Patents

Literature

53results about How to "Reduce application viscosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blends of dibenzoate plasticizers

ActiveUS20130274396A1Efficient Tg suppressionFaster processing timeNon-macromolecular adhesive additivesInksElastomerAdhesive

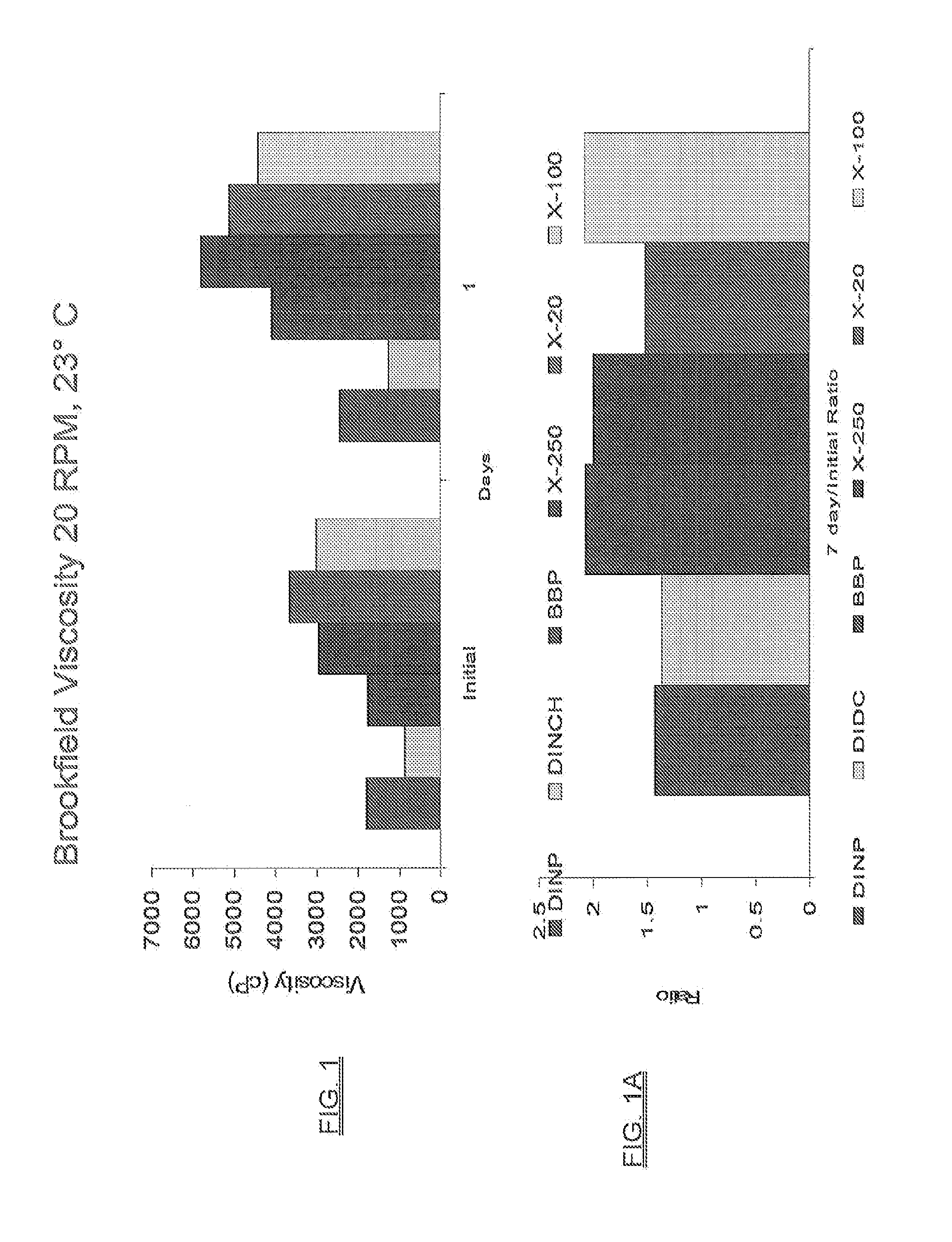

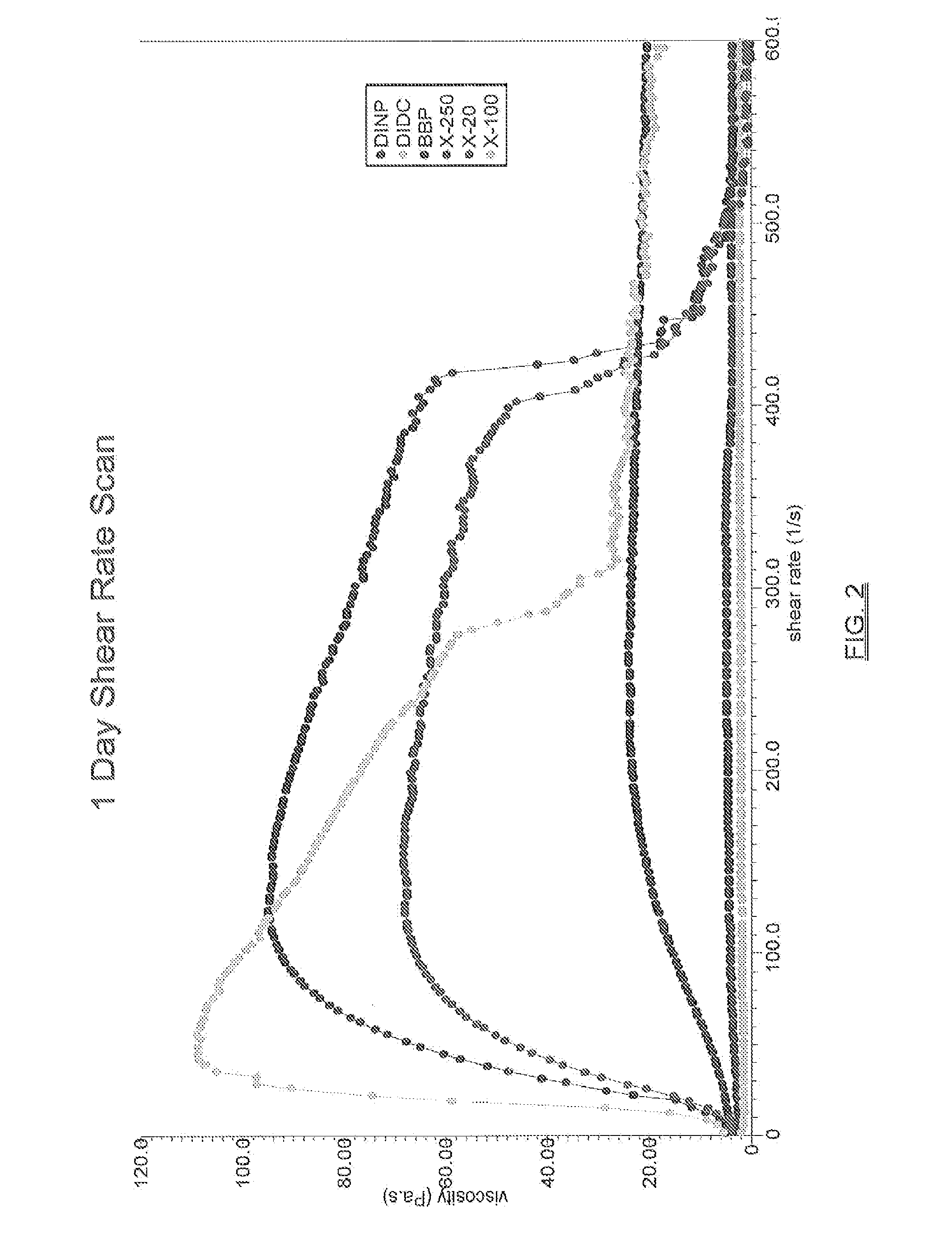

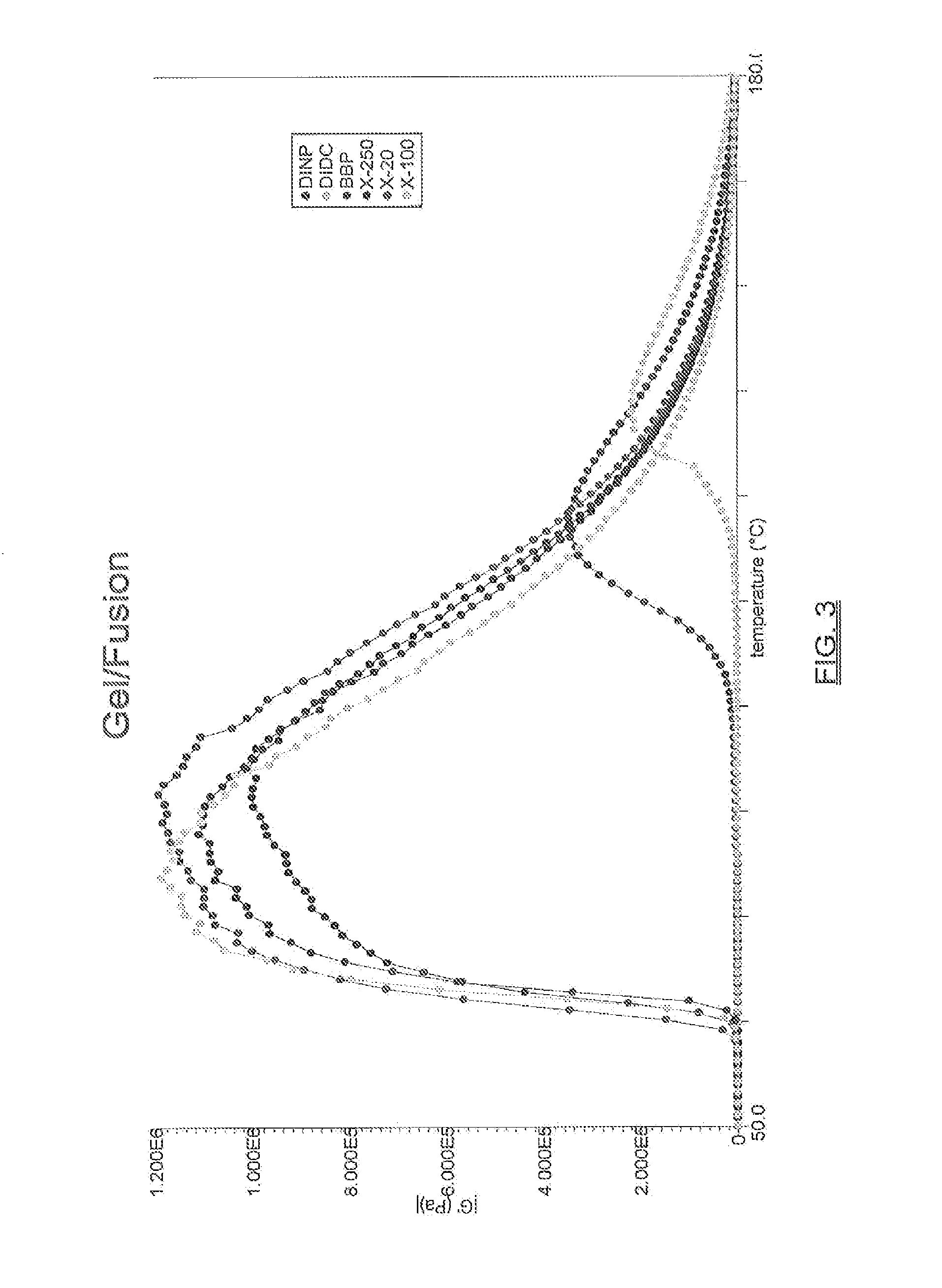

Plasticizer blends comprise a triblend of diethylene glycol dibenzoate, dipropylene glycol dibenzoate, and 1,2-propylene glycol dibenzoate, in specified ratios, useful in combination with a multitude of thermoplastic polymers, thermosetting polymers, and elastomeric polymers and numerous applications, including but not limited to plastisols, adhesives, sealants, caulks, architectural coatings, industrial coatings, OEM coatings, inks, overprint varnishes, polishes, and the like. The advantages rendered by the use of the triblend depend on the type of polymer and application in which it is utilized and include among other advantages higher solvating power and lower processing time, low VOC's, reduced plasticizer freeze point, improved gelation and fusion characteristics, higher tensile strength, superior stain and extraction resistance, and improved rheology over traditional diblends of diethylene glycol dibenzoate and dipropylene glycol dibenzoate.

Owner:EMERALD KALAMA CHEM

Mono-component varnish composition, preparation method and purpose thereof

ActiveCN106916503AImprove radiation resistanceGood weather resistancePretreated surfacesPolyurea/polyurethane coatingsWeather resistanceAcrylic resin

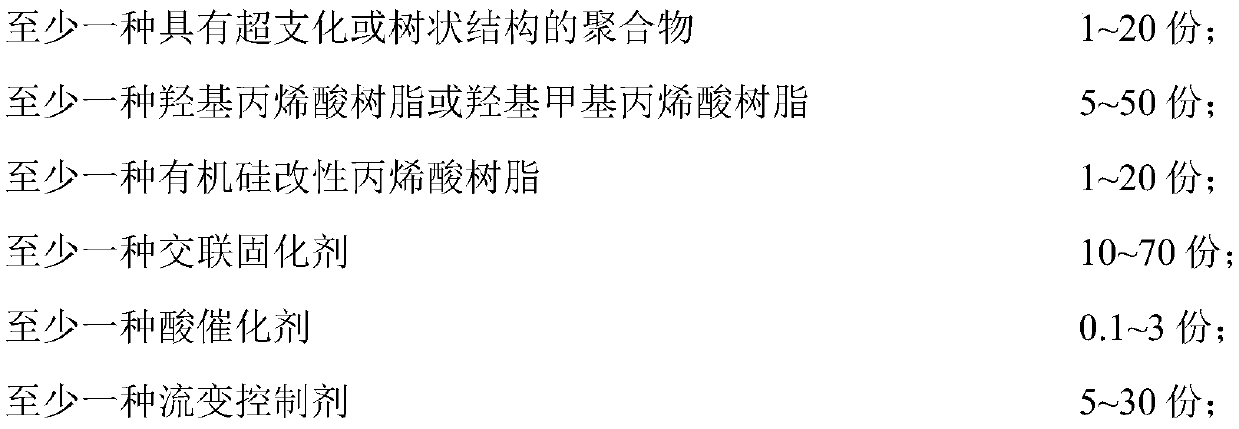

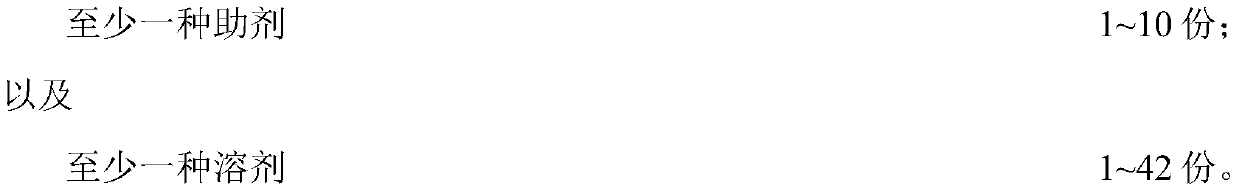

The invention discloses a mono-component varnish composition, which comprises at least a polymer having a hyper branched or dendritical structure; at least one type of hydroxyl acrylic resin or hydroxyl methacrylate resin; at least one type of organosilicon-modified acrylic resins; at least a crosslinking curing agent; at least an acid catalyst; at least a rheological control agent; at least an auxiliary agent and at least a solvent; and the mono-component varnish composition has the advantages of high scratch resistance and high weather resistance. The provided mono-component varnish composition can effectively increase the smoothness of the surface of a varnish composition film, and increases the rub resistance of the film; in addition, the introduction of the organosilicon-modified acrylic resin can further increase the weatherability of the varnish composition film.

