Patents

Literature

35results about How to "Fast drying and curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-temperature quick-drying type polyurethane acrylate coating and preparation method thereof

ActiveCN104804633AImprove adhesionHigh mechanical strengthPolyurea/polyurethane coatingsAcrylic resinLow temperature curing

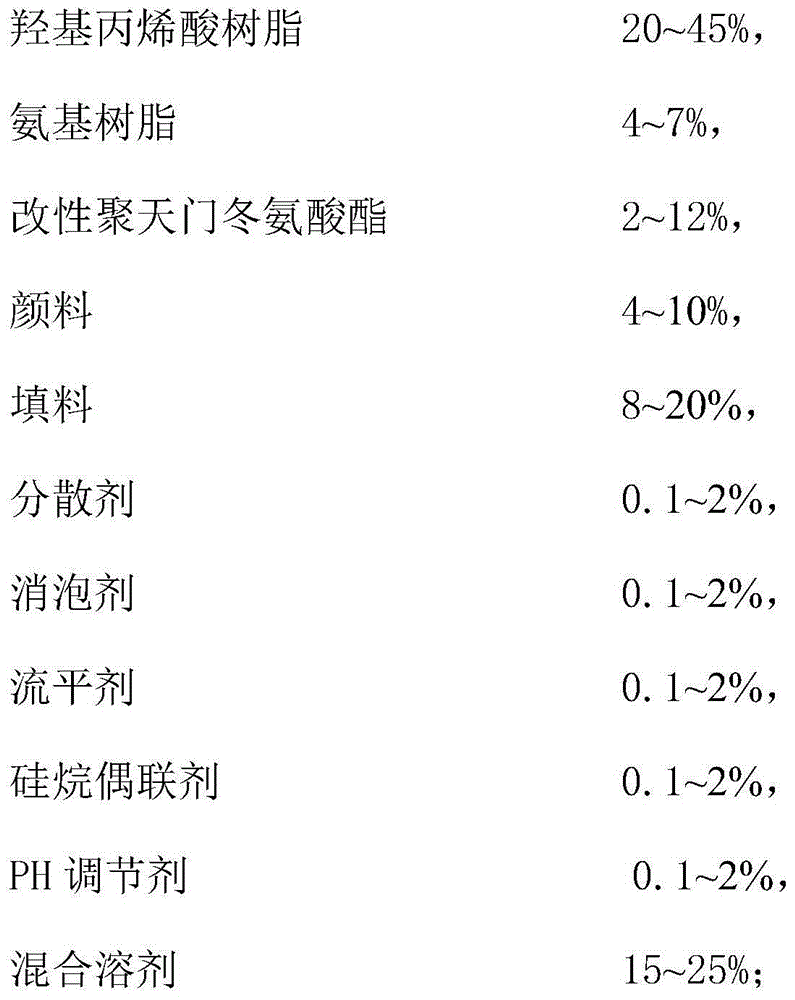

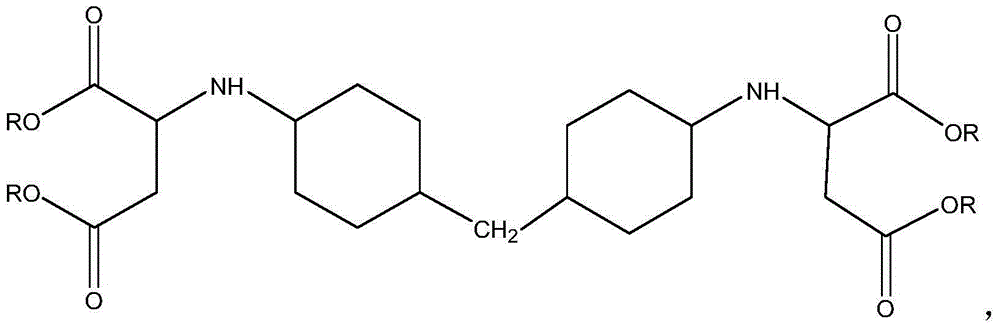

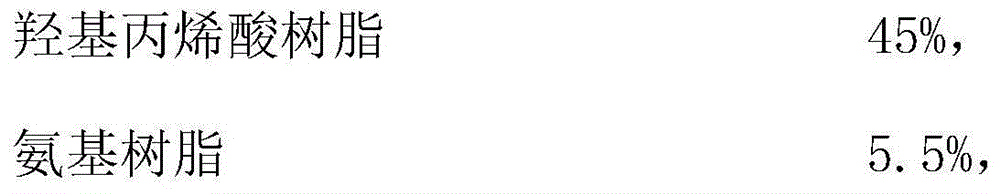

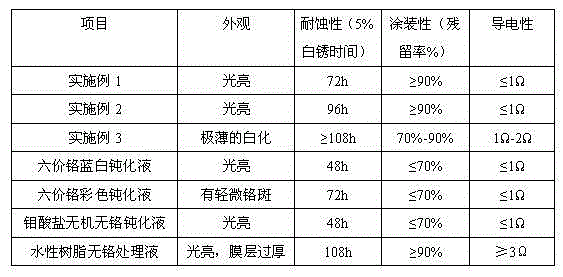

The invention discloses a low-temperature quick-drying type polyurethane acrylate coating. The coating consists of a component A and a component B by a mass ratio of 100 to (20-27), wherein the component A comprises the following components in percentage by mass: 20-45 percent of hydroxyl acrylic resin, 4-7 percent of amino resin, 2-12 percent of modified polyaspartic acid ester, 4-10 percent of a pigment, 8-20 percent of filler, 0.1-2 percent of a dispersant, 0.1-2 percent of a defoaming agent, 0.1-2 percent of a flatting agent, 0.1-2 percent of a silane coupling agent, 0.1-2 percent of a PH regulating agent and 15-25 percent of a mixed solvent; the component B is isophorone diisocyanate. The coating disclosed by the invention has the characteristics of being rapid, cured at low temperature, excellent in physical and mechanical properties and the like, is excellent in adhesive force to various base materials (iron, aluminum alloy, zinc plated plates, stainless steel and the like), and can be widely applicable to industrial coating of costly furniture, steel structures, railway locomotives and the like. The invention also discloses a preparation method of the low-temperature quick-drying type polyurethane acrylate coating.

Owner:东莞市惠尔明高分子材料科技有限公司

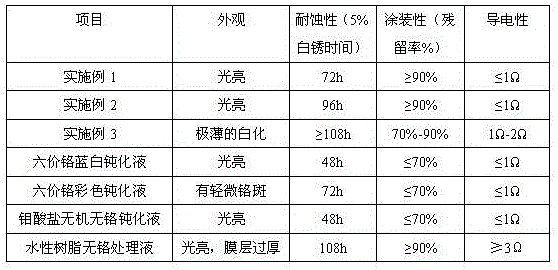

Water-based composite passivation solution for galvanized steel plate and preparation method of water-based composite passivation solution

InactiveCN104451641AImprove corrosion resistanceQuality improvementMetallic material coating processesWater basedChromium free

The invention relates to a water-based composite chromium-free passivation solution for a galvanized steel plate. The passivation solution contains 10-30g / L of sodium molybdate, 0-10g / L of sodium phosphate, 5-10g / L of organic phosphoric acid, 1-10g / L of fluotitanic acid, 5-15g / L of a silane coupling agent, 5-20g / L of sodium metasilicate, 0.1-1% of a wetting dispersant and the balance of deionized water. The passivation solution provided by the invention consists of an organic phosphoric acid-molybdate system in match with the modified hydrolysis type silane coupling agent and a nano-inorganic filler, does not contain a chromate and is in line with ROHS requirements; the passivation and drying curing time is short, the degree of stability is high, the quality of a film layer is good, the white rust area in a 72h salt fog test does not exceed 5%, the cost is relatively low, a passivation process device does not need to be changed, and continuous passivation can be realized by using a hexavalent chromium passivation device in early period.

