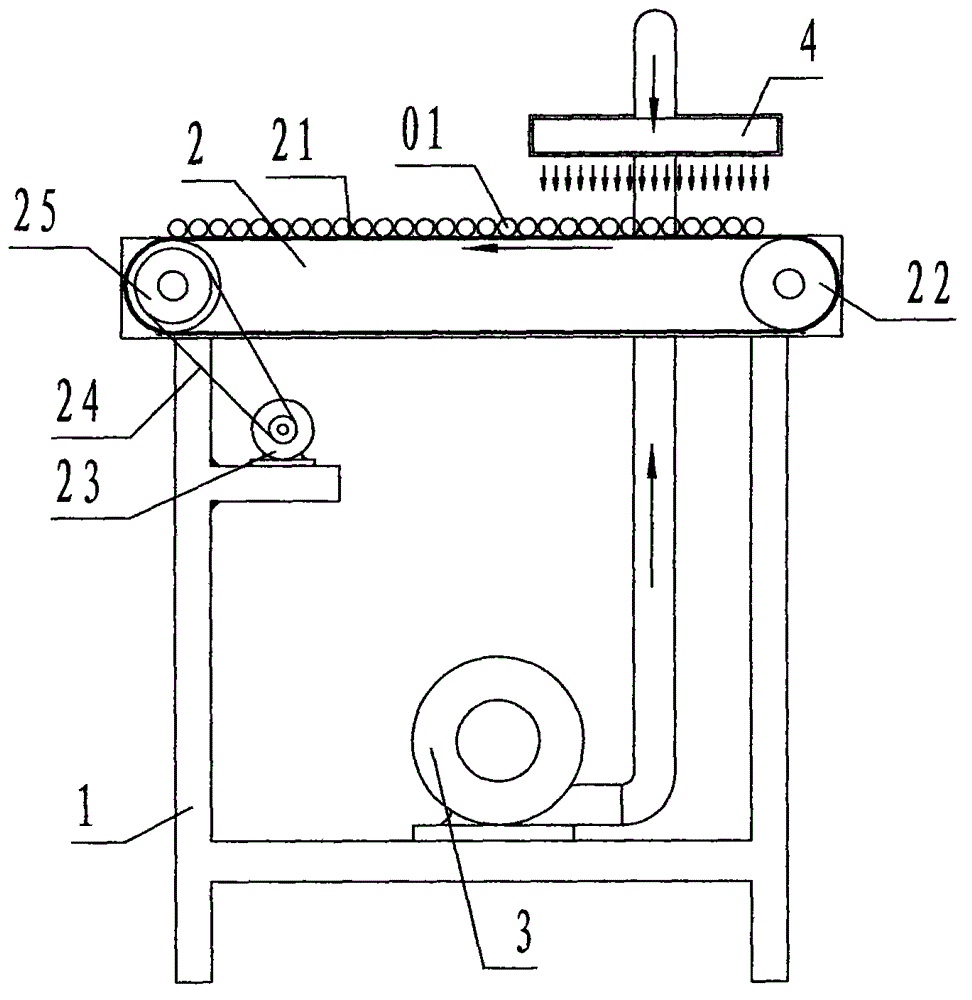

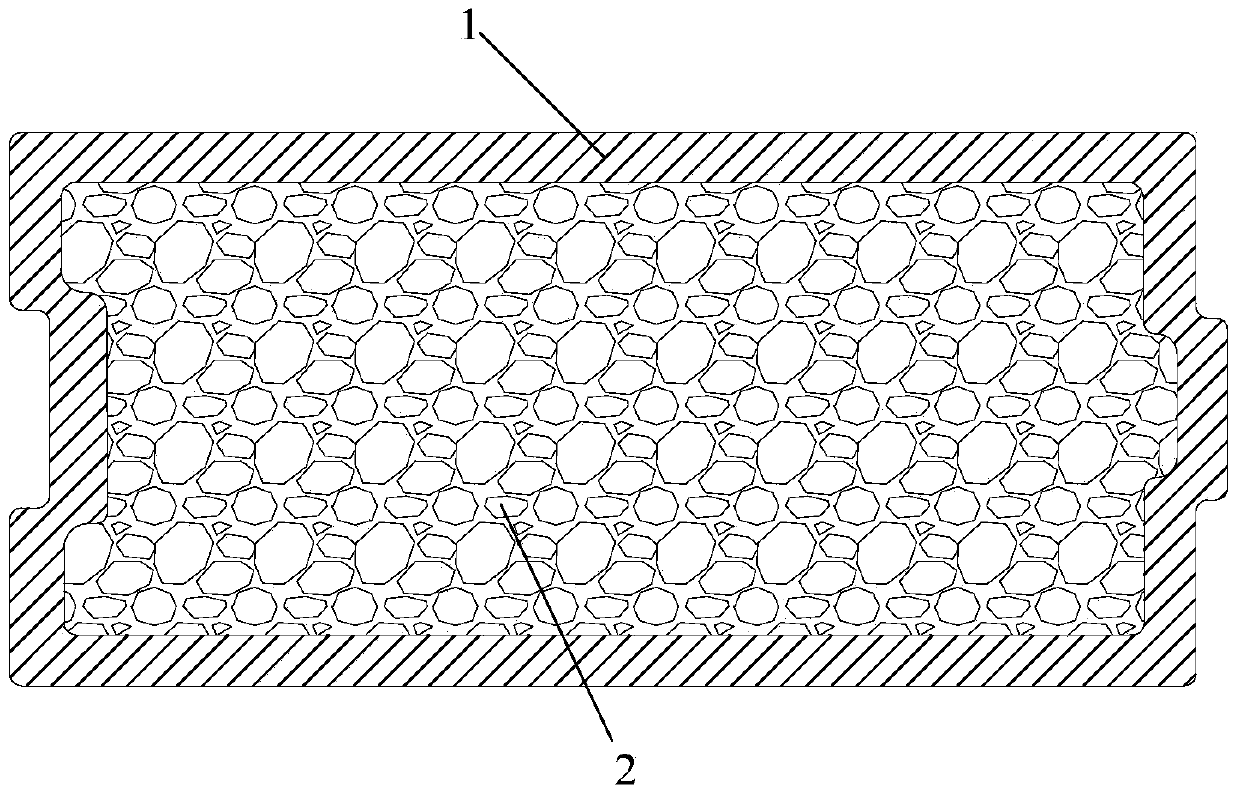

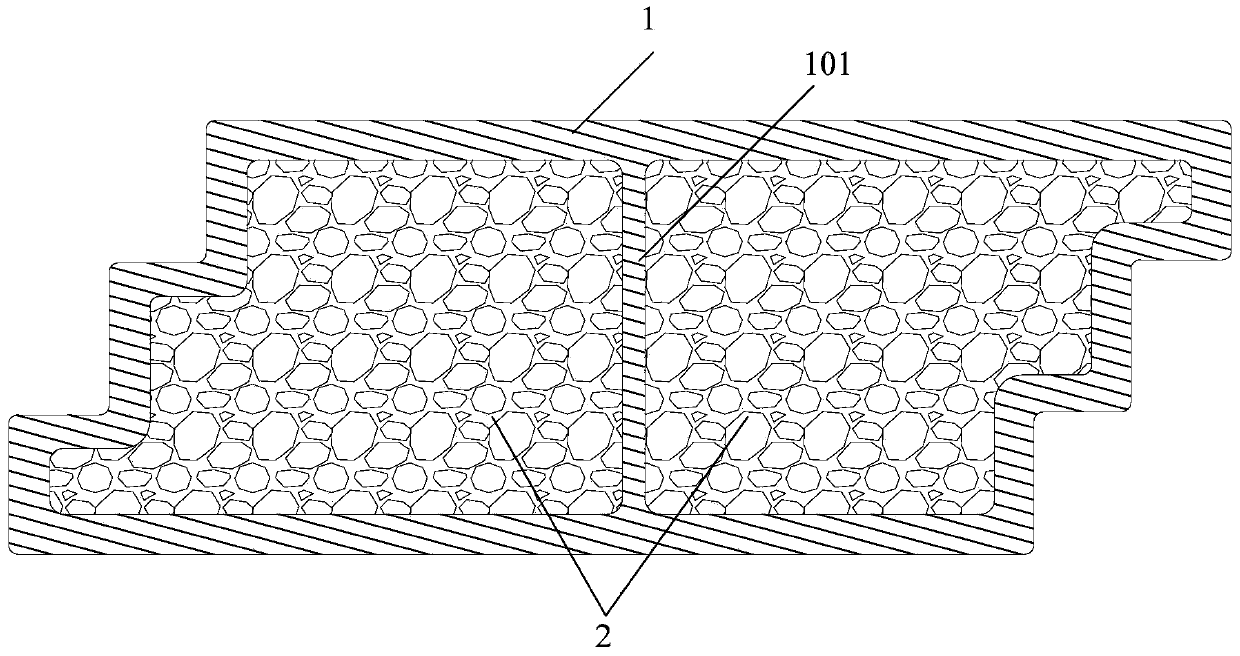

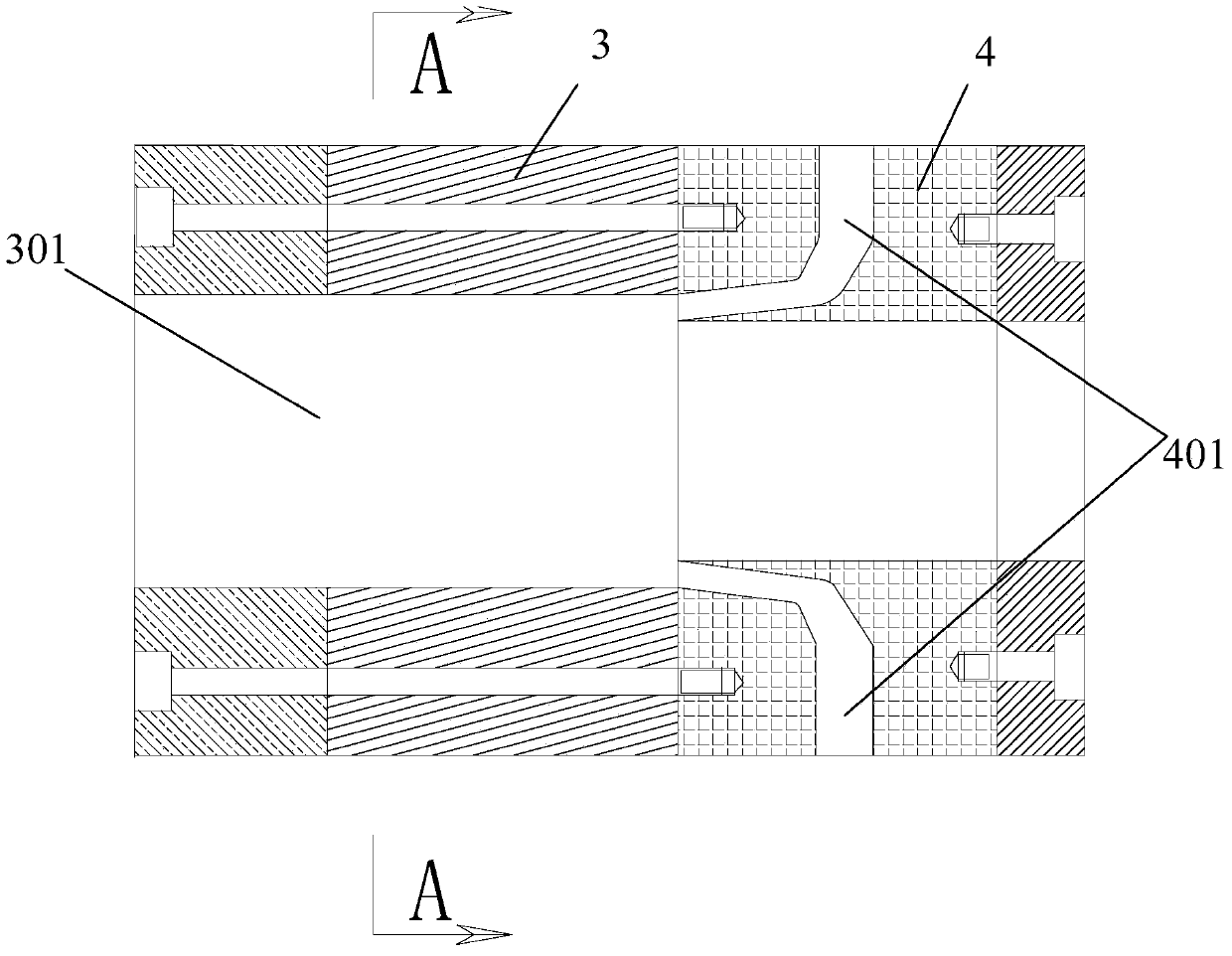

Quick blow-drying device for transfer printing marks of shaping rubber pipe products