Owner:LANGFANG NIPPON PAINT +2

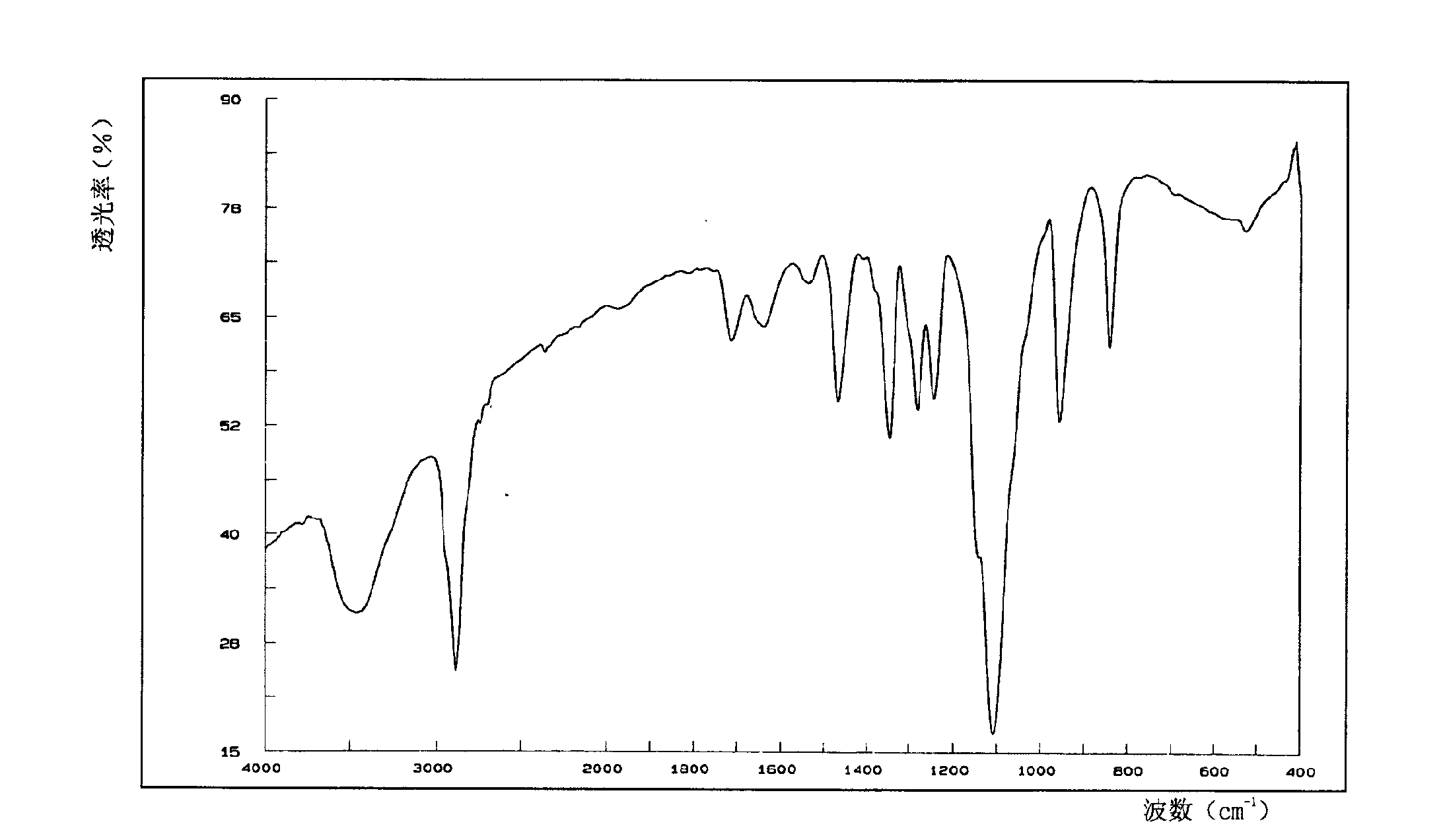

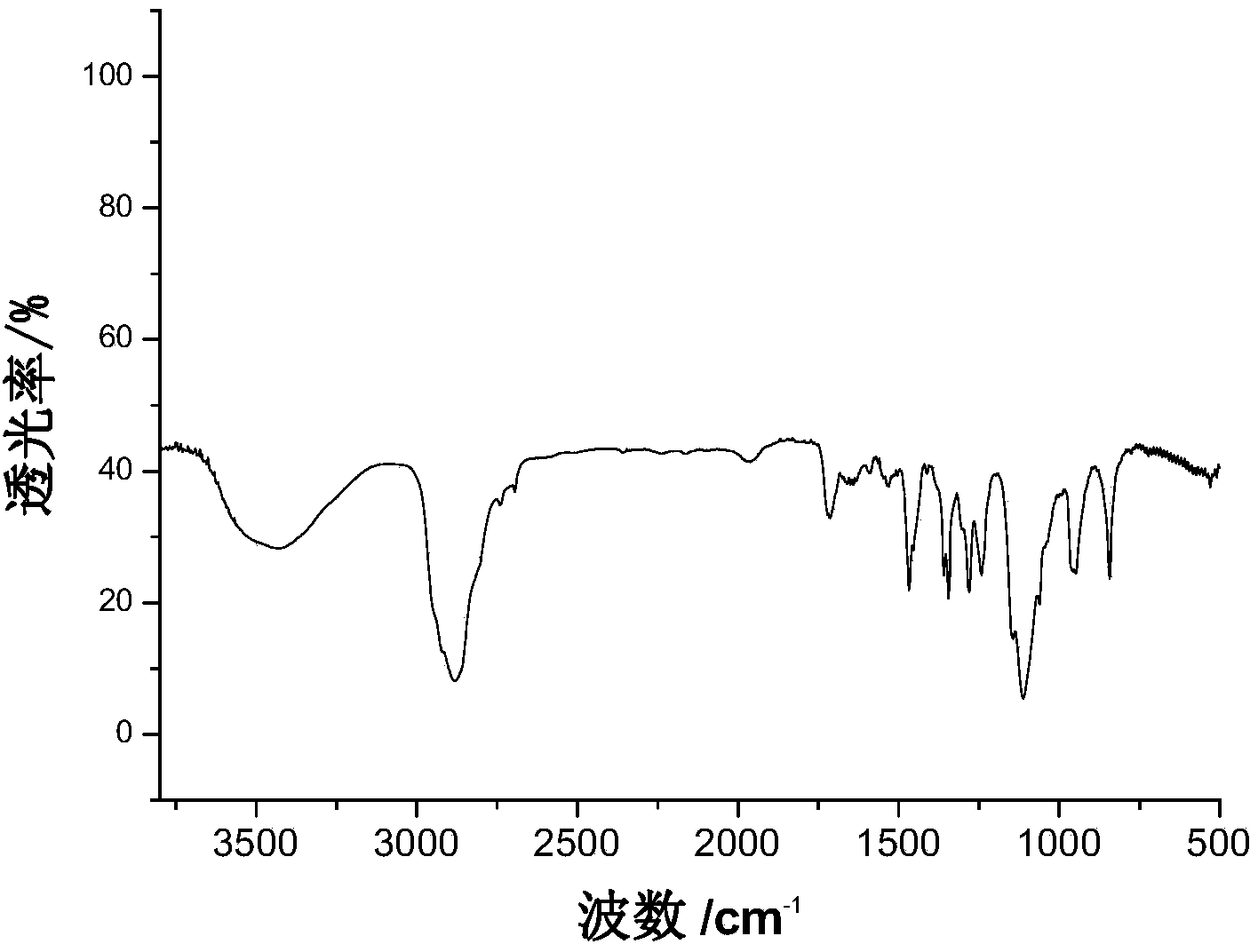

Organic silicon modified epoxy acrylate aqueous dispersion and preparation method thereof

InactiveCN101974143AHigh solid contentReduce application viscosityInksModified epoxy resin adhesivesPrepolymerMaleic anhydride

The invention discloses an organic silicon modified epoxy acrylate aqueous dispersion and a preparation method thereof. The method comprises the following steps of: mixing a polyether epoxy diluent and epoxy resin, and reacting the mixture with a crylic acid monomer to obtain low-viscosity epoxy acrylate prepolymer; performing grafting modification on the low-viscosity epoxy acrylate prepolymer by using maleic anhydride and introducing a hydrophilic group on a molecular chain; mixing micro-molecular amino silicone oil and organic alkali to obtain a neutralizer; and neutralizing the system, adding water for dilution and dispersion, and regulating solid content and viscosity to obtain the UV-curable organic silicon modified epoxy acrylate aqueous dispersion. The organic silicon modified epoxy acrylate aqueous dispersion has high solid content of over 60 percent and low viscosity of between 1,500 and 5,500 mPa.s. A UV cured film has high hardness of between 4H and 6H, high flexibility and water resistance and low water absorption of below 5.0 percent, and can be applied to the fields of furniture, buildings, household appliances, papermaking and printing, and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

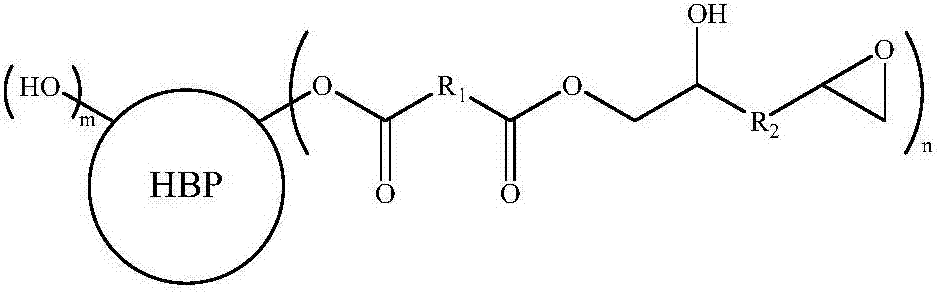

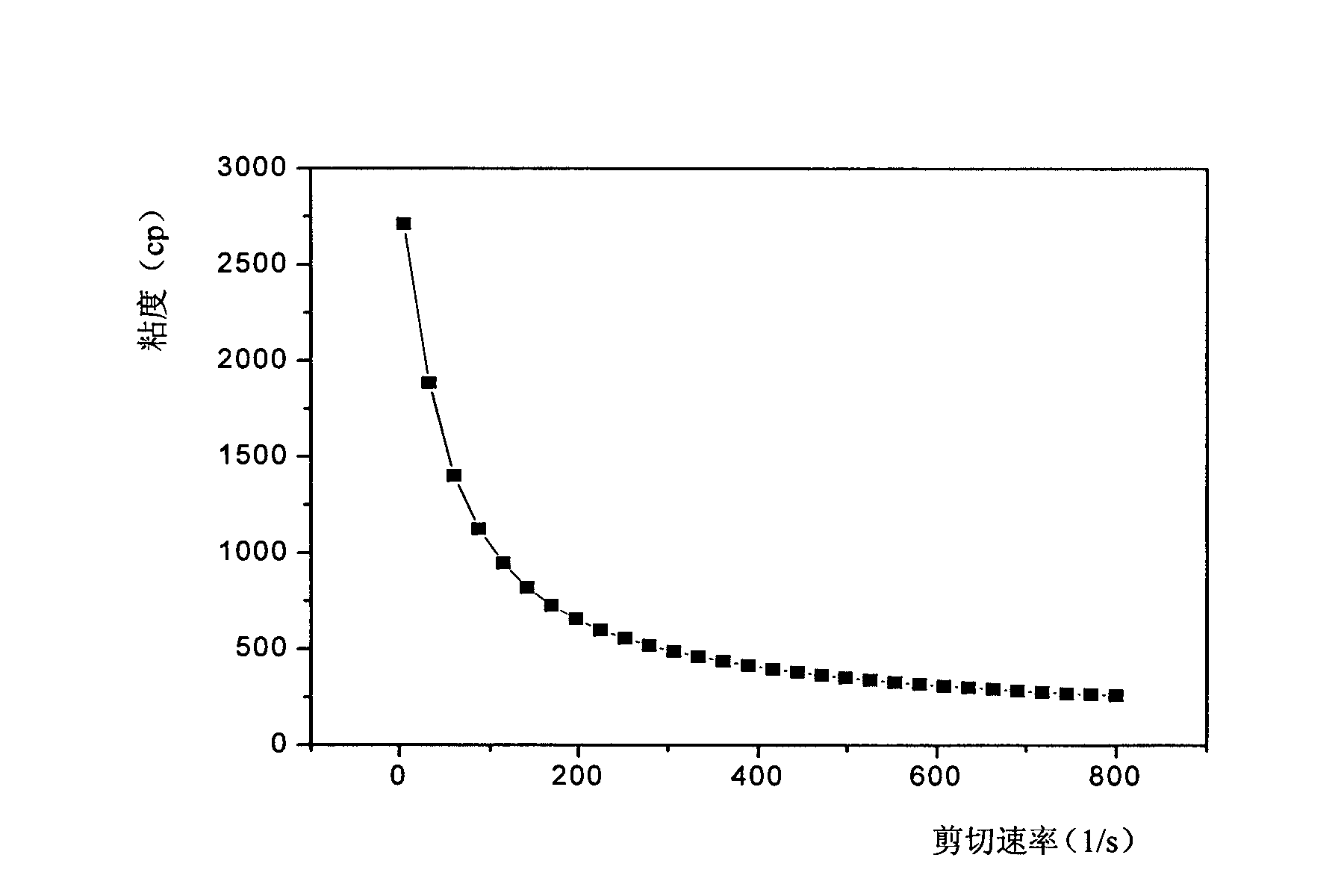

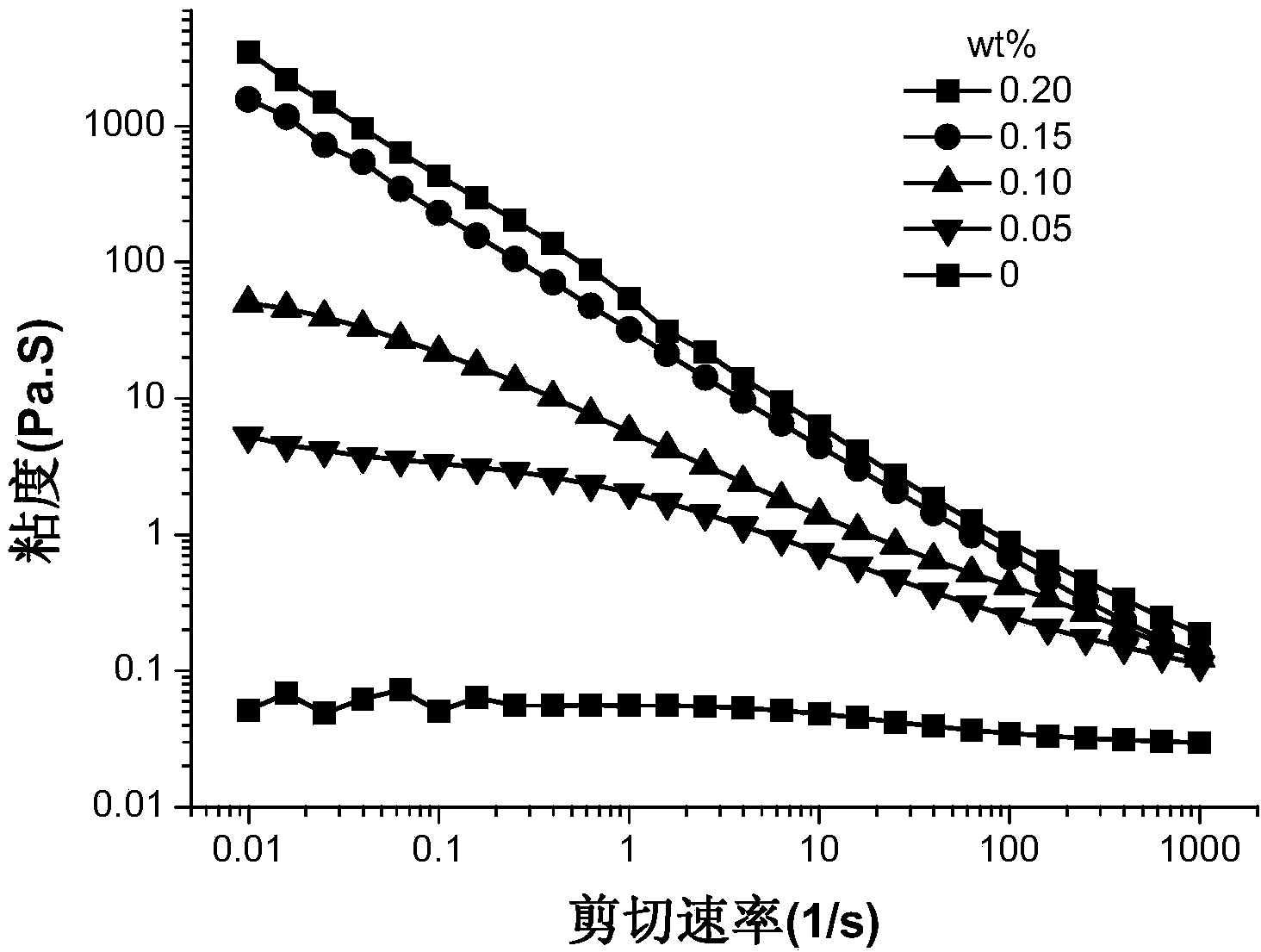

Comb polyurethane associated thickener and preparation method and application thereof

InactiveCN101633718AReduce application viscosityHigh viscosityCosmetic preparationsCoatings with pigmentsPolymer scienceEmulsion

The invention discloses a comb polyurethane associated thickener and a preparation method and an application thereof and the preparation method comprises the following steps: adopting primary amine and diglycidyl ether to react, obtaining hydrophobic diol; then adopting polyether diol, catalyst, diisocyanate, hydrophobic diol and alkanol to react, using precipitate for precipitation after finishing the reaction, drying the precipitation and obtaining the comb polyurethane associated thickener. More than two hydrophobic groups (long chain alkyl) in the molecules of the comb polyurethane associated thickener so that the consistency of the emulsion paint can be greatly improved, the emulsion paint has not only high viscosity under low shear but also low applicable viscosity under high shear, and the quality of the emulsion paint is increased. The polyurethane associated thickener is applicable to thickening the water-containing system and can be used in emulsion paint, varnish, adhesive, leather, papermaking, dyeing and printing, ink, cosmetics and the like.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

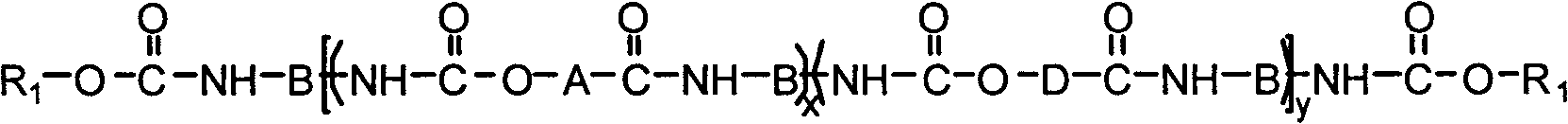

Polyurethane associated thickener, and preparation method and application thereof

InactiveCN103936960AEnhanced hydrophobic associationHigh viscosityCoatingsPolymer sciencePetroleum ether

The invention discloses a polyurethane associated thickener, and a preparation method and application thereof. The preparation method comprises the following steps: adding polyether polyol and methylbenzene to a reaction container under protection of nitrogen, heating up to 110-130 DEG C, and drying and dewatering in vacuum for 2-4 hours; adding a catalyst and diisocyanate after cooling to 30-50 DEG C, heating up to 50-80 DEG C and reacting for 2-6 hours, so as to obtain a methylbenzene solution of a polyurethane prepolymer; adding a chain extender to expand the chain, reacting for 2-6 hours, and then adding a hydroxyl-containing dendric molecule capping agent; heating up to 60-100 DEG C and reacting for 2-8 hours, and then adding a precipitator petroleum ether or normal hexane; drying the sediment in vacuum to finally obtain white solid powder, namely the polyurethane associated thickener. By adopting the polyurethane associated thickener, the viscosity of an emulsion paint can be effectively improved at low dosage, so that the emulsion paint has high viscosity in a low shear state, and also has the characteristic of low construction viscosity in a high shear state; the polyurethane associated thickener has a better application prospect.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of anticorrosive polyurea coating

InactiveCN102786870AHigh bonding strengthSimple processPretreated surfacesPolyurea/polyurethane coatingsSurface layerSand blasting

The invention belongs to the field of metal corrosion and protection and discloses a preparation method of an anticorrosive polyurea coating. The preparation method comprises processes of preprocessing a metal structure, removing oil, performing sand blasting, treating a metal surface, drying, spraying bottom polyurea paint and spraying surface polyurea paint. The preparation method is characterized in that an inositol phosphate solution is adopted in the metal surface treatment to form a chemical conversion film of inositol phosphate on the surface a the metal structure substrate; the bottom polyurea paint is aromatic polyurea paint; the surface polyurea paint is an aliphatic polyurea paint; the metal comprises steel, aluminum alloy and a zinc-plated steel structure; and the coating is 500-1500 mu m thick, the bottom layer is 300-1200 mu m thick, the surface layer is 200-400 mu m thick, and the bonding strength of the coating is higher than 10MPa. The preparation method provided by the invention is simple in process, convenient to operate and free from coating a primer.