Owner:北京蓝星清洗有限公司

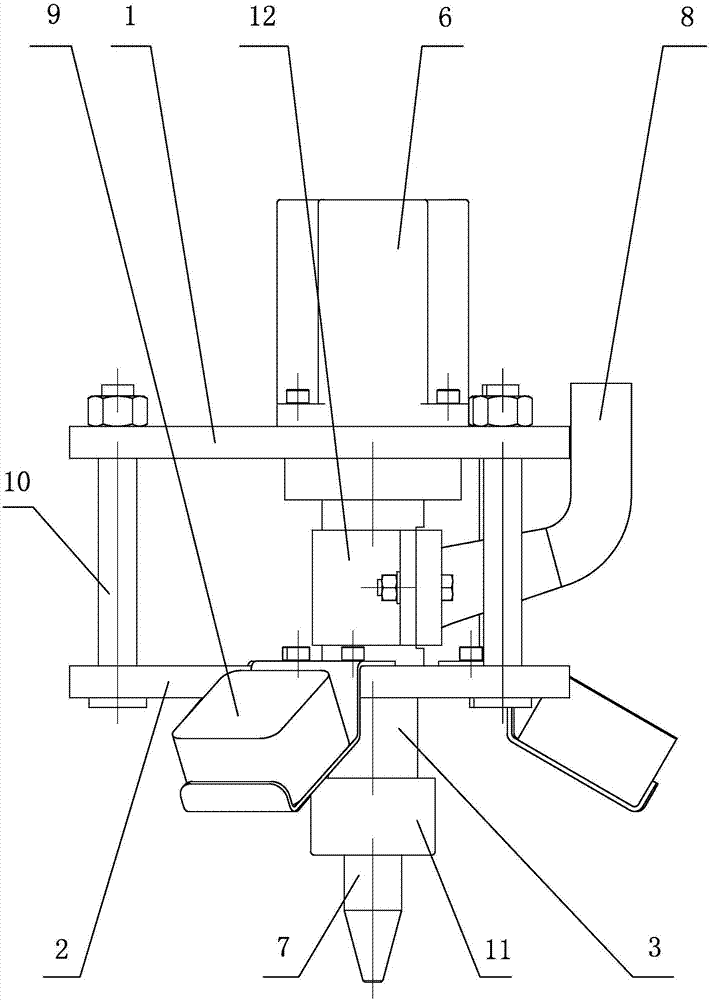

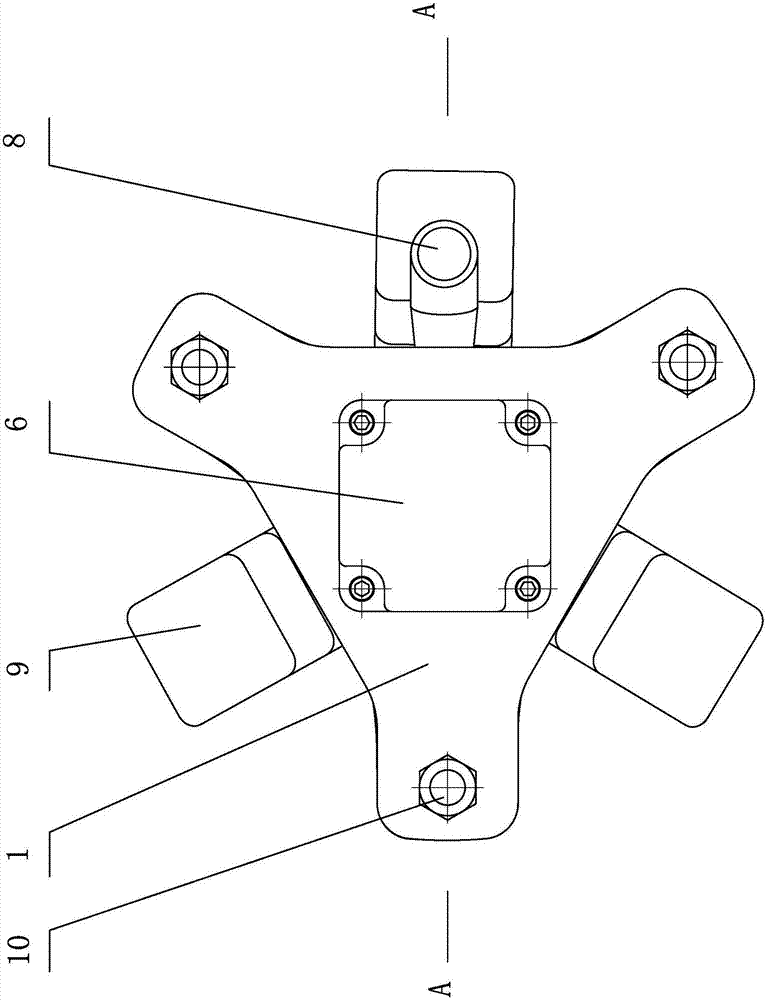

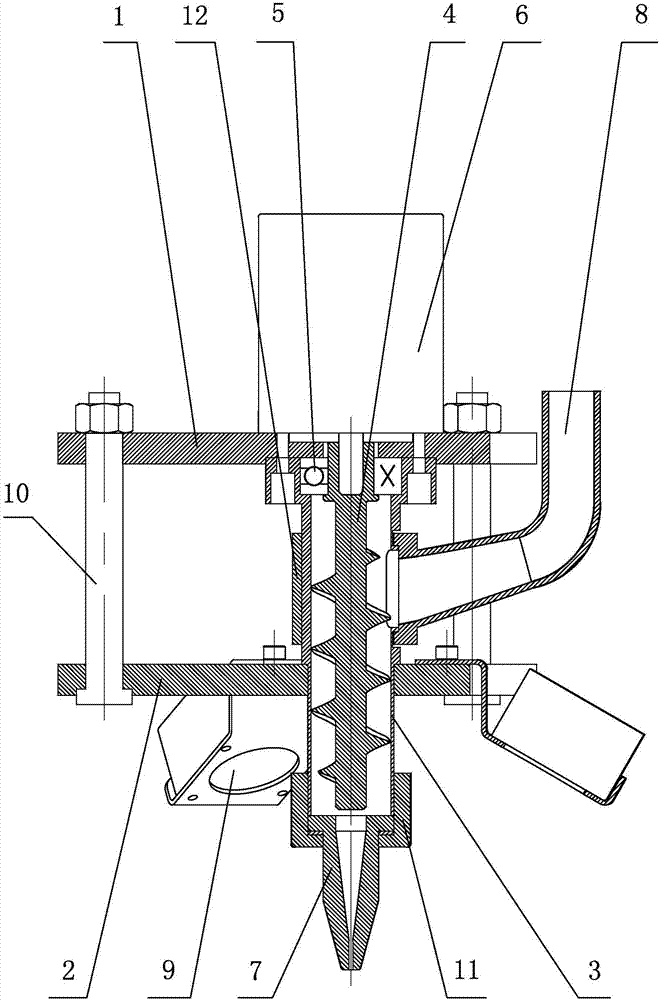

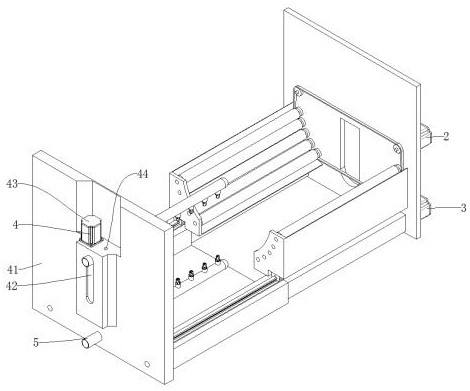

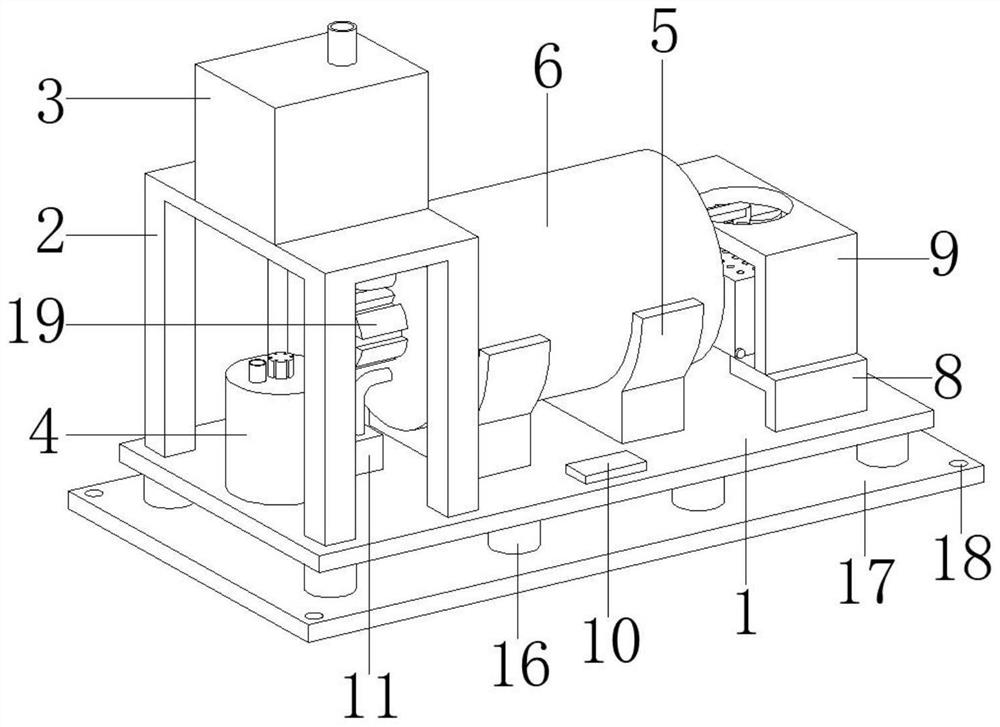

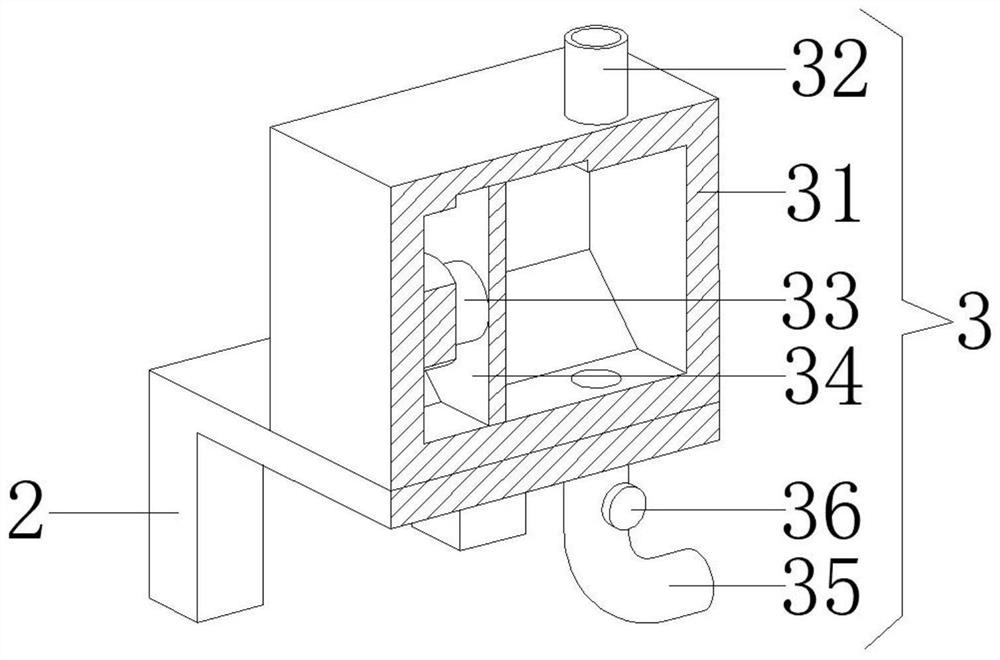

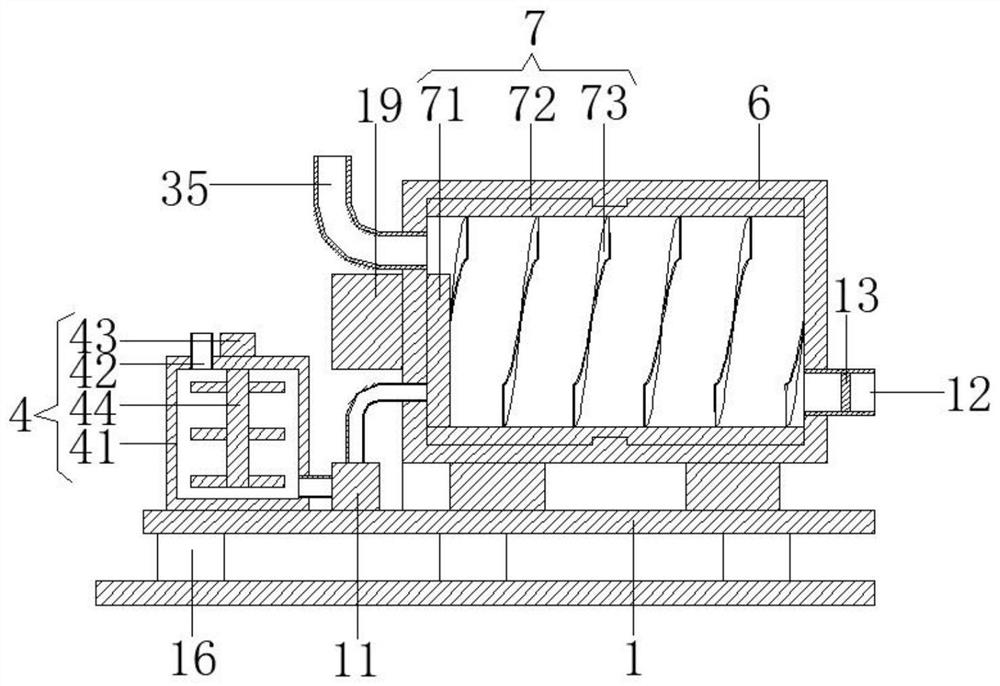

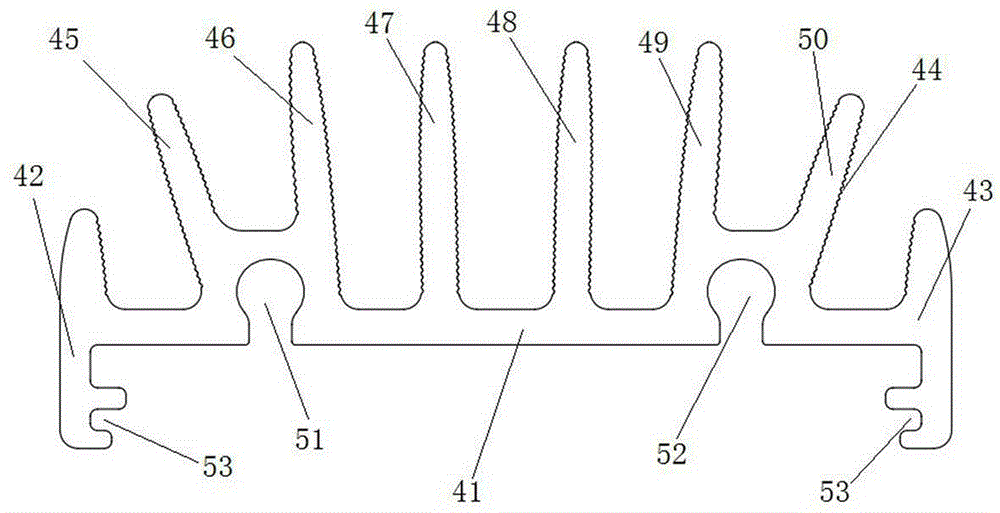

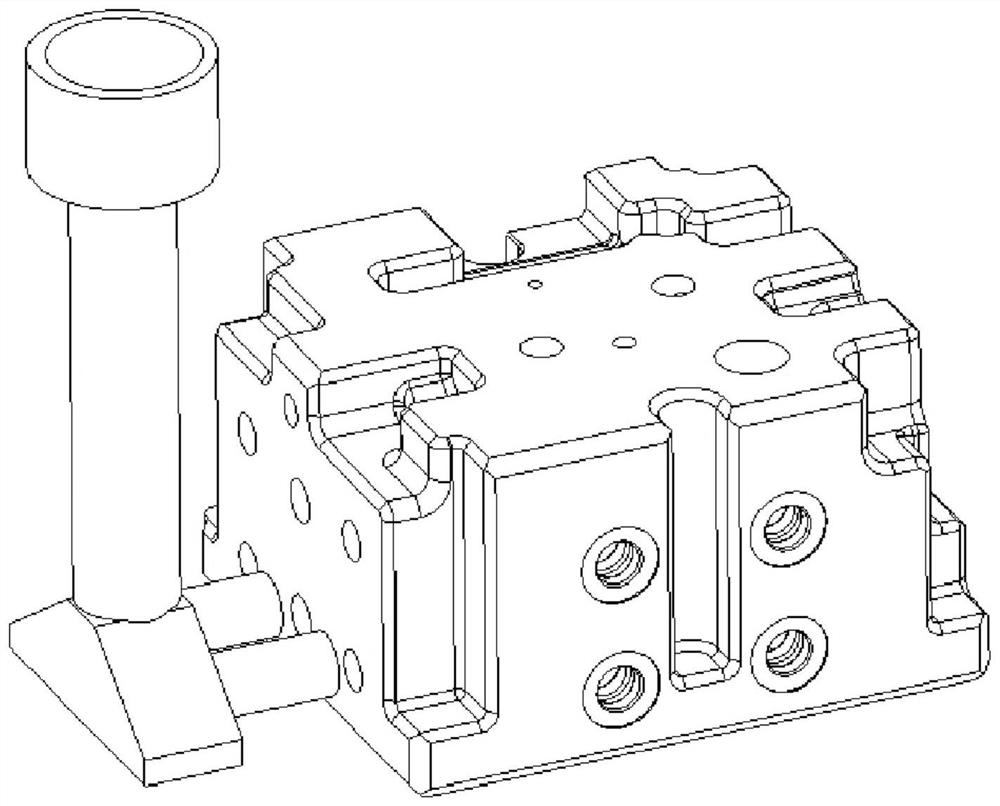

3D printing spray head device

PendingCN107415220ANo cloggingHelp with cleanupManufacturing heating elementsCeramic shaping apparatus3d printRolling-element bearing

The invention discloses a 3D printing spray head device. The 3D printing spray head device comprises an extruding mechanism, a feeding mechanism and a heating mechanism. The extruding mechanism comprises a material guide cylinder which is positioned and mounted through an upper fixing plate and a lower fixing plate. A feeding screw mounted through a rolling bearing is arranged in the material guide cylinder. The upper end of the feeding screw extends out of an upper cylinder opening of the material guide cylinder and is connected with a motor output shaft mounted on the upper fixing plate. A detachable spray head is mounted on a lower cylinder opening of the material guide cylinder. The feeding mechanism comprises a feeding pipe. The feeding pipe communicates with a feeding opening in a material guide cylinder body. The heating mechanism comprises air heaters arranged on the lower fixing plate. Air blowing openings of the air heaters all face a spray nozzle of the spray head. The 3D printing spray head device is simple in structure, good in extrusion effect, uniform to heat and capable of quickly curing a model, and the spray head is not likely to be blocked.

Owner:桂林市新众科技有限公司

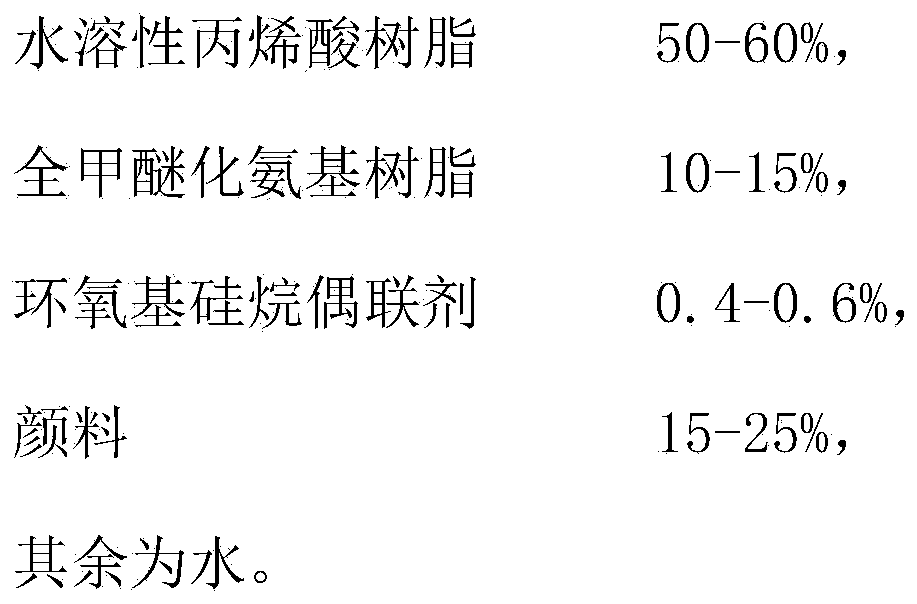

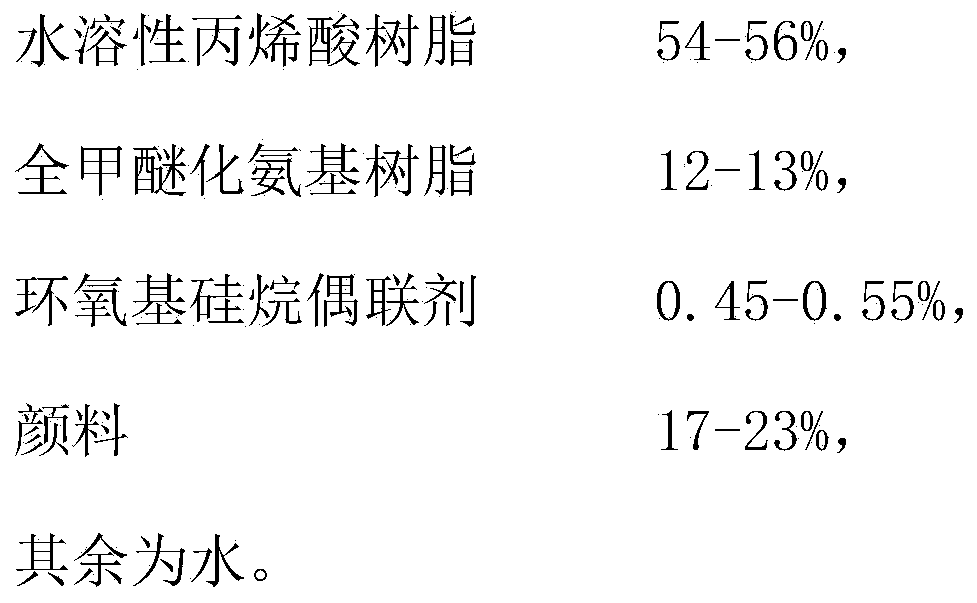

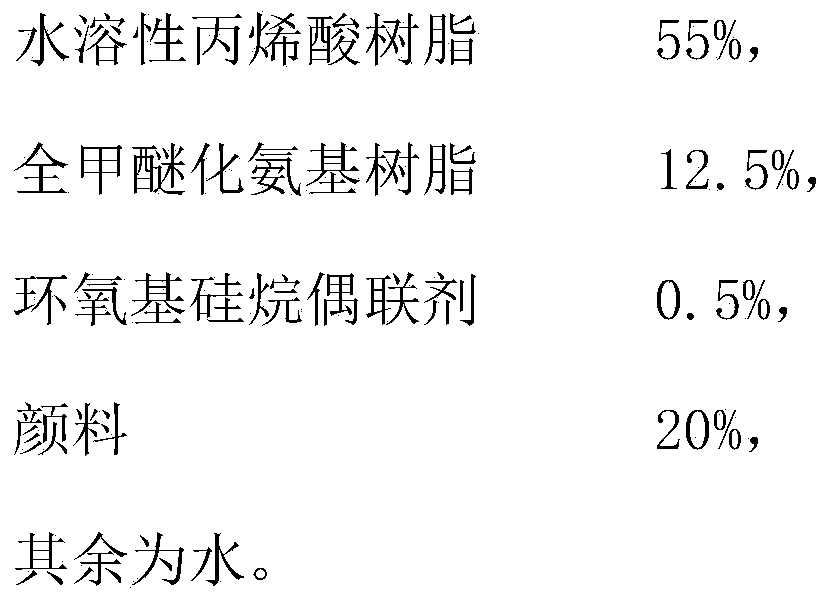

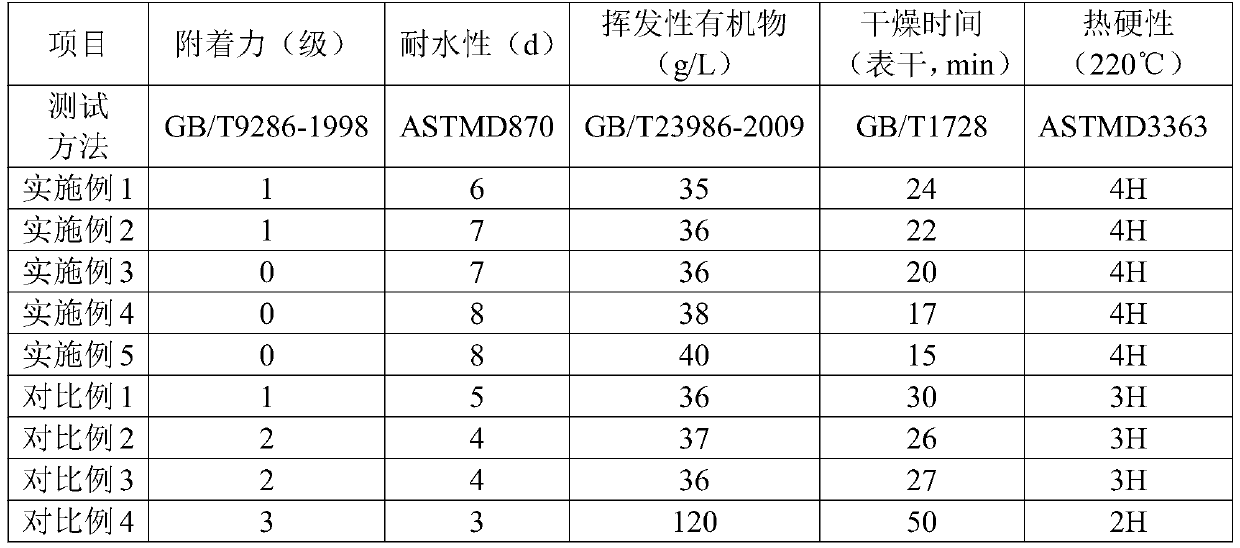

Water-based acrylic amino stoving varnish

The invention discloses a water-based acrylic amino stoving varnish which comprises the following materials in weight percentage: 50-60% of water-soluble acrylic resin, 10-15% of full methylated amino resin, 0.4-0.6% of an epoxy group silane coupling agent, 15-25% of a pigment, and the balance of water. The water-based acrylic amino stoving varnish uses the water-soluble acrylic resin as a film forming agent and the full methylated amino resin as a coupling agent, as the water-soluble acrylic resin and the full methylated amino resin have a hydrophilic group and can be directly dissolved in water, then no residual emulgators exist after the water-based acrylic amino stoving varnish is dried and solidified, and the water resisting property of the water-based acrylic amino stoving varnish is greatly improved. The water-based acrylic amino stoving varnish adopts the epoxy group silane coupling agent, then the pigment is excellent in compatibility with the film forming agent and the coupling agent, and the service life of the water-based acrylic amino stoving varnish is prolonged. The drying and solidifying speeds of the water-based acrylic amino stoving varnish are high, and the required drying temperature is low.