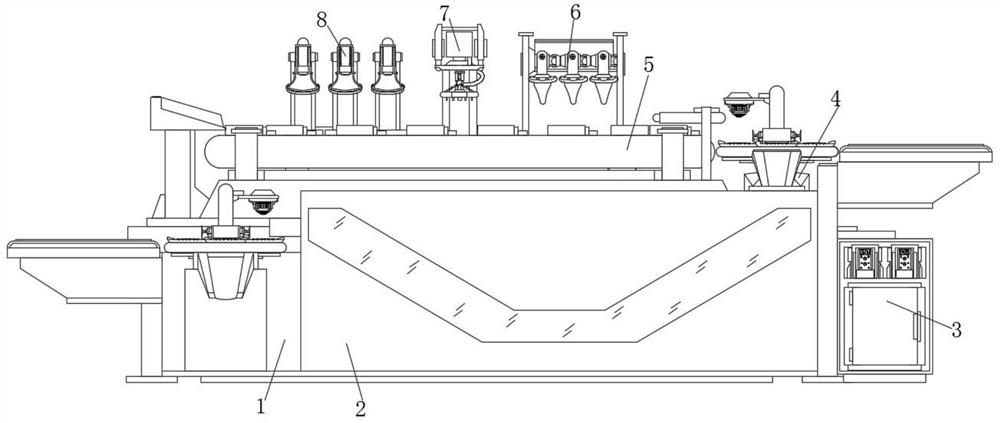

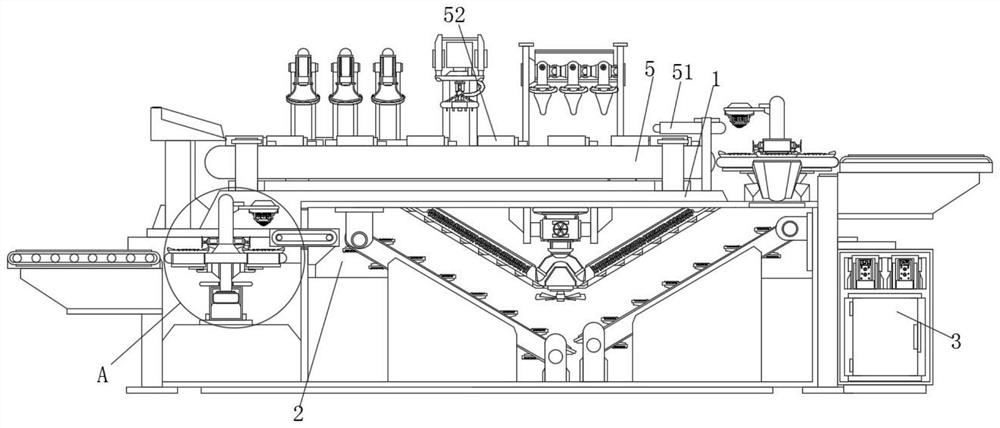

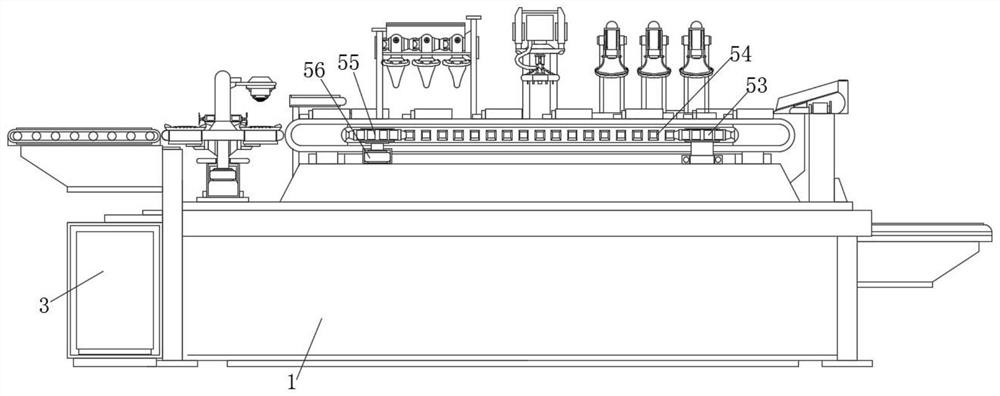

ActiveCN102765248AQuick drying and curingImprove efficiencyPrinting press partsAir blowerBelt conveyor

The invention discloses a quick blow-drying device for transfer printing marks of shaping rubber pipe products. The quick blow-drying device comprises a support (1), a belt conveyor (2), an air blower (3) and a blow pipe (4). The technical scheme includes that the blow pipe is arranged above the belt conveyor, air provided by the air blower is dispersed through the air pipe to be upwardly blown to the belt conveyor, and when the quick blow-drying device is in operation, rubber pipe products after transfer printing of marks are placed on the belt conveyor and carried by the belt conveyor to pass through a blow-drying area of the blow pipe to enable ink marks to be quickly dried and cured. The defects of low efficiency and high cost of prior art are overcome, and efficiency improvement and cost reduction in transfer printing of the shaping rubber pipe products are realized by means of blowing for quick drying and automatic conveying.

Owner:宁波市天普橡胶科技股份有限公司

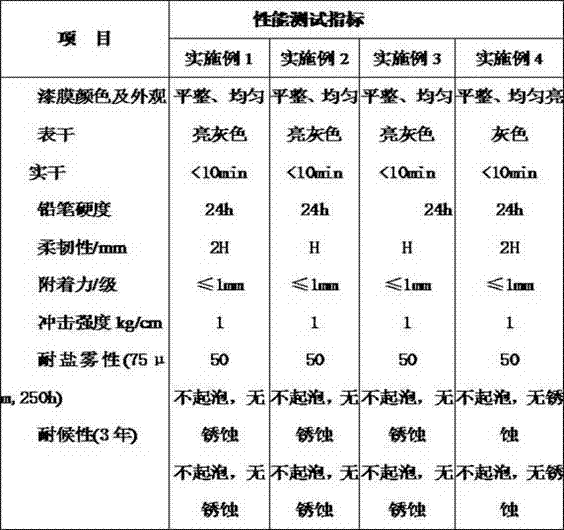

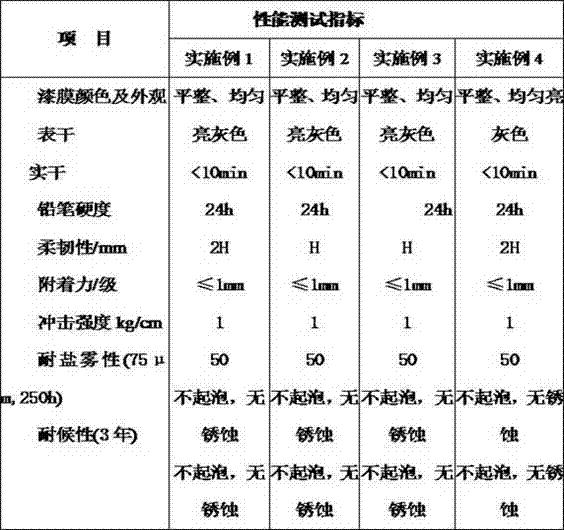

Anticorrosive paint based on amination linoleic acid copolymerized acrylic resin and preparation method of anticorrosive paint

ActiveCN102816481AAvoid corrosionHigh solid contentAnti-corrosive paintsPolymer scienceAcrylic resin

The invention discloses an anticorrosive paint based on amination linoleic acid copolymerized acrylic resin and a preparation method of the anticorrosive paint. The paint comprises following components of amination linoleic acid copolymerized acrylic resin, mica iron oxide, zinc phosphate, aluminium triphosphate, mica powder, talcum powder, organic bentonite, butyl acetate, ethyl acetate and the like. The process for preparing the amination linoleic acid copolymerized acrylic resin comprises steps that firstly acrylic prepolymer is prepared through mass polymerization, and then the acrylic prepolymer is further copolymerized with amination linoleic acid through free radicals through a solution polymerization method. The components are mixed according to a given proportion and then are rapidly blended and uniformly ground into particles with granularity of less than 50 micrometers. The prepared paint is coated on the metal surface and dried at normal temperature to form a membrane. The paint membrane has advantages of high solid content, rapid drying speed, good mechanical performance, good corrosion resistance and the like.

Owner:SUZHOU JIREN HIGH TECH MATERIAL CO LTD

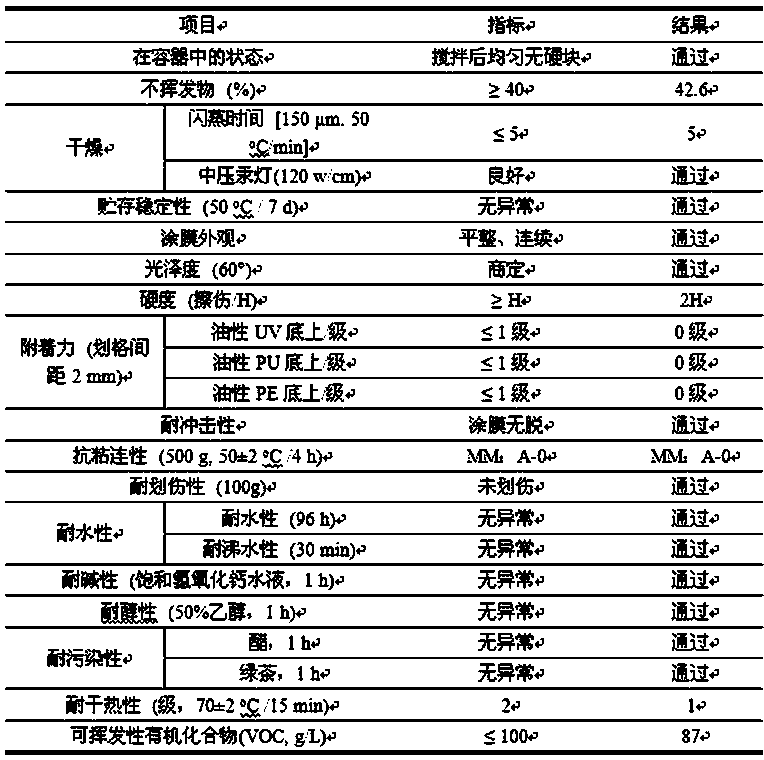

Crystal water-permeability UV (Ultraviolet) matte top-coat

InactiveCN103436158AQuick drying and curingExcellent mechanical properties of paint filmPolyurea/polyurethane coatingsWaxCoated surface

The invention provides a crystal water-permeability UV (Ultraviolet) matte top-coat. The high transparency waterborne UV spraying matter top-coat is prepared from a waterborne polyurethane-acrylic acid copolymer with an UV curing characteristic, high transparency extinction powder and wax dispersion, has the environmental protection property of waterborne wood paint, the rapid drying curing performance of oil UV paint and excellent paint film mechanical property, can be used for overcoming the defects of difficulty in extinction, poor transparency and the like existing in UV paint and is the crystal water-permeability UV matte top-coat with the high transparency, which is widely applied to wood doors, office furniture, panel-type furniture and children furniture. The construction manner of the high transparency waterborne UV spraying matter top-coat is spraying. The detection and the trail prove that the crystal water-permeability UV matte top-coat has the advantages of fast curing speed, high production efficiency and environmental protection, and a coating has a fine and smooth surface, uniform luster, excellent transparency, good hand feeling, abrasion resistance and scratch resistance.

