A kind of fast-drying silver paste for large keyboard conductive film circuit and preparation method thereof

A conductive film and circuit technology, used in circuits, printed circuits, printed circuit components, etc., can solve the problem of long drying and curing time, and achieve the effects of accelerated shrinkage drying, rapid curing, and a wide range of substrate applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

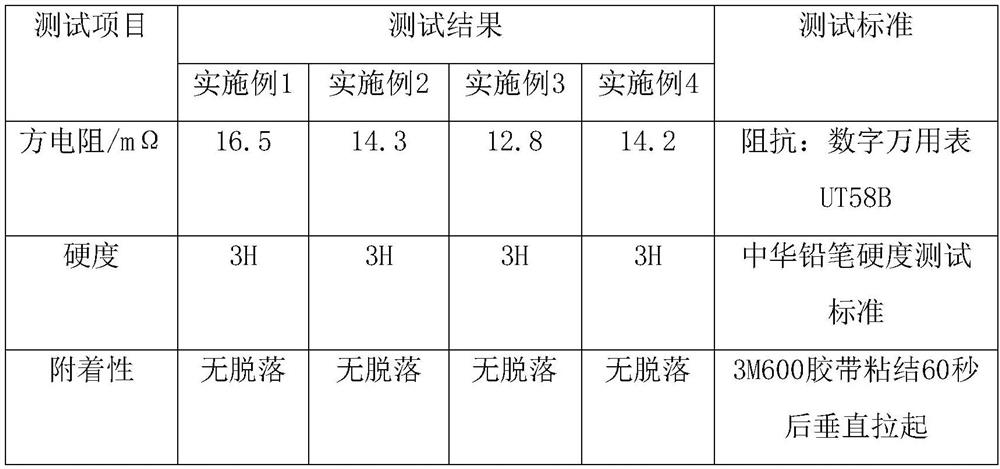

Examples

Embodiment 1

[0019] A quick-drying silver paste for a large keyboard conductive film circuit, comprising the following components in parts by mass: 52 parts of metallic silver powder, 6 parts of polymer resin, 1 part of auxiliary agent, and 30 parts of solvent;

[0020] Among them, the metal silver powder is a mixture of flaky silver powder and nano-silver powder, and the components in the metal silver powder are composed of 80 parts of flaky silver powder and 10 parts of nano-silver powder, wherein the average particle size of the flaky silver powder is 5-10 μm , The average particle size of nano silver powder is 20-80nm. The polymer resin is vinyl resin. The auxiliary agent includes nano-oxide and dispersant, wherein the weight ratio of nano-oxide and dispersant is 3:1, and the nano-oxide used is a mixture of silicon oxide, lithium oxide and magnesium oxide with a mass ratio of 3:2:2 , the dispersant used is a commercially available hyperdispersant. The solvent is a dibasic acid ester....

Embodiment 2

[0026] A quick-drying silver paste for a large keyboard conductive film circuit, comprising the following components by mass: 45 parts of metallic silver powder, 5 parts of polymer resin, 0.5 parts of additives, and 32 parts of solvent;

[0027] Among them, the metal silver powder is a mixture of flaky silver powder and nano-silver powder, and the components in the metal silver powder are composed of 84 parts of flaky silver powder and 6 parts of nano-silver powder, wherein the average particle size of the flaky silver powder is 5-10 μm , The average particle size of nano silver powder is 20-80nm. The polymer resin is vinyl resin. The auxiliary agent includes nano-oxide and dispersant, wherein the weight ratio of nano-oxide and dispersant is 7:1, and the nano-oxide used is a mixture of silicon oxide, lithium oxide and magnesium oxide with a mass ratio of 4:2:2 , the dispersant used is a commercially available hyperdispersant. The solvent is a dibasic acid ester.

[0028] Fo...

Embodiment 3

[0030] A quick-drying silver paste for a large keyboard conductive film circuit, comprising the following components in parts by mass: 60 parts of metallic silver powder, 10 parts of polymer resin, 3 parts of additives, and 40 parts of solvent;

[0031] Among them, the metal silver powder is a mixture of flaky silver powder and nano-silver powder, and the components in the metal silver powder are composed of 87 parts of flaky silver powder and 4 parts of nano-silver powder, wherein the average particle size of the flaky silver powder is 5-10 μm , The average particle size of nano silver powder is 20-80nm. The polymer resin is vinyl resin. The auxiliary agent includes nano-oxide and dispersant, wherein the weight ratio of nano-oxide and dispersant is 1:1, and the nano-oxide used is a mixture of silicon oxide, magnesium oxide and bismuth oxide with a mass ratio of 1:1:1 , the dispersant used is a commercially available hyperdispersant. The solvent is a dibasic acid ester.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com