A kind of high solid content polyvinyl acetate emulsion and preparation method thereof

A technology of polyvinyl acetate and high solid content, which is applied in the field of high solid content polyvinyl acetate emulsion and its preparation, which can solve the problems that the special requirements cannot be realized, and the solid content of the product is difficult to exceed 65%, so as to achieve fast drying and curing speed , Improved water resistance, slow viscosity response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

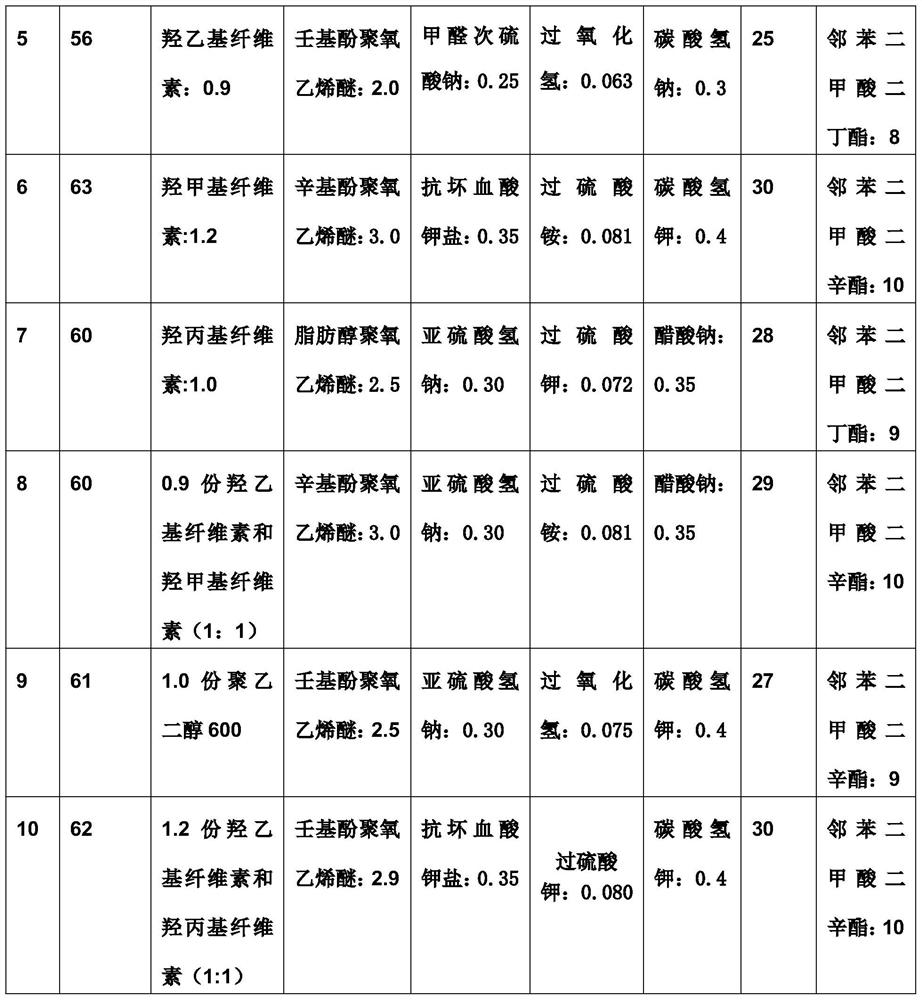

Examples

Embodiment 1

[0039] Add 27.1 parts of hydroxyethyl cellulose aqueous solution with a dissolved concentration of 4% into the reactor, start stirring, and add 2.8 parts X-305 (nonylphenol polyoxyethylene ether) and 0.3 parts of zinc formaldehyde sulfoxylate, and start to cool down at the same time. When the temperature of the reaction kettle drops to 40°C, add 3 parts of vinyl acetate monomer, and then heat up; when the temperature reaches 52°C, add 0.6 parts of oxidant, and then the reaction temperature begins to rise due to the exothermic polymerization, when the temperature reaches 80°C, Start to add 57 parts of monomer and 2 parts of oxidant dropwise, and the dropping time is 60 minutes. After the continuous addition of monomers, continue to drop 1.4 parts of oxidizing agent, and the dropping time is 20 minutes. After completion, the temperature of the reactor is raised to 85°C Heat preservation for 30 minutes; after the heat preservation is completed, the temperature of the reaction ke...

Embodiment 2

[0053] Add 26.5 parts of dissolved hydroxymethylcellulose aqueous solution with a concentration of 3.4% into the reactor, start stirring, add 2 parts of octylphenol polyoxyethylene ether and 0.25 part of sodium ascorbate, and start to cool down at the same time. When the temperature of the reaction kettle drops to 40°C, add 1.12 parts of vinyl acetate monomer, and then raise the temperature; when the temperature reaches 58°C, add 0.35 parts of oxidant, and then the reaction temperature begins to rise due to the exothermic polymerization. When the temperature reaches 80°C, Start to add 54.88 parts of monomer and 1.75 parts of oxidizing agent dropwise, and the dropping time is 70 minutes. After the continuous addition of monomers, continue to drop 1.4 parts of oxidizing agent, and the dropping time is 20 minutes. After completion, the temperature of the reactor is raised to 85°C Heat preservation for 30 minutes; after the heat preservation is completed, the temperature of the rea...

Embodiment 3

[0058] Add 29.2 parts of 4% hydroxypropyl cellulose aqueous solution into the reactor, start stirring, add 2.2 parts of fatty alcohol polyoxyethylene ether and 0.35 part of zinc formaldehyde sulfoxylate, and start to cool down at the same time. When the temperature of the reaction kettle drops to 40°C, add 5.04 parts of vinyl acetate monomer, and then raise the temperature; when the temperature reaches 50°C, add 0.9 parts of oxidant, and then the reaction temperature begins to rise due to the exothermic polymerization. When the temperature reaches 80°C, Start to add 57.96 parts of monomer and 2.7 parts of oxidizing agent dropwise, and the dropping time is 60 minutes. After the continuous addition of monomers, continue to drop 0.9 parts of oxidizing agent, and the dropping time is 20 minutes. After completion, the temperature of the reactor is raised to 85°C Heat preservation for 30 minutes; after the heat preservation is completed, the temperature of the reaction kettle is lowe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com