Preparation method of weather resistant coating for color steel plate

A technology of weather-resistant coatings and color steel plates, applied in anti-corrosion coatings, fire-resistant coatings, radiation-absorbing coatings, etc., can solve problems such as poor surface performance and non-salt corrosion resistance, and achieve good compatibility, small light pollution hazards, and pollution less harmful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] This embodiment relates to a weather-resistant coating for color steel plates and a preparation method thereof. The coating consists of the following raw materials in parts by weight:

[0058] 47 parts of acrylic resin;

[0059] 22 parts of furan resin;

[0060] 4 parts red stone fat;

[0061] 6 parts of periclase powder;

[0062] 8 parts of isopropanol;

[0063] 3.5 parts of snail mucus;

[0064] 1 part of cellulose acetate butyrate;

[0065] 2.5 parts of ultrafine hexagonal boron nitride nanoparticles;

[0066] Accelerator 0.6 parts;

[0067] 0.9 parts of crosslinking agent;

[0068] 0.5 parts of coupling agent;

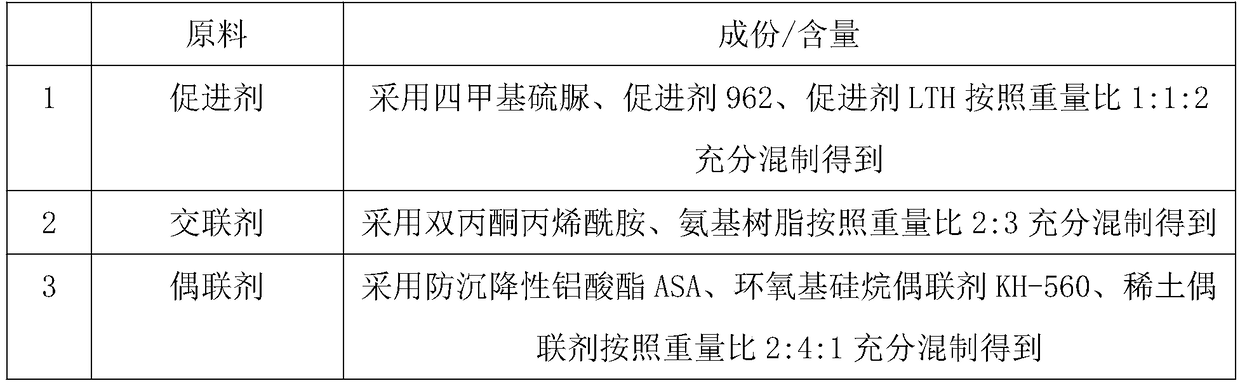

[0069] The selection and preparation of accelerator, cross-linking agent and coupling agent in the present embodiment are shown in Table 1 below:

[0070] Table 1

[0071]

[0072] The preparation method of present embodiment coating is carried out according to the following steps:

[0073] Ⅰ: Take red stone resin and periclase powder, add 112% b...

Embodiment 2

[0078] This embodiment relates to a weather-resistant coating for color steel plates and a preparation method thereof. The coating consists of the following raw materials in parts by weight:

[0079] 49 parts of acrylic resin;

[0080] 24 parts of furan resin;

[0081] 4.5 parts of red stone fat;

[0082] 6.5 parts of periclase powder;

[0083] 9 parts of isopropanol;

[0084] 4 parts snail slime;

[0085] 1.2 parts of cellulose acetate butyrate;

[0086] 2.8 parts of ultrafine hexagonal boron nitride nanoparticles;

[0087] Accelerator 0.65 parts;

[0088] 0.95 parts of crosslinking agent;

[0089] 0.55 parts of coupling agent;