Owner:ANHUI JINDUN PAINT

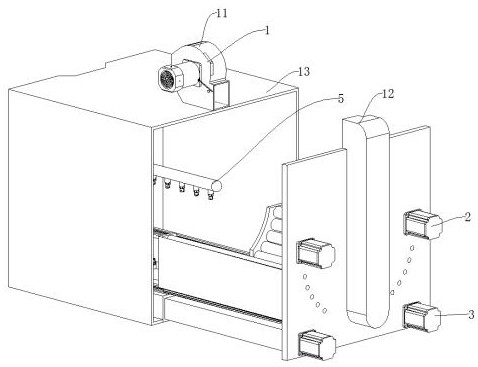

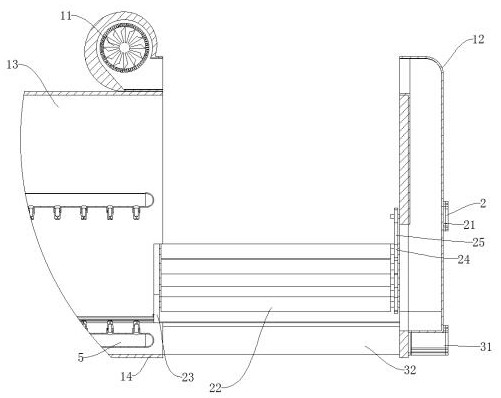

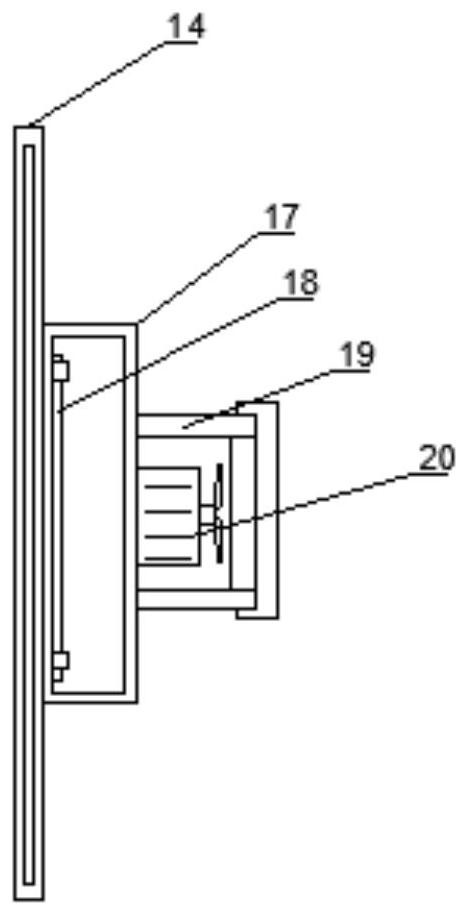

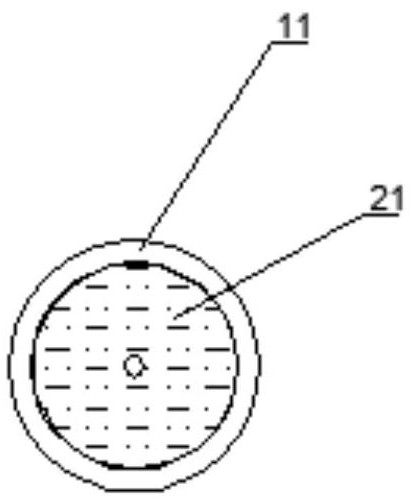

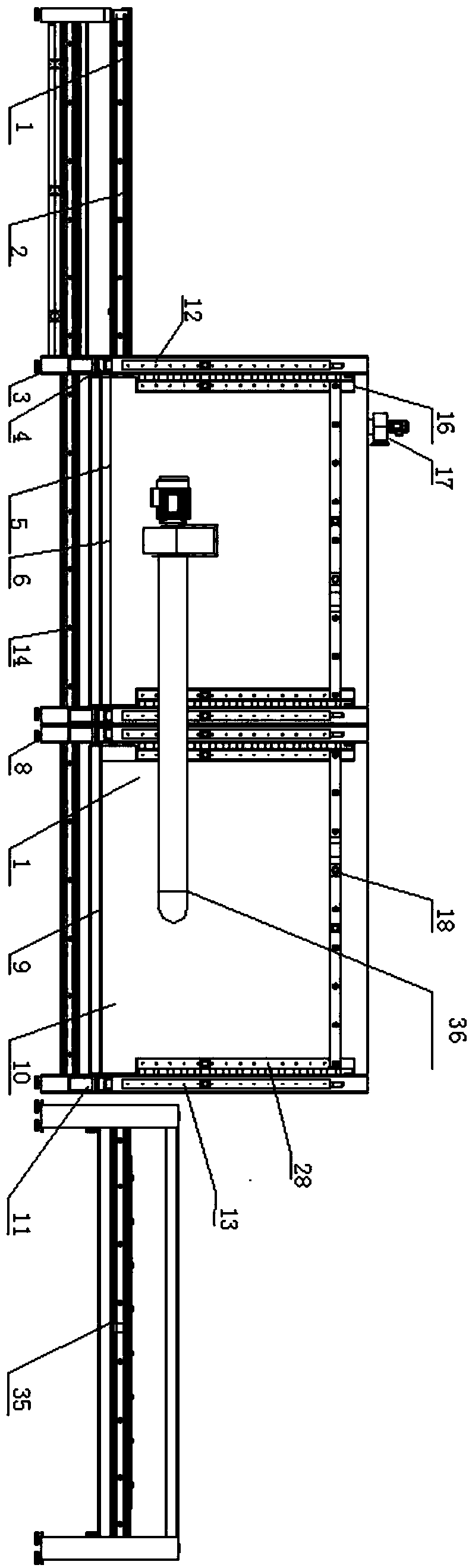

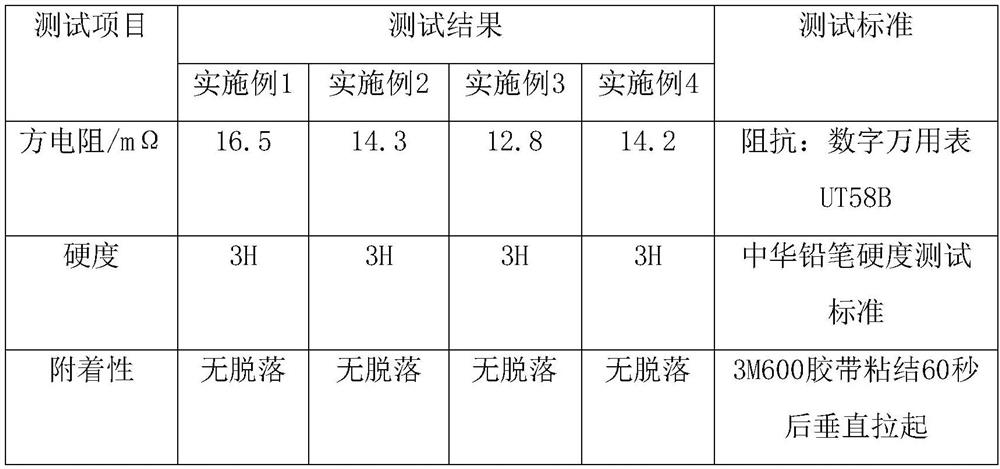

Anticorrosive treatment coating device for cement culvert pipe production

The invention discloses an anticorrosive treatment coating device for cement culvert pipe production. The device comprises a moving mechanism, an adjusting mechanism for adjusting the coating distance, a coating pipe, a drying mechanism and a rotating mechanism. The moving mechanism is located on one side of the adjusting mechanism, and the coating pipe is located on the inner side of the adjusting mechanism. The drying mechanism comprises an air heater, an air supply pipe, a shielding can and an isolation plate. The shielding can is connected with the adjusting mechanism, and the isolation plate is connected with the adjusting mechanism. According to the anticorrosive treatment coating device for cement culvert pipe production, a rotating motor is used for driving a chain and a chain wheel to drive annularly-distributed rotating rollers to rotate, and therefore anti-corrosion coating operation can be conducted on the cement culvert pipes with different diameters; the hot-air blower isused for conducting high-temperature purging on the interior and exterior of the cement culvert pipes in the shielding can, sprayed epoxy resin anticorrosive materials can dry and cure more quickly.