Owner:GUANGDONG BADESE CHEM

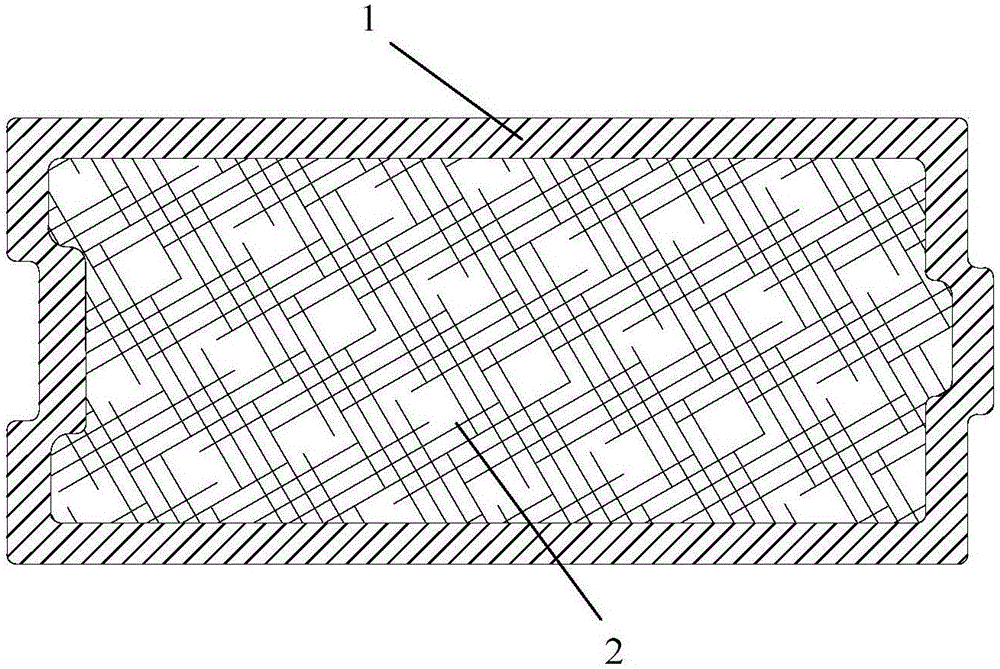

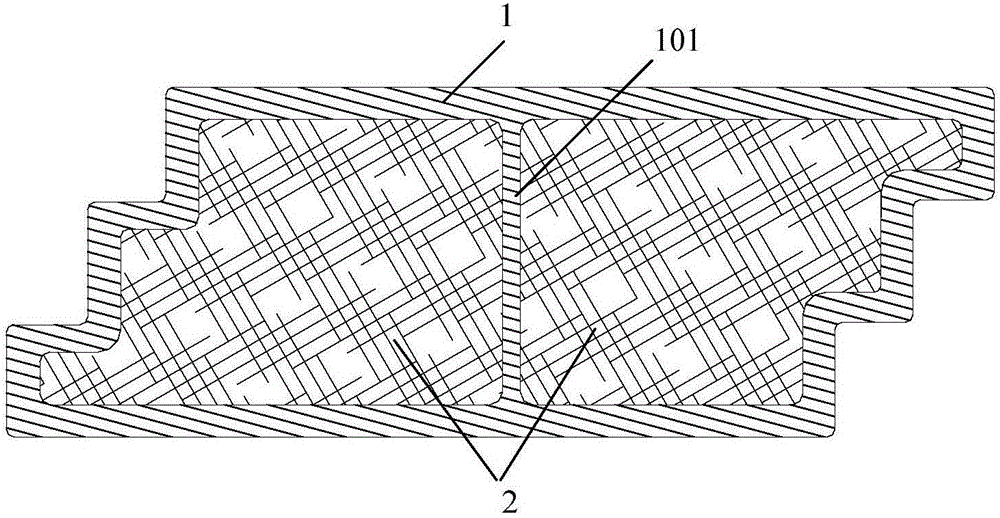

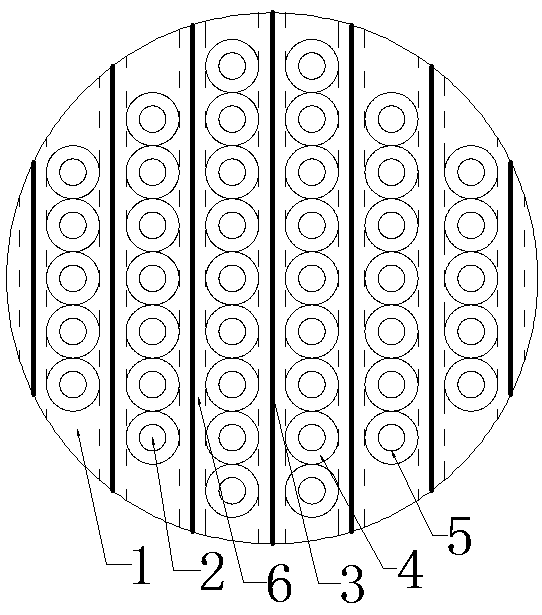

Preparation method of inorganic fiber and wood plastic composite plate

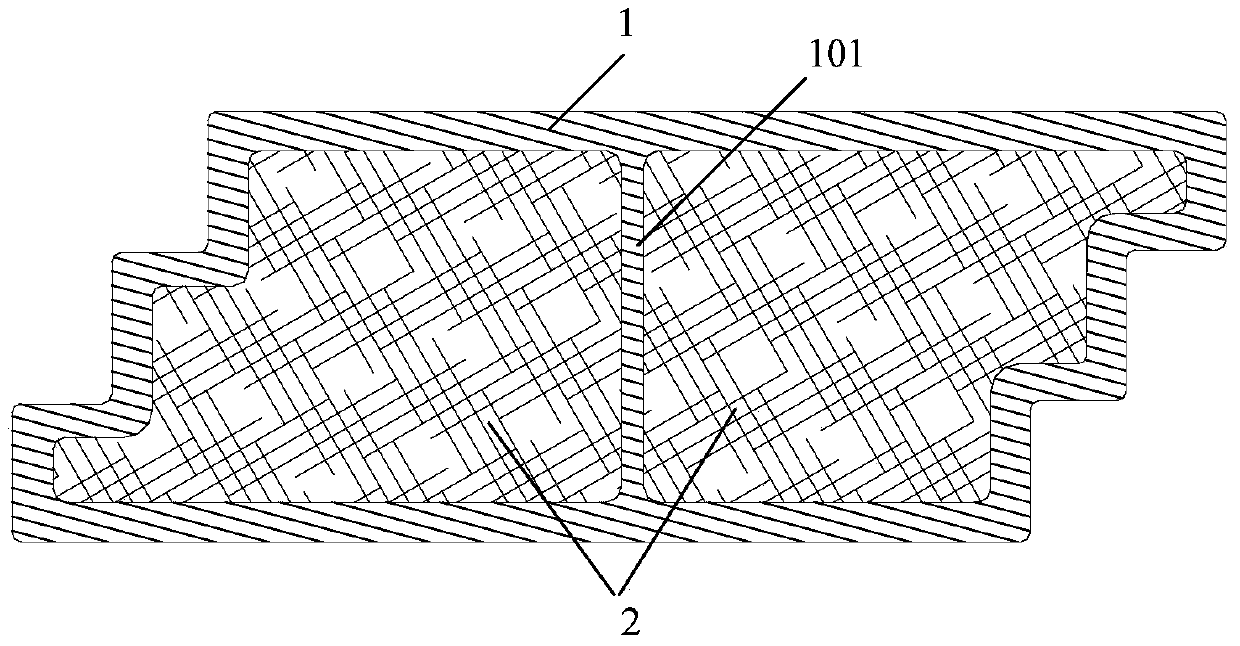

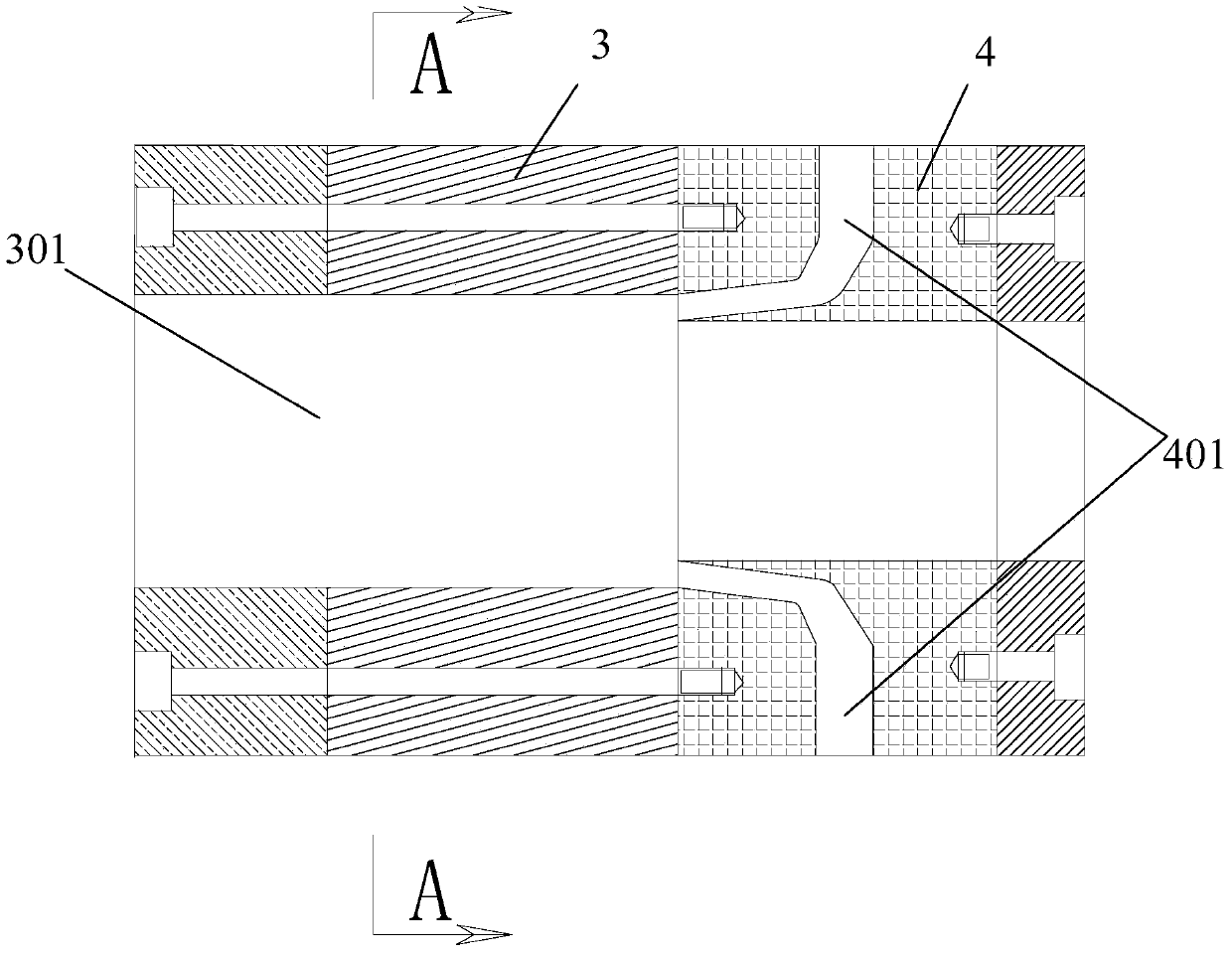

The invention discloses a preparation method of an inorganic fiber and wood plastic composite plate. The inorganic fiber and wood plastic composite plate is molded through coextrusion of a mold, the mold is provided with a hollow cavity in the length direction, a feed end of the mold communicates with a wood plastic runner of the hollow cavity, and an outlet of the wood plastic runner faces a discharge end of the mold. The preparation method comprises the steps that a molten wood plastic material is sent into the hollow cavity by virtue of the wood plastic runner through an extruder, the wood plastic material is cooled and molded in the hollow cavity, and a hollow wood plastic frame is formed and is extruded from the discharge end of the mold; and inorganic fibers and a binder are synchronously and uniformly sprayed into the wood plastic frame in the mold, the inorganic fibers are blown to the wood plastic frame and are bound with the wood plastic frame by virtue of the binder, the wood plastic frame is filled, and a filled layer is formed. The invention relates to the field of buildings, and provides the preparation method of the inorganic fiber and wood plastic composite plate. According to the preparation method, procedures can be simplified, and the composite plates are synchronously molded at a time.

