Water-based environment-friendly paint and preparation method thereof

An environmentally friendly paint and water-based technology, applied in the field of paint, can solve problems such as poor adsorption capacity, achieve fast drying and curing speed, overcome construction difficulties, and achieve good overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

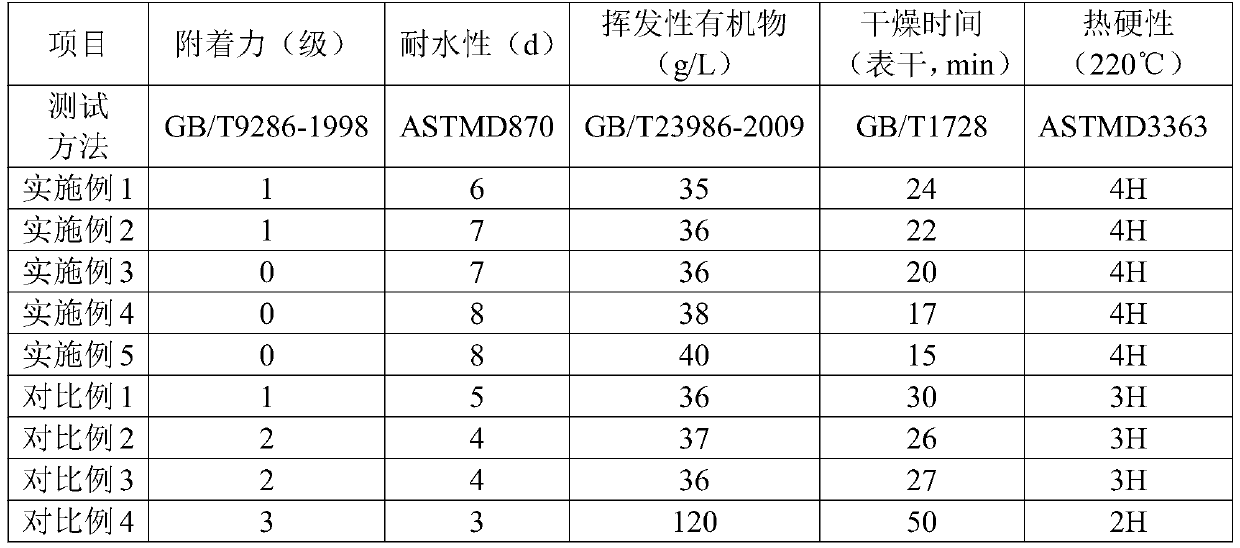

Examples

Embodiment 1

[0030] A kind of water-based environmental protection paint, it is characterized in that, comprises each raw material of following parts by weight to make: hyperbranched polyurethane acrylate 40 parts, based on acrylonitrile cross-linked polymer hollow microsphere 4 parts, chloro (difluoro) allyl acetate Ionized N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid 3 parts, 2,2-dimethylethylene boronic acid pinacol ester 1 part, N,N'-(1,2- Dihydroxyethylene) diacrylamide 1 part, benzoin 0.3 part, shell powder 10 parts, sodium hexametaphosphate 1 part, tributyl phosphate 0.5 part, water 25 parts.

[0031]The preparation method for ionizing N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid with allyl chloro(difluoro)acetate comprises the following steps: allyl chloro(difluoro)acetate Add 10g, 12.5g of N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid into 80g of diethyl ether, stir and react at 30°C for 4 hours, then remove the solvent by rotary evaporation, and wash the crude pr...

Embodiment 2

[0035] A kind of water-based environmental protection paint, it is characterized in that, comprises each raw material of following parts by weight to make: hyperbranched polyurethane acrylate 42 parts, based on acrylonitrile cross-linked polymer hollow microsphere 5 parts, chloro (difluoro) allyl acetate Ionized N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid 3.5 parts, 2,2-dimethylethylene boronic acid pinacol ester 1.5 parts, N,N'-(1,2- Dihydroxyethylene) diacrylamide 1.5 parts, benzoin ethyl ether 0.4 parts, pumice powder 11 parts, polycarboxylate sodium salt 1.5 parts, defoamer Deqian 31000.6 parts, water 27 parts.

[0036] The preparation method of ionizing N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid with allyl chloro(difluoro)acetate comprises the steps of: allyl chloro(difluoro)acetate Add 10 g of N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid 12.5 g into 90 g of ethyl acetate, stir and react at 33°C for 4.5 hours, then remove the solvent by rotary evapora...

Embodiment 3

[0040] A kind of water-based environmental protection paint, it is characterized in that, comprises each raw material of following parts by weight to make: hyperbranched polyurethane acrylate 45 parts, based on acrylonitrile cross-linked polymer hollow microsphere 6 parts, chloro (difluoro) allyl acetate Ionized N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid 4 parts, 2,2-dimethylethylene boronic acid pinacol ester 2 parts, N,N'-(1,2- 2 parts of dihydroxyethylene) diacrylamide, 0.45 parts of diphenyl ethyl ketone, 13 parts of attapulgite, 2 parts of sodium hexametaphosphate, 0.8 parts of defoamer BYK0888, 30 parts of water.

[0041] The preparation method for ionizing N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid with allyl chloro(difluoro)acetate comprises the following steps: allyl chloro(difluoro)acetate Add 10g, 12.5g of N,N-bis(2-hydroxyethyl)-2-aminoethanesulfonic acid into 100g of acetone, stir and react at 35°C for 5 hours, then remove the solvent by rotary eva...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com