Owner:衡阳市畅通管业有限公司

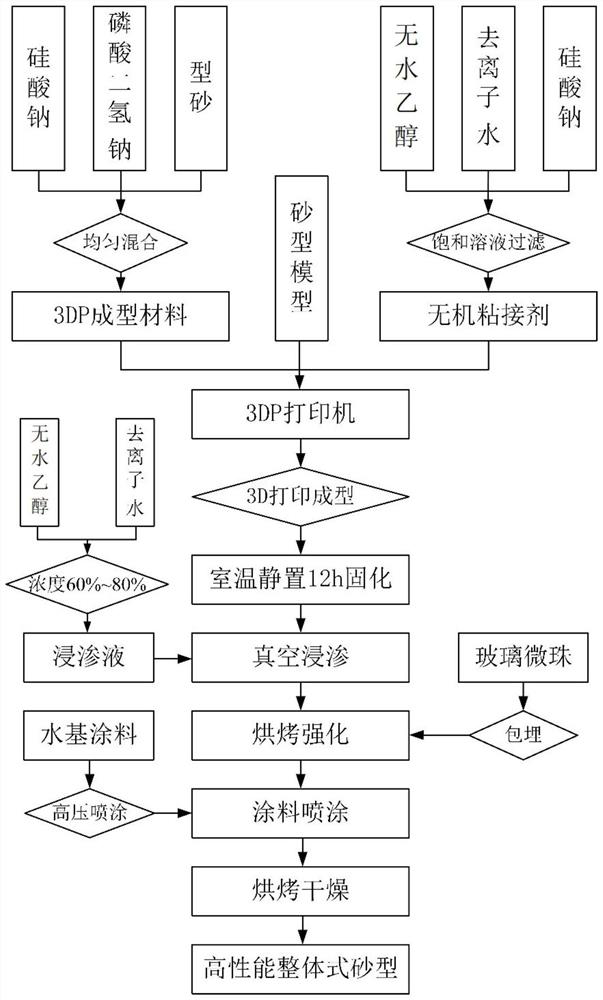

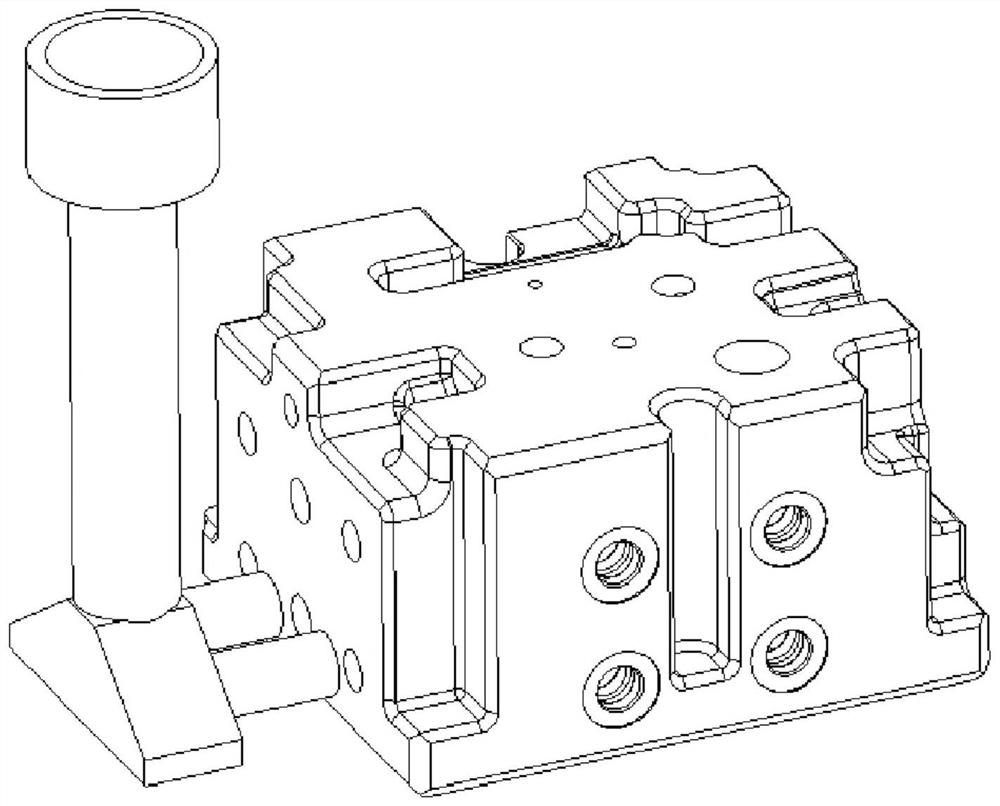

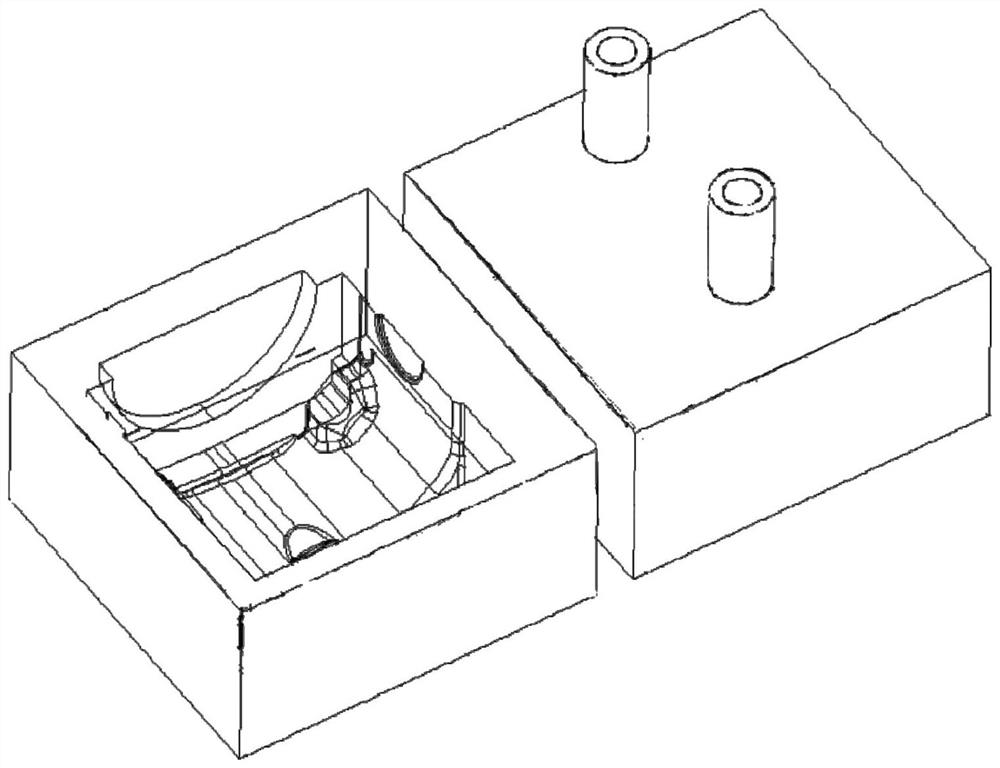

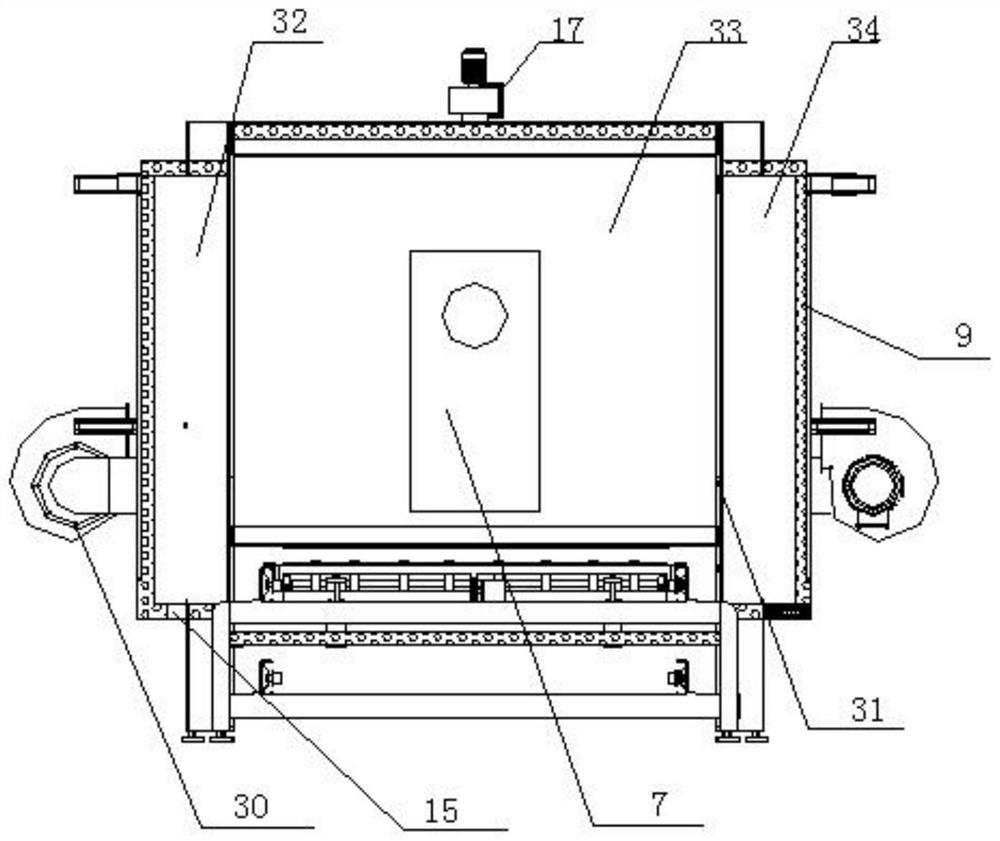

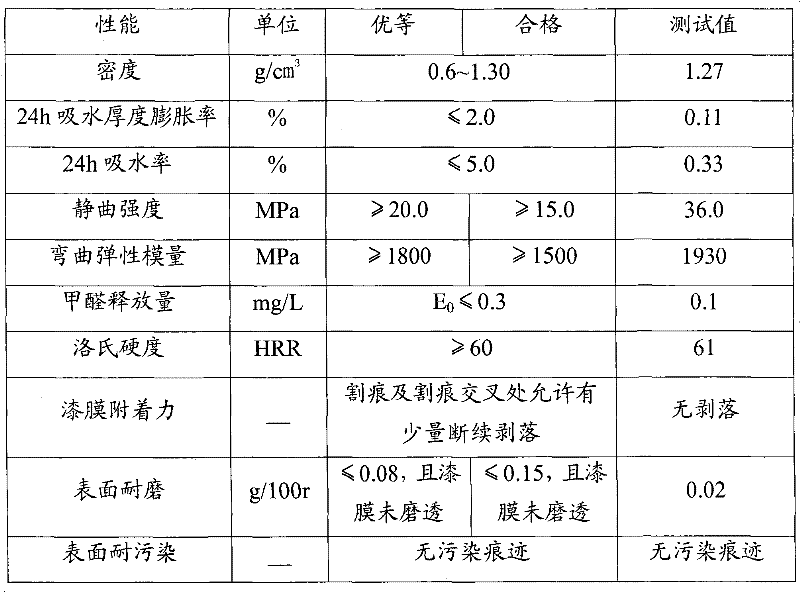

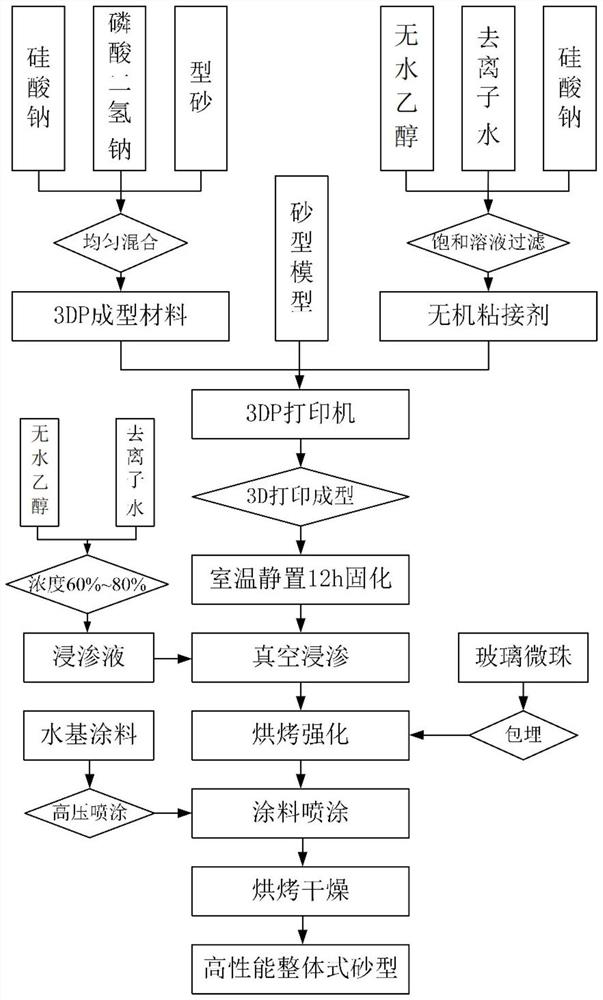

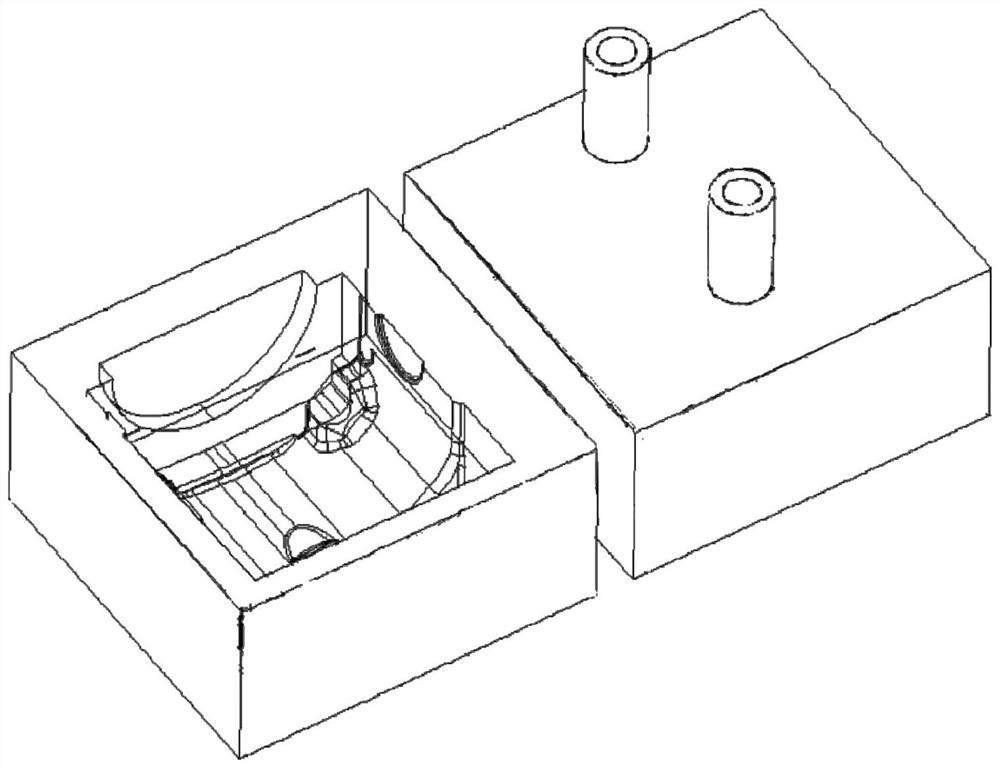

Method for preparing 3DP of integral sand mold

ActiveCN114054673AAvoid the problem of sharp drop in accuracyHigh strengthAdditive manufacturing apparatusSolid waste managementAlcoholPhysical chemistry

The invention discloses a 3DP preparation method of an integral sand mold, which comprises the following processes: 3DP molding is carried out by using a 3DP molding material and an inorganic binder, the obtained integral sand mold is subjected to standing curing, and the 3DP molding material is obtained by uniformly mixing sodium silicate powder, disodium hydrogen phosphate powder and 3D printing molding sand; the inorganic binder is obtained by adding sodium silicate powder into a mixed solution of absolute ethyl alcohol and deionized water until the sodium silicate powder is dissolved to be saturated and then filtering; the cured integral sand mold is subjected to vacuum infiltration, so that the integral sand mold fully absorbs the infiltration liquid; the integral sand mold is subjected to reinforced baking and then cooled, and coating spraying treatment is conducted on the surface of the integral sand mold; and the integral sand mold of which the surface is subjected to coating spraying treatment is dried so as to obtain the high-performance integral sand mold. According to the invention, sodium silicate can be used as a binder to carry out 3DP molding of the integral sand mold, and the high-performance integral sand mold with good performance is obtained through an adaptive post-treatment process.

Owner:XI AN JIAOTONG UNIV

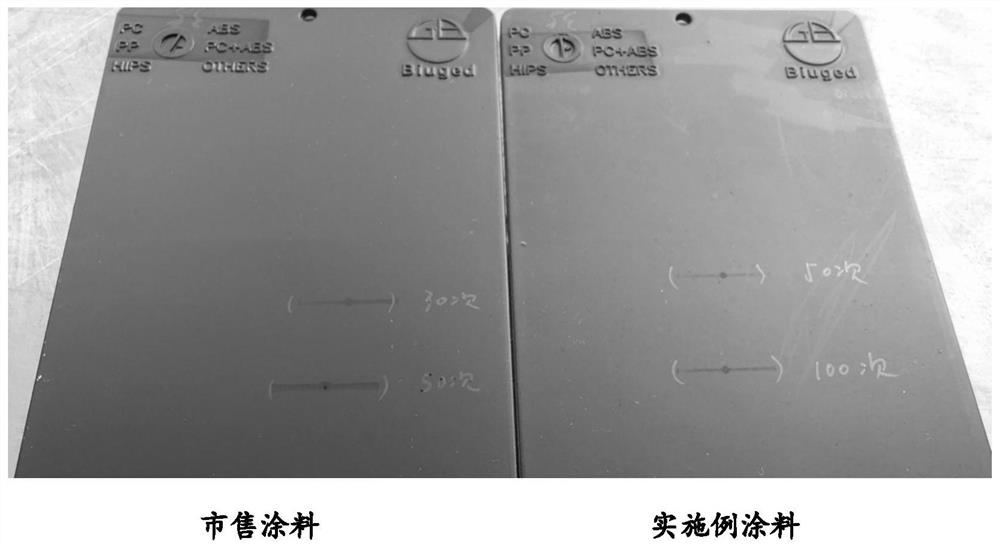

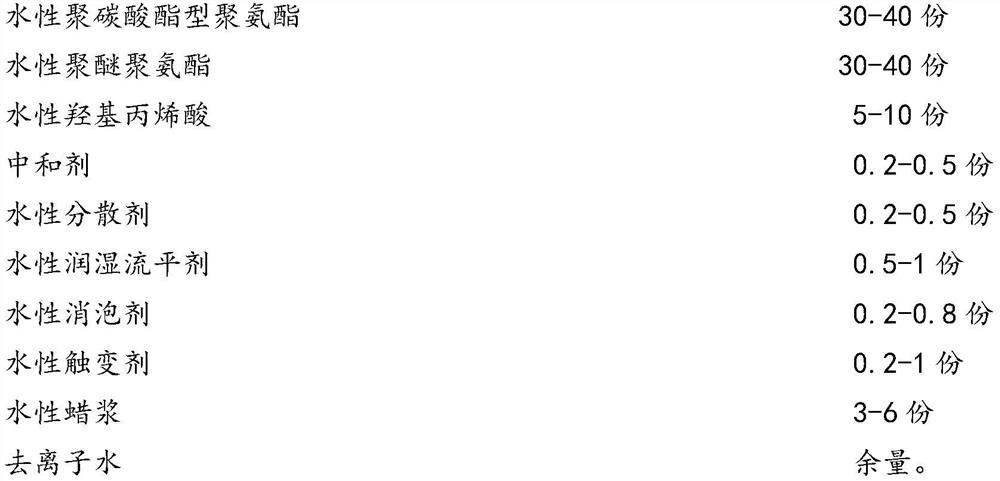

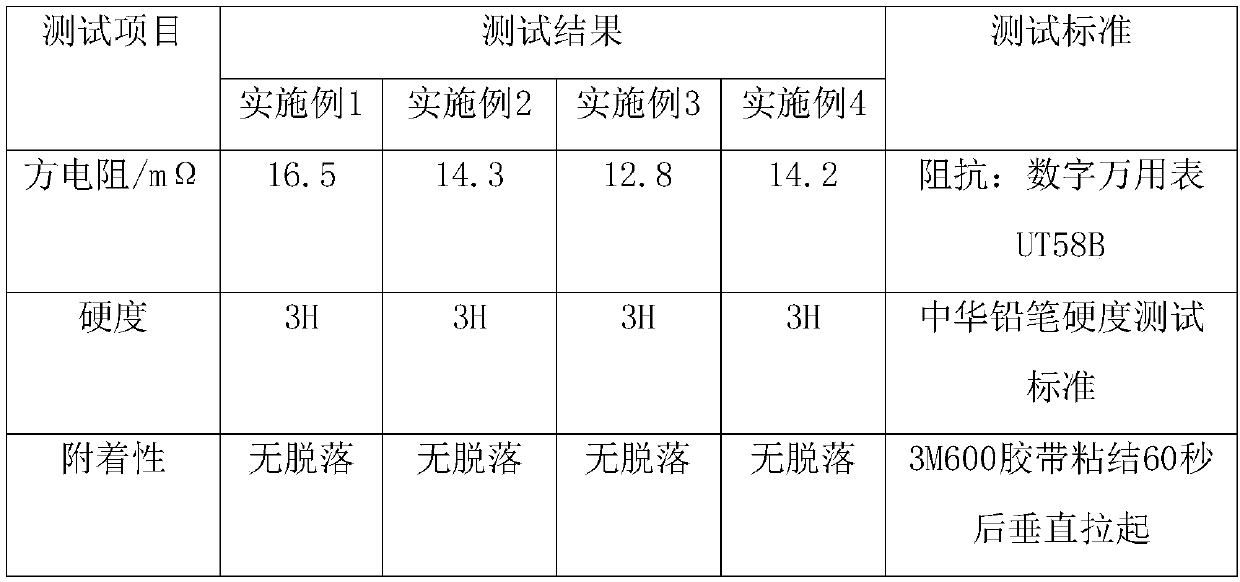

Plastic material based on high-wear-resistance water-based elastic coating

InactiveCN112029400AImprove wear resistanceGood extinction stabilityPolyurea/polyurethane coatingsPolyether polyurethanePlastic materials

The invention discloses a plastic material based on a high-wear-resistance water-based elastic coating. The plastic material is composed of a plastic substrate and a coating layer on the surface of the plastic substrate. The coating layer is prepared from the high-wear-resistance water-based elastic coating; the high-wear-resistance water-based elastic coating comprises an agent A and an agent B;the agent A comprises water-based polycarbonate polyurethane, water-based polyether polyurethane, water-based hydroxy acrylic acid, a neutralizer, a water-based dispersing agent, a water-based wettingleveling agent, a water-based defoamer, a water-based thixotropic agent, water-based wax slurry and deionized water; and the agent B comprises a curing agent and a diluent. According to the formula,the matte effect is achieved, the required matte effect can be achieved by adding little or even no matting powder into an elastic paint system, the matting stability of the system is better, the permeability of a paint film is good, the three kinds of resin serve as main bodies and are combined with a small amount of auxiliaries, and the effects that the paint film has the high abrasion resistance and meanwhile the hand feeling is excellent are achieved.