Owner:BEIJING NEW BUILDING MATERIALS PLC

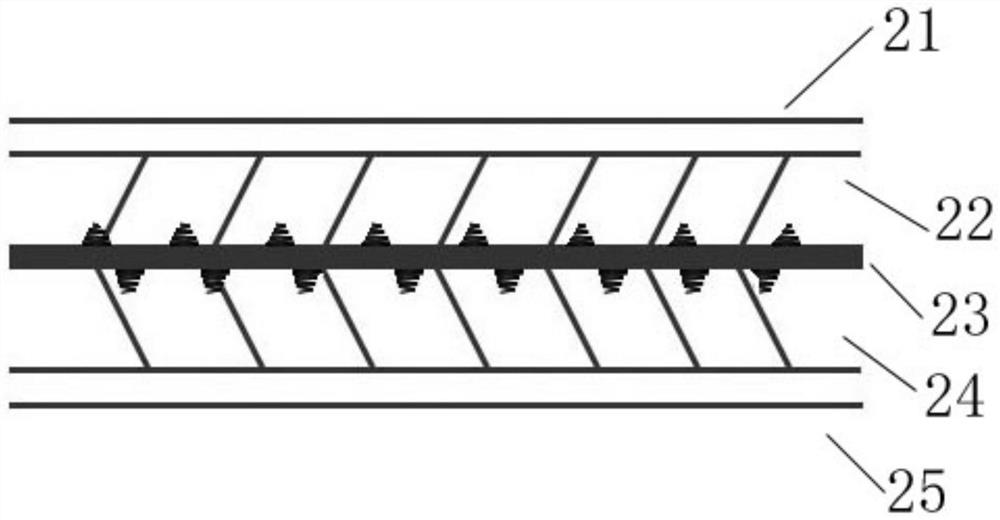

Broadband dual-shielding functional decorative wallpaper and construction method thereof

InactiveCN107385951AImprove surface adhesionSolve the problem that the pattern cannot be printed directlyPaperhangingTextiles and paperFiberMetal filament

The invention relates to a broadband dual-shielding functional decorative wallpaper and a construction method thereof. The wallpaper is composed of a basic material layer with an electromagnetic shielding performance, a coupling layer, and a decorative surface layer. The coupling layer is arranged between the basic material layer and the decorative surface layer. The basic material layer is composed of metal coated conductive fabrics, metal filament fabrics, blended fabrics of metal filaments and chemical fibers, or metal coated chemical fiber fabrics. The coupling layer is composed of chromium complexes, titanate / silane coupling agent, and coupling agent carrier compounds. The wallpaper can be divided into a single naked edge type, a dual naked edge type, and a full edge type. In construction, the single naked edge type wallpaper can be assembled in sequence; or the single naked edge type wallpaper, the dual naked edge type wallpaper, and the full edge type wallpaper can be assembled in sequence. The wallpaper is subjected to a coupling treatment. The adhesion force of the decorative surface layer on the wallpaper surface is enhanced. The beauty of the wallpaper is strengthened. According to the construction method, the corners of walls and the naked edges between neighbored wallpaper are covered by a shielding layer to prevent wave leakage and the shielding effect is improved.

Owner:北京仲基应用技术研究院有限公司

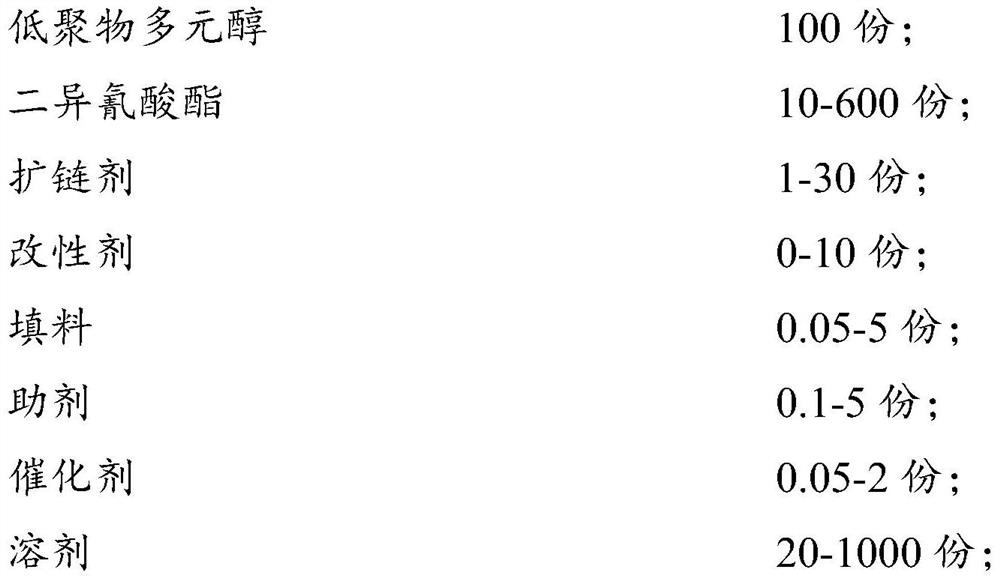

Wear-resistant and deformation-resistant invisible car cover

ActiveCN112795325AQuick drying and curingGood wear resistance and deformation resistanceInksPolyurea/polyurethane coatingsPtru catalystOligomer

The invention provides a wear-resistant and deformation-resistant invisible car cover. The wear-resistant and deformation-resistant invisible car cover comprises a substrate, one side of the substrate is covered with a top coating, the side, away from the substrate, of the top coating is covered with a first release film, the other surface of the substrate is covered with an adhesive layer, and the side, away from the substrate, of the adhesive layer is covered with a second release film; the top coating is prepared from a top coating liquid, and the top coating liquid is mainly prepared from the following raw materials in parts by weight: 100 parts of oligomer polyol, 10 to 600 parts of diisocyanate, 1 to 30 parts of a chain extender, 0 to 10 parts of a modifier, 0.05 to 5 parts of a filler, 0.1 to 5 parts of an auxiliary agent, 0.05 to 2 parts of a catalyst and 20 to 1000 parts of a solvent. The invisible car cover has the properties of wear resistance, deformation resistance, yellowing resistance, acid and alkali resistance and high toughness, and can effectively protect a car paint surface.

Owner:广东粤港澳大湾区黄埔材料研究院

Current variable elastomer material for 3D printing and preparation method thereof

InactiveCN108395697AQuick responseImprove printing accuracyAdditive manufacturing apparatusEtherPower flow

The invention relates to a current variable elastomer material for 3D printing and a preparation method thereof, and belongs to the field of a 3D printing material. The preparation method of the current variable elastomer material for 3D printing comprises the following preparation steps that a, after liquid-state silicon rubber and a cross-linking agent are uniformly mixed, the mixture is put into a freezing pulverization machine; through freezing pulverization, silicone rubber particles are obtained; the silicone rubber particles, starch and silicone oil are mixed; the temperature is raisedto 50 to 80 DEG C; stirring is performed for 1 to 4h to obtain starch silicone rubber; b, the starch silicone rubber is added into swollen cellulose ether; then, plaster and an antifoaming agent are added; after the mixture is uniformly ground by a ball grinding machine, the pasty 3D printing material containing a current variable elastomer is prepared. Compared with the current variable liquid for 3D printing, the prepared current variable elastomer material for 3D printing has the advantages that the defect that the printing product precision is influenced since the liquid state cannot be precisely controlled is overcome; the printing precision is higher.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