Owner:SHANDONG UNIV +1

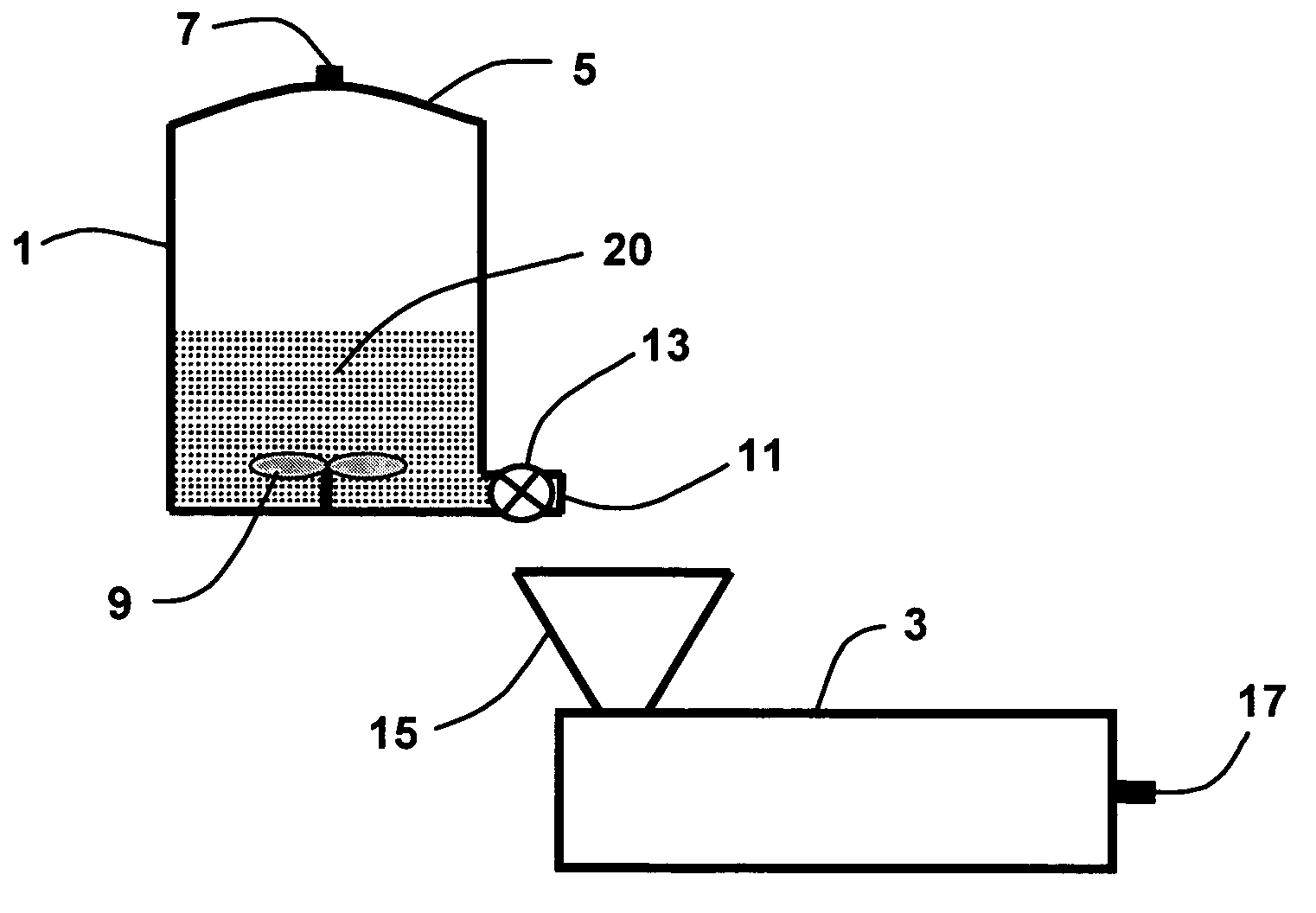

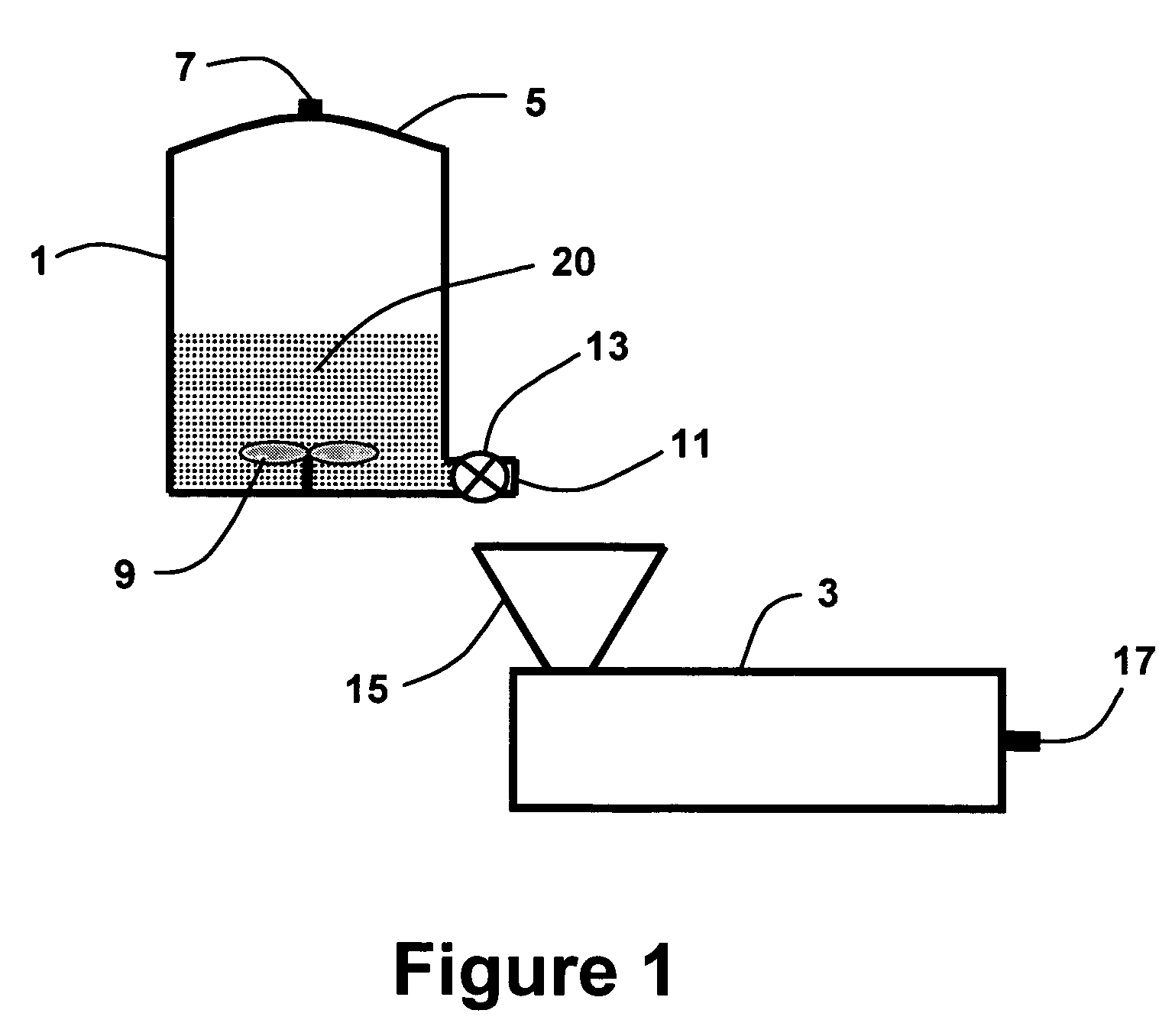

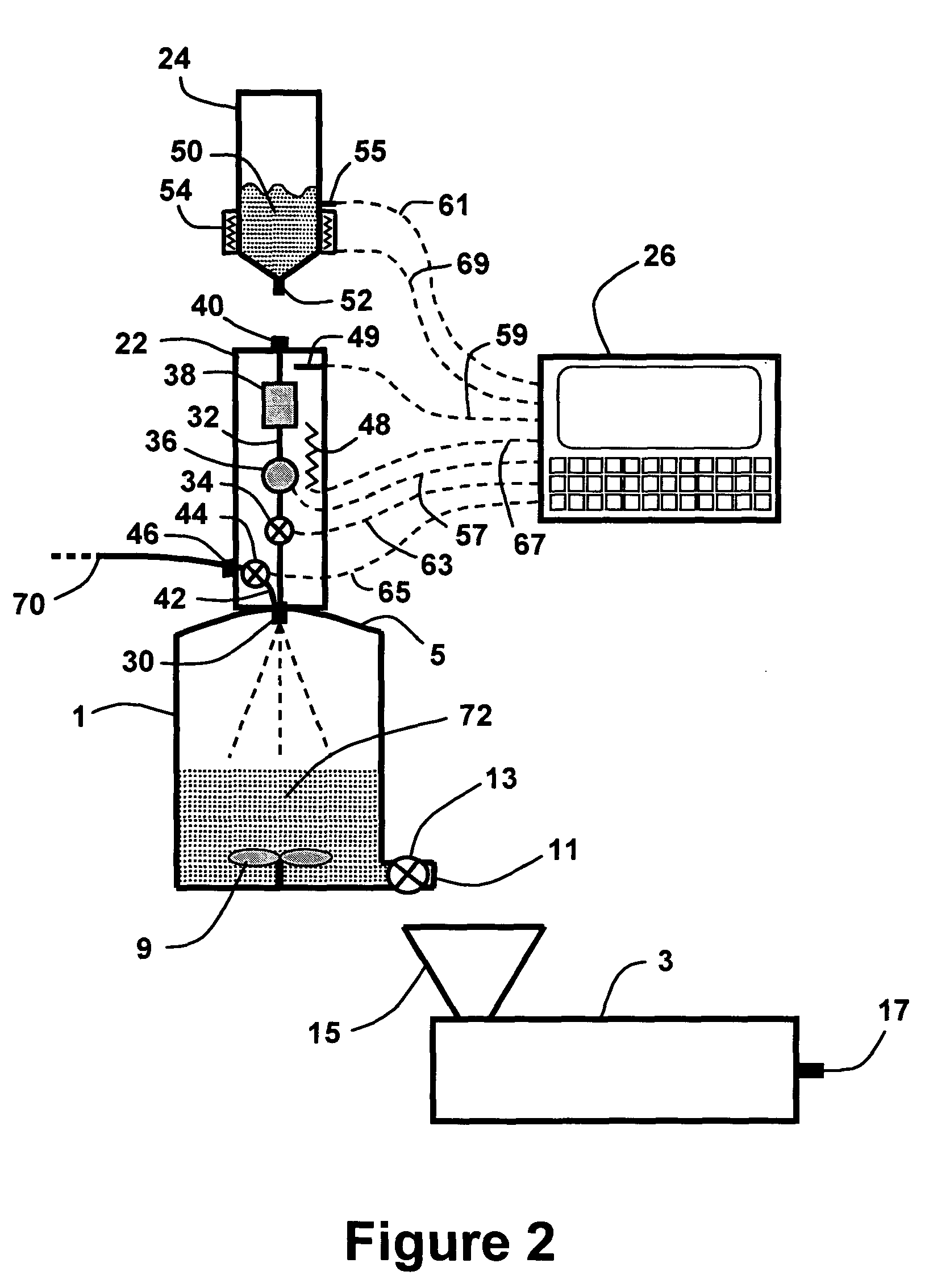

Liquid additive spray injection to polymeric powders

InactiveUS20040028808A1Reduce application viscosityLiquid/solution decomposition chemical coatingSolid/suspension decomposition chemical coatingImproved methodMaterials science

An improved method and apparatus for adding relatively small amounts of one or more liquid additives to powder coating composition where the liquid is sprayed onto granular or particulate components of the powder composition during mechanical mixing to blend the components before further homogenizing by a melt mixing process.

Owner:THE LUBRIZOL CORP

High-sinking-resistance transparent primer and preparation method thereof

The invention relates to a high-sinking-resistance transparent primer and a preparation method thereof. The high-sinking-resistance transparent primer is particularly suitable for application on a wood substrate and especially suitable for application on a substrate with deeper wood-grain guide tubes. The primer is prepared from a main paint, a curing agent and a diluter in a mass ratio of 1:0.5:(0.3-1):0.5:0.7. The main paint is prepared from the following raw materials in parts by mass: 55-70 parts of small-oil-length alkyd resin, 5-15 parts of castor oil modified alkyd resin, 3-10 parts of zinc stearate, 0-30 parts of talcum powder, 0.5-1 part of anti-settling agent, 0.3-1 part of defoamer, 0.2-0.5 part of leveling agent, 0.1-0.5 part of wetting and dispersing agent, 0.1-0.3 part of drier and 5-15 parts of environment-friendly mixed solvent. The primer can be well combined with the substrate after being applied, and has excellent properties in the aspect of wood grain / guide tube filling. After the primer is placed for a long time, the paint film of the finish paint can not shrink, and can not generate the phenomenon of sinking.

Owner:SKSHU PAINT

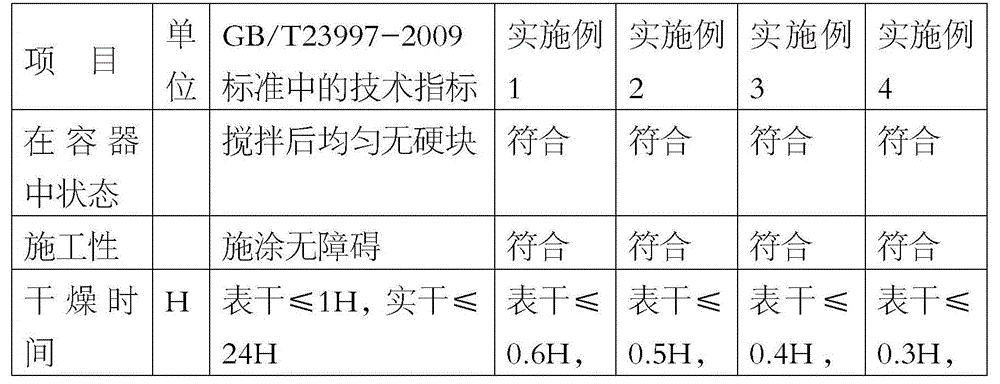

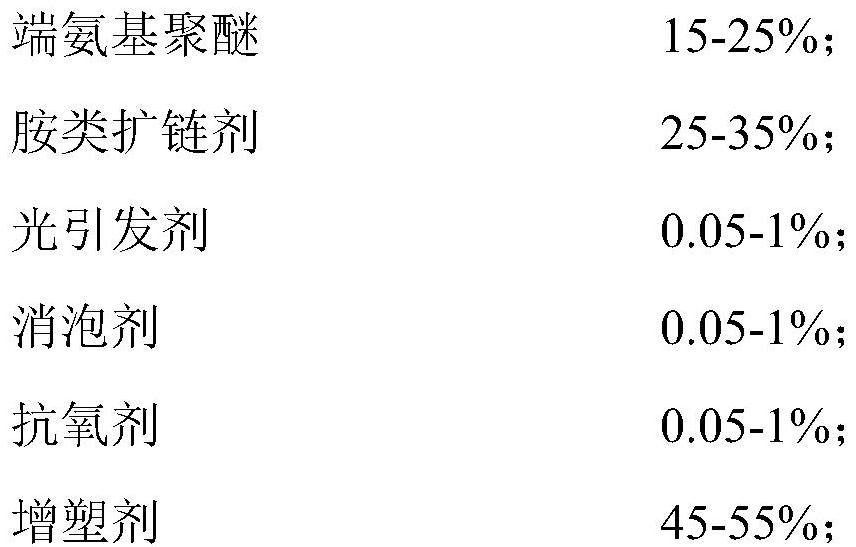

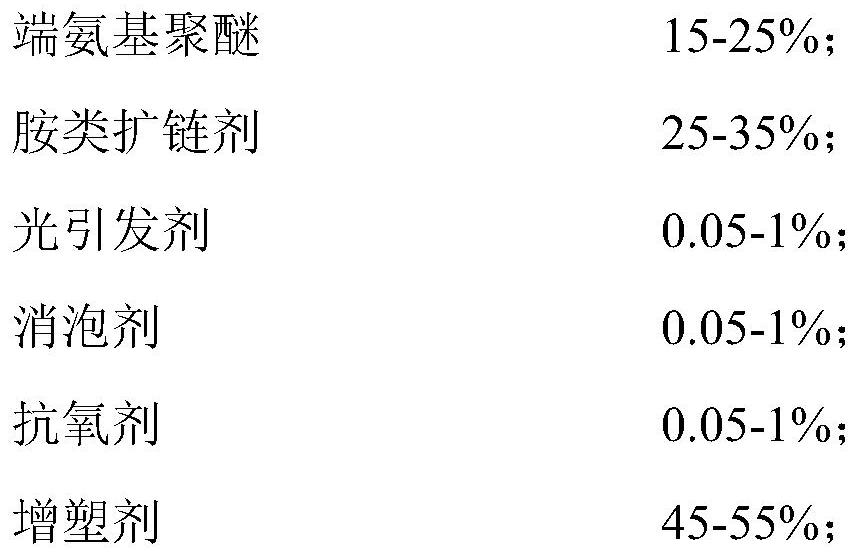

Photocuring double-component polyurea waterproof coating and preparation method thereof

ActiveCN112778886AGood weather resistanceFlexiblePolyurea/polyurethane coatingsPolymer scienceAntioxidant

The invention relates to a photocuring double-component polyurea waterproof coating and a preparation method thereof. The photocuring double-component polyurea waterproof coating is composed of a component A and a component B. The raw material formula of the component A comprises a polyurea prepolymer and an acrylic acid modified polyurea prepolymer, and the polyurea prepolymer is prepared through a reaction of isocyanate and steric hindrance secondary amine. The raw material formula of the component B comprises amino-terminated polyether, an amine chain extender, a photoinitiator, a defoaming agent, an antioxidant and a plasticizer. The steric hindrance secondary amine and the amine chain extender are respectively selected from asparaginic acid ester steric hindrance type secondary amine. An asparaginic acid ester compound is introduced into the component A and the component B at the same time, the photoinitiator is used in cooperation, the coating can be rapidly and deeply dried and cured to form a film after being irradiated by ultraviolet rays, and the weather resistance is good. Acrylic acid is introduced for modification, so that the coating has the flexibility of polyurethane and the hardness of acrylic acid at the same time, and the coating also has excellent cohesiveness, excellent self-repairing and self-healing performance and long opening time.