Owner:SUZHOU BETELY POLYMER MATERIALS CO LTD +1

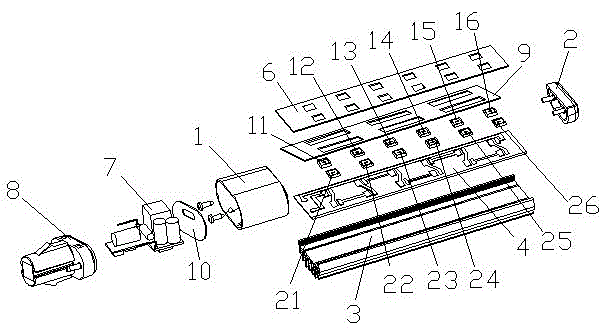

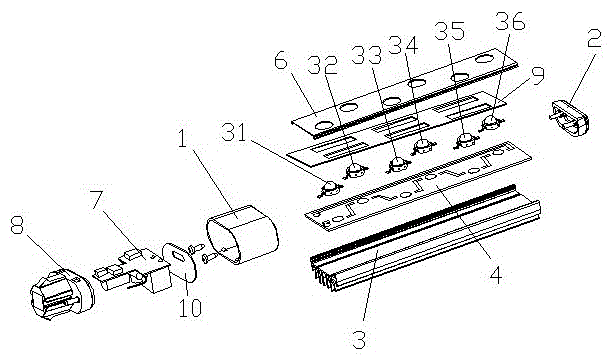

Quick-drying silver paste for large keyboard conductive film circuit, and preparation method thereof

ActiveCN111511099AFast drying and curingEasy transferNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteSilver Nano

The invention discloses quick-drying silver paste for a large keyboard conductive film circuit. The quick-drying silver paste is prepared from, by mass, 45-65 parts of metal silver powder, 5-10 partsof a macromolecule resin, 0-5 parts of an auxiliary agent and 30-40 parts of a solvent, wherein the metal silver powder is a mixture of flaky silver powder and nano silver powder, the metal silver powder is prepared from the following components in parts by mass: 80 to 90 parts of flaky silver powder and 5 to 10 parts of nano silver powder, the average particle size of the flaky silver powder is 5to 10 microns, the average particle size of the nano silver powder is 20 to 80 nm, and the macromolecular resin is an ethylene resin. The quick-drying silver paste can be quickly cured, is wide in base material application range and good in conductivity, can meet the full-automatic production process of customers, and achieves the purposes of reducing the labor cost and improving the product competitiveness.

Owner:上海玖银电子科技有限公司

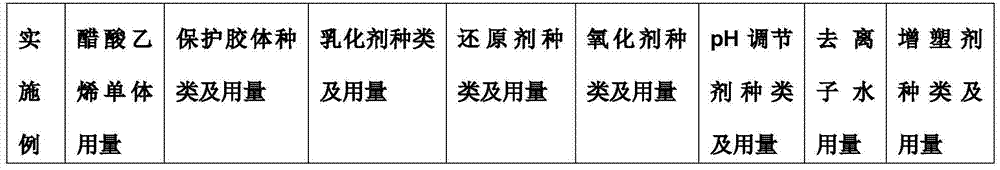

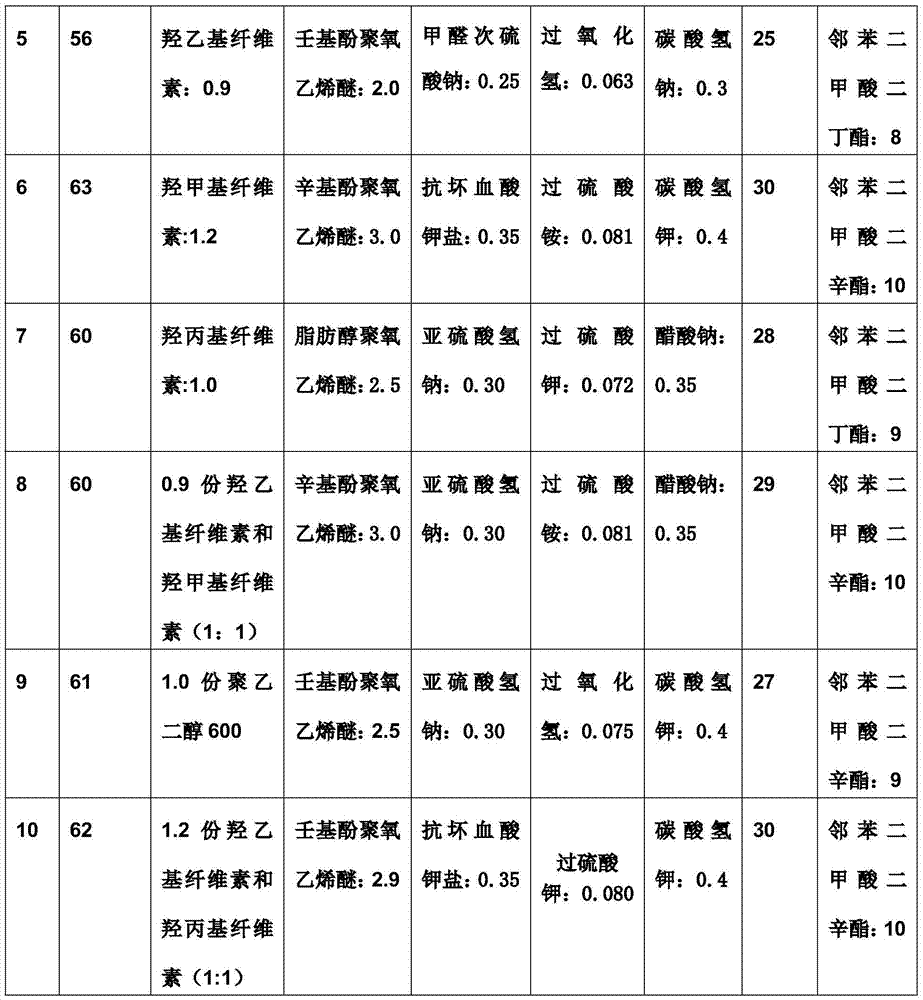

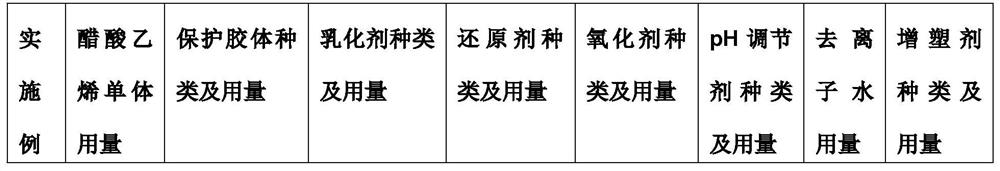

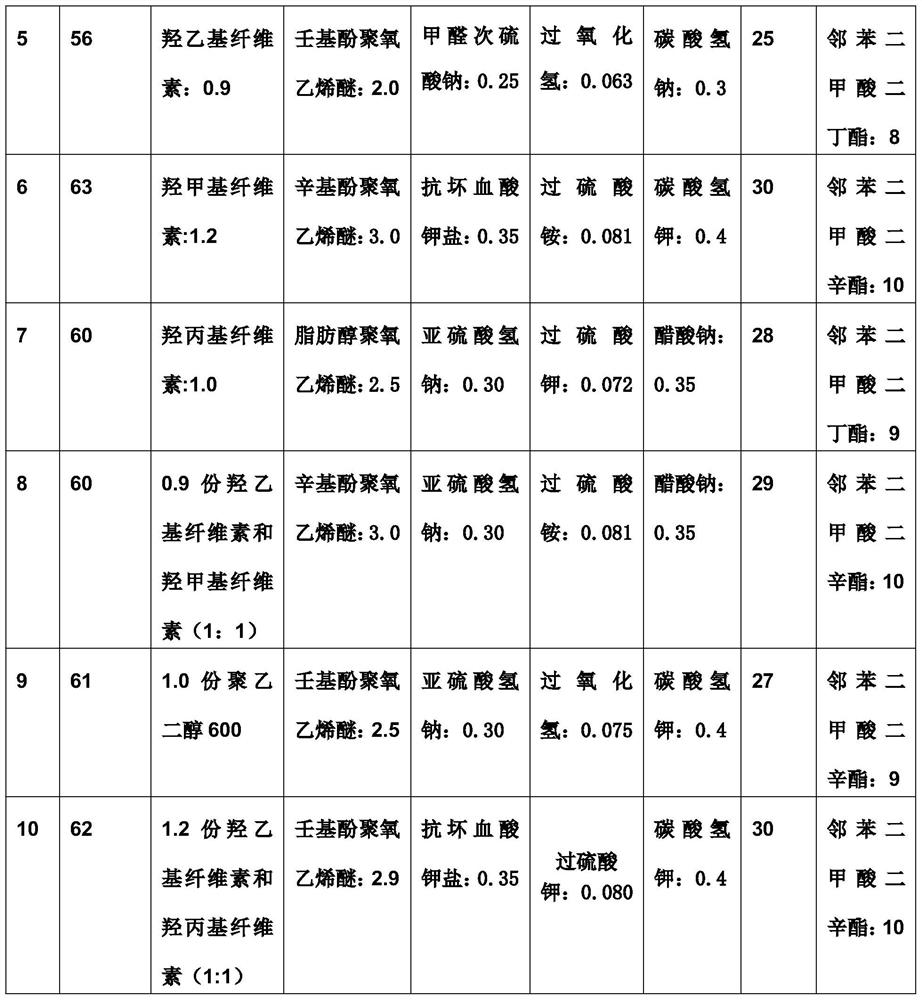

High solid content polyvinyl acetate emulsion and preparation method thereof

The present invention discloses a high solid content polyvinyl acetate emulsion, which is prepared from vinyl acetate, a protection colloid, an emulsifier, an oxidizing agent, a reducing agent, a pH value adjuster, deionized water and a plasticizer. According to the present invention, the high solid content polyvinyl acetate emulsion has the solid content of 66-70%, has the viscosity of less than 3000 mPa.s, has advantages of rapid drying and curing rate and good water resistance, and is widely used in the manufacturing fields of paper processing, coating material decoration, wood processing, nonwoven fabrics, carpets, and the like; and by adding the plasticizer, the viscosity response is slow, such that the product is especially used for high-speed cigarette glues and high-speed laminating. The invention further discloses a preparation method of the emulsion, wherein the method has characteristics of simple operation and easily available raw materials, and is suitable for industrial production.

Owner:SINOPEC SICHUAN VINYLON FACTORY +1

Highly automated fly ash curing device

InactiveCN111745824AGuaranteed stabilityImprove automationDischarging apparatusNon-rotating vibration suppressionEngineeringCement Material

The invention discloses a highly automated fly ash curing device. The highly automated fly ash curing device comprises a bottom plate, a quantitative discharging structure, a chelating agent mixing structure, a chelating structure, a curing structure and an unloading structure. A supporting table is arranged on the left side of the upper surface of the bottom plate, brackets are symmetrically arranged left and right in the middle of the upper surface of the bottom plate, the inner arc-shaped walls of the brackets are fixedly connected to an outer arc-shaped surface of a chelating barrel, L-shaped plates are symmetrically arranged front and back on the right side of the upper surface of the bottom plate, a metering water pump is arranged on the left side of the upper surface of the bottom plate, a water outlet in the right side surface of the metering water pump communicates to a water inlet in the lower end of the left side surface of the chelating barrel through a pipeline, and a conveying pipe is arranged at a discharge position at the lower end of the right side surface of the chelating barrel. The highly automated fly ash curing device can control the discharging amount of materials and further can overturn and chelate the internal materials, so that fly ash is cured to cement and the materials can be air-dried and cured quickly. Influence caused by vibration when equipmentoperates can be further reduced, and the stability of an integral structure is protected.

Owner:江苏西玛环境科技有限公司

Water-based environment-friendly paint and preparation method thereof

InactiveCN110885628ASimple manufacturing methodReduce manufacturing costFireproof paintsAnti-corrosive paintsMicrosphereAcrylonitrile

The invention discloses a water-based environment-friendly paint. The water-based environment-friendly paint is characterized by being prepared from the following raw materials by weight: 40-50 partsof hyperbranched urethane acrylate, 4-8 parts of acrylonitrile-based cross-linked polymer hollow microspheres, 3-5 parts of allyl chloro(difluoro)acetate ionized N, N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid, 1-3 parts of 2, 2-dimethylethenylboronic acid pinacol ester, 1-3 parts of N, N'-(1, 2-dihydroxyethylene)diacrylamide, 0.3-0.6 part of a photoinitiator, 10-15 parts of filler, 1-3 partsof a dispersing agent, 0.5-1.5 parts of a defoaming agent and 25-35 parts of water. The invention also discloses a preparation method of the water-based environment-friendly paint. The water-based environment-friendly paint disclosed by the invention has the characteristics of good comprehensive performance, large adhesive force to a base material, excellent storage and transportation stability, excellent corrosion resistance, flame retardance and high temperature resistance, fast drying and curing speed, convenient construction, large coating hardness, good toughness and weather resistance, and long in service life.

Owner:郭涛

Novel efficient and environment-friendly metal passivation solution and preparing method thereof

InactiveCN105256299AEasy to prepareEasy to implementMetallic material coating processesSilicic acidSalicylic acid

The invention discloses a novel efficient and environment-friendly metal passivation solution and a preparing method thereof. The passivation solution comprises, 5-8 g / L of film forming agent, 5-8 g / L of sealing agent, 10-15 g / L of sodium nitrate, 6-10 g / L of sodium phosphomolybdate hydrate, 15-20 g / L of ammonium molybdophosphate, 8-15 g / L of ammonium phosphate, 5-8 g / L of hexafluorozirconic acid zinc, 8-13 g / L of zirconyl chloride, 3-8 g / L of salicylic acid, 10-15 g / L of corrosion inhibitor, 0.5-1 g / L of surfactant and 3-5 g / L of antioxidant additive. The film forming agent is sodium fluosilicate, and the sealing agent is ortho-silicic acid. The preparing method of the metal passivation solution is simple, convenient and easy to implement, due to reasonable formula design, the prepared metal passivation solution has good film performance, sealing performance and oxidation resistance in the high-temperature spraying process, the drying and curing speed is high, and performance is stable.