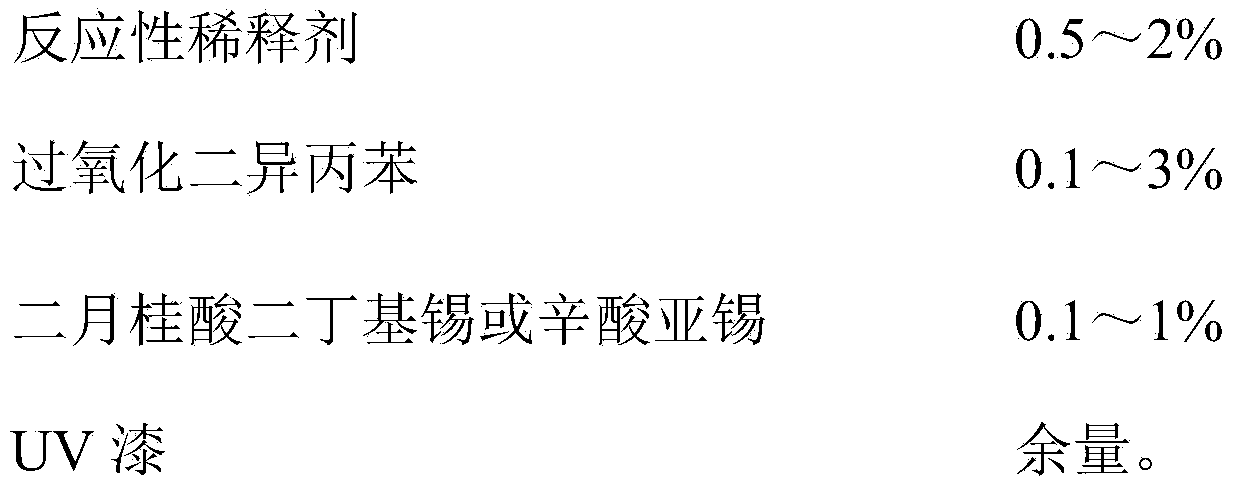

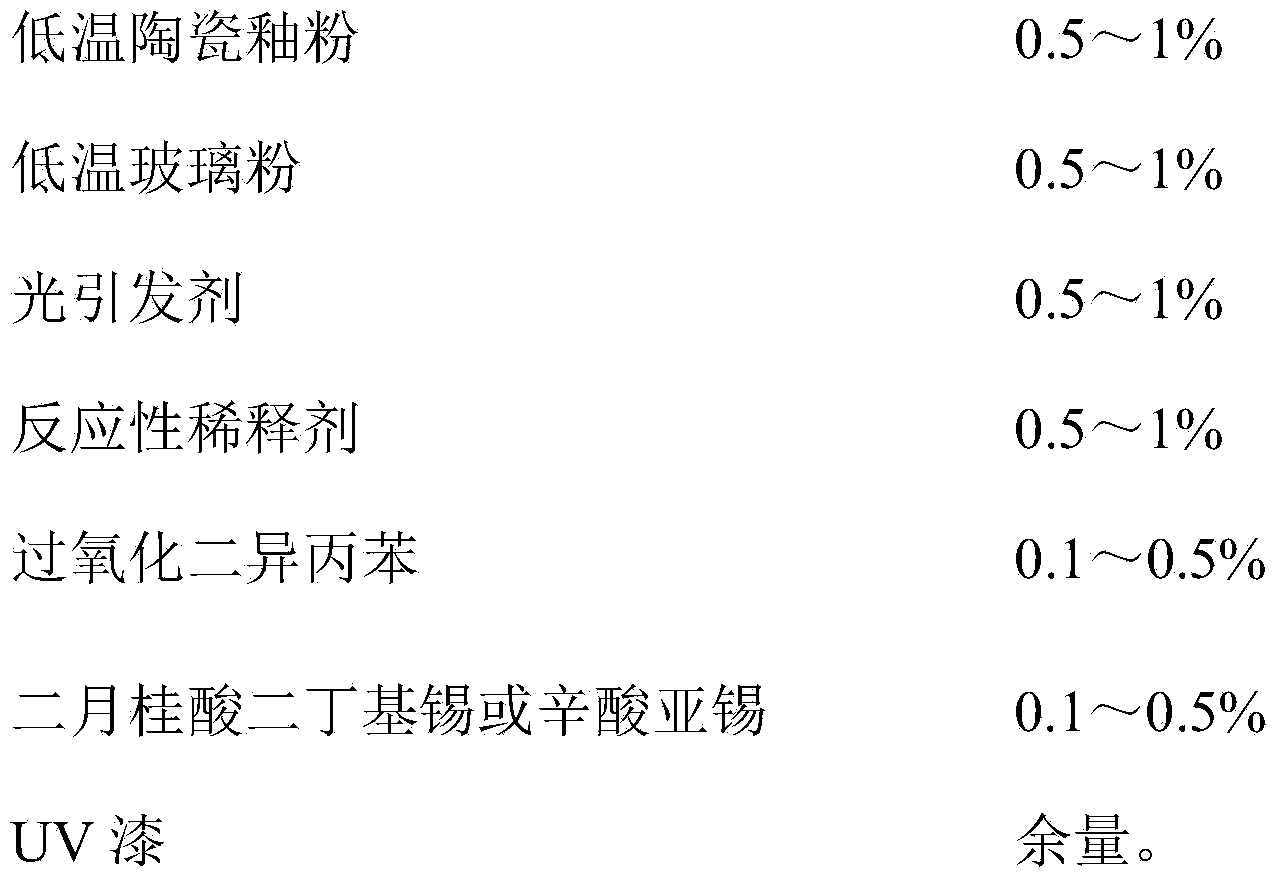

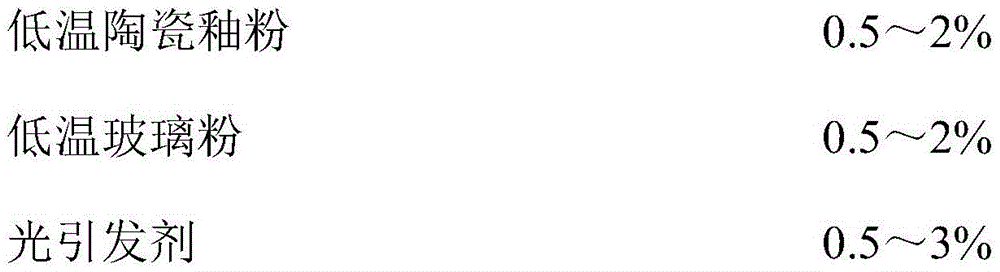

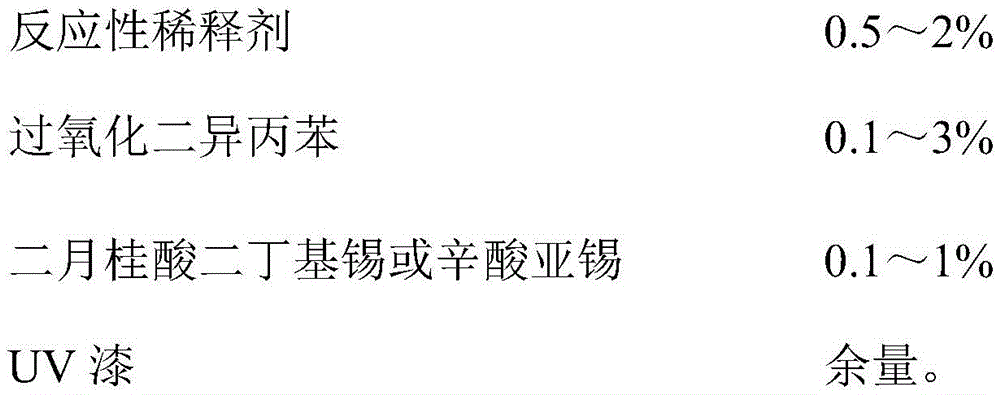

UV (ultraviolet) paint capable of being quickly dried from inside to outside

The invention discloses UV (ultraviolet) paint capable of being quickly dried from inside to outside. The quick-dry paint comprises the following components by weight percent: 0.5%-2% of low-temperature ceramic glaze powder, 0.5%-2% of low-temperature glass powder, 0.5%-3% of a photoinitiator, 0.5%-2% of a reactive diluent, 0.1%-3% of dicumyl peroxide, 0.1%-1% of dibutyltin dilaurate or stannous octoate and the balance of UV paint. According to the quick-dry paint, a paint formula is improved, the paint can be quickly dried from inside to outside, no waste gas is discharged, the drying speed is high, the production efficiency is improved, and the production cost is reduced.

Owner:GUANGDONG HULUBAO CULTURE TECH CO LTD

Pavement coating and preparation method thereof

The invention relates to a pavement coating and a preparation method thereof. The pavement coating comprises a first composition and a second composition; the first composition comprises, by weight, the following raw materials: 50-100 parts of aqueous acrylic acid modified epoxy resin emulsion, 10-100 parts of water, 1-5 parts of bentonite, 50-100 parts of barium sulfate, 50-150 parts of non-metallic mineral and 200-600 parts of wear-resistant aggregate; the second composition comprises, by weight, the following raw materials: 0.1-3 parts of a cross-linking agent, 4-55 parts of a curing agent,0.4-5 parts of an emulsifier and 1-20 parts of water; each composition is independently packaged. The coating components does not contain an organic solvent, is not inflammable or explosive, and is safe to transport and store; the preparation process is simple and environment-friendly, the influence on workers and environment is small, the materials are common and easy to obtain, the cost is low,and the shelf life is long; the coating can be applied indoors and outdoors and has very wide application space.

Owner:重庆东吴道路工程有限公司

Heating forming plate for organic fertilizer granulating machine

PendingCN109847648AEasy to compressImprove granulation efficiencyGranulation by material expressionOrganic manureAgricultural engineering

The invention discloses a heating forming plate for an organic fertilizer granulating machine. The heating forming plate comprises a plate body; and the plate body is cylindrical, the plate body is provided with forming holes, and the interior of the plate body is provided with heating wires. In general, the heating forming plate provided by the invention has the advantages of a simple structure and reasonable design, can effectively improve a compression degree of organic fertilizer granules, reduce generation of crushed residues, improve quality of the organic fertilizer granules, and can directly heat, dry and solidify the organic fertilizer in the forming process, thereby greatly improving production efficiency; and the heating forming plate has the advantage of extremely-high use value.

Owner:河南惠农土质保育研发有限公司

A quick-drying uv paint from the inside out

Owner:GUANGDONG HULUBAO CULTURE TECH CO LTD

A dual cure scratch and abrasion resistant waterborne black gloss finish

ActiveCN103333602BPromote environmental protectionImprove film formationPolyurea/polyurethane coatingsWater basedWear resistant

The invention discloses a dual-cured scratch-resistant wear-resistant water-based black luster finish coat which is prepared from the following components in parts by weight: 70-80 parts of aliphatic PUV (polyurethane acrylate), 0.1-0.2 part of pH regulator, 0.3-0.5 part of substrate wetting agent, 0.3-0.5 part of defoamer, 0.2-0.4 part of dispersing agent, 8-10 parts of water-based black paste, 1-1.5 parts of photoinitiator 1, 1-1.5 parts of photoinitiator 2, 0.1-0.2 part of leveling agent, 1-3 parts of film-forming assistant, 0.3-0.5 part of antifoamer, 0.1-0.3 part of wetting and anti-shrinkage agent, 0.6-1.0 part of thickener, 0.1-0.2 part of anti-settling agent, 0.5-1.0 part of scratch-resistant wear-resistant agent, 1-3 parts of wax dispersion, 0.1-0.2 part of anticorrosive bactericide, 0.1-0.2 part of moldproof algaecide and 1-8 parts of water. The black luster finish coat disclosed by the invention is prepared from dual-cured aliphatic PUV, has excellent scratch resistance and wear resistance, and has both the environment-friendly property of the water-based wood paint and the high drying and curing speed and excellent paint film mechanical properties of the oil-based UV paint. The invention is a favorable substitute for both the oil-based UV solid color paint and the water-based single-component solid color paint.

Owner:广东花王涂料有限公司

Water-based PRT colored pavement

The invention discloses a water-based PRT colored pavement which mainly comprises a water-based emulsion, a curing agent and composite powder in a ratio of 3: 1: 12. The coating does not contain an organic solvent, has no pungent smell, has no harm to the working environment and the health of constructors, and is more environment-friendly and safer in the transportation process; by adopting the mode that spraying is matched with traditional construction and the corresponding proportion of materials, the opening time on the pavement is long, drying and curing are rapid, the binding force with the pavement is higher, and by spraying colored paint, the water-based perfluoroethylene transparent cover face and the anti-skid layer, the color vividness, the skid resistance, the wear resistance and other performance are further enhanced.

Owner:朱广清

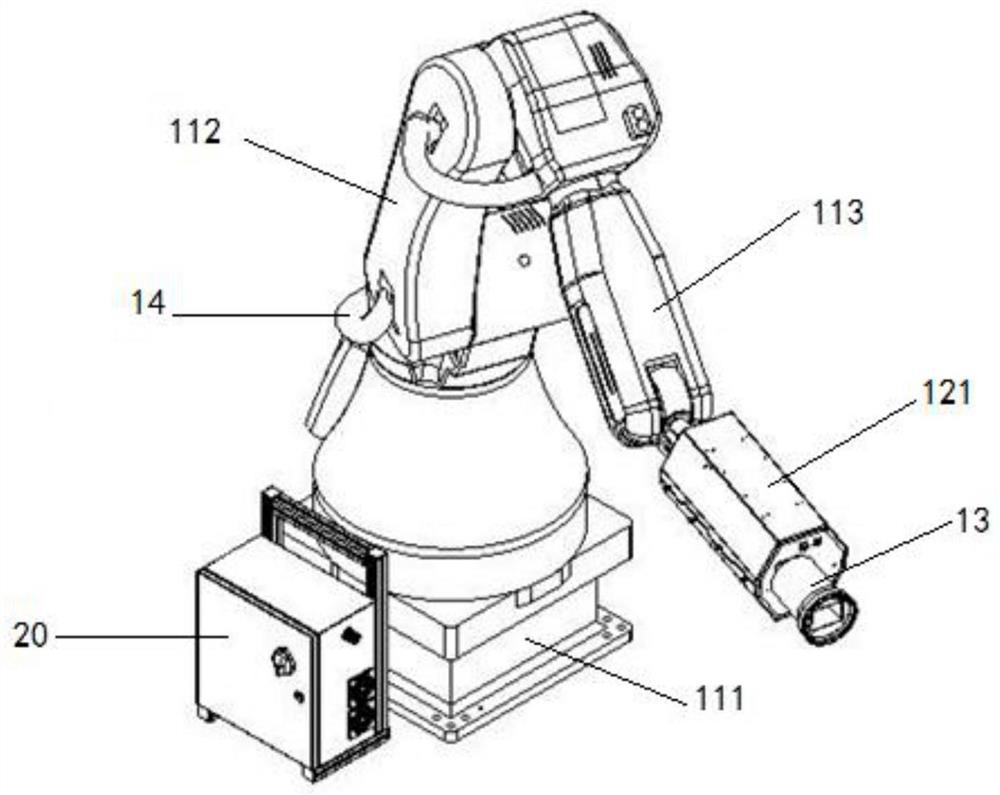

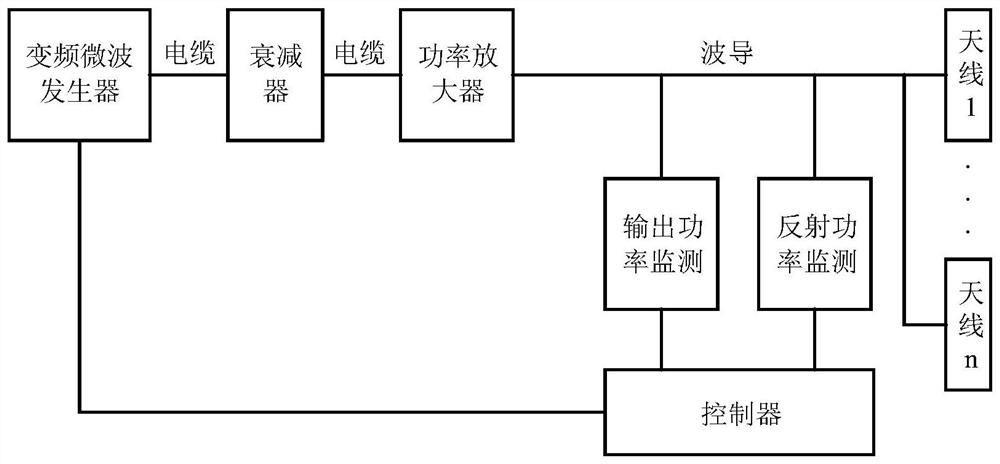

Variable-frequency microwave heating device

PendingCN113939056AIncrease energy densityQuick drying and curingMicrowave heatingHigh energyActuator