Owner:JIANGSU CANLON BUILDING MATERIALS

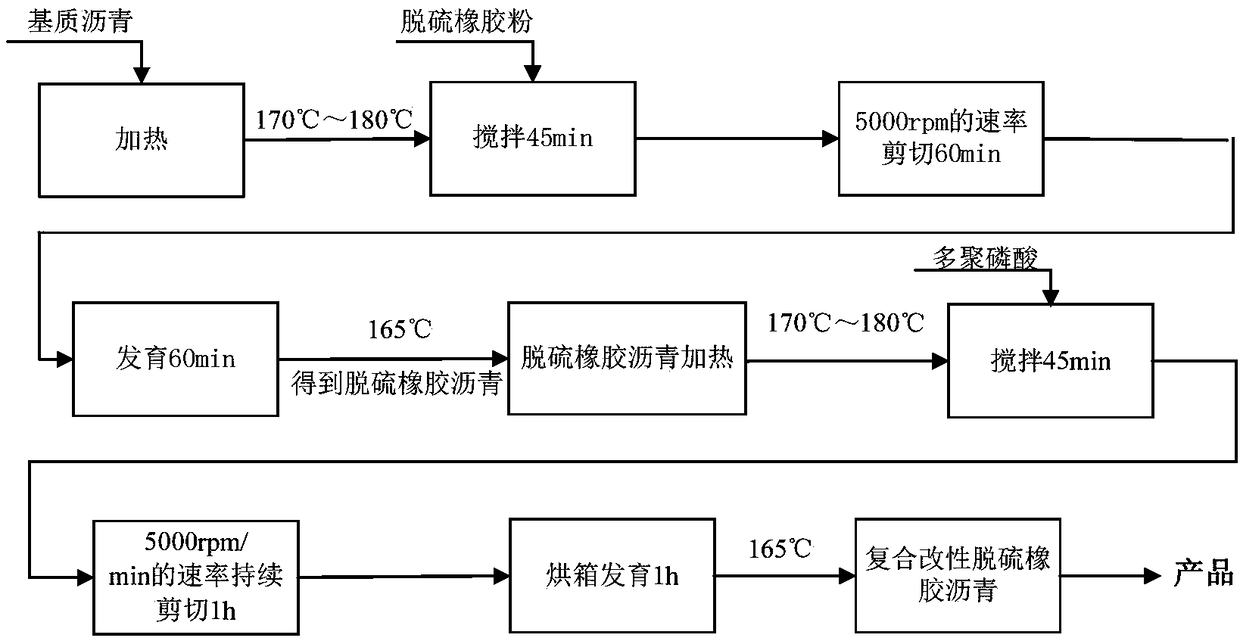

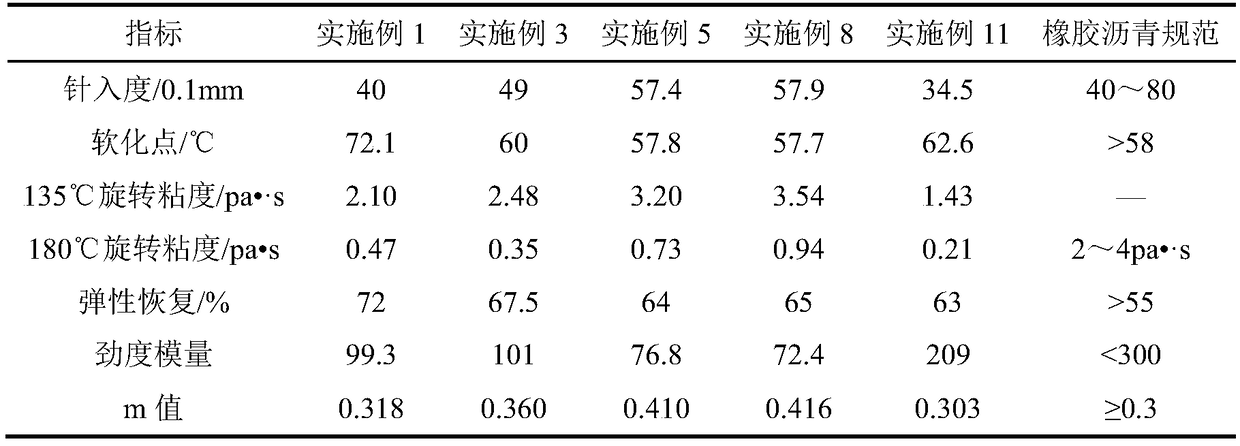

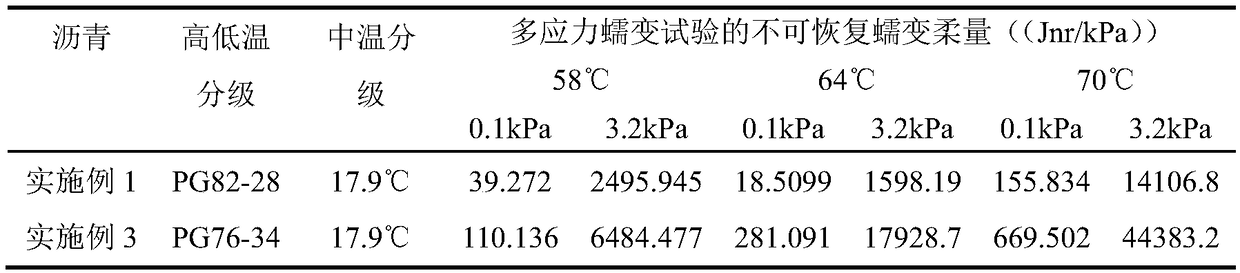

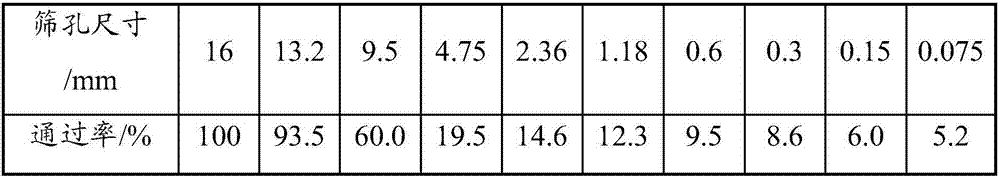

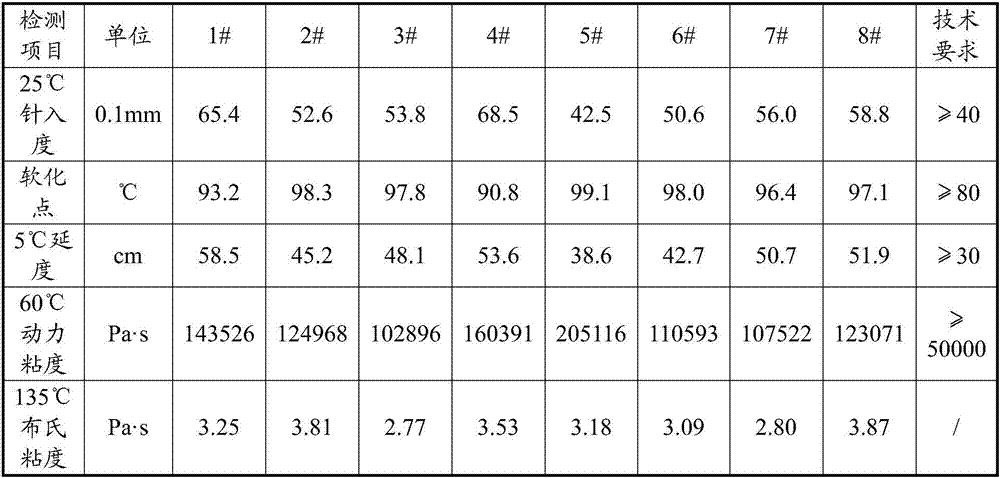

Composite modified desulfurized rubber asphalt and preparation method thereof

InactiveCN108727843AEnvironmental protection is goodGood environmental protection performance, good high and low temperature performanceBuilding insulationsPolymer scienceViscosity

The invention discloses composite modified desulfurized rubber asphalt and a preparation method thereof. After desulfurized rubber powder is added into matrix asphalt, the desulfurized rubber powder is evenly dispersed in the matrix asphalt, then the evenly-dispersed mixture is subjected to shearing, and the desulfurized rubber powder is finer through shearing under high-speed rotation, so that more reaction opportunities of the desulfurized rubber powder and the light component are created, then through a development technology, the desulfurized rubber powder swells in the matrix asphalt to form desulfurized rubber asphalt with good performance, after the desulfurized rubber asphalt is prepared, a composite modifying agent is added, a shearing technology is conducted, polyphosphoric aciddisperses more evenly in the desulfurized rubber asphalt, the reaction depth is improved, and through development, the polyphosphoric acid better swells in the desulfurized rubber asphalt to form thecomposite modified desulfurized rubber asphalt with good performance. The obtained composite modified desulfurized rubber asphalt is good in environment-friendly performance and high-and-low temperature performance, low in applicable viscosity and good in storage stability.

Owner:CHANGAN UNIV

Solvent-free oil pipeline anti-corrosion and anti-drag special coating and preparation method thereof

ActiveCN111205746AImprove thixotropyEvenly dispersedAnti-corrosive paintsEpoxy resin coatingsFatty amineSolvent free

The invention discloses a solvent-free oil pipeline anti-corrosion and anti-drag special coating and a preparation method thereof, belongs to the field of anti-corrosion coatings, and solves the problems that an existing solvent-free anti-corrosion coating is high in construction difficulty, a coating is prone to scale formation and the like. The coating is prepared from two components, wherein the component I is prepared from bisphenol A epoxy resin, polyethersulfone modified epoxy resin, aromatic hydrocarbon resin, glass fiber powder, polytetrafluoroethylene wax powder, potassium hexatitanate whiskers, silica powder, a dispersing agent, a leveling agent, an epoxy active diluent, polyethylene wax powder, talcum powder, phthalocyanine blue, lemon yellow and an antifoaming agent, and the component II consists of a cashew nut shell oil modified phenolic aldehyde amine curing agent and a resin type modified fatty amine curing agent. The preparation method comprises the following steps: mixing the component I and the component II according to a mass ratio of (4-12): 1, and uniformly stirring. The coating has the advantages of favorable long-acting property, favorable flexibility, favorable temperature resistance, favorable chemical resistance, favorable drag reduction effect, environment friendliness and easiness in construction. The preparation method is simple, and the productionefficiency can be obviously improved.

Owner:西北永新涂料有限公司

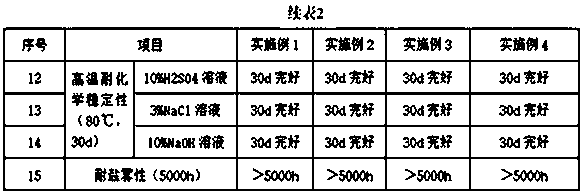

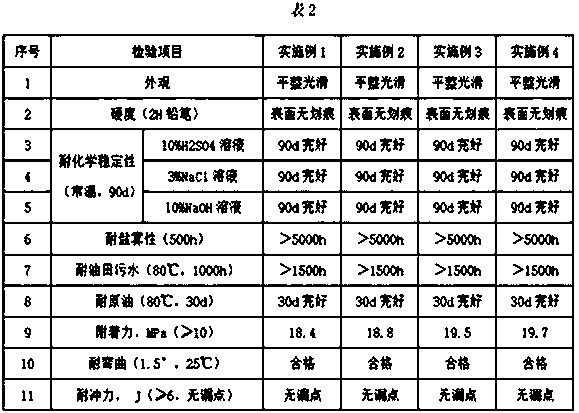

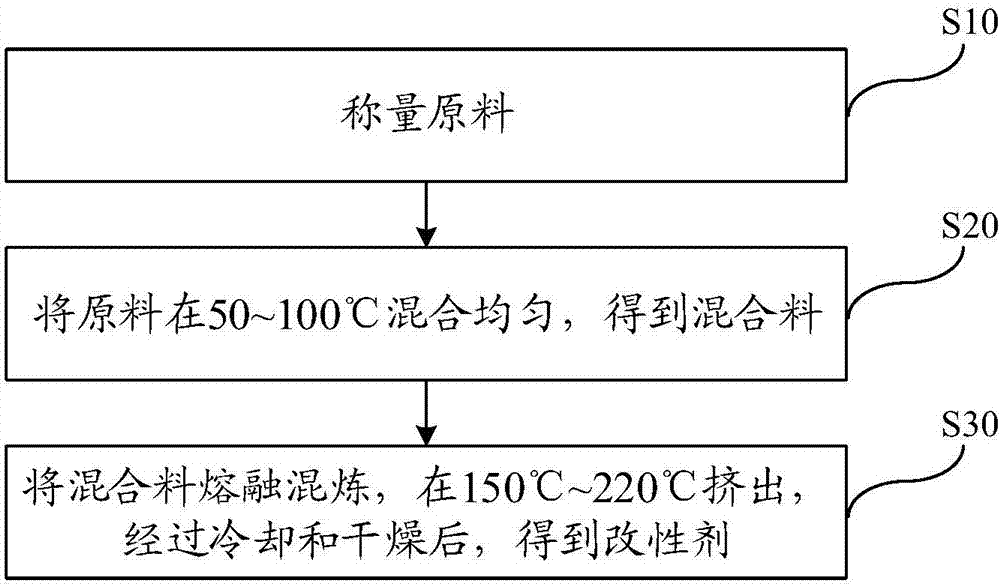

Modifier as well as preparation method and application thereof

InactiveCN107880576AGuaranteed high and low temperature performanceImproved melt dispersion propertiesBuilding insulationsPlasticizerAntioxidant

The embodiment of the invention discloses a modifier as well as a preparation method and application thereof. The modifier is prepared from the following raw materials in parts by weight: 40-80 partsof thermoplastic elastomer polymer, 10-30 parts of modified petroleum resin, 5-20 parts of thermally sensitive resin, 1-5 parts of a stabilizer, 5-20 parts of a plasticizer and 1-3 parts of an antioxidant. The thermoplastic elastomer polymer in the embodiment of the invention has an effect of enhancing and toughening the modifier, so that the high / low-temperature service performance of the modifier can be ensured; the modified petroleum resin has strongly polar groups and is matched with the thermoplastic elastomer polymer, so that the viscosity of asphalt at a service temperature can be obviously improved, and the pavement performance of the mixture is ensured; the thermally sensitive resin has the characteristic of excellent temperature sensitivity and is matched with the plasticizer andthe stabilizer, so that the applicable viscosity of the asphalt at a high temperature can be effectively reduced, and the construction workability of the mixture is improved; and moreover, since thehigh temperature viscosity is reduced, the melting dispersion characteristic of the modifier can be improved.