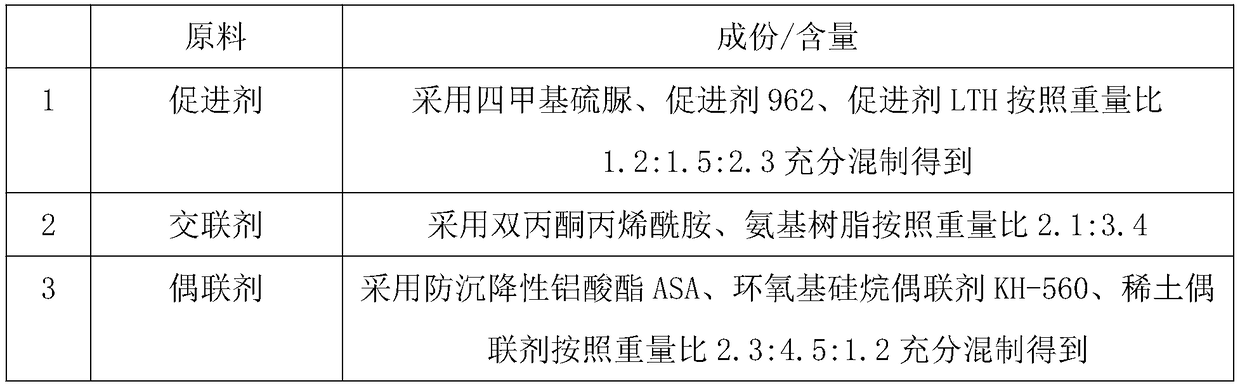

[0090] The selection and preparation of accelerator, cross-linking agent and coupling agent in the present embodiment are shown in Table 2 below:

[0091] Table 2

[0092]

[0093] The preparation method of present embodiment coating is carried out according to the following steps:

[0094] Ⅰ: Take red stone fat and periclase powder, ad...

Embodiment 3

[0099] This embodiment relates to a weather-resistant coating for color steel plates and a preparation method thereof. The coating consists of the following raw materials in parts by weight:

[0100] Acrylic resin 51 parts;

[0101] 25 parts of furan resin;

[0102] 5 parts red stone fat;

[0103] 7 parts of periclase powder;

[0104] 10 parts of isopropanol;

[0105] 4.5 parts of snail mucus;

[0106] 1.4 parts of cellulose acetate butyrate;

[0107] 3.2 parts of ultrafine hexagonal boron nitride nanoparticles;

[0108] Accelerator 0.7 parts;

[0109] 1.0 parts of crosslinking agent;

[0110] 0.6 parts of coupling agent;

[0111] 1 part anti-cracking agent;

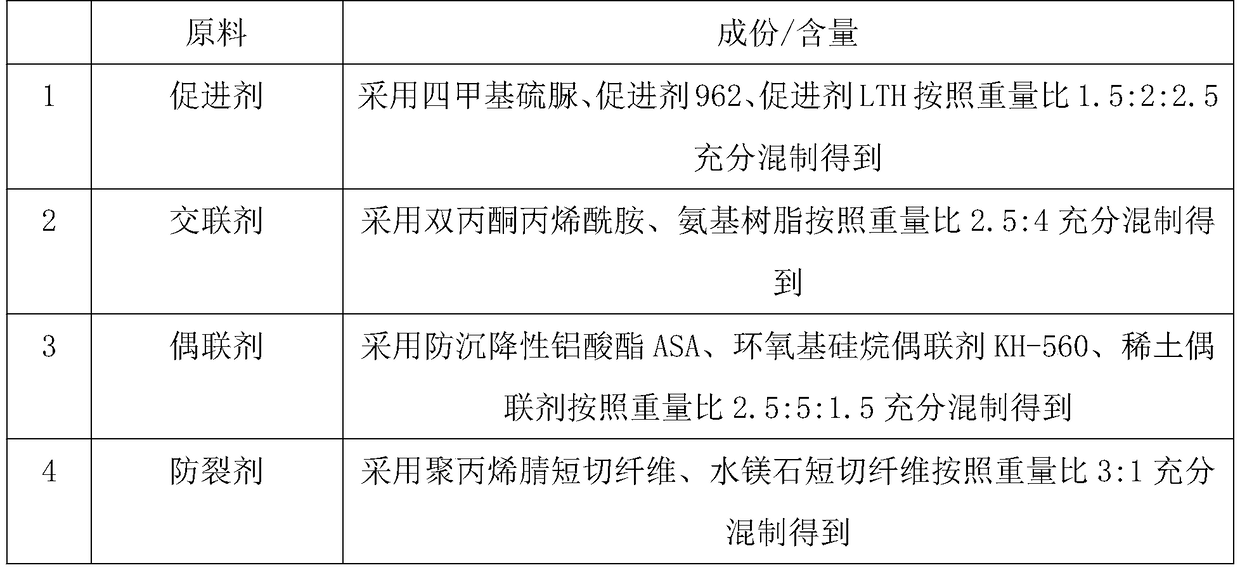

[0112] The selection and preparation of accelerator, cross-linking agent, coupling agent and anti-cracking agent in the present embodiment are shown in Table 3 below:

[0113] table 3

[0114]

[0115] The preparation method of present embodiment coating is carried out according to the following steps:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com