The invention provides a variable-frequency microwave heating device. The variable-frequency microwave heating device comprises a robot, a first controller, an actuator, one or more microwave antennas, a power supply and a plurality of cables, and the actuator comprises a shell, a microwave attenuator, a frequency conversion microwave generator and a power amplifier. After the technical scheme is adopted, microwave energy generated by the variable-frequency microwave heating device is concentrated in a small-range point-shaped area of the microwave antenna end, a microwave electromagnetic field environment with high power and high energy density can be instantly generated in a small-range space, fixed-point and point-by-point microwave heating is carried out on a material, and drying and curing can be completed within an extremely short time. Besides, the variable-frequency microwave heating device has the advantages of being small in size, light in weight, capable of being conveniently held and operated by a robot and the like, the use requirement for automatic batch production of industrial products is completely met, and by means of the device, the production process innovation that microwave heat treatment is converted into online operation from offline operation can be achieved.

Owner:SH INTELLIGENT EQUIP SHANGHAI CO LTD

Anticorrosive paint based on amination linoleic acid copolymerized acrylic resin and preparation method of anticorrosive paint

ActiveCN102816481BAvoid corrosionHigh solid contentAnti-corrosive paintsPolymer scienceAcrylic resin

The invention discloses an anticorrosive paint based on amination linoleic acid copolymerized acrylic resin and a preparation method of the anticorrosive paint. The paint comprises following components of amination linoleic acid copolymerized acrylic resin, mica iron oxide, zinc phosphate, aluminium triphosphate, mica powder, talcum powder, organic bentonite, butyl acetate, ethyl acetate and the like. The process for preparing the amination linoleic acid copolymerized acrylic resin comprises steps that firstly acrylic prepolymer is prepared through mass polymerization, and then the acrylic prepolymer is further copolymerized with amination linoleic acid through free radicals through a solution polymerization method. The components are mixed according to a given proportion and then are rapidly blended and uniformly ground into particles with granularity of less than 50 micrometers. The prepared paint is coated on the metal surface and dried at normal temperature to form a membrane. The paint membrane has advantages of high solid content, rapid drying speed, good mechanical performance, good corrosion resistance and the like.

Owner:SUZHOU JIREN HIGH TECH MATERIAL CO LTD

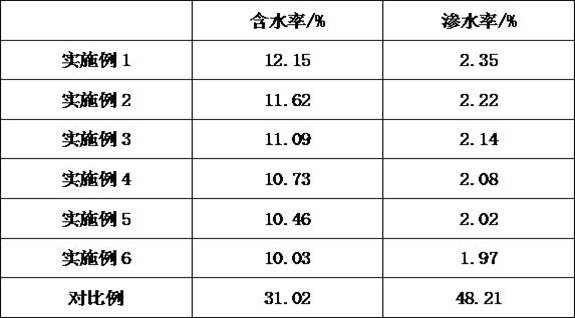

Waterproof protective material for deep well and preparation method of waterproof protective material

The invention discloses a waterproof protective material for a deep well and a preparation method of the waterproof protective material. The waterproof protective material is prepared from water-based polymethyl silicone resin, deionized water, butyl stearate, an antioxidant, a water repellent agent, carboxymethylcellulose, polyacrylamide, fatty glyceride and a coloring agent. The water-based coating comprises the following components in parts by weight: 78-84 parts of water-based polymethyl silicone resin, 15-19 parts of deionized water, 3-5 parts of butyl stearate, 2-4 parts of an antioxidant, 2-4 parts of a water repellent agent, 1-3 parts of carboxymethylcellulose, 2-4 parts of polyacrylamide, 1-3 parts of fatty glyceride and 1-3 parts of a coloring agent. The hydrophobic agent formed by mixing the dimethyl silicone oil, the calcium palmitate and the microcrystalline wax is added, so that the waterproof performance of the material is greatly improved, the problem of underground water leakage is not easy to occur after long-term use, a protective layer is maintained, the problems of damp deformation, cracking and collapse of a deep well are avoided, and the use is safer.

Owner:河南蓝翎环科防水材料有限公司

Fast-to-dry indoor coating

InactiveCN108384436AImprove catalytic performanceSpeed up catalytic decompositionPolyurea/polyurethane coatingsFoaming agentIdle time

The invention discloses fast-to-dry indoor coating, which is prepared from the following ingredients including shell powder, diatomite, polyurethane modified acrylic resin emulsion, organic silicon resin, a photocatalyst material, dispersing agents, anti-foaming agents, leveling agents and light calcium carbonate, wherein the photocatalyst material is loaded onto the diatomite. The coating has theadvantages that the idle time of a room after the decoration can be effectively shortened; the degradation efficiency of indoor harmful volatile matters is improved; after the coating, the fast drying and curing can be realized.