Owner:ROADMAINT CO LTD

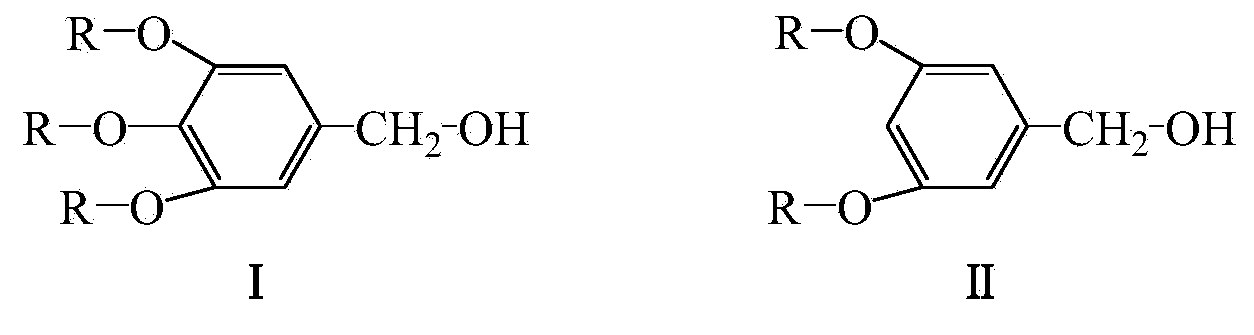

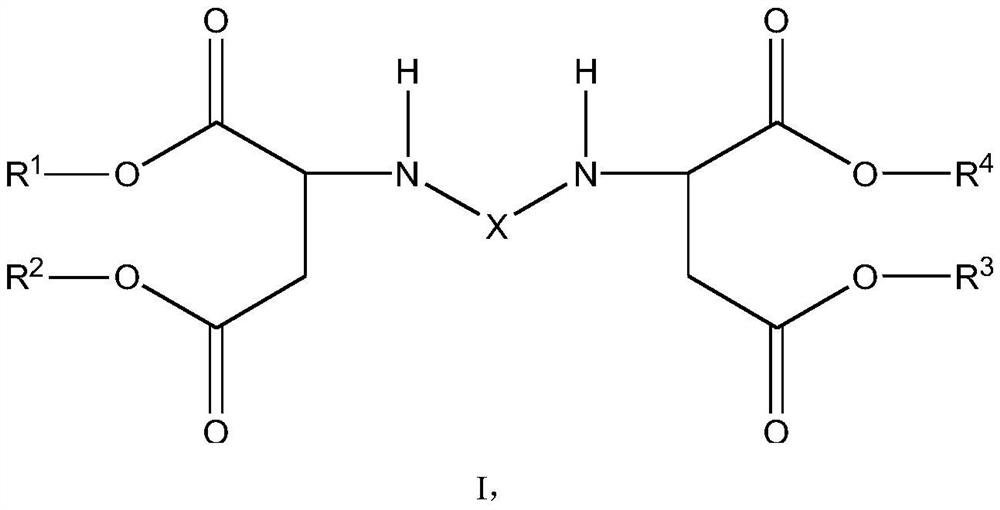

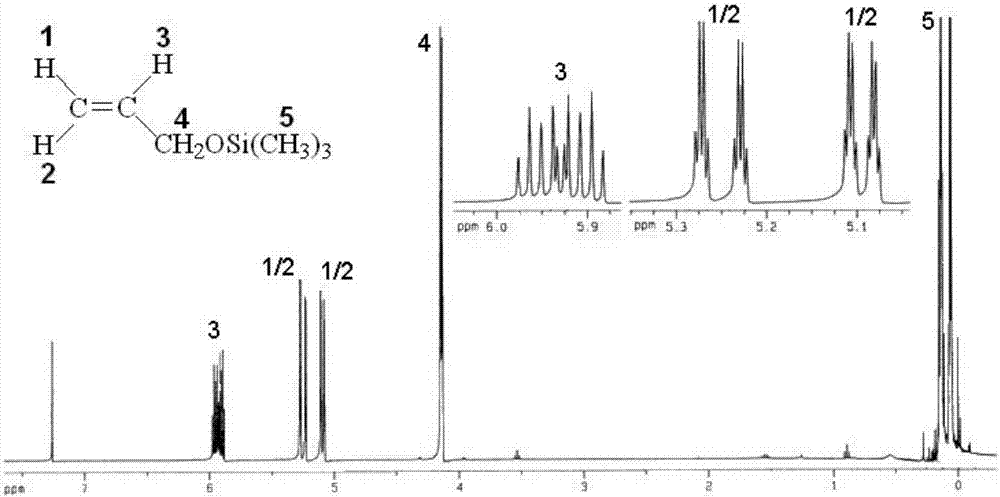

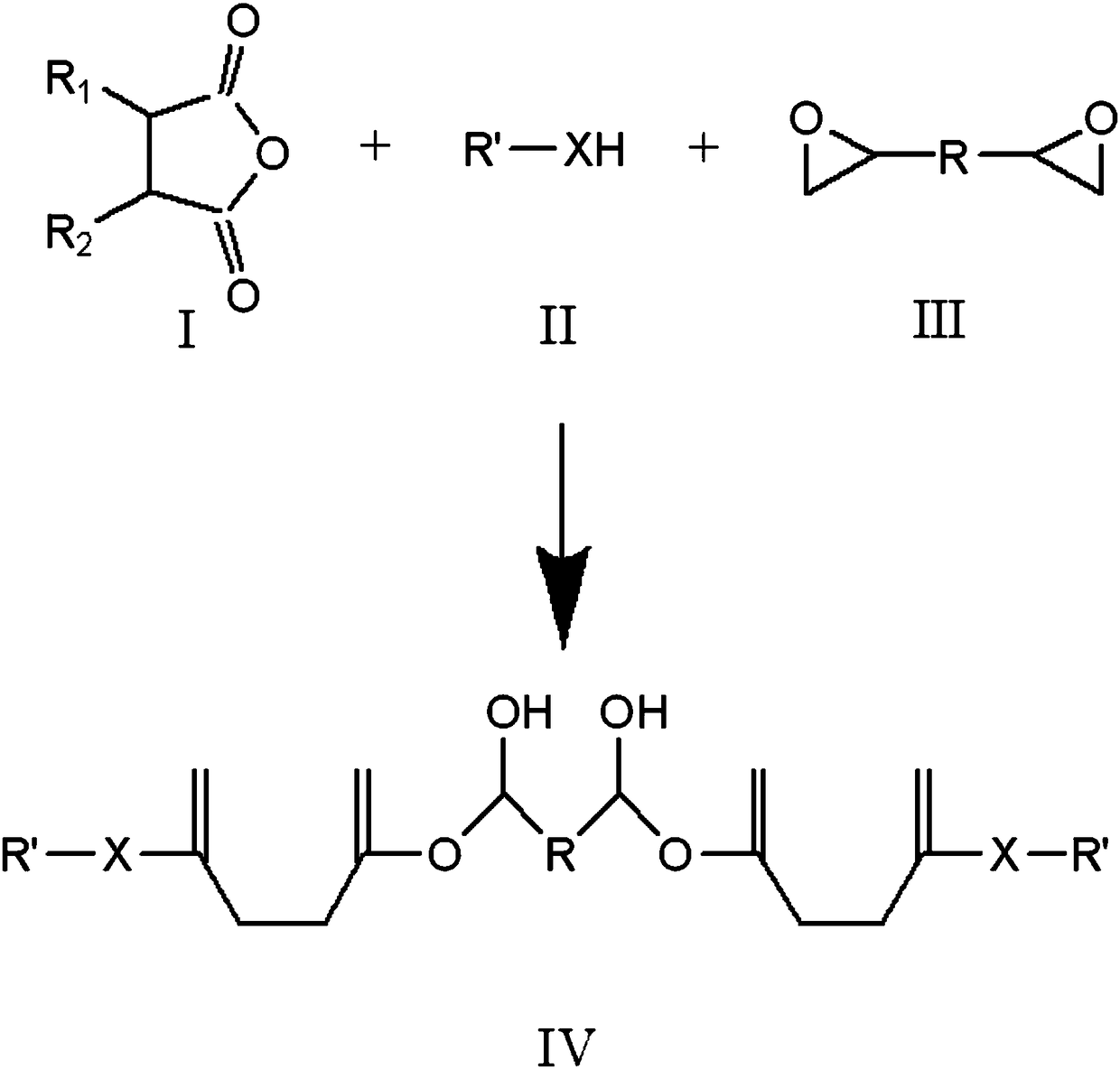

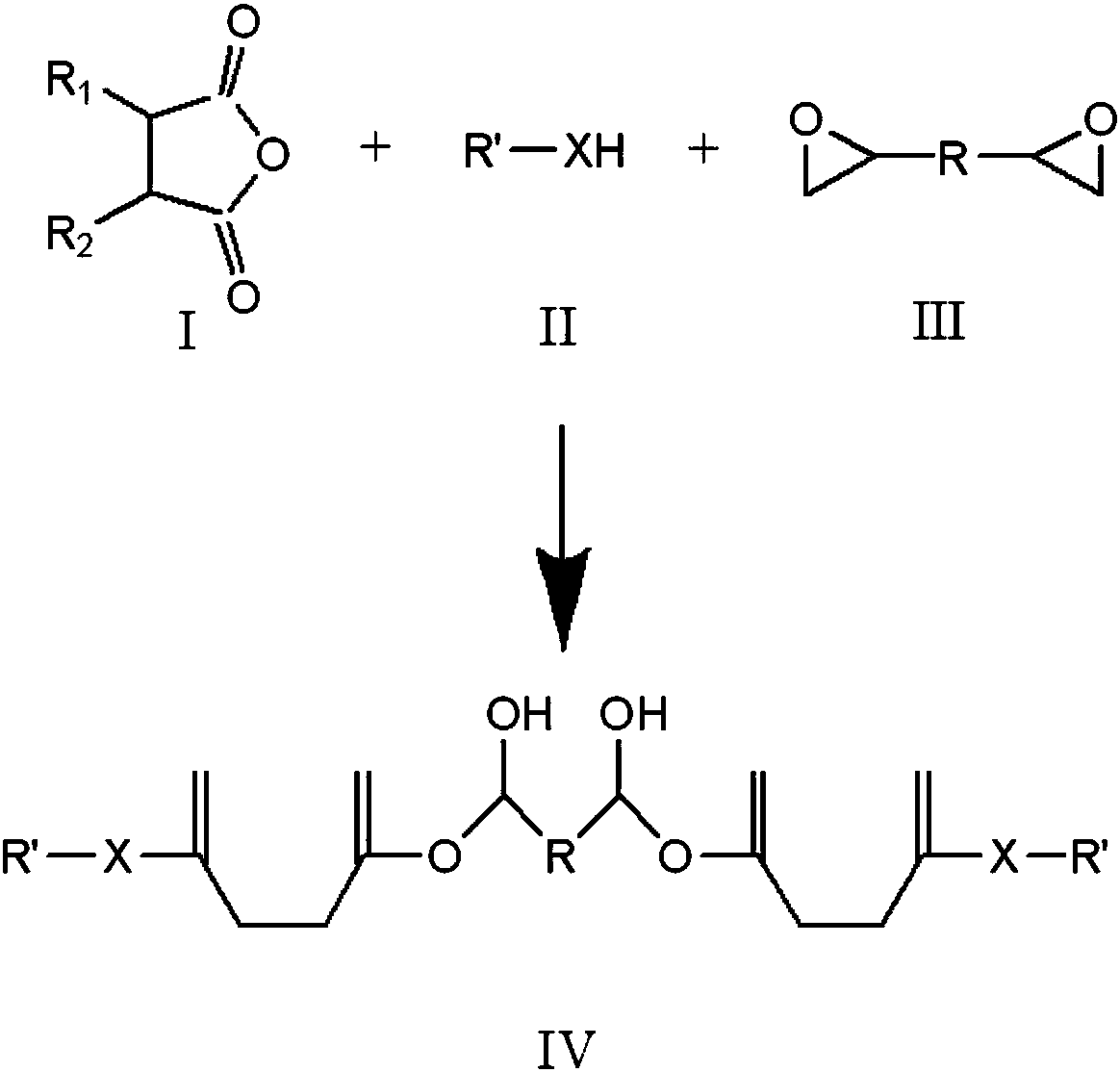

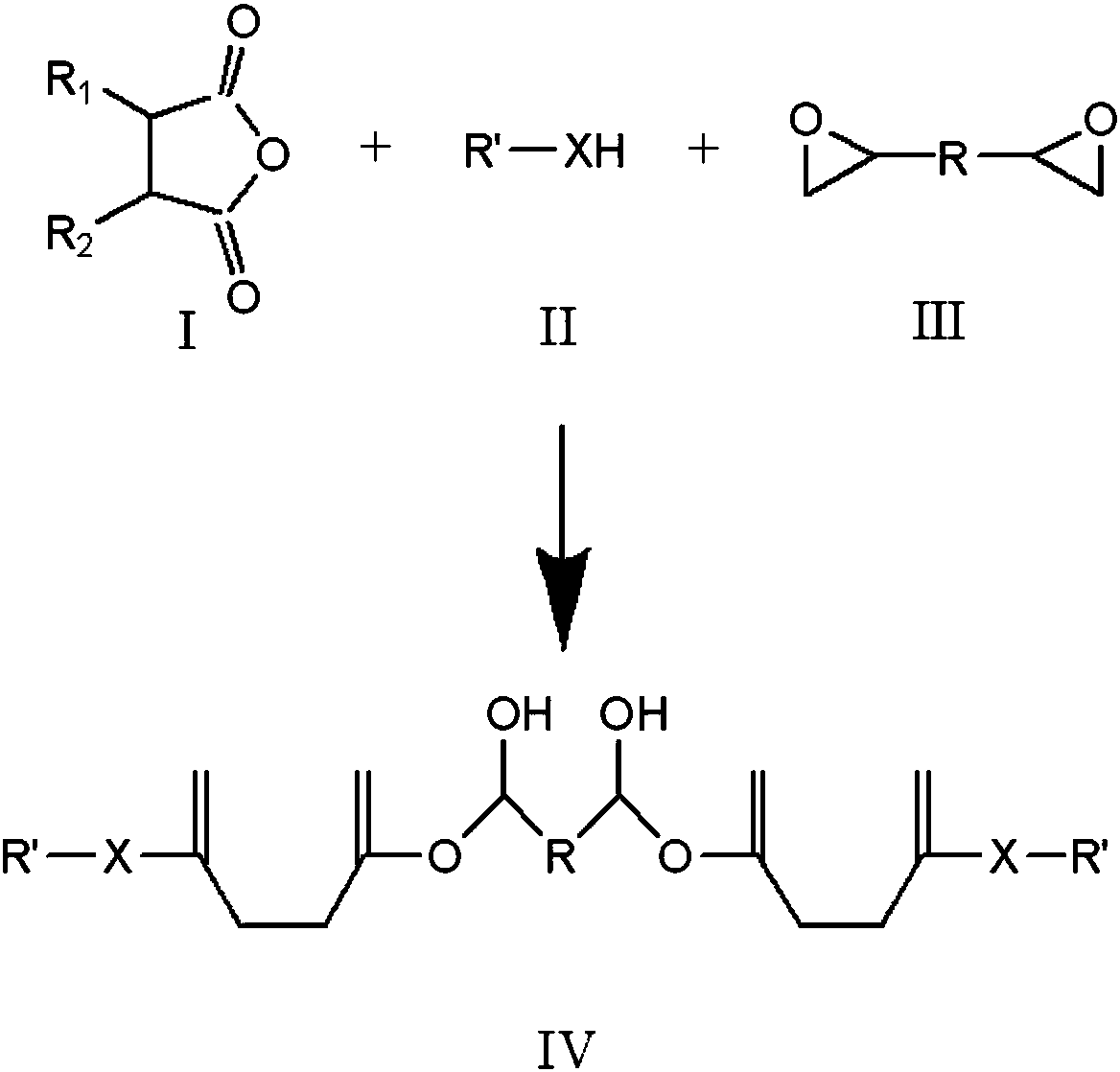

High-solid and low-viscosity organosilicone-modified acrylate resin, preparation method and applications

ActiveCN106928410AImprove radiation resistanceGood weather resistanceAntifouling/underwater paintsPaints with biocidesPolymer scienceViscosity

The invention discloses a high-solid and low-viscosity organosilicone-modified acrylate resin, the structure of which is shown as the general formula I, wherein the definitions of substituted groups in the formula are shown in a specification. The high-solid and low-viscosity organosilicone-modified acrylate resin can endow a varnish film with high rubbing resistance and smooth performances.

Owner:NIPPON PAINT CHINA +2

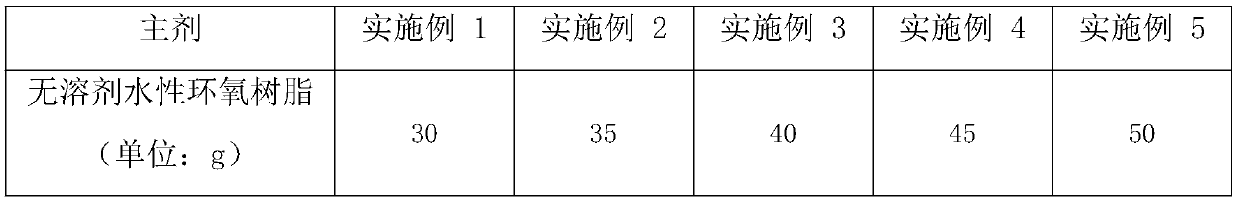

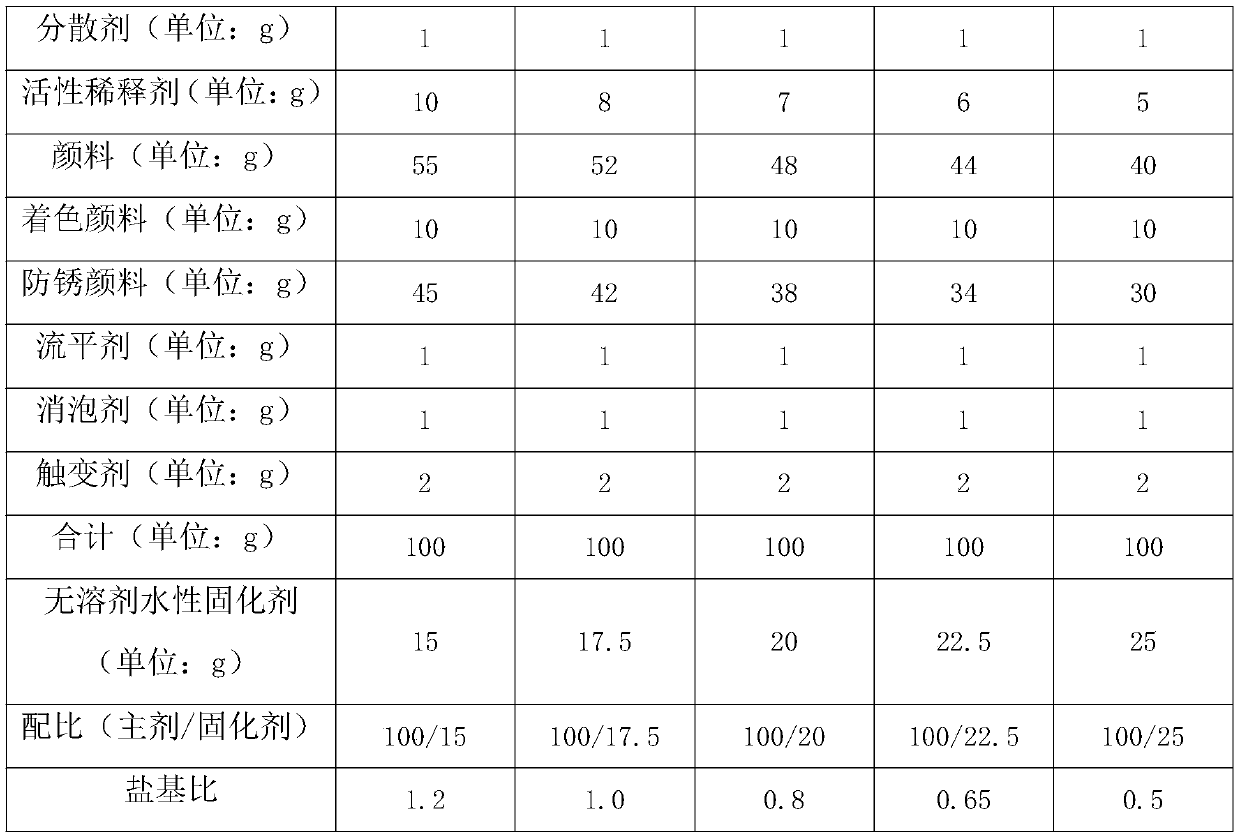

Water-based solvent-free epoxy anticorrosive coating and preparation method thereof

InactiveCN110564264AReduce application viscosityLow viscosityAnti-corrosive paintsEpoxy resin coatingsWater basedChemical storage

The invention relates to the technical field of heavy corrosion prevention in petrochemicals, and in particular relates to a water-based solvent-free epoxy corrosion prevention coating used in the environment of heavy corrosion of the inner walls of crude oil and chemical storage tanks and a preparation method thereof. The water-based solvent-free epoxy corrosion prevention coating comprises the following components in percentage by weight: 30 to 50 percent of solvent-free aqueous epoxy resin, 1 to 10 percent of a reactive diluent, 40 to 55 percent of a pigment and 1 to 5 percent of an auxiliary agent, wherein the sum of the percentages of the components is 100 percent. In the invention, the solvent-free aqueous epoxy resin and a solvent-free aqueous epoxy curing agent are innovatively used as main film-forming substances, a small amount of hydrophilic groups are introduced into the molecular structure of the resin and the curing agent, and the hydrophilic reactive diluent is added inthe design of the coating to reduce the viscosity of the product. The product itself has the characteristics of low viscosity, no solvent and excellent corrosion resistance. At the same time, due to the introduction of hydrophilic groups into the molecular structure, the product can be dissolved in water.

Owner:珠海展辰新材料股份有限公司

Warm-mixed modified rubber asphalt and preparation method

InactiveCN111138878AImprove reuseReduce the temperatureClimate change adaptationBuilding insulationsRaw materialPitch

The invention discloses warm-mixed modified rubber asphalt which is prepared from the following raw materials (by weight): 21-32% of rubber powder, 2-4% of a warm-mixing agent, 0.5-5.5% of a modifierand the balance of matrix asphalt. A preparation method of the warm-mixed modified rubber asphalt comprises the following steps: heating the matrix asphalt to 100-115 DEG C by adopting a reaction kettle, externally doping 0.5%-5.5% of the modifier, and uniformly stirring at the stirring speed of 300-600 r / min; keeping the rotating speed constant, heating to 125-140 DEG C, adding 2-4% of a warm-mixing agent, and uniformly stirring; heating to 170-185 DEG C and boosting pressure, doping 21%-32% of rubber powder, conducting high-speed shearing at the speed of 2500-3500 r / min, keeping the pressureat 0.8-1.5 MPa, and maintaining for 30-45 min to obtain the warm-mixed modified rubber asphalt. The preparation method realizes waste utilization, and is energy-saving, environment-friendly and low-cost.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