Owner:CHANGSHU FENGFAN POWER EQUIP

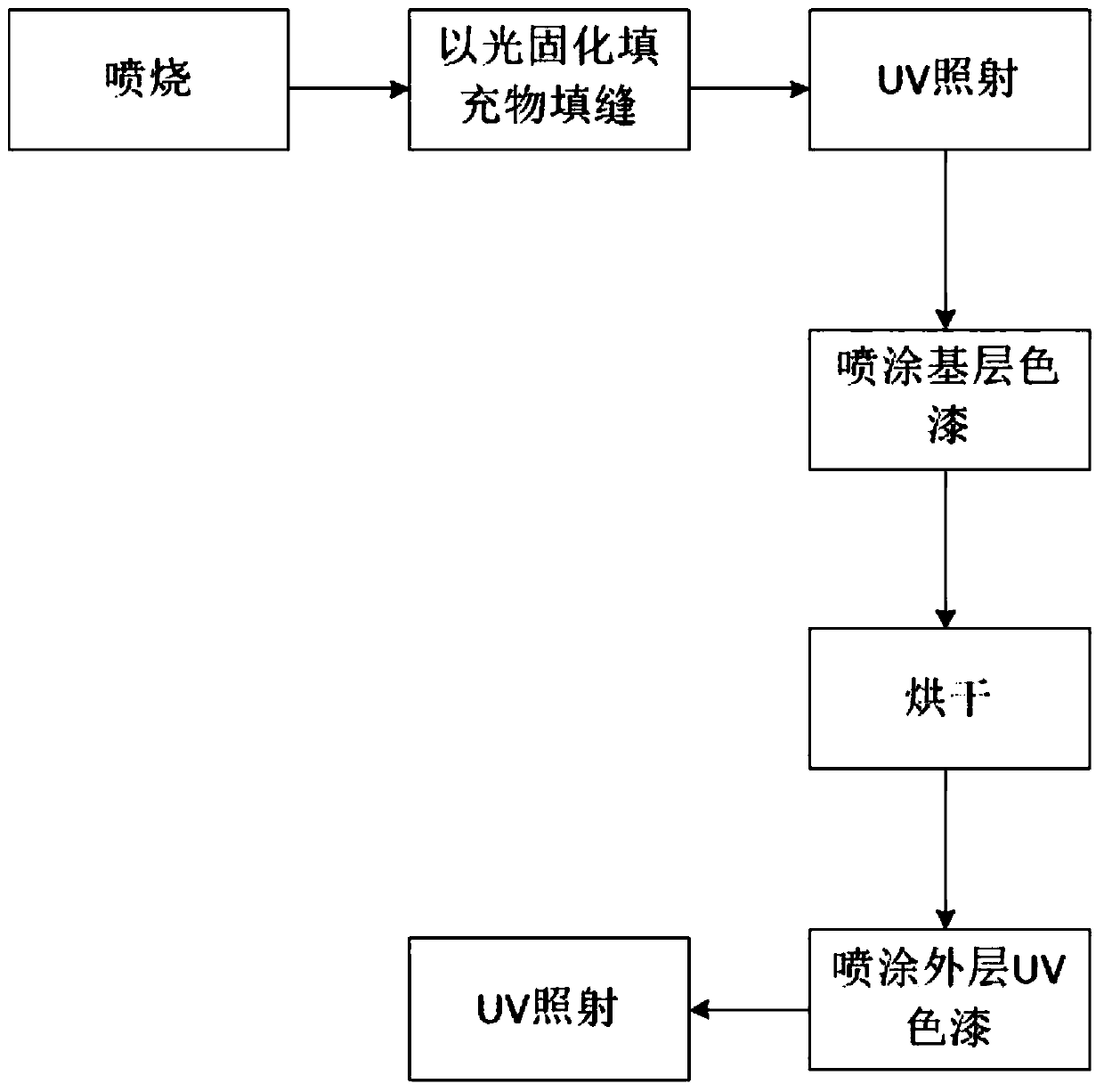

Furniture antique-finishing process

InactiveCN110936459AFast drying and curingShort curing timeWood charring/burningPolyester coatingsPolishingChemistry

The invention discloses a furniture antique-finishing process. The process comprises the following steps that S1, spray burning is conducted on the surface of furniture; S2, the cracking position of the surface of the furniture is filled with a photocuring filler; S3, UV irradiation is conducted on the filled furniture at the normal temperature; S4, a base layer colored paint is sprayed and dried;S5, polishing is conducted; S6, a UV colored paint is sprayed on the outer layer; and S7, UV irradiation is conducted on the furniture. The antique finishing process of the furniture is simplified, and the production efficiency is improved.

Owner:福州立雅家具有限公司

Nail polish glue curing lamp

InactiveCN104998804AUniform drying irradiation areaFast drying and curingPretreated surfacesManicure/pedicureControl systemEngineering

The invention discloses a nail polish glue curing lamp which comprises a lamp holder hood and a chock plug, wherein a radiator is mounted between the lamp holder hood and the chock plug; a base plate is mounted on the radiator; LED lamp beads with the wavelength coverage being 365-405 nm are mounted on the base plate; a cover plate is mounted on the LED lamp beads; a circuit control system is mounted in the lamp holder hood; the lamp holder hood is connected with a lamp holder. Through reasonable model selection and layout arrangement of the LED lamp beads, the nail polish glue curing lamp is enabled to be uniform in drying irradiated area, high in drying curing speed and more energy-saving.

Owner:绍兴市滨海新城燎原照明电器厂

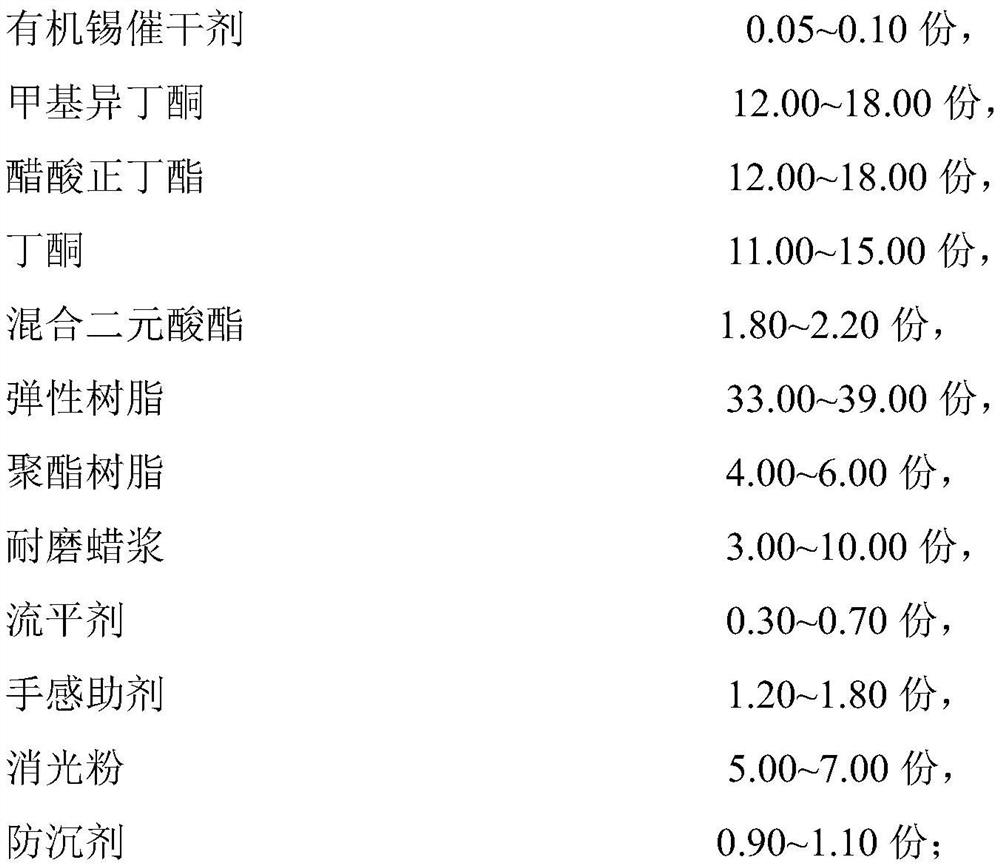

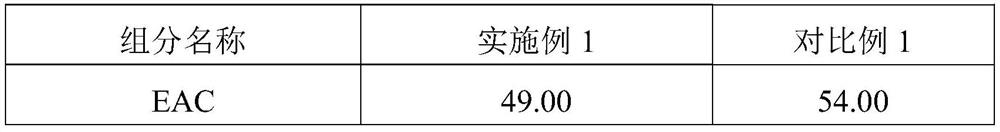

A kind of quick-drying elastic paint and using method thereof

ActiveCN112175500BFast drying and curingShorten the lengthSiccativesPretreated surfacesDiacetone alcoholPolymer science

The invention relates to a quick-drying elastic paint and a method for using the same, comprising a main agent A component, a curing agent B component and a dilute solvent C component, wherein the A component includes: Butanone, n-butyl acetate, butanone, mixed dibasic acid ester, elastic resin, polyester resin and wear-resistant wax slurry, etc.; B component is curing agent resin, C component includes ethyl acetate, diacetone alcohol, Isopropyl alcohol, organotin driers and organotin complexing aids. Compared with the prior art, the present invention has the advantages of fast drying and curing speed and long activation period, and can flexibly adjust the elasticity of the elastic paint by adjusting the ratio of the organotin drier in the main agent A component and the diluent C component. Pot life and drying speed.

Owner:DONGLAI COATING TECH SHANGHAI

Aqueous quick-dry coating for synthetic paper combination

The invention discloses an aqueous quick-dry coating for synthetic paper combination. The aqueous quick-dry coating comprises a terpene resin, titanium dioxide, a polyamide alcohol-soluble resin, extinction powder, isopropanol, nitrocotton, an aqueous acrylic emulsion, silicon dioxide, ethyl ester and a printing ink electrostatic agent. The coating comprises two layers, which are respectively a connecting layer applied to the surface of synthetic paper and a surface layer applied to the connecting layer. The coating comprises the silicon dioxide, the production and curing time of common synthetic paper is 3-4 days, and after addition of the silicon dioxide, the drying and curing speed of the coating can be shortened to 20-30 minutes, so that the time for curing the synthetic paper can be greatly shortened, and the synthetic paper production efficiency can be improved; with the combination of the connecting layer and the surface layer of the coating, the connecting layer is used for treating the surface of paper, in addition, a function of connecting the surface layer and the paper is achieved, the adhesion effect of the coating can be greatly improved, the surface of the connectinglayer can be modified by using the surface layer, and synthetic paper of a smooth surface can be provided.