Owner:成都经纬云图科技有限公司

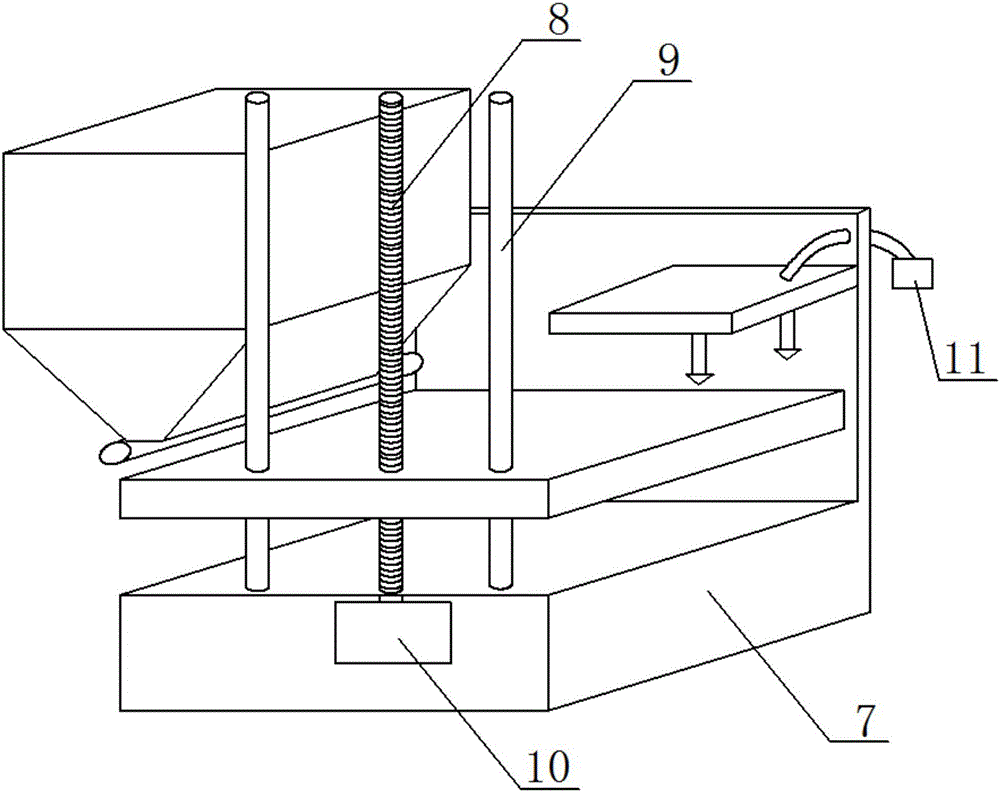

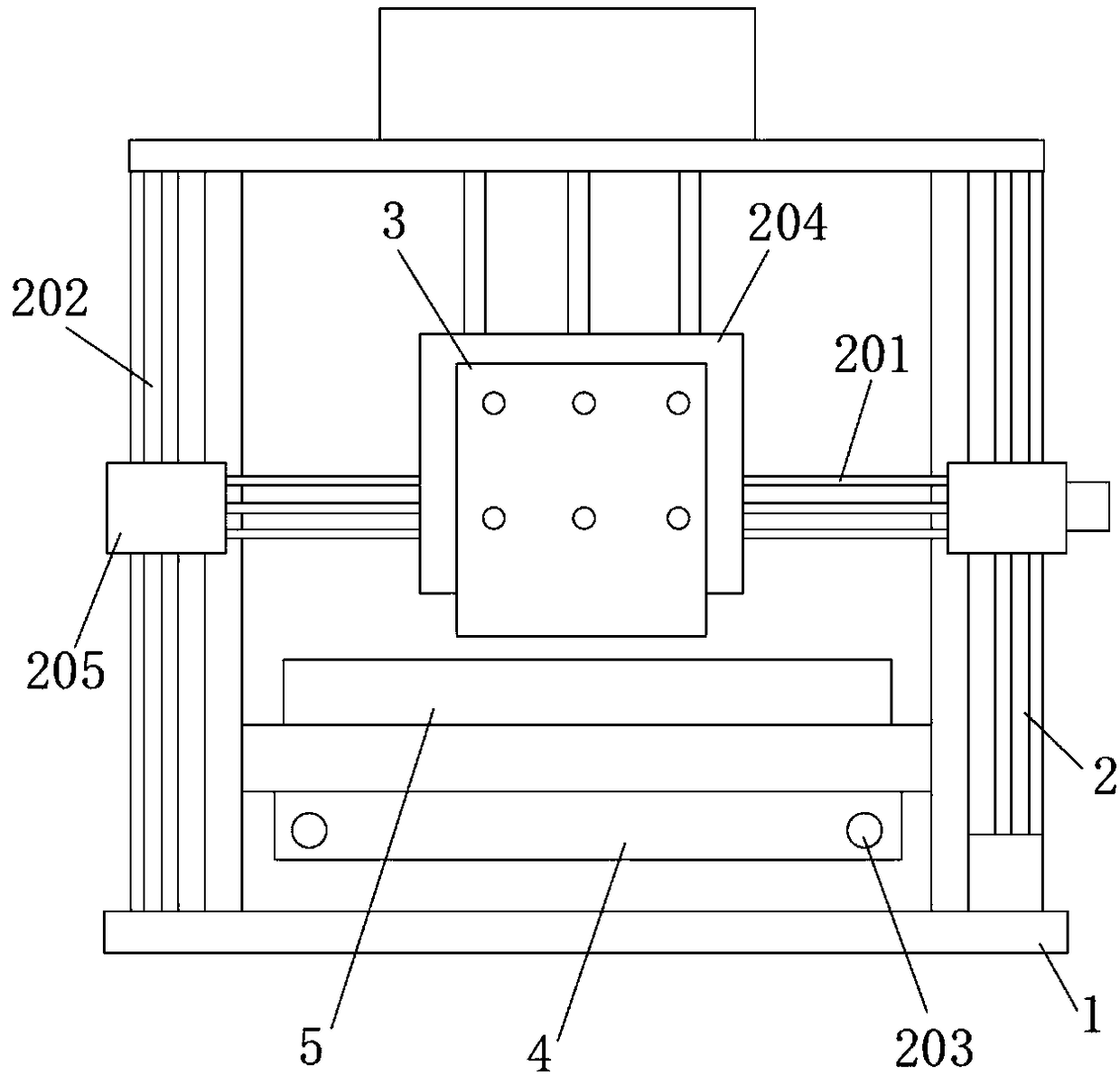

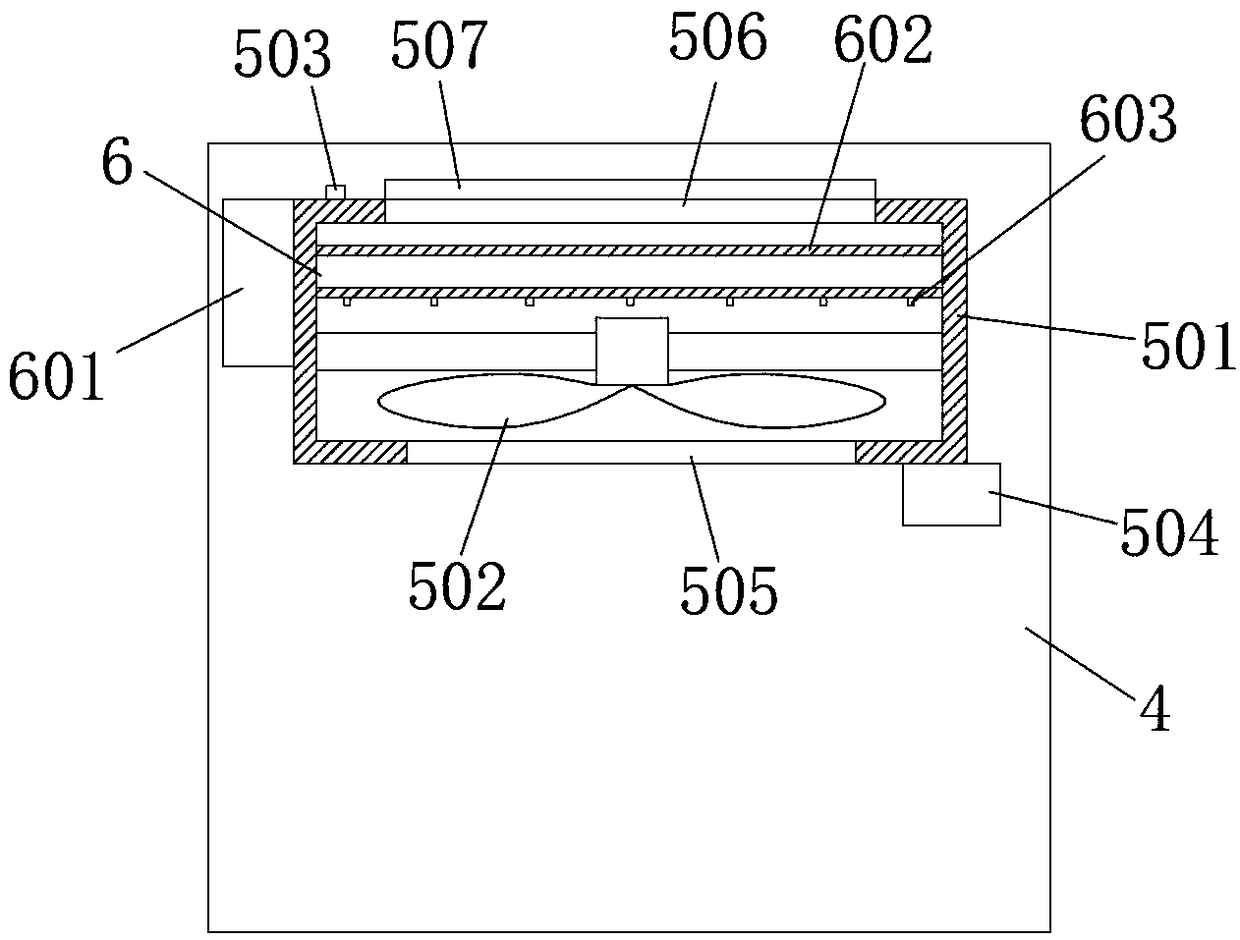

Static electricity-eliminating mechanism special for printer

InactiveCN108973119AQuick drying and curingEasy maintenanceAdditive manufacturing apparatusManufacturing material handlingSprayerMetal sheet

The invention discloses a static electricity-eliminating mechanism special for a printer. The static electricity-eliminating mechanism special for the printer comprises a printer main body; the printer main body comprises a three-dimensional motion mechanism, a sprayer, a fixed platform, a curing device and a static electricity-eliminating device; the fixed platform is arranged under the printer main body; the curing device is arranged on one side above the fixed platform; the curing device is fixedly connected with the static electricity-eliminating device through bolts; the curing device comprises a shell; the shell is fixed on the fixed platform through bolts; a metal sheet is jointed on one side under the shell; a grounding wire is connected with the shell through a rivet; a fan is arranged in the shell; the static electricity-eliminating device comprises a high voltage power generator; outlets are uniformly formed on a drum. The static electricity-eliminating mechanism special forthe printer has the advantages of reasonable design, simple structure, good static electricity-eliminating effect, simple maintenance, high reliability and capability of quickly drying and curing a printed piece and improving the printing efficiency.