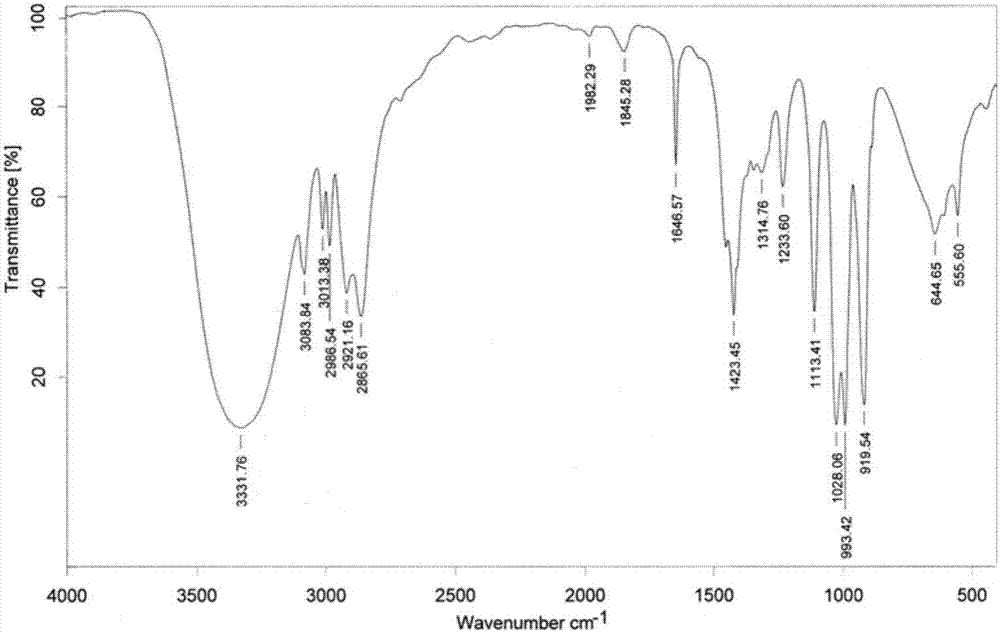

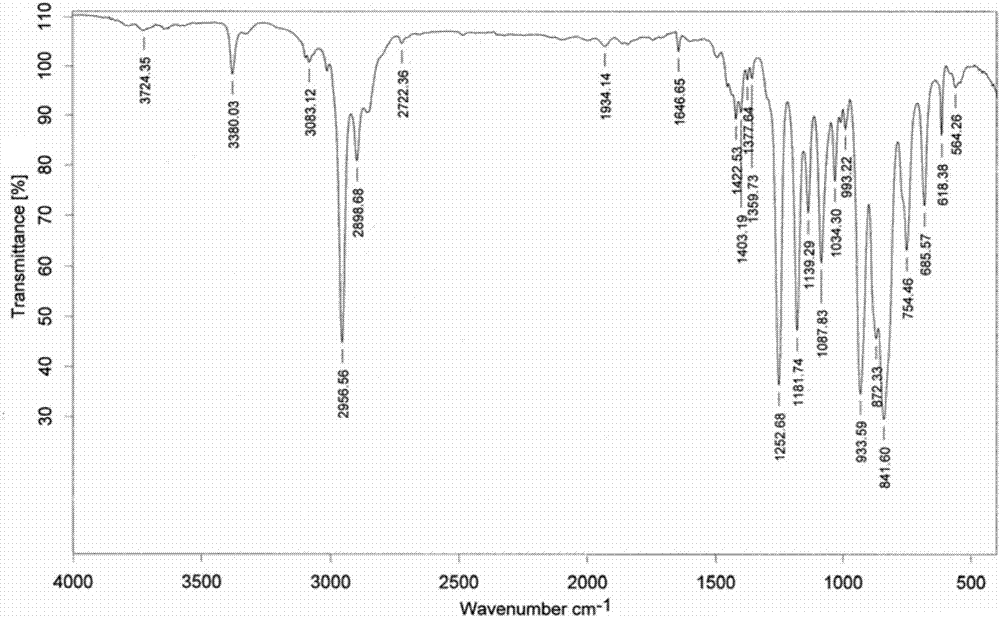

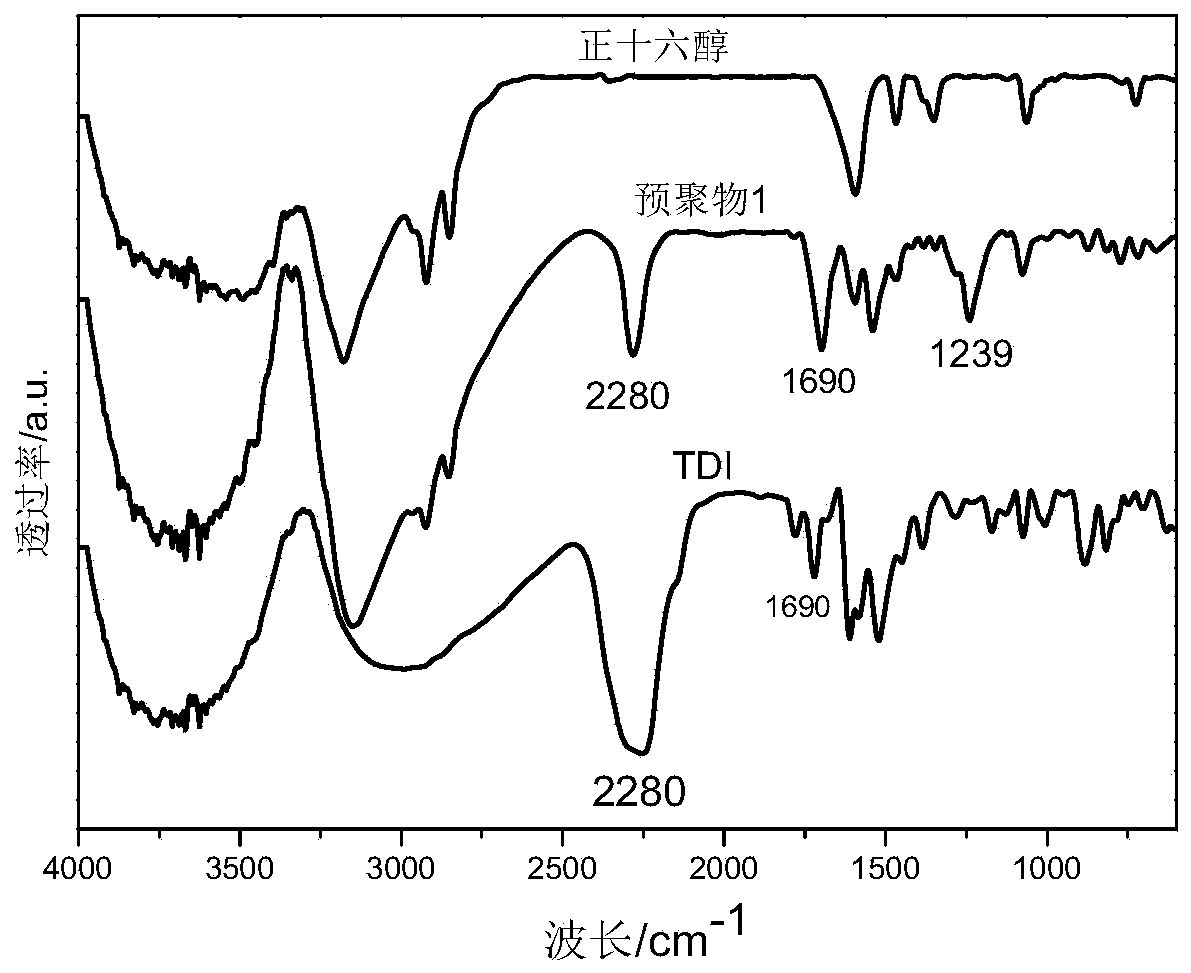

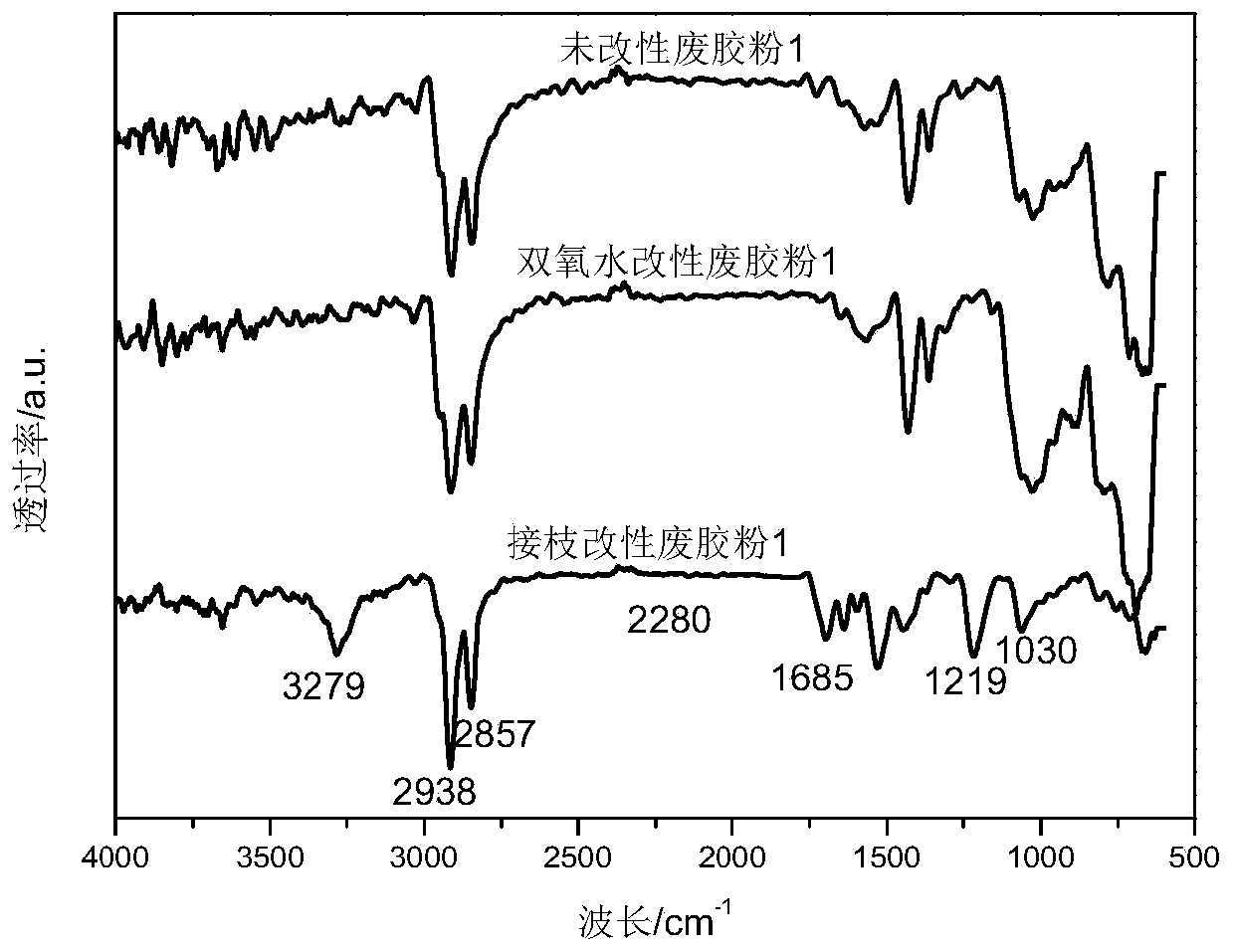

Grafting modification method of waste rubber powder used for asphalt modification

ActiveCN109957084AEasy to implementEasy to clean and environmentally friendlyBuilding insulationsPolymer scienceAlcohol

The invention discloses a grafting modification method of waste rubber powder used for asphalt modification. The grafting modification method of waste rubber powder used for asphalt modification comprises following steps: ultrasonic dispersion is adopted to prepare a waste rubber powder suspension liquid, hydrogen peroxide is added into the waste rubber powder suspension liquid dropwise, reactionis carried out so as to obtain hydrogen peroxide modified waste rubber powder; a monohydric alcohol and an isocyanate are added into an obtained prepolymer to prepare modified waste rubber powder, wherein the surface of the modified waste rubber powder is grafted with oxygen-containing groups and alkyl long chains. The rubber modified asphalt material prepared through adding of the grafted modified waste rubber powder into asphalt is friendly to the environment, is high in stability, and is excellent in performance.

Owner:SOUTH CHINA UNIV OF TECH

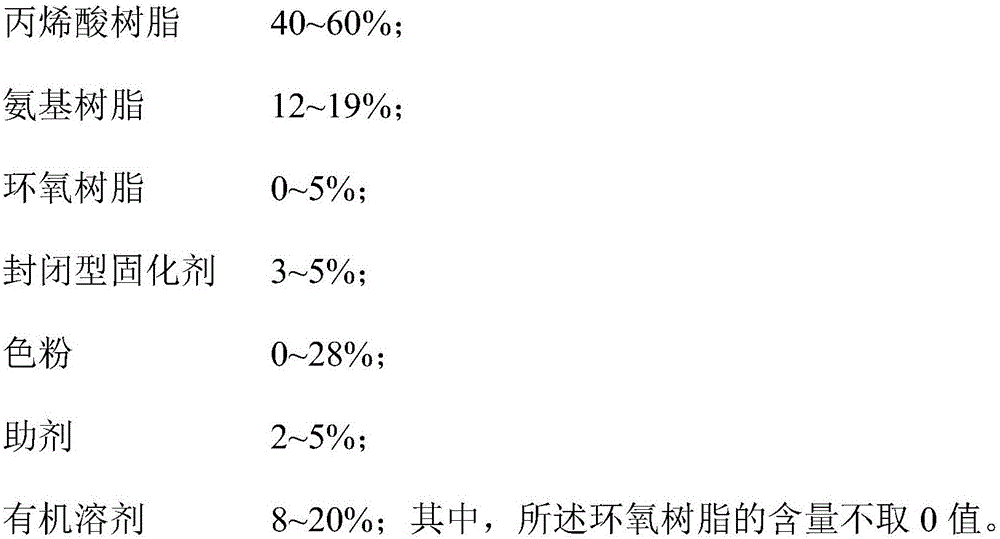

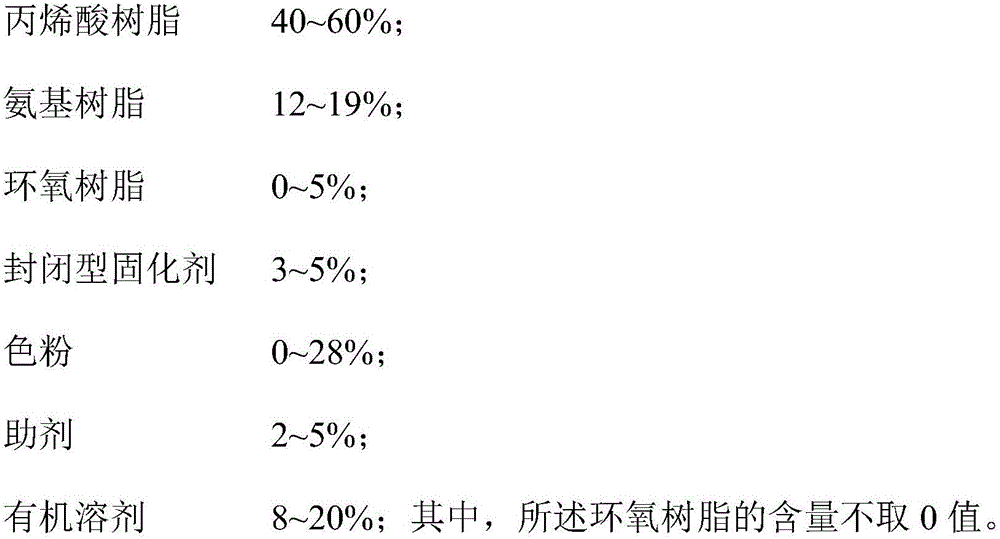

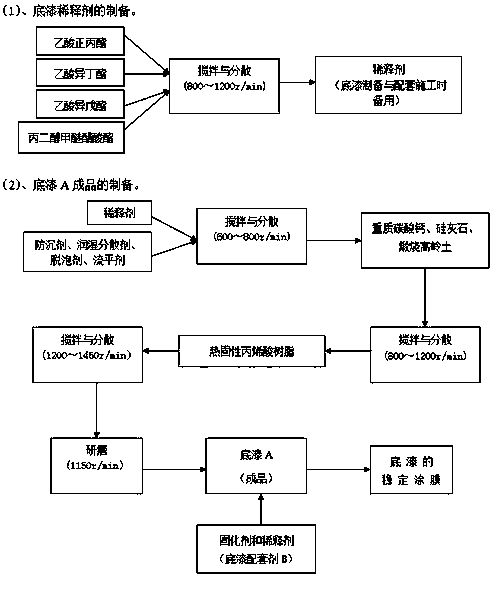

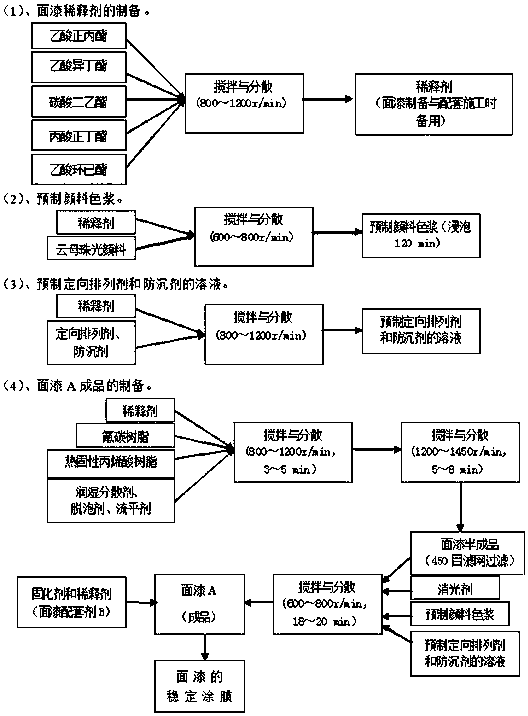

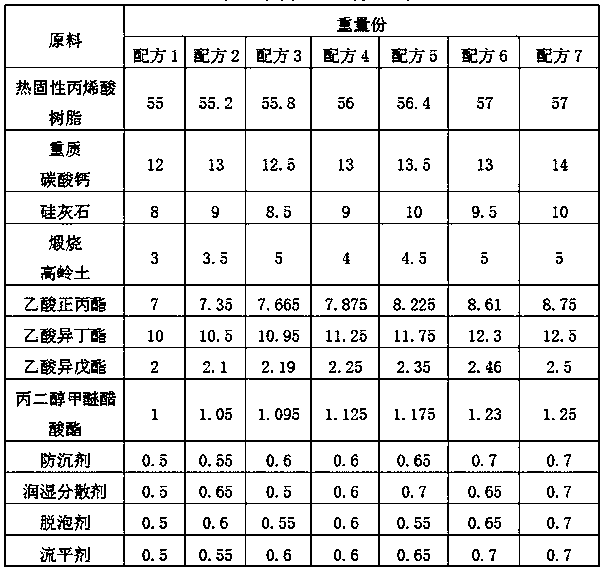

Paint for electric irons, and preparation and application method thereof

ActiveCN106085056AImprove spraying effectFlat surfaceFireproof paintsEpoxy resin coatingsEpoxyOrganic solvent

The invention provides a paint for electric irons, and a preparation and application method thereof. The paint at least comprises the following components in percentage by weight: 40-60% of acrylic resin, 12-19% of amino resin, 0-5% of epoxy resin, 3-5% of enclosed-type curing agent, 0-28% of toner, 2-5% of aid and 8-20% of organic solvent. The content of the epoxy resin is not 0. The paint is a single-component acrylic amino baking varnish, and has the advantages of favorable spraying effect, smooth surface, high gloss and uniform color. More importantly, the paint film formed by drying at the temperature of lower than 160 DEG C has favorable hardness, and especially can still have higher hot hardness, favorable adhesion to the substrate, excellent damp heat resistance and excellent wear resistance in a 120-DEG C environment.

Owner:CHINA PAINT MFG CO SHENZHEN

Novel composite rubber modified asphalt and preparation method thereof

InactiveCN107365506AImprove high temperature resistanceReduce application viscosityBuilding insulationsRubberized asphaltWaste tires

The invention discloses novel composite rubber modified asphalt and a preparation method thereof, relating to the field of road paving materials. The problems that the conventional waste tire rubber powder has low utilization rate, the conventional rubber asphalt is poor in high temperature resistance and the applicable viscosity is high due to increase of the doping amount are solved. The novel composite rubber modified asphalt disclosed by the invention comprises the following components in parts by weight: 65-75 parts of petroleum asphalt, 4-6 parts of waste recycled plastic particles, 1-3 parts of SBS (Styrene Butadiene Styrene), 60-75 parts of tire crown rubber powder, 15-30 parts of tire side wall rubber powder, 10-15 parts of tire bead rubber powder, 1.5 parts of white oil, 0.5 part of a TMTD accelerant, 1 part of an activator, 0.2-0.4 part of a stabilizer and 0.1-0.2 part of an anti-aging agent, wherein the granularity of the tire crown rubber powder is 25-40 meshes, the granularity of the tire side wall rubber powder is 30-40 meshes, and the granularity of the tire bead rubber powder is 40-60 meshes. The composite rubber modified asphalt disclosed by the invention is excellent in high temperature resistance, low in applicable viscosity and long in service life, and the utilization rate of waste tire rubber powder is increased.

Owner:吉林省嘉瑞沥青科技有限公司

Metal-imitated coating for building external walls and preparation method of metal-imitated coating

InactiveCN107828323AGood flash effectImprove solubilityPolyurea/polyurethane coatingsDiluentSolid content

The invention provides a metal-imitated coating for building external walls and a preparation method of the metal-imitated coating. The metal-imitated coating is a double-component coating for constructional engineering. The metal-imitated coating is prepared from primer A, a primer auxiliary agent B, finish paint A and a finish paint auxiliary agent B. During construction, the primer auxiliary agent B is added to the primer A, and the primer is applied to flat walls provided with diving joints, subjected to putty grinding and capable of being constructed directly in a coated manner; the finish paint auxiliary agent B is added to the finish paint A, the dried primer is coated with the finish paint, and finally, the building external walls achieve the decorative effect of an imitation aluminium plastic sheet curtain wall. According to the invention, solid content of a product under the construction condition is increased, an ester mixture is selected as a diluent, toxicity of a solventin a using process is reduced, pollution to the environment is reduced, dissolving capacity for resin and the coating is improved, applicable viscosity, diluent consumption and VOC content are reducedbetter, good paint film property of a product is kept while environmental protection property of product use is improved, and a coating film has the characteristics of good flashing property, low probability of oxidizing discoloration and long service life.

