Waterproof coating for color plate

A color steel plate and coating technology, applied in antifouling/underwater coatings, anti-corrosion coatings, fire-proof coatings, etc., can solve the problems of salt corrosion resistance and poor surface performance, and achieve small pollution hazards, good compatibility, non-volatile effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] This embodiment relates to a coating for waterproof color steel plate and its preparation method. The coating consists of the following raw materials in parts by weight:

[0043] Acrylic resin 47 parts;

[0044] 22 parts of furan resin;

[0045] 4 parts red stone fat;

[0046] 6 parts of periclase powder;

[0047] 8 parts of isopropanol;

[0048] 3.5 parts of snail mucus;

[0049] 1 part cellulose acetate butyrate;

[0050] 2.5 parts of ultrafine hexagonal boron nitride nanoparticles;

[0051] Accelerator 0.6 part;

[0052] 0.9 parts of cross-linking agent;

[0053] 0.5 parts of coupling agent;

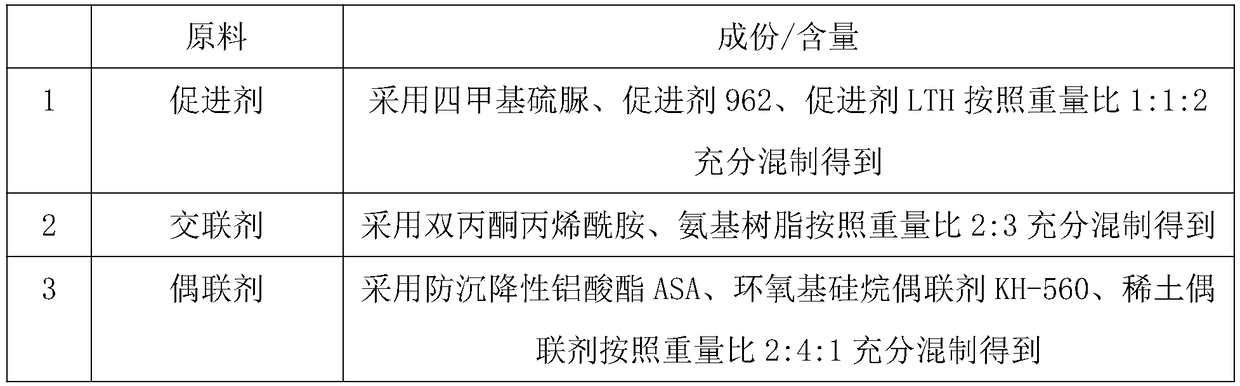

[0054] The selection and preparation of accelerator, cross-linking agent and coupling agent in the present embodiment are shown in Table 1 below:

[0055] Table 1

[0056]

[0057] The preparation method of present embodiment coating is carried out according to the following steps:

[0058] Ⅰ: Take red stone resin and periclase powder, add 112% by weight of RO wat...

Embodiment 2

[0063] This embodiment relates to a coating for waterproof color steel plate and its preparation method. The coating consists of the following raw materials in parts by weight:

[0064] Acrylic resin 49 parts;

[0065] 24 parts of furan resin;

[0066] 4.5 parts of red stone fat;

[0067] 6.5 parts of periclase powder;

[0068] 9 parts of isopropanol;

[0069] 4 parts snail slime;

[0070] 1.2 parts of cellulose acetate butyrate;

[0071] 2.8 parts of ultrafine hexagonal boron nitride nanoparticles;

[0072] Accelerator 0.65 part;

[0073] 0.95 parts of cross-linking agent;

[0074] 0.55 parts of coupling agent;

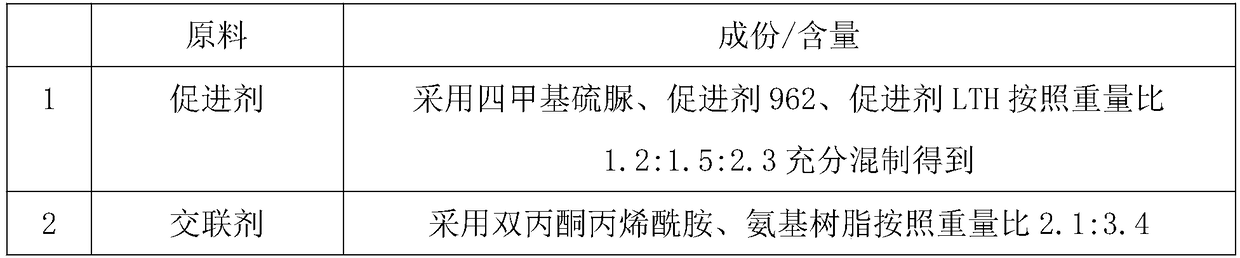

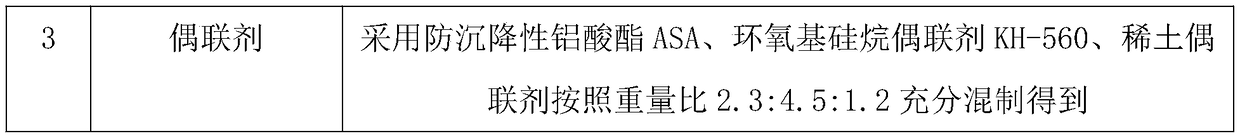

[0075] The selection and preparation of accelerator, cross-linking agent and coupling agent in the present embodiment are shown in Table 2 below:

[0076] Table 2

[0077]

[0078]

[0079] The preparation method of present embodiment coating is carried out according to the following steps:

[0080] Ⅰ: Take red stone fat and periclase powder, add 114...

Embodiment 3

[0085] This embodiment relates to a coating for waterproof color steel plate and its preparation method. The coating consists of the following raw materials in parts by weight:

[0086] Acrylic resin 51 parts;

[0087] 25 parts of furan resin;

[0088] 5 parts red stone fat;

[0089] 7 parts of periclase powder;

[0090] 10 parts of isopropanol;

[0091] 4.5 parts of snail mucus;

[0092] 1.4 parts of cellulose acetate butyrate;

[0093] 3.2 parts of ultrafine hexagonal boron nitride nanoparticles;

[0094] Accelerator 0.7 part;

[0095] 1.0 parts of crosslinking agent;

[0096] 0.6 parts of coupling agent;

[0097] 1 part anti-cracking agent;

[0098] The selection and preparation of accelerator, cross-linking agent, coupling agent and anti-cracking agent in the present embodiment are shown in Table 3 below:

[0099] table 3

[0100]

[0101] The preparation method of present embodiment coating is carried out according to the following steps:

[0102] Ⅰ: Take r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com