Owner:HEFEI AIRWREN AUTOMATIC EQUIP CO LTD

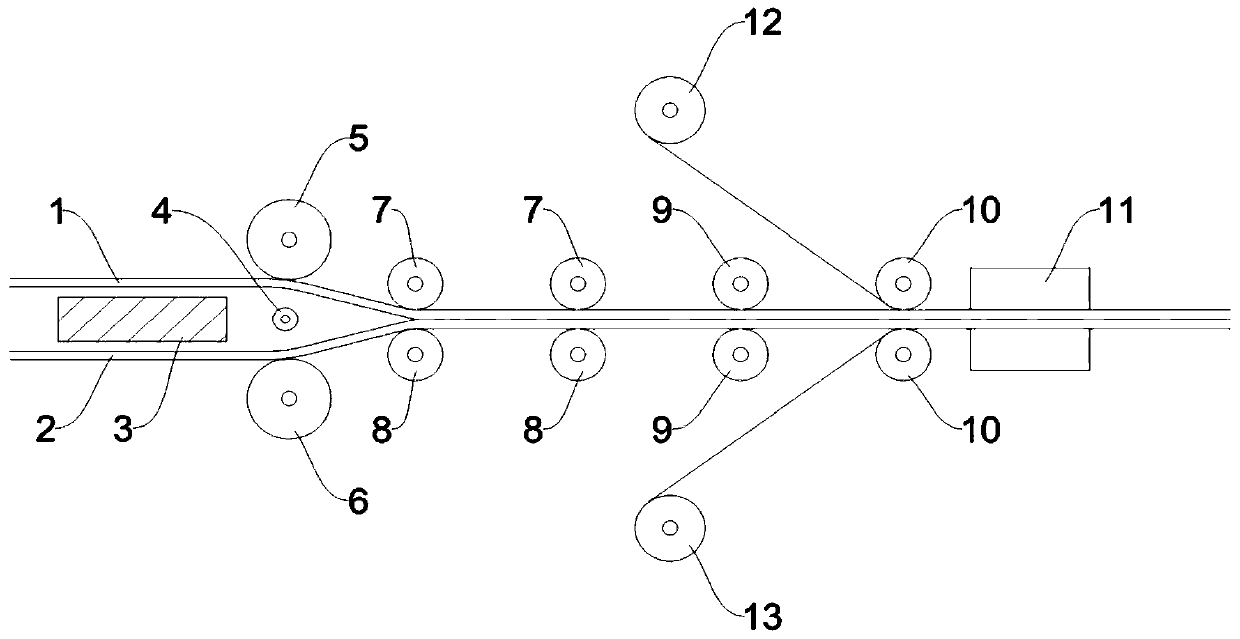

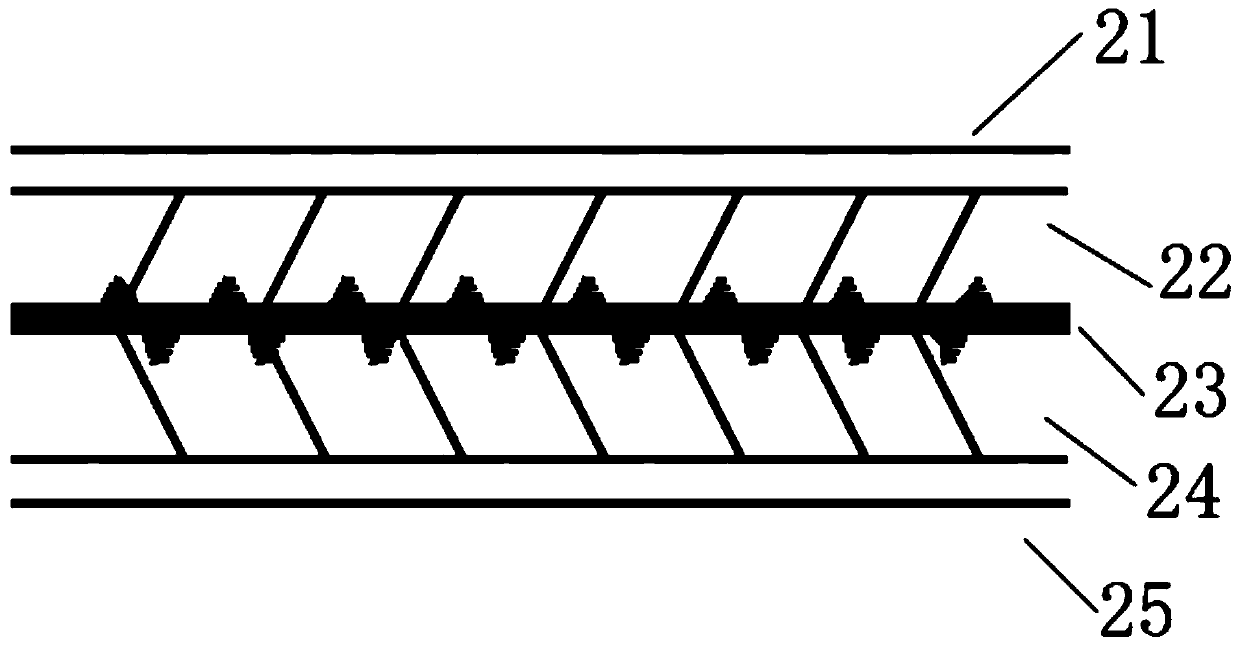

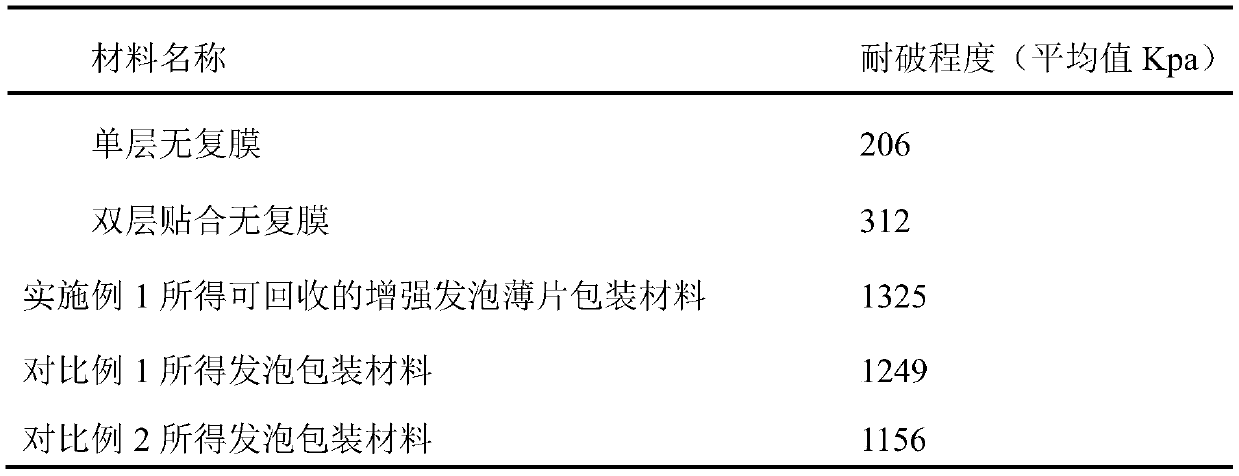

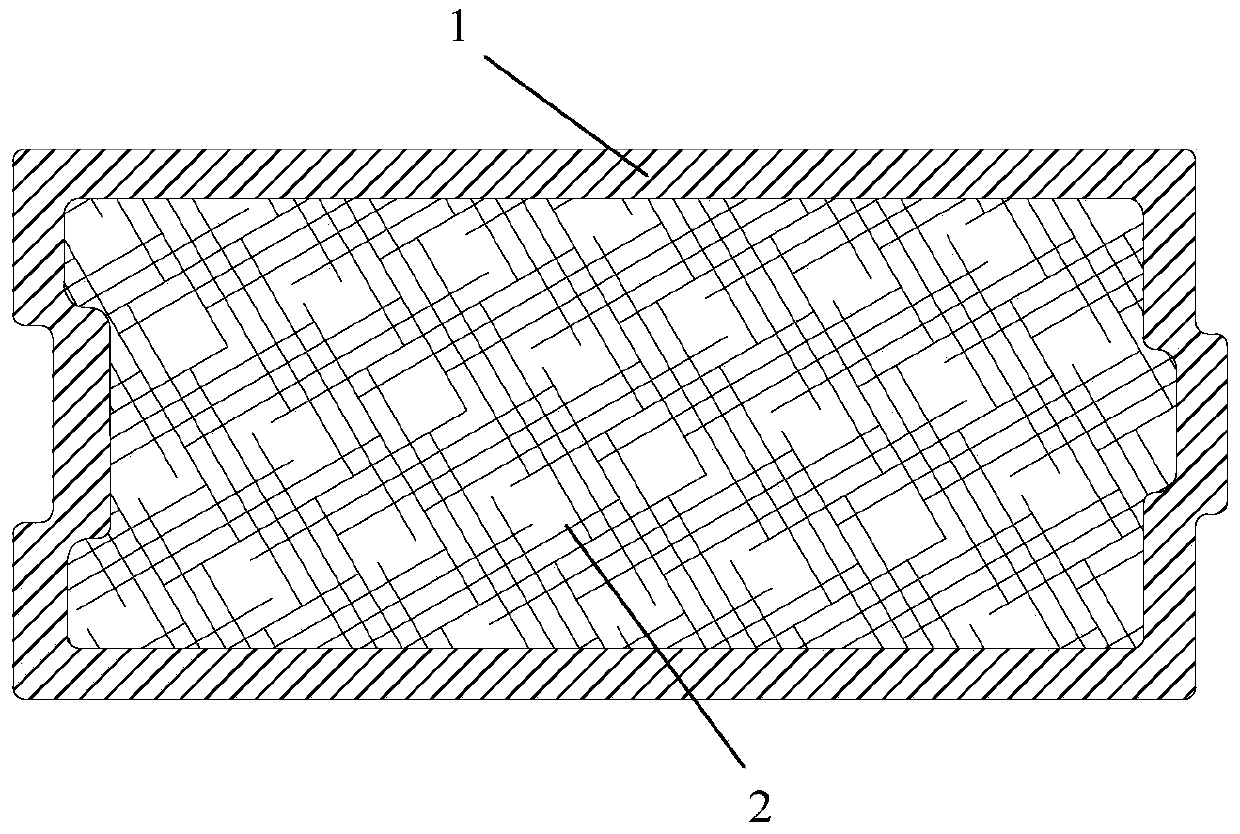

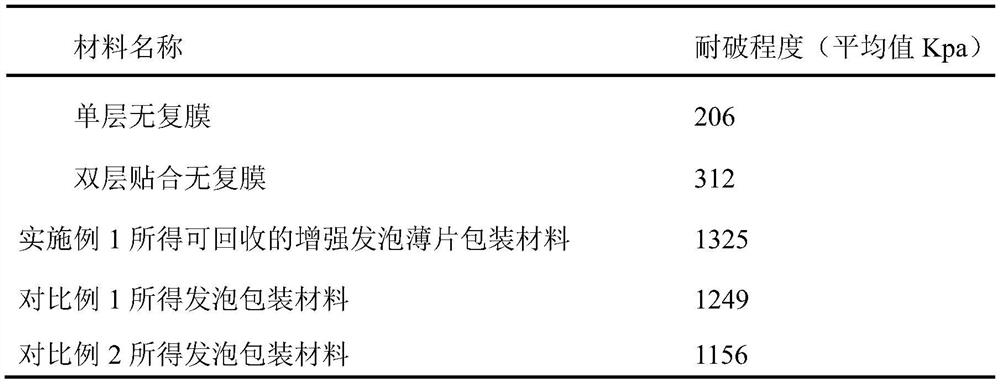

Recoverable reinforced foaming sheet packing material and preparation method thereof

ActiveCN110126312AMeet environmental protection requirementsEasy bonding processSynthetic resin layered productsDomestic containersUV curingHigh pressure

The invention relates to a recoverable reinforced foaming sheet packing material and a preparation method thereof. The preparation method comprises the following steps that (1) an upper foaming boardand a lower foaming board are prepared with a foaming process; (2) the upper foaming board is arranged between an upper insulation roller and a high-voltage discharging rod, the lower foaming board isarranged between a lower insulation roller and the high-voltage discharging rod, the lower surface, heated and molten through corona discharging, of the upper foaming board and the corresponding upper surface of the lower foaming board synchronously pass through a corona heating area and are pressed and combined by a composite roll, thus a heat permeation layer is formed between the lower surfaceof the upper foaming board and the upper surface of the lower foaming board, the heat permeation layer connects the upper foaming board with the lower foaming board, and thus the upper foaming boardand the lower foaming board become a composite whole; and (3) BOPP / PE / PET plastic film layers / a BOPP / PE / PET plastic film layer are / is attached to the upper surface of the upper foaming board and / or the lower surface of the lower foaming board with PUR glue through UV curing technology. After corona treatment is combined with pressing combination by the composite roll, the lower surface of the upper foaming board and the corresponding upper surface of the lower foaming board permeate each other to form the heat permeation layer, overall strength can be improved, strength can be enhanced by about 50%, and toughness can also be improved.

Owner:广东领先环保科技有限公司

A kind of preparation method of inorganic fiber and wood-plastic composite board

The invention discloses a preparation method of an inorganic fiber and wood plastic composite plate. The inorganic fiber and wood plastic composite plate is molded through coextrusion of a mold, the mold is provided with a hollow cavity in the length direction, a feed end of the mold communicates with a wood plastic runner of the hollow cavity, and an outlet of the wood plastic runner faces a discharge end of the mold. The preparation method comprises the steps that a molten wood plastic material is sent into the hollow cavity by virtue of the wood plastic runner through an extruder, the wood plastic material is cooled and molded in the hollow cavity, and a hollow wood plastic frame is formed and is extruded from the discharge end of the mold; and inorganic fibers and a binder are synchronously and uniformly sprayed into the wood plastic frame in the mold, the inorganic fibers are blown to the wood plastic frame and are bound with the wood plastic frame by virtue of the binder, the wood plastic frame is filled, and a filled layer is formed. The invention relates to the field of buildings, and provides the preparation method of the inorganic fiber and wood plastic composite plate. According to the preparation method, procedures can be simplified, and the composite plates are synchronously molded at a time.

Owner:BEIJING NEW BUILDING MATERIALS PLC

A kind of recyclable reinforced foam sheet packaging material and preparation method thereof

ActiveCN110126312BAvoid lostHigh mechanical strengthSynthetic resin layered productsDomestic containersPolymer scienceUV curing

The invention relates to a recyclable reinforced foam sheet packaging material and a preparation method thereof, comprising the following steps: 1) preparing an upper foam board and a lower foam board through a foaming process; (2) placing the upper foam board on the upper Between the insulation roller and the high-voltage discharge rod, the lower foam board is placed between the lower insulation roller and the high-voltage discharge rod. The halo heating zone is pressed by composite rollers, so that a heat permeable layer is formed between the lower surface of the upper foam board and the upper surface of the lower foam board, and the heat permeable layer connects the upper foam board and the lower foam board, making it a composite whole (3) The BOPP / PE / PET plastic film layer is pasted on the upper surface of the upper foam board and / or the lower surface of the lower foam board by UV curing technology with PUR glue. After corona treatment combined with composite roller pressing, the lower surface of the upper foam board and the upper surface of the corresponding lower foam board penetrate each other to form a heat permeable layer, which can improve the overall strength, the strength can be increased by about 50%, and the toughness can also be improved.

Owner:广东领先环保科技有限公司

Multi-core optical fiber connector intelligent processing equipment and processing method

ActiveCN113751276BEasy to receiveImprove intelligencePretreated surfacesCoupling light guidesGear wheelOptical fiber connector

The invention discloses multi-core optical fiber connector intelligent processing equipment and a processing method, including a machine table, a drying mechanism and a connecting material guide mechanism. Holding mechanism, driven gear, ring rack, driving gear, motor, endless conveyor belt and limit fixing seat, the guide plate is located on one side of the top of the endless conveyor belt; the present invention receives the workpiece to be processed through the conveying mechanism and conveying, and automatically clamp and position the workpiece. During the period, the automatic ferrule, glue injection and optical fiber insertion work are carried out in sequence, without manual assistance from the operator, which increases the intelligence of the workpiece processing. , it is convenient to receive the conveyed workpiece, and automatically and quickly transfer the workpiece to the next station, thereby reducing the possibility of optical fiber position inclination and misalignment, and improving the processing efficiency of optical fiber connectors.

Owner:深圳市博邦精密科技有限公司

Preparation method of alumina catalyst carrier

ActiveCN106179520BSolve the problem of dry crackingHigh activityCatalyst carriersCatalyst activation/preparationMixed materialsAbnormal shaped

The invention discloses a method for preparing an alumina catalyst carrier. The method comprises the following steps: uniformly mixing the following components in the ratio: 30-80 percent of pseudo-boehmite, 10-50 percent of superfine cellulose powder and 5-30 percent of quick-dehydrating powder; uniformly mixing, and grinding the mixed materials; preparing an acid solution in a weight ratio of acid to water being (0.5-30):100; adding the ground powder into a charging container; adding the prepared acid solution into a pressurized and flow-controllable container; printing the charging container filled with powder on a 3D printing mechanism under computer control layer by layer to obtain a finished product of a profiled large active alumina carrier. The method can be used for manufacturing mass integrated active alumina catalyst and preventing the phenomenon of dry cracking.

Owner:JIANGXI ACICHEMSHUN IND

Pavement coating and preparation method thereof

ActiveCN109796874BHigh mechanical strengthGood adhesionIn situ pavingsCoatingsFirming agentCross linker

Owner:重庆东吴道路工程有限公司

Quick blow-drying device for transfer printing marks of shaping rubber pipe products

ActiveCN102765248BQuick drying and curingImprove efficiencyPrinting press partsEngineeringAir blower

The invention discloses a quick blow-drying device for transfer printing marks of shaping rubber pipe products. The quick blow-drying device comprises a support (1), a belt conveyor (2), an air blower (3) and a blow pipe (4). The technical scheme includes that the blow pipe is arranged above the belt conveyor, air provided by the air blower is dispersed through the air pipe to be upwardly blown to the belt conveyor, and when the quick blow-drying device is in operation, rubber pipe products after transfer printing of marks are placed on the belt conveyor and carried by the belt conveyor to pass through a blow-drying area of the blow pipe to enable ink marks to be quickly dried and cured. The defects of low efficiency and high cost of prior art are overcome, and efficiency improvement and cost reduction in transfer printing of the shaping rubber pipe products are realized by means of blowing for quick drying and automatic conveying.

Owner:宁波市天普橡胶科技股份有限公司

A kind of preparation method of refractory lightweight particle and wood-plastic composite board

ActiveCN107433720BHigh strengthQuick drying and curingDomestic articlesPlastic materialsComposite plate

Owner:BEIJING NEW BUILDING MATERIALS PLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com