Owner:玉渊

Solvent-free two-component reactive type polyurethane adhesive applied to woodworking industry and using method of adhesive

InactiveCN108531122ALow viscosityImprove permeabilityPolyureas/polyurethane adhesivesPolyurethane adhesiveSolvent free

The invention discloses a solvent-free two-component reactive type polyurethane adhesive applied to a woodworking industry. The polyurethane adhesive disclosed by the invention is a two-component reactive type polyurethane adhesive, and through self-researched formulas and production processes of a component A and a component B, the two-component reactive type polyurethane adhesive is prepared; and the adhesive has low viscosity, is a liquid at normal temperature, has low construction viscosity in the early stage, and is more easily penetrated into wood textures to improve adhesion; and the adhesive is quickly cured in the later stage to generate adhesion, and the adhesive can be used for continuous production and improve production efficiency.

Owner:广东中粘新材料科技有限公司

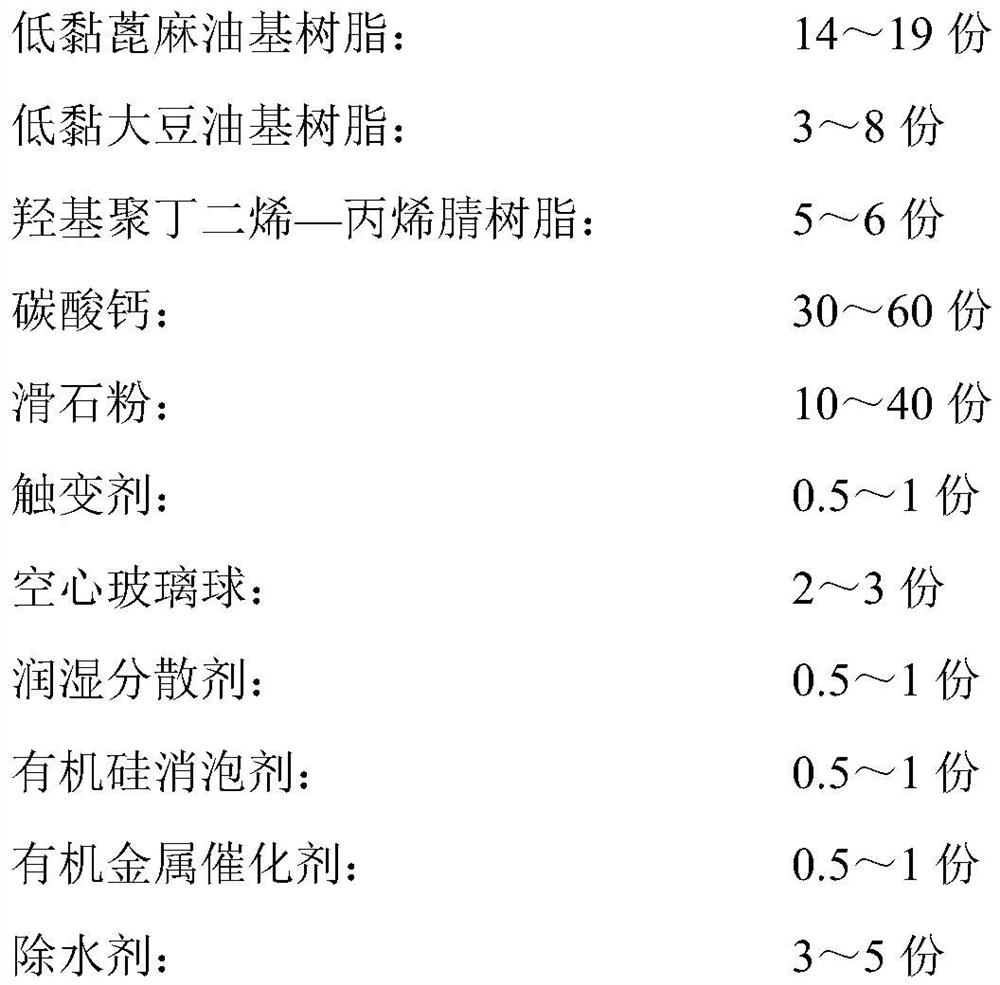

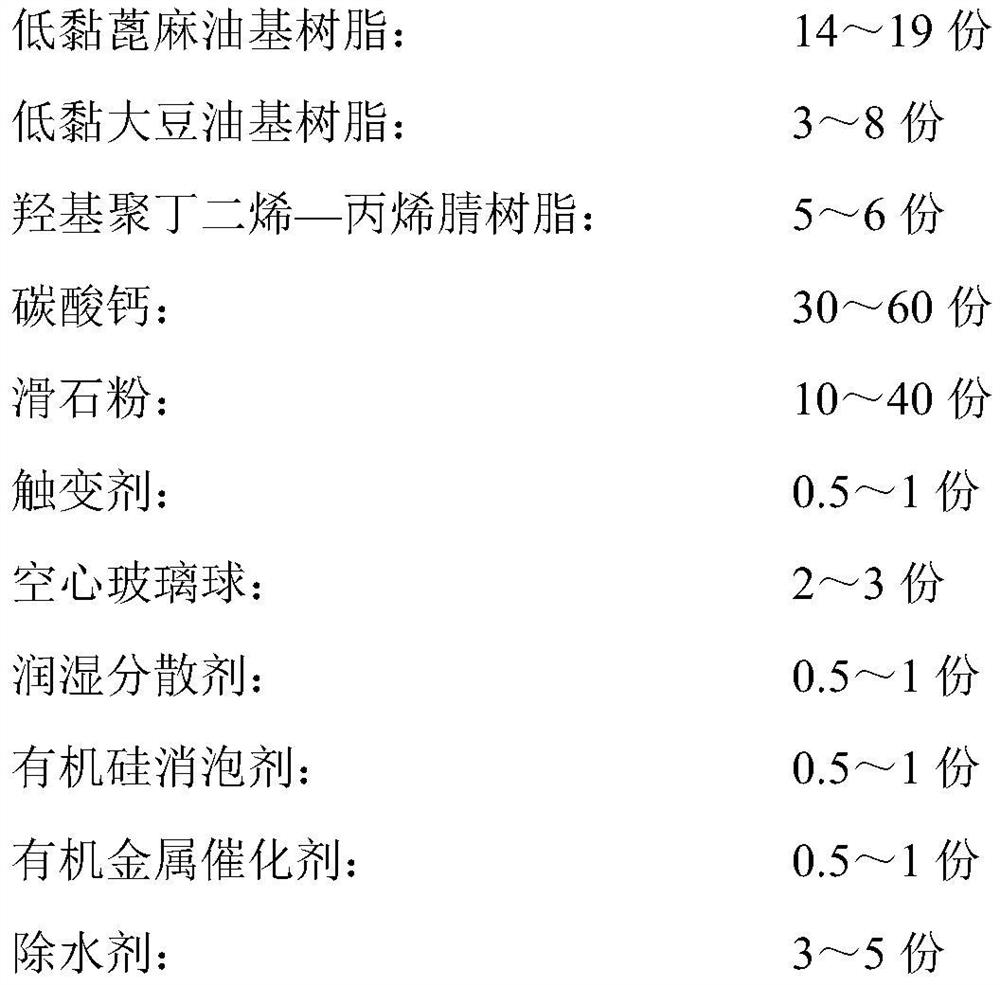

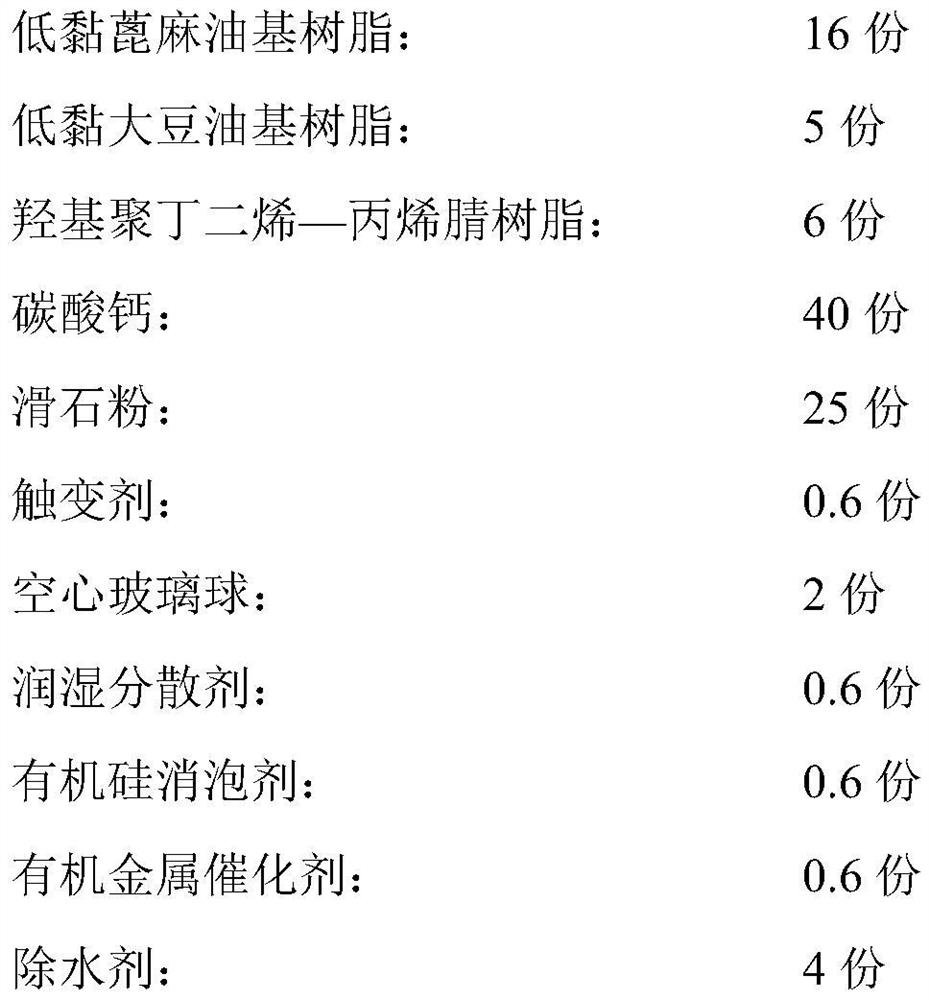

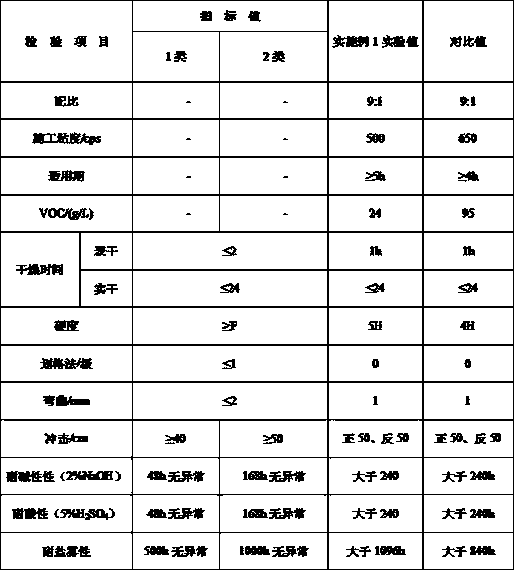

Sprayable solvent-free two-component polyurethane putty and preparation method and use method thereof

InactiveCN111621185ANo flammable and explosive hazardsRealize three effects in oneFilling pastesPolymer scienceAcrylonitrile

The invention provides sprayable solvent-free two-component polyurethane putty which comprises low-viscosity solvent-free bio-based resin and a low-viscosity polyisocyanate curing agent so that the viscosity of a whole coating mixing system is relatively low; in addition, hydroxyl-terminated polybutadiene-acrylonitrile resin is introduced into a formula system so that the wet adhesion and the flexibility of the system to a metal substrate are improved, and the corrosion resistance of the system is greatly improved. Resin used in the invention is solvent-free soybean oil-based and castor oil-based resin, no volatile component exists, other components are inorganic powder, and no low-boiling-point organic volatile matter exists in the whole formula system so that the product is more environment-friendly, and no flammable and combustible hidden danger exists; compared with an existing solution, three effects of priming paint, putty and floating coat are integrated, the construction linksare greatly reduced, the construction efficiency is improved, and the unit labor cost is reduced; the polyurethane material has better cold temperature performance, and the repair quality is greatly improved.

Owner:榕珍新材料科技发展(上海)有限公司

Emulsions with improved stability

InactiveUS20160104556A1Reducing and eliminating monomer contentReduce application viscosityPlastic/resin/waxes insulatorsSpecial tyresPolyesterActive agent

Disclosed are methods of lowering application viscosities of or of reducing or eliminating monomer content in electrical impregnating materials comprising or consisting of an emulsion of an unsaturated polyester or a mixture of unsaturated polyesters, water, at least one radical polymerisation initiator or radical polymerisation initiator / promoter mixture, at least one surfactant having an HLB-value of greater than 15, optionally at least one reactive diluent, and optionally further additives, a process for preparing zero or low VOC electrical impregnation materials, a method of impregnating electrical or electromechanical devices and a method of increasing the stability of aqueous emulsions of unsaturated polyesters.

Owner:ELANTAS PDG

Low-viscosity steel structure anticorrosive paint and construction process thereof

InactiveCN109929428AImprove adhesionReduce application viscosityPretreated surfacesAnti-corrosive paintsCellulosePliability

The invention discloses low-viscosity steel structure anticorrosive paint and a construction process thereof. The low-viscosity steel structure anticorrosive paint is prepared from the following components in parts by mass: components a and b, the component a comprises the following components in parts by weight: 80-100 parts of waterborne hydroxyl acrylic acid, 1.5-2.5 parts of a dispersing agent, 0.6-1.5 parts of a defoaming agent, 0.8-2 parts of an anticorrosive bactericide, 5-7 parts of cellulose, 38-42 parts of titanium dioxide, 0.4-0.9 part of a coalescing agent and 18-24 parts of deionized water; and the component b comprises 20-24 parts of isocyanate, 15-20 parts of propylene glycol methyl ether acetate and 0.2-0.5 part of tartaric acid; the construction process of the low-viscosity steel structure anticorrosive paint comprises the following steps: step 1, cleaning the surface of a steel structure; step 2, stirring, diluting and curing; and step 3, brushing. The low-viscosity steel structure anticorrosive paint is a double-component polyurethane anti-rust primer and takes water as a solvent, so that the low-viscosity steel structure anticorrosive paint has a long-term efficient rust-proof and anti-corrosion capability, good flexibility and impact resistance, low construction viscosity and low VOC (volatile organic compound) content.

Owner:广东德丽雅新材料有限公司

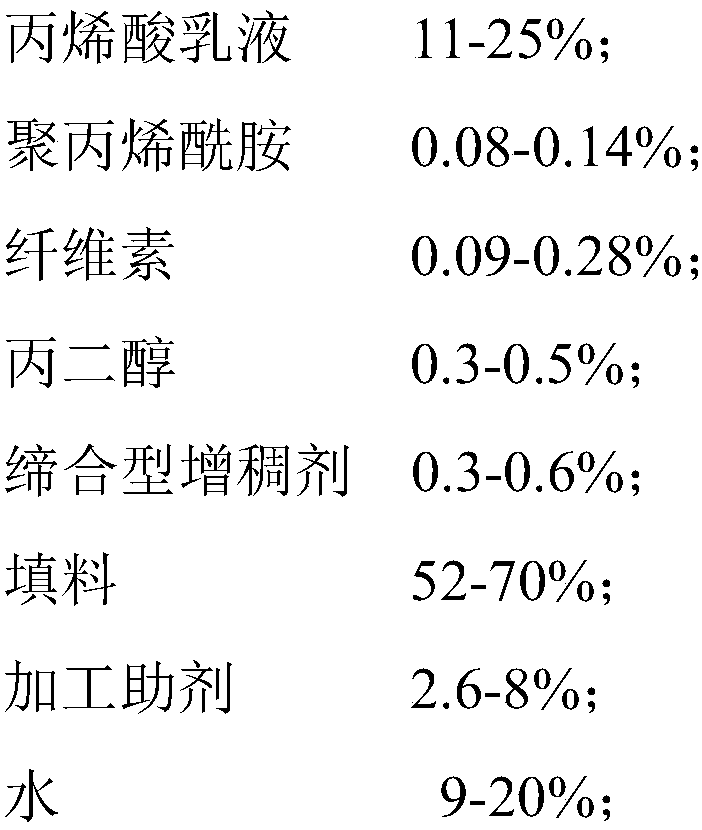

Texture coating and preparation method thereof

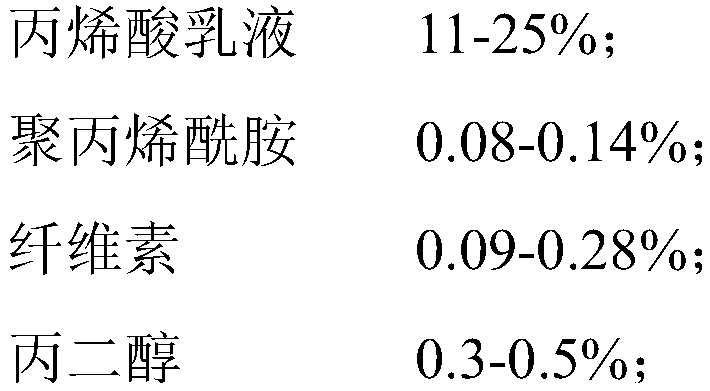

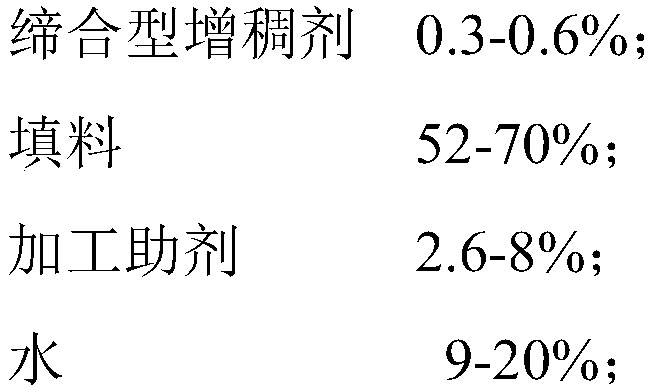

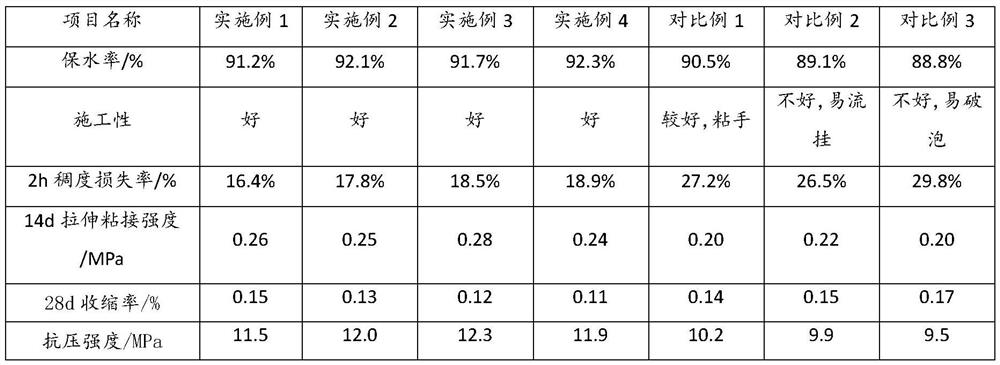

The invention relates to a texture coating. The texture coating comprises the following raw materials in percentage by weight: 11 to 25% of an acrylic emulsion, 0.08 to 0.14% of polyacrylamide, 0.09 to 0.28% of cellulose, 0.3 to 0.5% of propylene glycol, 0.3 to 0.6% of an associative thickening agent, 52-70% of a filler, 2.6-8% of other processing aids and 9-20% of water, wherein the polyacrylamide is non-ionic polyacrylamide, and has a molecular weight of no greater than 3 million; and the solid content of the acrylic emulsion is 45%-60%. The texture coating is good in moisture retention, convenient to construct, energy-saving and environment-friendly.

