Anticorrosive treatment coating device for cement culvert pipe production

A technology of anti-corrosion treatment and coating device, which is applied to the device for coating liquid on the surface, the spray device, the pretreatment surface, etc., which can solve the problems of shortening the life of the pipeline, the thickness of artificial coating is not uniform, and affecting the production and sales of cement culvert pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

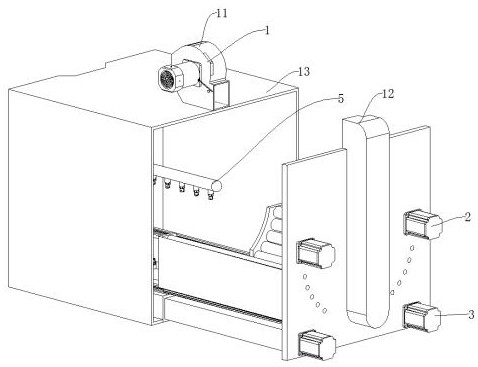

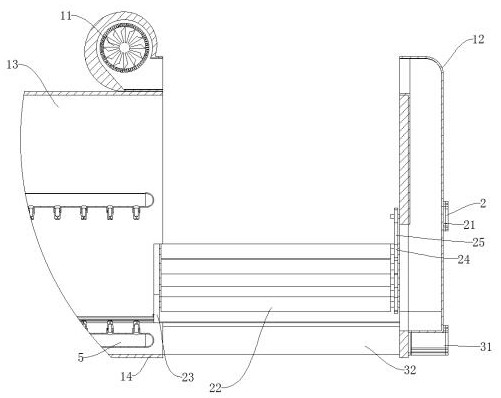

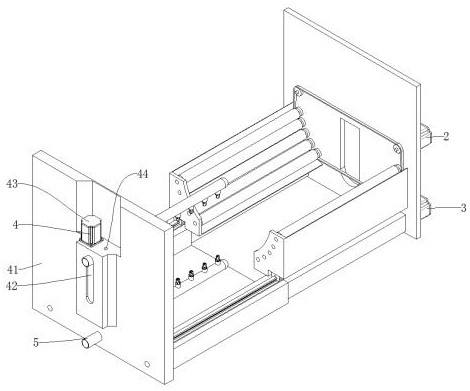

[0043] Such as figure 1 , figure 2 , image 3 , Figure 5 , Figure 7 , Figure 8 As shown, the moving mechanism 3 includes a moving motor 31, a moving seat 32, and a moving screw 33. One end of the moving screw 33 is threaded to the lower side of the fixed frame 41, and the other end of the moving screw 33 is connected to the lower side of the moving seat 32 through a bearing. , the moving motor 31 is connected to the other side of the moving seat 32 by bolts, and the rotating part of the moving motor 31 is used to drive the moving lead screw 33 to rotate, and the moving lead screw 33 is rotated to drive the moving seat 32 to move to one side; the adjustment mechanism 4 includes Fixed mount 41, adjusting seat 42, adjusting motor 43, adjusting leading screw 44, adjusting seat 42 is arranged on the middle position of fixed mounting 41, adjusting motor 43 is connected on the fixed mounting 41 side by bolt, adjusting leading screw 44 is connected on fixed by bearing. On one...

Embodiment 2

[0046] Such as Figure 4 , Image 6 As shown, the difference between Embodiment 2 and Embodiment 1 is that the adjustment mechanism 4 includes a fixed frame 41, an adjustment seat 42, and an adjustment cylinder 413. On one side of the fixed frame 41, the telescopic part of the adjusting cylinder 413 is threadedly connected to the top of the adjusting seat 42, and the adjusting part of the adjusting cylinder 413 is used to drive the adjusting seat 42 to move up and down, and the movement of the adjusting seat 42 drives the coating tube on the upper side 5 Make adjustments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com