Owner:阜阳市尤美新材料科技有限公司

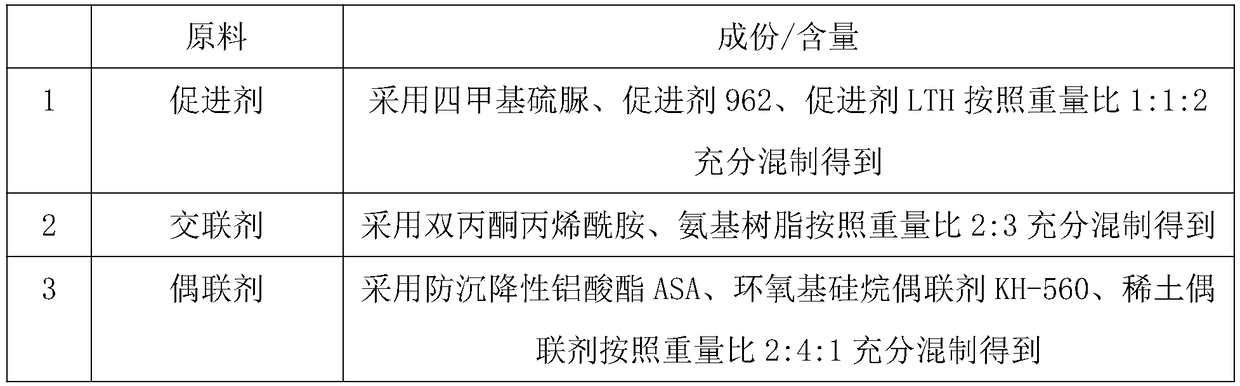

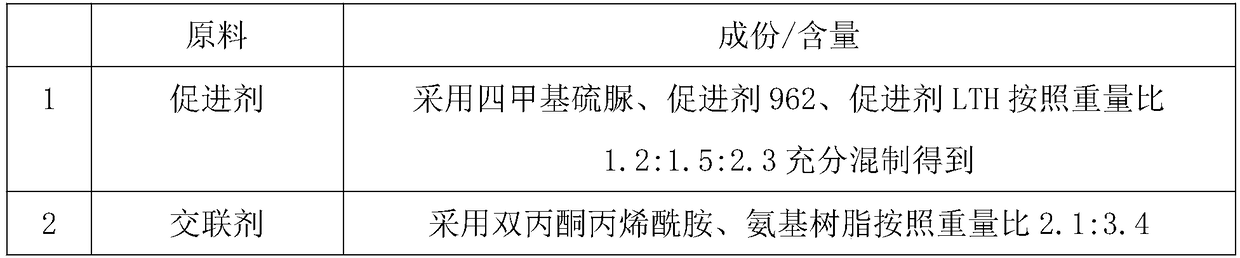

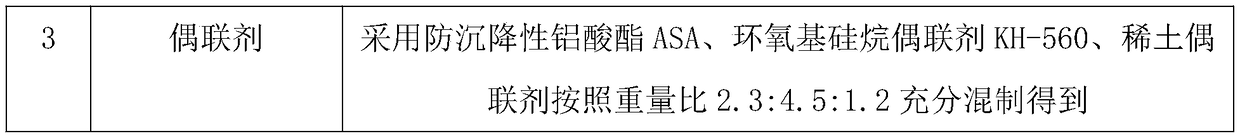

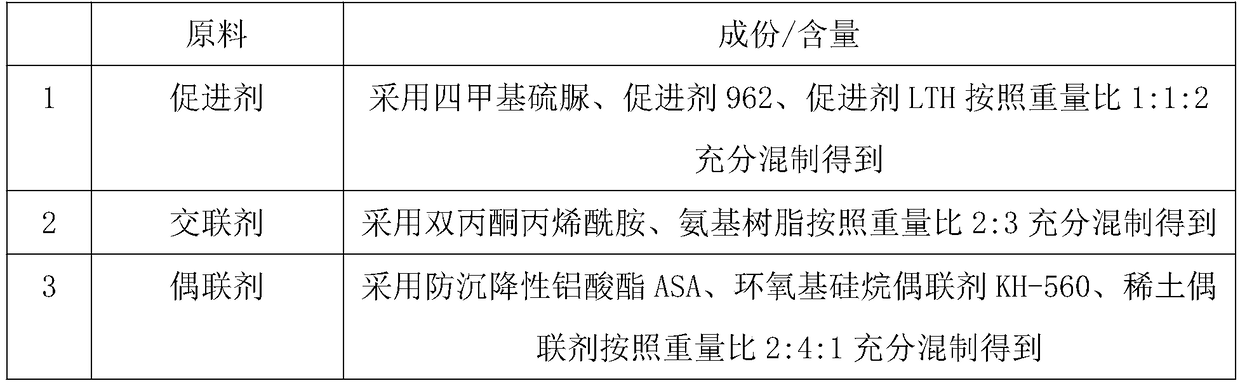

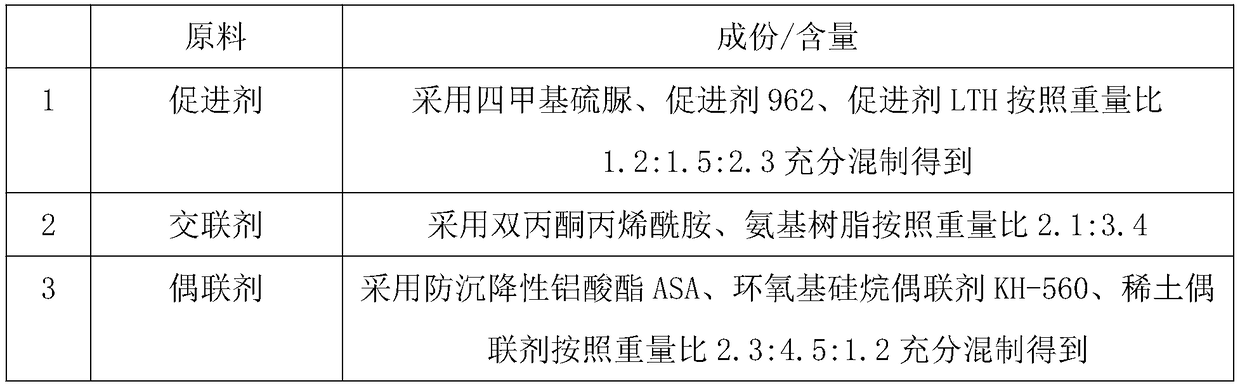

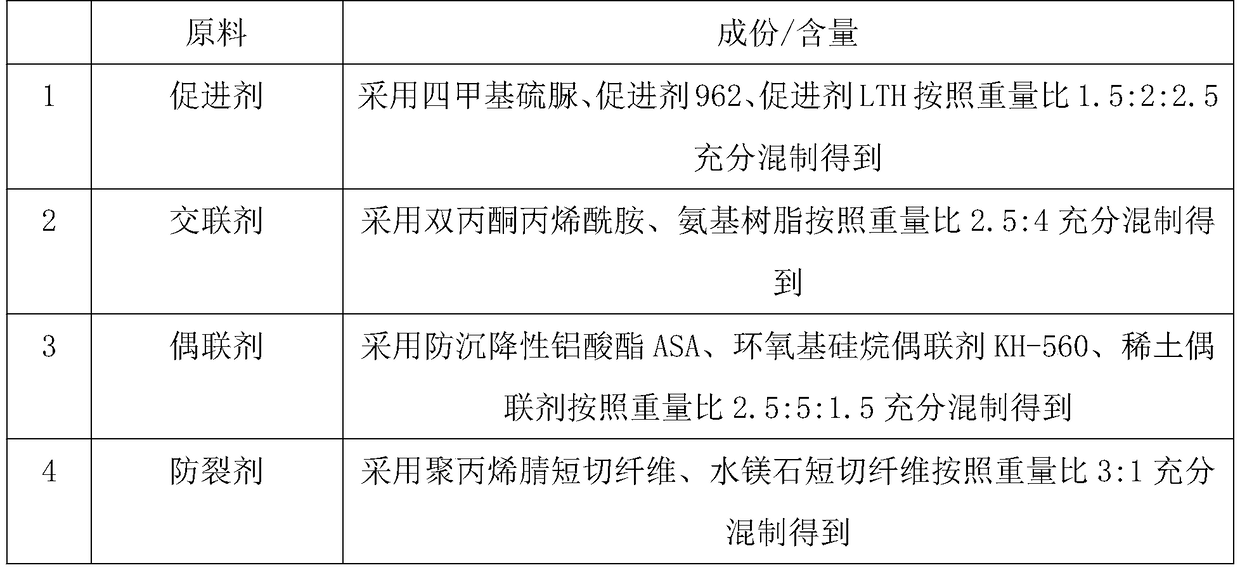

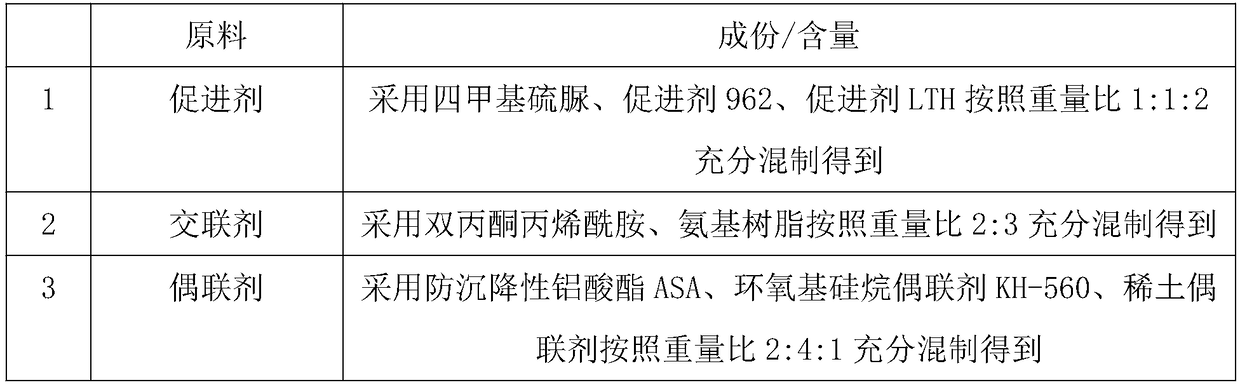

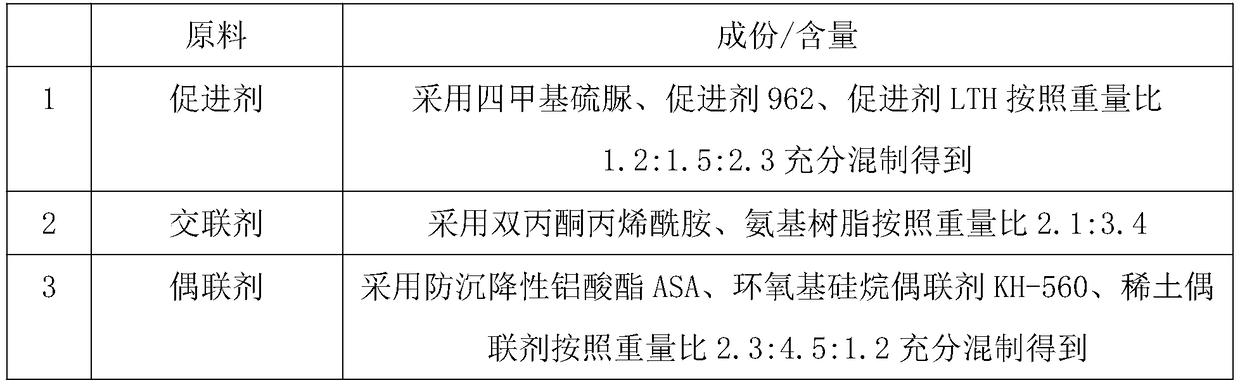

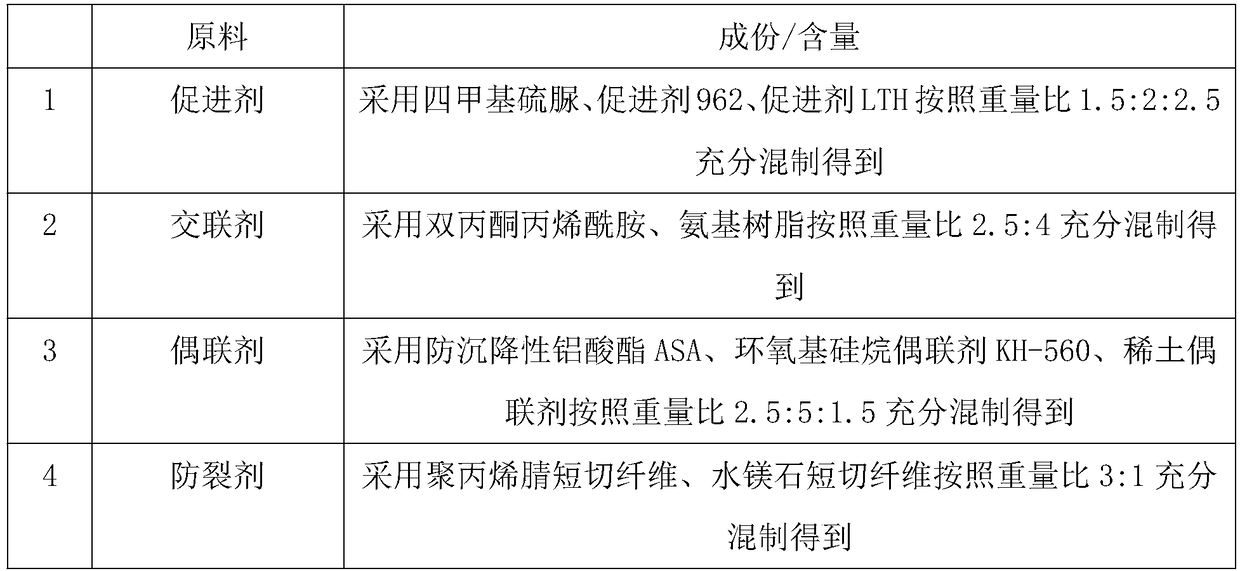

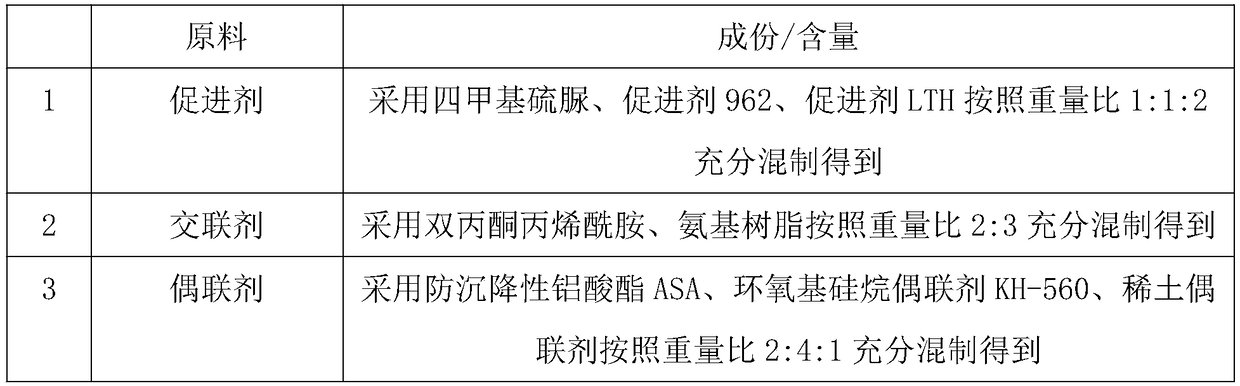

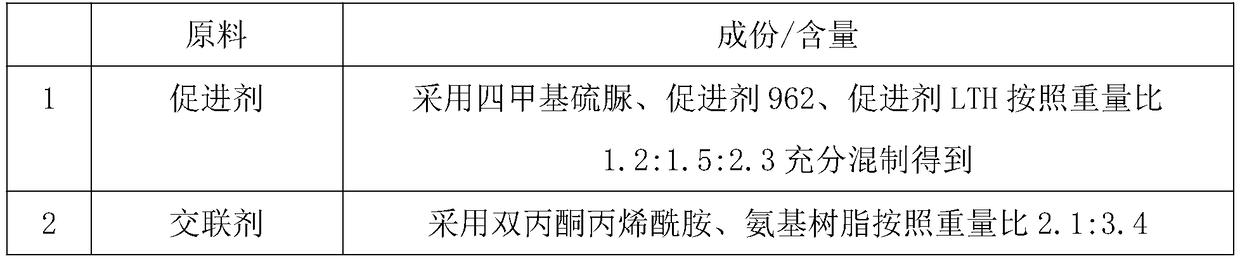

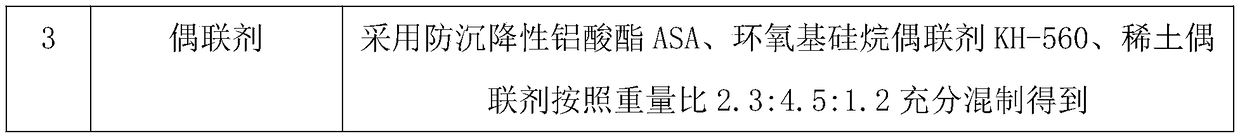

Waterproof coating for color plate

InactiveCN108912914AEasy to prepareGood compatibilityFireproof paintsAntifouling/underwater paintsCross-linkFuran

The invention discloses a waterproof coating for a color plate, and relates to the technical field of color plate coatings. The coating comprises the following raw materials of acrylic resin, furan resin, red halloysite, periclase powder, isopropanol, snail mucus, cellulose acetate butyrate, superfine hexagonal boron nitride nano-particles, an accelerant, a cross-linking agent and a coupling agent. The coating for the color plate provided by the invention has the advantages that the functionality is high, the application performance is good, the scope of application is wide and the service life is longer.

Owner:HEFEI YAKELI NEW BUILDING MATERIAL CO LTD

Preparation method of weather resistant coating for color steel plate

InactiveCN108948917AEasy to prepareGood compatibilityFireproof paintsAnti-corrosive paintsSteel platesMetallurgy

The invention discloses a preparation method of a weather resistant coating for a color steel plate and relates to the technical field of color steel plate coatings. The method includes: 1) adding redhalloysite and periclase powder to RO water for dissolution, heating the solution and adding acrylic resin with mixing and stirring to prepare a mixture A; 2) under stirring, adding an accelerant anda coupling agent at certain amount with complete mixing, adding furan resin with uniform mixing, heating the mixture, and stirring the mixture with temperature maintained, cooling the mixture, and adding snail slime with complete mixing to prepare a mixture B; 3) adding isopropanol to the mixture B with uniform mixing, under stirring condition, adding the rest of accelerant and coupling agent with mixing, heating the mixture, adding cellulose acetate butyrate and ultrafine hexagonal boron nitride nanoparticles with complete mixing, and performing heat-insulation stirring to prepare a mixtureC; 4) feeding the mixture C and a crosslinker into a stirring tank for carrying out stirring reaction. The coating has good functionality and applicability, is extensive in application scope and is longer in service life.

Owner:合肥易美特建材有限公司

A kind of water-based composite passivation solution for galvanized steel sheet and preparation method thereof

InactiveCN104451641BImprove corrosion resistanceQuality improvementMetallic material coating processesWater basedChromium free

The invention relates to a water-based composite chromium-free passivation solution for a galvanized steel plate. The passivation solution contains 10-30g / L of sodium molybdate, 0-10g / L of sodium phosphate, 5-10g / L of organic phosphoric acid, 1-10g / L of fluotitanic acid, 5-15g / L of a silane coupling agent, 5-20g / L of sodium metasilicate, 0.1-1% of a wetting dispersant and the balance of deionized water. The passivation solution provided by the invention consists of an organic phosphoric acid-molybdate system in match with the modified hydrolysis type silane coupling agent and a nano-inorganic filler, does not contain a chromate and is in line with ROHS requirements; the passivation and drying curing time is short, the degree of stability is high, the quality of a film layer is good, the white rust area in a 72h salt fog test does not exceed 5%, the cost is relatively low, a passivation process device does not need to be changed, and continuous passivation can be realized by using a hexavalent chromium passivation device in early period.

Owner:北京蓝星清洗有限公司

Woven tape marking machine capable of drying quickly

InactiveCN107020831AEasy to fixFast drying and curingTypewritersOther printing apparatusPulp and paper industryCooling channel

The invention discloses a fast-drying ribbon marking machine, comprising: a base, a cylinder and a bracket, the cylinder is fixedly installed on the upper end of the base through the bracket, the base is provided with a longitudinal cooling channel, Marking channel, drying channel and transverse transportation channel, the cooling channel is located in front of the marking channel, the drying channel is located in the rear of the marking channel, the lower end of the output shaft of the cylinder is installed with a marking Marking head, the marking head is interspersed in the marking channel, through the above method, the present invention can carry out pre-cooling treatment before marking the ribbon, and then dry the marking pattern after the marking process treatment, greatly improving the drying speed, and the marks are firmly fixed.

Owner:SUZHOU SHENGDA RIBBON

Fiber tension adjusting process and equipment

PendingCN113322611ATension adjustmentFast drying and curingLiquid/gas/vapor treatment machines driving mechanismsTextile treatment machine arrangementsYarnFiber

The invention discloses fiber tension adjusting process and equipment. The equipment comprises a mounting side plate and a moving column; a limiting piece is welded to one side of the mounting side plate; a rubber sleeve is mounted on one side of the limiting piece through a screw; a fixed pulley is arranged at one end of the bottom of the rubber sleeve through a fixed frame; a sponge block is arranged in the rubber sleeve in a sleeved mode; guide rods are welded to the top end and the bottom end of the mounting side plate; threaded blocks are welded to the two sides of each guide rod; a movable column is arranged at one end of each guide rod; guide sleeves are arranged at the two ends of each movable column; the guide rods penetrate through the guide sleeves; a protective cover is welded to the top end of one end of the corresponding movable column; and winding discs are arranged at the lower end of the protective cover through driving motors. According to the fiber tension adjusting process and equipment, the steps of the method are greatly reduced, the process cost is saved, an anti-corrosion protection layer is conveniently formed on the surface of fiber yarn, and the equipment is simple, high in automation degree, convenient to operate, high in practicability and suitable for wide application and popularization.

Owner:桐乡市你我纺织股份有限公司

Water-based PRT colored pavement

The invention discloses a water-based PRT colored pavement which mainly comprises a water-based emulsion, a curing agent and composite powder in a ratio of 3: 1: 12. The coating does not contain an organic solvent, has no pungent smell, has no harm to the working environment and the health of constructors, and is more environment-friendly and safer in the transportation process; by adopting the mode that spraying is matched with traditional construction and the corresponding proportion of materials, the opening time on the pavement is long, drying and curing are rapid, the binding force with the pavement is higher, and by spraying colored paint, the water-based perfluoroethylene transparent cover face and the anti-skid layer, the color vividness, the skid resistance, the wear resistance and other performance are further enhanced.