Owner:广东自然涂化工有限公司

Building mortar additive and plastering mortar containing same

ActiveCN112479628AReduce application viscosityImprove water retentionSolid waste managementCellulosePolyvinyl alcohol

The invention discloses a mortar additive for buildings. The mortar additive comprises the following components in parts by weight: 20-40 parts of methyl cellulose, 5-10 parts of modified polyacrylamide, 5-10 parts of polyvinyl alcohol, 20-30 parts of vegetable gum, 3-5 parts of an air entraining agent, 5-10 parts of a moisture absorbent, 5-10 parts of magnesium aluminum silicate, 5-10 parts of awater reducing agent, 5-10 parts of starch ether and 5-10 parts of a dispersing agent. The formula of the building mortar additive provided by the invention does not contain toxic and harmful substances, so the environmental protection property of building materials can be ensured. In addition, production is easy and convenient, a reaction kettle and heating treatment are not needed, only stirringequipment needs to be used for evenly mixing the components, and therefore other toxic and harmful substances are prevented from being generated.

Owner:广东龙湖科技股份有限公司

One-component varnish composition, preparation method and use thereof

ActiveCN106916503BImprove radiation resistanceGood weather resistancePretreated surfacesPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a one-component varnish composition, comprising at least one polymer with hyperbranched or tree structure; at least one hydroxyacrylic resin or hydroxymethacrylic resin; at least one silicone-modified acrylic resin at least one crosslinking curing agent; at least one acid catalyst; at least one rheology control agent; at least one auxiliary agent, and at least one solvent; the one-component varnish composition is high scratch resistance and high Weather resistant one-component clearcoat composition. The one-component varnish composition with high scratch resistance and high weather resistance provided by the present invention can effectively improve the slipperiness of the coating film surface of the varnish composition, thereby increasing the friction resistance of the coating film; in addition, silicone-modified acrylic acid The introduction of the resin can further improve the weather resistance of the coating film of the varnish composition.

Owner:LANGFANG NIPPON PAINT +2

A kind of anti-adhesive PU matte transparent topcoat and preparation method thereof

ActiveCN104087151BLow viscosityReduce application viscosityPolyurea/polyurethane coatingsPolyester coatingsPolymer scienceMembrane surface

The present invention relates to a kind of PU transparent topcoat and its preparation method; especially to a kind of anti-stain PU matte transparent topcoat and its preparation method, the present invention is suitable for furniture coating, especially suitable for often contact with hands and other body The coating of oil-secreting and sweat-contact parts and other furniture products that come into contact with oil. The present invention achieves the above-mentioned purpose by adopting the following formula, a kind of anti-adhesion PU matte transparent finish paint, it is formulated by the weight of 1:0.5:0.4-1:0.5:0.8 by main paint, curing agent and diluent than formulated. The anti-adhesive PU matte transparent topcoat provided by the invention can not only form a special long-term dense protective film on the surface of the fully film-formed coating film after painting, but also effectively block pollution such as hand sweat and oil stains Corrosion of the paint film by substances; and has the characteristics of good adhesion to the primer and good hardness.

Owner:SKSHU PAINT

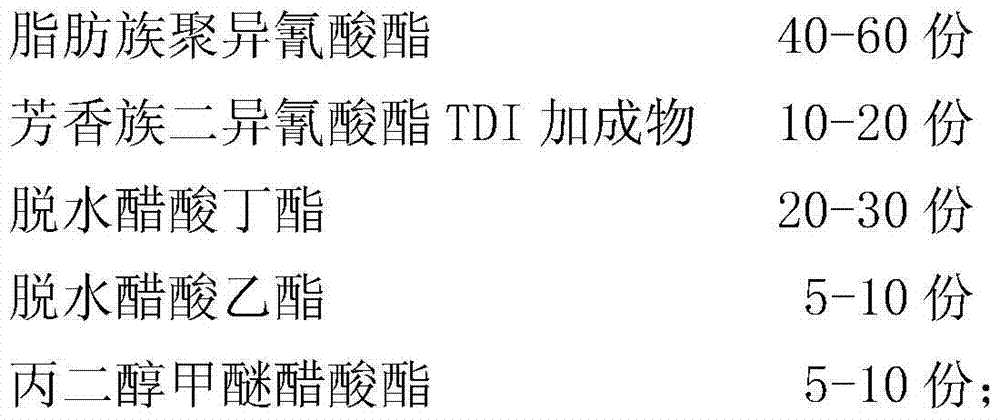

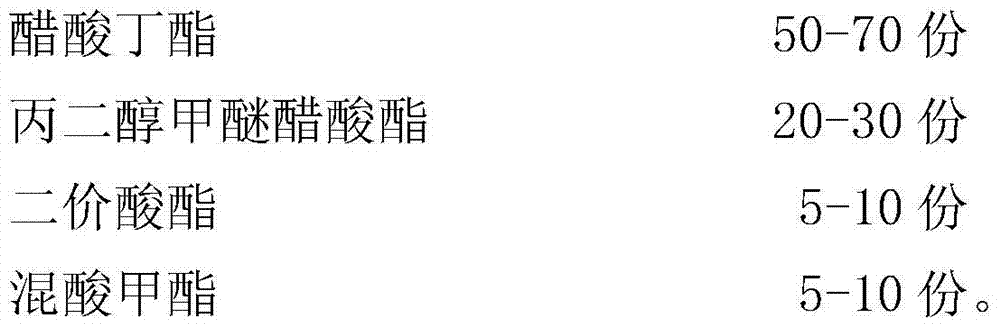

PU sealing primer capable of high wetting and high permeability substrate and preparation method thereof

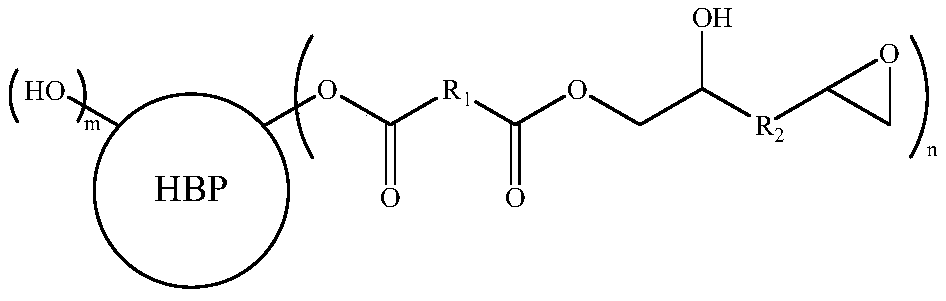

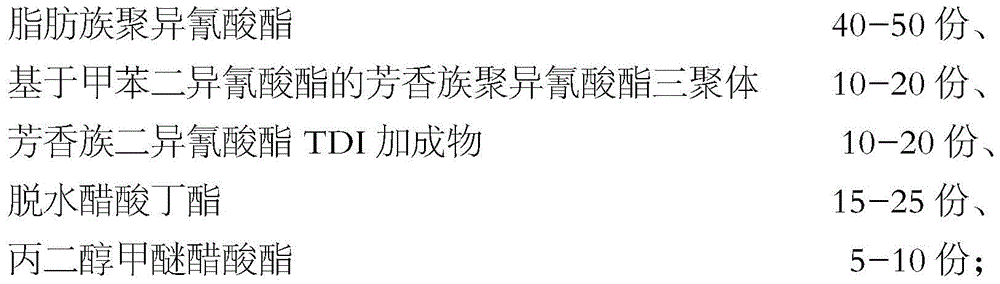

ActiveCN104497839BImprove wettabilityHigh mechanical strengthPolyurea/polyurethane coatingsEthyl acetateDefoaming Agents

The invention relates to a PU (polyurethane) seal primer capable of highly wetting and highly infiltrating a substrate and a preparation method of the PU seal primer. The PU seal primer capable of highly wetting and highly infiltrating the substrate is prepared by mixing a main coating, a curing agent and a diluting agent, wherein the main coating comprises the following components in parts by weight: castor oil modified alkyd resin, tall oil alkyd resin, butyl acetate, propylene glycol methyl ether acetate, acetic ether, a defoaming agent, a drier and zinc stearate; the curing agent comprises the following components in parts by weight: aliphatic polyisocyanate, an aromatic diisocyanate TDI additive compound, dehydrated butyl acetate, dehydrated ethyl acetate and propylene glycol methyl ether acetate; and the diluting agent comprises the following components in parts by weight: butyl acetate, propylene glycol methyl ether acetate, dihydric acid ester and mixed acid methyl ester. The PU seal primer capable of highly wetting and highly infiltrating the substrate, prepared by the method provided by the invention, not only has good penetrability and wettability to the substrate but also has good environmental friendliness.

Owner:SKSHU PAINT

Transparent primer with high anti-sag performance and preparation method thereof

The invention relates to a high-sinking-resistance transparent primer and a preparation method thereof. The high-sinking-resistance transparent primer is particularly suitable for application on a wood substrate and especially suitable for application on a substrate with deeper wood-grain guide tubes. The primer is prepared from a main paint, a curing agent and a diluter in a mass ratio of 1:0.5:(0.3-1):0.5:0.7. The main paint is prepared from the following raw materials in parts by mass: 55-70 parts of small-oil-length alkyd resin, 5-15 parts of castor oil modified alkyd resin, 3-10 parts of zinc stearate, 0-30 parts of talcum powder, 0.5-1 part of anti-settling agent, 0.3-1 part of defoamer, 0.2-0.5 part of leveling agent, 0.1-0.5 part of wetting and dispersing agent, 0.1-0.3 part of drier and 5-15 parts of environment-friendly mixed solvent. The primer can be well combined with the substrate after being applied, and has excellent properties in the aspect of wood grain / guide tube filling. After the primer is placed for a long time, the paint film of the finish paint can not shrink, and can not generate the phenomenon of sinking.

Owner:SKSHU PAINT

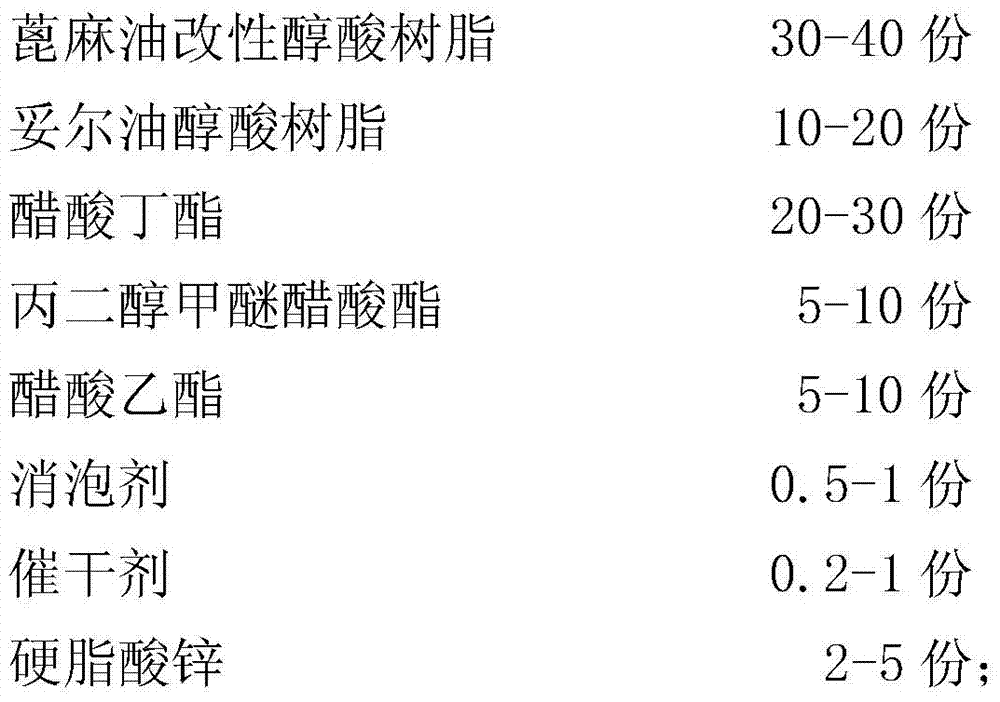

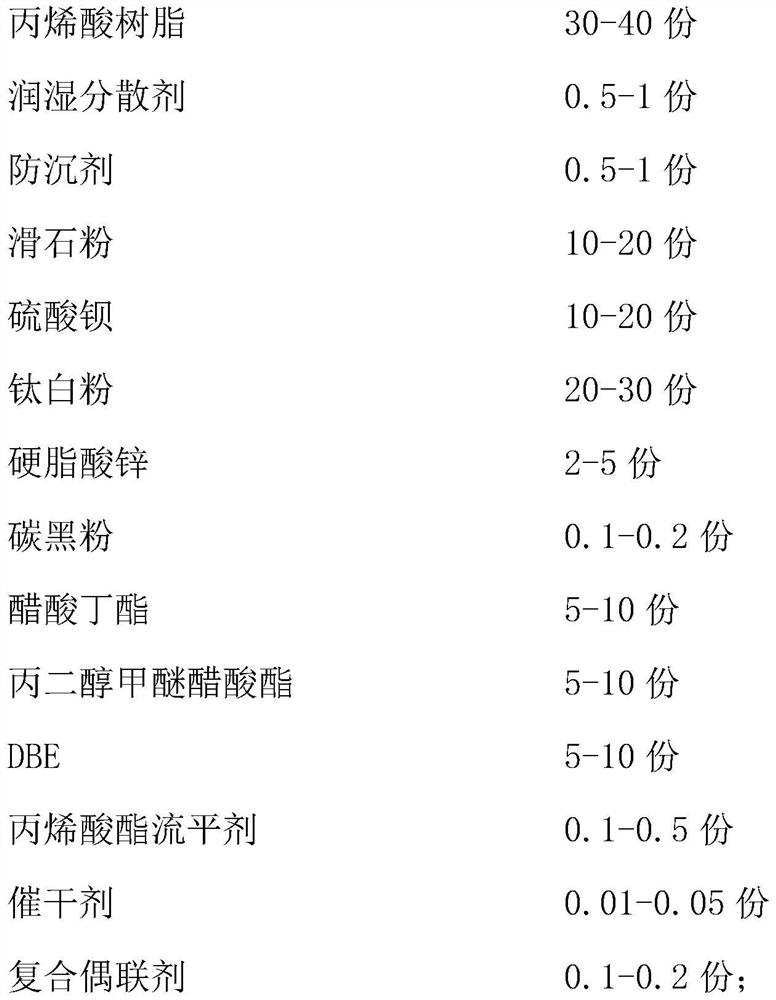

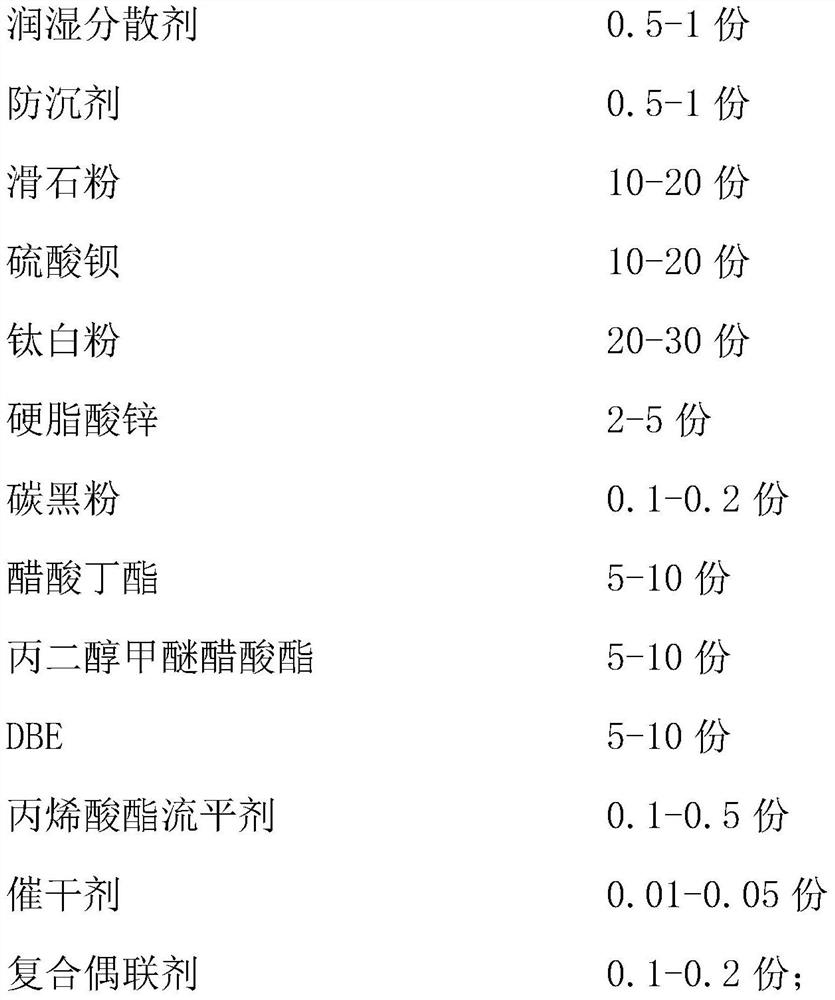

Solvent type low-VOC bus intermediate coat and preparation method thereof

The invention discloses a solvent type low-VOC bus intermediate coat and a preparation method thereof. The solvent type low-VOC bus intermediate coat is composed of a component A and a component B which are equal in weight, wherein the component A is prepared from the following components in parts by weight: 30-40 parts of acrylic resin, 0.5-1 part of wetting dispersant, 0.5-1 part of anti-settling agent, 10-20 parts of talcum powder, 10-20 parts of barium sulfate, 20-30 parts of titanium dioxide, 2-5 parts of zinc stearate, 0.1-0.2 part of carbon black powder, 5-10 parts of butyl acetate, 5-10 parts of propylene glycol methyl ether acetate, 5-10 parts of DBE, 0.1-0.5 part of an acrylate leveling agent, 0.01-0.05 parts of a drier, and 0.1-0.2 parts of a composite coupling agent; and the component B is prepared from the following components in parts by weight: 50-70 parts of isocyanate, 10-30 parts of butyl acetate and 10-20 parts of DBE. The invention further provides a preparation method of the solvent type low-VOC bus intermediate coating. The solvent type low-VOC bus intermediate coating provided by the invention has very low VOC content and viscosity, and also has very good adhesive force and flexibility.

Owner:GUANGDONG YATU CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com