Multi-core optical fiber connector intelligent processing equipment and processing method

A multi-core fiber, intelligent processing technology, applied in the direction of instruments, optics, light guides, etc., can solve the problems of increasing the position offset of the fiber, the tilt and position offset of the fiber, and reducing the stability of the fiber, so as to reduce the position tilt and misalignment. , The effect of improving processing efficiency and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

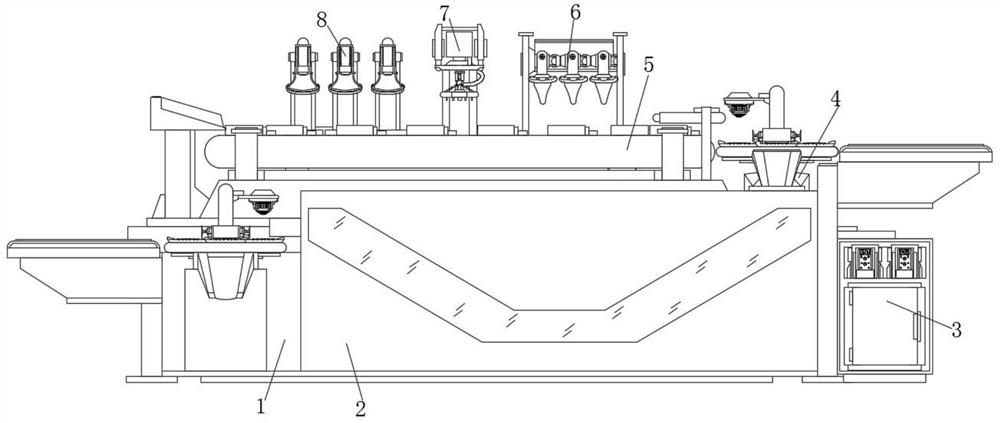

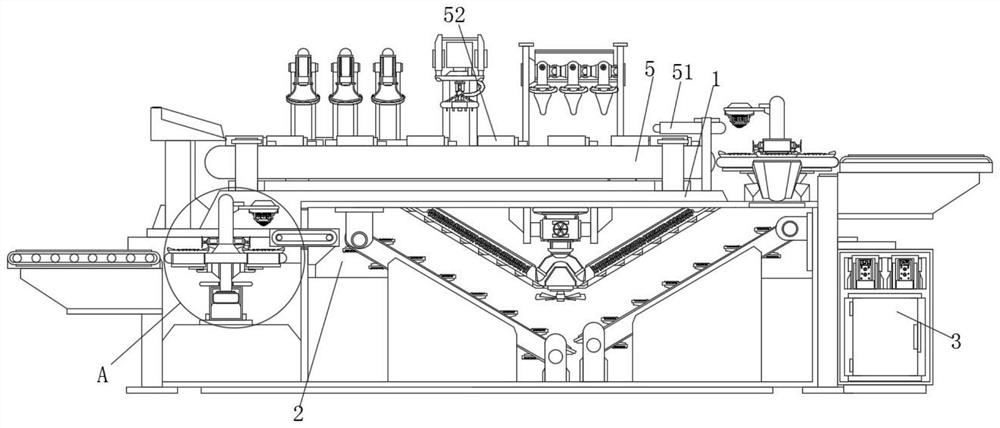

[0047] Example 1, such as Figure 1-4 As shown, when the workpiece being transferred is connected and transferred using the connecting material guide mechanism 4, the different states of the two sets of optical detectors 45 are used to detect whether the optical fiber of the workpiece is misaligned and whether it is qualified. The qualified workpiece is normally conveyed, but not Qualified workpieces will rotate to the next station with the 90° rotation of the mounting base 41, and the electric push rod 47 can push the push plate 48 to send the workpieces to the surface of the waste conveyor belt, so that the unqualified workpieces are automatically recovered under intelligent control. Add functionality and intelligence to your device.

Embodiment 2

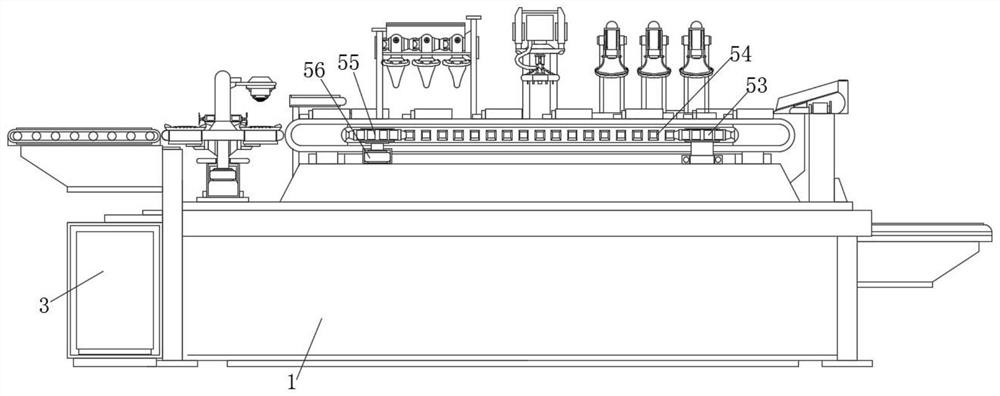

[0048] Example 2, such as Figure 4 As shown, when the workpiece is placed on the surface of the endless conveyor belt 57, the start of the electric telescopic rod can drive the clamping plate to move, so that the workpiece can be clamped and fixed under the cooperation of the clamping plate and the V-shaped groove, so that it can be stably conveyed in the loop. The surface of the belt 57 is conveyed and moved, increasing the stability and precision of the workpieces being processed in the multi-station optical fiber insertion mechanism 6 , the glue injection mechanism 7 and the multi-station core insertion mechanism 8 .

[0049] Working principle: when the equipment is in use, the workpiece is first sent to the surface of the endless conveyor belt 57, and the workpiece is clamped and positioned by the clamping mechanism 52. At this time, the motor 56 can be controlled by the console 3 to start, and the motor 56 is used to drive the driving gear 55 rotates and meshes with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com