Owner:朱广清

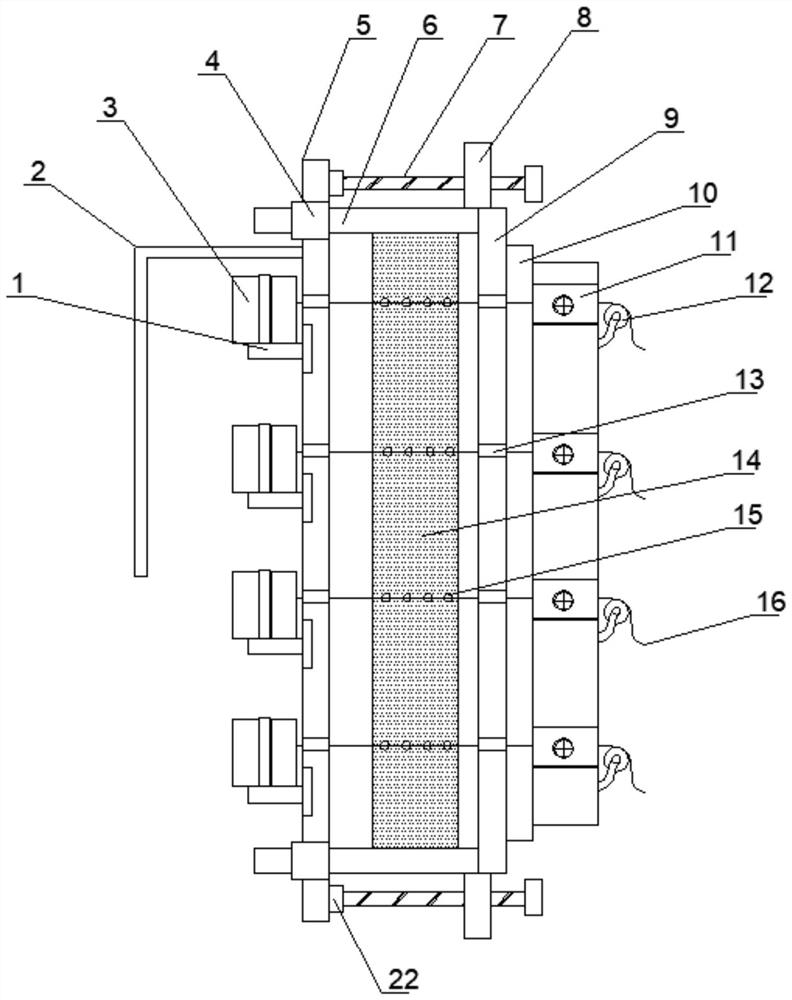

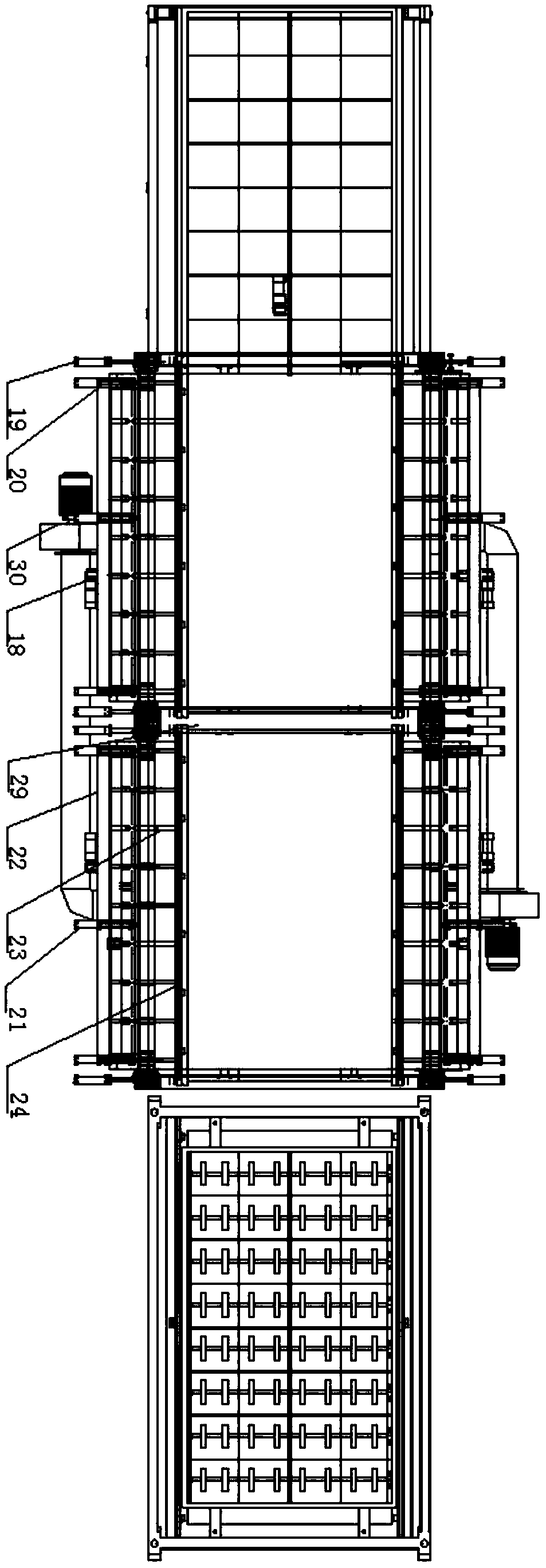

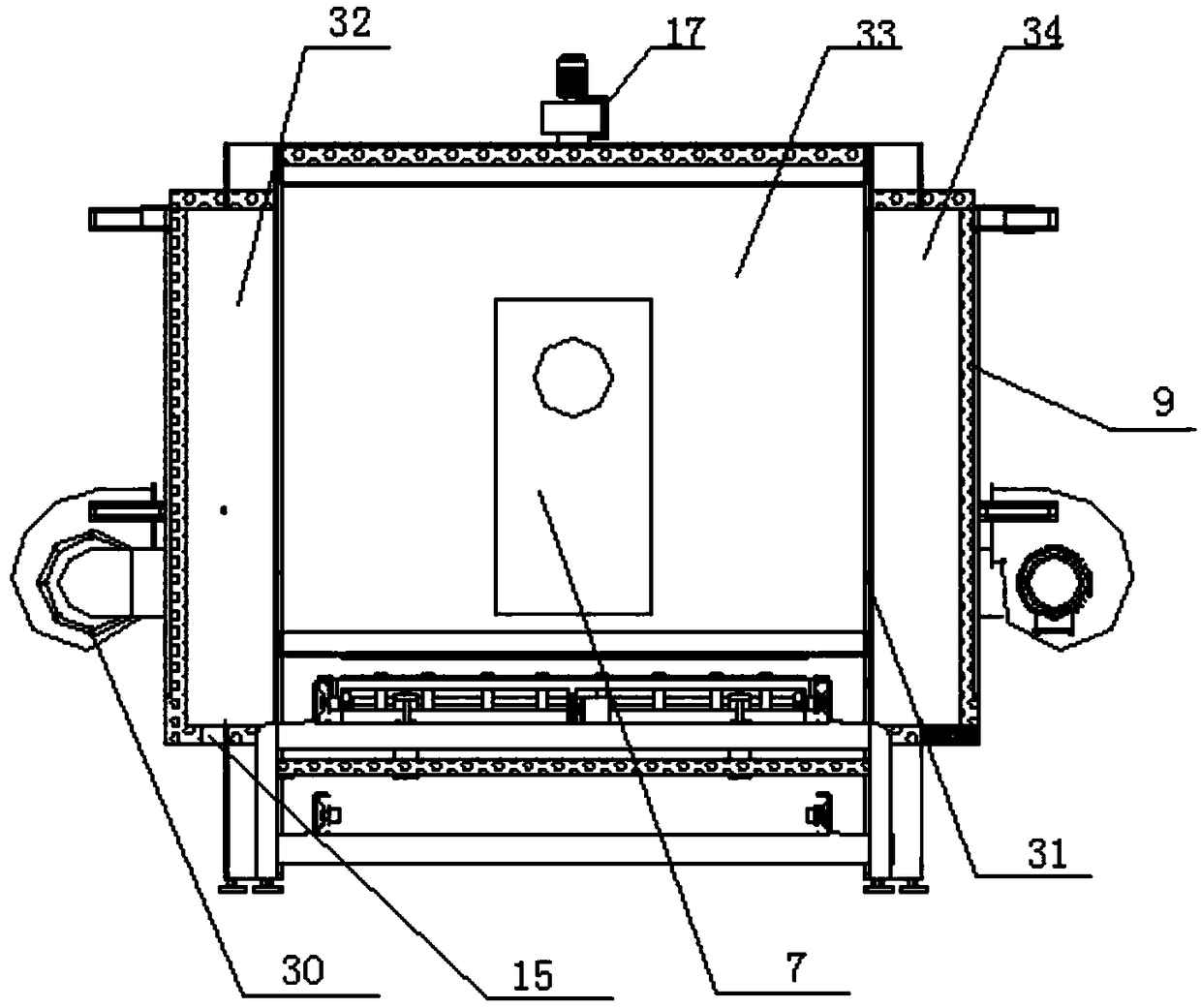

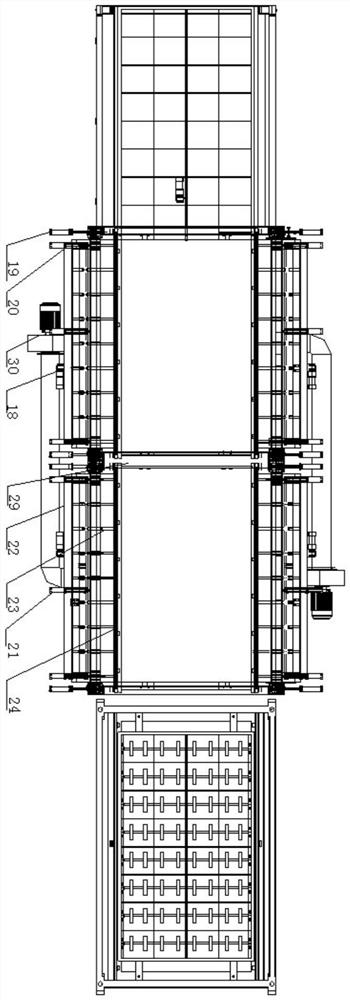

Stacking type drying oven

ActiveCN109332124AFast drying and curingImprove curing and drying efficiencyPretreated surfacesCoatingsHydraulic cylinderEngineering

The invention discloses a stacking type drying oven. The drying oven comprises a tray plate feeding preparation zone and stand columns, wherein the tray plate feeding preparation zone is located on one sides of the stand columns, a loading tray is arranged at the top of the tray plate feeding preparation zone, one side of the tray plate feeding preparation zone is in transmission connection with alower layer tray entrance transmission motor, lifting bolt stand columns are arranged on the stand columns, lifting hydraulic cylinders are installed on the lifting bolt stand columns, a first tray transmission guide rail and a second tray transmission guide rail are fixedly installed between the stand columns through bolts, the top of a bolt connecting plate and the top of a fixed bolt stand column are respectively connected with a jacking bolt air cylinder and a fixed bolt air cylinder, a heat circulating air pipe connected through a heat circulating fan is arranged on one sides of the stand columns, and the outer side of a porous air distribution plate is correspondingly provided with a hot air mixing chamber, a storage plate chamber and a secondary hot air distribution chamber. According to the drying oven, the curing and drying efficiency is improved, the processing efficiency of hot air is high, the hot air utilization rate is high, and the energy consumption is reduced.

Owner:上海坚睿实业有限公司

Surface coating used for low reflective index color steel plate

InactiveCN108948915AEasy to prepareGood compatibilityFireproof paintsAnti-corrosive paintsFuranSteel plates

The invention discloses a surface coating used for a low reflective index color steel plate and relates to the technical field of color steel plate coatings. The coating comprises: acrylic resin, furan resin, red halloysite, periclase powder, isopropanol, snail slime, cellulose acetate butyrate, ultrafine hexagonal boron nitride nanoparticles, an accelerant, a crosslinker, and a coupling agent. The coating has good functionality and applicability, is extensive in application scope and is longer in service life.

Owner:合肥易美特建材有限公司

Anti-impact bending-resistant paint for color steel plate

InactiveCN109021742AEasy to prepareGood compatibilityFireproof paintsAntifouling/underwater paintsSteel platesFuran

The invention discloses an anti-impact bending-resistant paint for a color steel plate, which relates to the technical field of a color steel plate paint. The anti-impact bending-resistant paint comprises the following raw materials: acrylic resin, furan resin, halloysitum rubrum, periclase powder, isopropanol, snail slime, cellulose acetate butyrate, ultrafine hexagonal boron nitride nanoparticles, an accelerator, a crosslinking agent, and a coupling agent. The color steel plate paint has the advantages of strong functionality, good application performance, wide application field, and long service life.

Owner:合肥易美特建材有限公司

A kind of high solid content polyvinyl acetate emulsion and preparation method thereof

The present invention discloses a high solid content polyvinyl acetate emulsion, which is prepared from vinyl acetate, a protection colloid, an emulsifier, an oxidizing agent, a reducing agent, a pH value adjuster, deionized water and a plasticizer. According to the present invention, the high solid content polyvinyl acetate emulsion has the solid content of 66-70%, has the viscosity of less than 3000 mPa.s, has advantages of rapid drying and curing rate and good water resistance, and is widely used in the manufacturing fields of paper processing, coating material decoration, wood processing, nonwoven fabrics, carpets, and the like; and by adding the plasticizer, the viscosity response is slow, such that the product is especially used for high-speed cigarette glues and high-speed laminating. The invention further discloses a preparation method of the emulsion, wherein the method has characteristics of simple operation and easily available raw materials, and is suitable for industrial production.

Owner:SINOPEC SICHUAN VINYLON FACTORY +1

A kind of fast-drying silver paste for large keyboard conductive film circuit and preparation method thereof

ActiveCN111511099BFast drying and curingEasy transferNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pastePolymer science

The invention discloses a quick-drying silver paste for a large keyboard conductive film circuit, which comprises the following components by mass: 45-65 parts of metal silver powder, 5-10 parts of polymer resin, 0-5 parts of auxiliary agent, and 30-30 parts of solvent 40 parts; metallic silver powder is the mixture of flaky silver powder and nano-silver powder, each component in the metallic silver powder is made into according to the mass fraction: 80-90 parts of flaky silver powder, 5-10 parts of nano-silver powder, wherein, the average particle size of flaky silver powder The diameter is 5-10μm, the average particle size of nano-silver powder is 20-80nm; the polymer resin is vinyl resin. It can be quickly cured, has a wide range of substrate applications, and has good conductivity. It can meet customers' fully automated production processes, reduce labor costs, and enhance product competitiveness.

Owner:上海玖银电子科技有限公司

A stacked oven

ActiveCN109332124BFast drying and curingImprove curing and drying efficiencyPretreated surfacesCoatingsHydraulic cylinderElectric machine

The invention discloses a laminated oven, which comprises a pallet feeding preparation area and a column, the tray feeding preparation area is located on one side of the column, a loading tray is arranged on the top of the tray feeding preparation area, and the tray feeding preparation area One side of the preparation area is connected with the bottom tray to enter the transmission motor. The columns are equipped with lifting pin columns, and the lifting pin columns are equipped with lifting hydraulic cylinders. The columns and the columns are fixed by bolts. The first tray transmission guide rail and the second tray transmission guide rail, the pin connection plate and the top of the fixed pin column are respectively connected with a jacking pin cylinder and a fixed pin cylinder. The outer side of the porous air distribution plate is respectively equipped with a hot air mixing box, a plate storage box and a secondary hot air distribution box. The invention improves the curing and drying efficiency, has high processing efficiency, high utilization rate of hot air, and reduces energy consumption.

Owner:上海坚睿实业有限公司

Wood grain processing technique for surface of waterproof floor substrate

ActiveCN101659073BKeep textureRealistic effectWood working apparatusOther printing apparatusSanderWear resistant

The invention discloses a wood grain processing technique for the surface of a waterproof floor substrate, which is used for carrying out wood grain printing processing on the surface of a carbonized waterproof wood-plastic floor substrate. The wood grain processing technique comprises the following steps: removing dust from the surface of the molded carbonized waterproof wood-plastic floor substrate; sanding the front of the floor substrate by using a sander; coating a coloring bottom layer; drying and curing the coloring bottom layer by using an ultraviolet light curing machine; grinding the coloring bottom layer; removing dust from the coloring bottom layer; printing simulated wood grains; and adding a wear resistant layer on the surface of the floor substrate. The wood grain processing technique directly prints wood grain patterns on the floor substrate by using a transparent color printer, thus the wood grain patterns having vivid effects are obtained, and the wood grain patternsare firmly attached to the surface of the floor substrate. Moreover, the transparent wear resistant layer is added on the wood grain patterns to protect the vivid wood grain patterns against discoloring when used for a long time and maintain the effect of the wood grains.

Owner:GUANGDONG OUMING NEW MATERIALS TECH

A kind of 3dp preparation method of integral sand mold

ActiveCN114054673BAvoid the problem of sharp drop in accuracyHigh strengthAdditive manufacturing apparatusSolid waste managementPhysical chemistrySodium silicate

The invention discloses a 3DP preparation method of a monolithic sand mold, which includes the following processes: 3DP molding is performed by using a 3DP molding material and an inorganic binder, the obtained monolithic sand mold is statically solidified, and the 3DP molding material is sodium silicate The powder, disodium hydrogen phosphate powder and 3D printing sand are uniformly mixed; the inorganic binder is obtained by adding sodium silicate powder to a mixture of absolute ethanol and deionized water until the sodium silicate powder is dissolved to saturation and then filtered; Vacuum infiltrate the solidified integral sand mold, so that the integral sand mold can fully absorb the impregnation liquid; then the integral sand mold is strengthened and baked, and then cooled and sprayed on the surface of the integral sand mold; the surface is coated The spray-treated monolithic sand mold is dried to obtain a high-performance monolithic sand mold. The invention can use sodium silicate as a binder to carry out 3DP molding of an integral sand mold, and obtain a high-performance integral sand mold with good performance through an adapted post-treatment process.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com